How to set the timing chain on a scooter

1. Install a new cylinder head gasket.

ATTENTION!

The cylinder head gasket is made of soft metal (copper, aluminum) and after tightening the cylinder head nuts it is deformed, thereby ensuring a tight connection. Reinstallation of the cylinder head gasket is not permitted.

2. Install the timing chain guide.

3. Install the cylinder head.

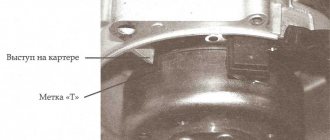

4. Set the piston to TDC according to the marks on the flywheel. This is usually the "T" mark on the flywheel. Align the mark with the tide on the engine crankcase.

ATTENTION!

The following operation is one of the most important when assembling the engine. It is important to align all the marks very accurately. An error in installing the chain even by 1-2 teeth will result in the engine not working correctly, and it will probably even lead to serious damage to the timing and cylinder-piston gas parts when trying to start the engine!

5. After making sure that the timing chain has not jumped off the drive sprocket on the crankshaft, install the camshaft into the cylinder head, at the same time putting a chain on its sprocket so that the marks on the camshaft sprocket are parallel to the plane of the edge of the cylinder head, and the cams are directed downward (inside the head).

6. Install the rocker arm support, orienting it according to the installation marks. Lubricate the cams and camshaft bearings.

On the rocker arm support are the letters “EX” - which means “EXHAUST” - release. The "EX" mark should be located above the exhaust valve.

ATTENTION!

• Check the correct axial alignment of the camshaft (make sure that the camshaft bearings are correctly positioned on the beds). Probably, on some scooter models, the holder will have the mark “IN” - “INTAKE” - inlet. Accordingly, the “IN” mark must be located above the inlet valve.

ATTENTION!

If the copper washers are severely deformed (flattened), they must be replaced, since if the washers do not fit tightly due to oil leakage, the pressure in the lubrication system will drop and the motor will quickly fail. Sealing this connection with any sealant is unacceptable.

7. Install sealing copper washers on the studs.

8. Screw on all four cylinder head nuts without tightening them.

9. We recess the working rod of the timing chain tensioner inside the housing.

10. Reinstall the timing chain tensioner and tighten its mounting bolts.

11. Insert the working bolt and the timing chain tensioner spring, tighten it. In this case, you can hear characteristic clicks - the ratcheting mechanism of the tensioner working rod will be activated, which, under the influence of a spring, will come out of the housing and tension the timing chain.

12. Sequentially, crosswise tighten the cylinder head nuts in 3-4 steps. The final tightening torque is 10-15 Nm (More accurate values can be found in the repair instructions for the specific scooter model).

13. Screw in and tighten the additional cylinder head bolts.

14. Using a socket wrench for the central bolt of the flywheel, or with your hands holding the flywheel, slowly turn the engine crankshaft clockwise 3-4 turns to make sure that the timing timing is set correctly and the piston does not collide with the valves.

15. We install the crankshaft at TDC of the compression stroke and once again check the correct installation of the camshaft according to the marks.

17. Rotate the crankshaft several turns and once again check that the valve clearances are set correctly.

18. Install the cylinder head cover and tighten its bolts.

19. Place the crankcase ventilation hose onto the fitting in the cylinder head cover.

20. Install the cylinder cooling casing.

ATTENTION!

Do not forget to remove the paper from the intake manifold if you covered it from dirt during disassembly.

21. Install the inlet pipe assembly with the carburetor.

ATTENTION!

In most cases, when installing an exhaust system, the exhaust pipe gasket will need to be replaced. It is better to replace it with a new one during assembly.

Proper maintenance and adjustment of the motorcycle timing chain

Modern engines of imported motorcycles require almost no attention, except for timely oil and filter changes. But on motorcycles with a fairly high mileage, there still comes a moment when the engine itself suggests with increased noise that it is time to start servicing the timing system - gas distribution mechanism. We will look at how to do this correctly without harming your engine in this article. Unlike modern car engines (ancient Ladas and Muscovites do not count), (and Italian exclusives, such as Ducati motorcycles), where the gas distribution mechanism is controlled by a rubber gear belt; on most modern imported motorcycles, the timing chain commands the timing chain. Of course, there are exceptions on some large cruisers, or English classic motorcycles, which use camshaft drive using gears. But such a drive does not need adjustment at all, since if after a very long mileage parts wear out, they are simply replaced with new ones (the same gears).

With a chain, everything is not as simple as it seems, since it must be constantly tensioned with a certain force in order to accurately transmit torque and serve the required period. After all, the camshaft of any engine must rotate absolutely synchronously with the crankshaft.

And if there is a slight lag or advance even by 1 -1.5 °, then the engine of your motorcycle will lose its power, and the wear of timing parts will increase. If the lag or advance increases by several degrees, then it is quite likely that the pistons will meet the valves, and this is already very serious. In most cases, many parts of the gas distribution mechanism will be destroyed, and most likely it will be easier to replace the engine head completely. I think many have understood the importance of the chain tension system, now it remains to understand all this in more detail.

To tension the chain with a certain force, a set of parts intended for this purpose is used, consisting in most cases of two dampers coated with anti-friction material, along which the chain slides during operation, and the chain tensioner itself.

The tensioner is mounted in the engine so as to rest against the driven arm of the chain, and this arm is constantly pressed with the required force. This entire unit (and its normal operation) is very important, since a malfunction of this unit is dangerous and can lead to the dire consequences described above. And although problems here are quite rare, it still deserves attention, since in order to correctly diagnose the tensioner parts and then assemble them correctly, you need to know well how this unit works. Semi-automatic mechanical tensioner. Tensioner designs, depending on the years of manufacture, vary some. On the most ancient models until the 80s, simple mechanical timing tensioners were installed (see photo on the left), which were very easy to set up.

All you had to do was loosen the tightening bolt (usually a 10mm wrench), then rotate the engine crankshaft as it rotates until the resistance weakens, and re-tighten the bolt. Everything is quite fast and simple.

But after 1980, tensioners began to appear that automatically tighten the chain relative to its stretch. They are still used today. Some automatic tensioner systems are slightly different from each other, but their essence is the same - if they once extend to the required distance, the tensioner rod is fixed in this position and cannot move back. Thanks to this, the timing chain is constantly tensioned at all times with a certain force, which is set by the tensioner spring.

But many will wonder: why bother with the tension system if everything is automated.

Well, first of all, I already said at the very beginning of the article that you only have to climb into this unit on motorcycles with high mileage, because after a certain mileage everything eventually wears out. And secondly, when disassembling the engine (for example, to repair it), or replacing tensioner parts, many novice repairmen make mistakes, which in the end can turn out to be very expensive. My goal, or rather the goal of this article, is to warn against these mistakes. One of the common mistakes of novice “masters” is when, when removing the valve cover of some engines, on which the damper is located, the chain naturally weakens, since there is no longer pressure on the damper, the cover is then removed .

And when the chain tension is weakened, a working tensioner will immediately tighten the chain by extending slightly. A novice “master”, having checked the chain tension, will naturally be pleased with the normal tension. Only now he will not be able to install the valve cover in place normally, since the damper located in the cover will rest against the tense chain.

The unfortunate mechanic begins to press harder on the cover and compress it with standard bolts. The chain guide into which the tensioner rod rests is slightly worn. If the chain is tightly tensioned, it can wear out in a few minutes of work. As a result, either the tensioner clamp or the tensioner shoe itself (or the tensioner) breaks. If the high-quality parts of the tensioner and stabilizer can withstand such abuse, then the next time the engine starts, the chain will be so tense that the friction material of the tensioner and stabilizer will be erased in a few minutes of operation.

And the chain itself, during the same short operating time, will stretch as if it had a long mileage. As a result, the wear and noise of this unit will increase many times over, and very quickly. Therefore, before assembling the unit, I advise you to study the principle of operation of the tensioner of your particular engine, and find a way to return the tensioner rod back.

Below I will tell you how to do this correctly. The sprocket of a modern silent chain looks like a gear. 1 - sprocket, 2 - additional gear of the motor transmission, 3 - main gear, 4 - damper springs. As a rule, with high mileage, the timing chain stretches and begins to ring. In most cases, eliminating this defect requires replacing the chain, and the dampers too. But many novice “mechanics”, placing one or more washers under the tensioner spring, think that they have solved the problem. But this does not help for very long, or does not help at all. After all, the sprocket of a modern silent chain looks like a gear. A modern silent chain (see photo) is designed in such a way that, unlike a conventional chain, it covers a tooth with a much larger link area.

When any chain is pulled out, increased gaps appear between the sprocket tooth and the link, which cannot be corrected by anything, the link is stretched, and the distance between the axes (pins) of the link increases, wear is wear. This causes increased noise, but that’s half the problem.

If you add all the increased clearances of each chain link together, you get a significant lag between the camshaft and the crankshaft. The engine loses some of its power because the valve timing begins to lag. For information: if the chain has 114 - 116 hinges (links) - depending on the type of engine, then the wear of each of these hinges by only 0.08 mm, as if adding another link to the total length of the chain, and from this the timing sprockets, ignition switches are shifted back in phase from the sprocket on the crankshaft, by an entire chain link! As a result, the power characteristics and economic indicators of the engine are significantly reduced. Now imagine that if the links wear out not by 0.08 mm, but more, how will the engine start to work? The conclusion suggests itself - an elongated motor chain will no longer be able to transmit rotation normally and in a timely manner from the crankshaft to the camshaft. A modern silent motor chain, the links of which almost completely cover the sprocket teeth.

From everything written above, let us understand for ourselves that only a new chain can return the engine to its former strength, and if the friction material of the tensioner and damper is worn out, then their replacement is also extremely necessary.

Inspect the chain sprockets; there should be no signs of wear visible to the naked eye. And if, with the tensioner mechanism assembled and the chain in place, the rod of your tensioner is fully extended, then the motor chain of your bike is completely stretched, and it’s time to replace it with a new one. To replace the chain without removing the sprockets, you need to unpress it, and then stretch a new chain and press it using a special tool. How to properly stretch a new chain, and about the device itself for pressing the chain, I advise you to read this article. Still, let’s look at some types of tensioners in a little more detail, since I think this will be useful for novice mechanics.

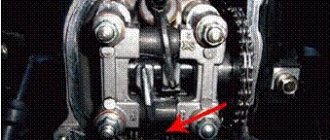

Rack tensioner. 1 - spring plug screw, 2 - tensioner housing, 3 - spring-loaded ratchet rack stopper, 4 - rack itself, 5 - spring, 6 - plug sealing washer. The red arrow shows where to press to pull out the latch and then recess the pusher rod.

Rack tensioner . This is one of the ancient mechanical tensioners, but it already works automatically (and not by adjusting it with a key, as I described above). It is quite reliable and does not require attention for quite a long time. The main working element of this type of tensioner is the pusher. It is constantly pressed by a spring in the direction of tensioning the chain, and an ordinary ratchet mechanism does not allow the pusher to return in the opposite direction (yes there, no back). The ratchet mechanism is very simple and is a spring-loaded stopper resting on a toothed rack. After removing the tensioner from the engine, the pusher on a working unit should move out completely, and if you try to push it even more with your hands, it will come out again, which means the spring has sagged and needs to be replaced.

Well, if, when trying to push the pusher inward, on the contrary, you managed to do this, then the ratchet mechanism of the ratchet is faulty (the teeth are broken or worn out). Naturally, you need to replace such a part with a new one.

Having pressed the lock with your finger, you can now push the pusher rod inward. Before installing such a tensioner back on the engine, inspect all parts for wear, and if there are no visible signs of wear and jamming of the mechanism, then you can install it back on the engine. To do this, you need to unscrew the spring plug 1 from the tensioner body (see photo above), and then by pulling the spring-loaded stopper away from the teeth of the rack (for example, with a thin screwdriver or with your finger as in the photo on the left), you can now push the pusher back (since you pull the lock with a screwdriver or a finger and it doesn’t interfere). Well, after you secure the pusher itself to your engine with screws, you can install the spring back and compress it with the screw plug 1.

Screw timing chain tensioner. 1 — bolt plug, 2 — screw tensioner body, 3 — the pusher itself.

Screw tensioner . On more modern motorcycle engines, a screw tensioner is installed, which, unlike the rack-and-pinion tensioner described above, regulates the spring tension more smoothly due to the rotation of the screw, which smoothly extends the pusher. And the thread of a special screw does not allow the pusher to slide back into the body. You can check the proper operation of such a tensioner as follows. Having unscrewed the screw plug from the pusher body, and then inserted a thin screwdriver into the body and felt the screw with it, turn it, and the pusher will begin to move into the body (the pusher should not move in or out with your hands, the pusher play should not be felt either). Then try to loosen the screw (remove the screwdriver), and at this moment the pusher should quickly move out with a click until it stops. When rotating the screw with a screwdriver, you should feel only the tension of the compressed spring, and the screw itself should rotate easily and without jamming. Checking the functionality of the screw tensioner. In the same way, such a tensioner is installed back on the engine, that is, we turn the screw with a screwdriver until the pusher is completely seated body, then holding the screw in this position with a screwdriver, with the help of an assistant, try to install the tensioner in place on the motor, tighten the bolts securing it, and only then release the screwdriver. All that remains is to tighten the plug screw. Wedge timing chain tensioner. 1 — wedge spring cover-plug, 2 — tensioner body, 3 — wedge, 4 — wedge spring, 5 — pusher spring, 6 — limiter bolt, 7 — groove for the limiter bolt, 8 — pusher. The red ring indicates a broken lid. Wedge tensioner . A motor timing chain tensioner with a wedge tensioner is less commonly installed on motorcycle engines, but it is still worth writing about. This tensioner is not as compact as the mechanisms described above, but it is impossible to break it, since it has neither small teeth nor fine and delicate threads. The tension of the motor chain is also smoothly adjustable, just like on a screw tensioner.

The pusher itself is pushed out by a spring, and is secured from unnecessary movement by a special bolt that presses on the groove in the pusher (see photo). And the pusher is prevented from returning back into the body by a wedge, constantly pressed by a spring.

After inspecting the tensioner parts for professional suitability, and not finding visible signs of wear, pusher play or jamming, you can return the tensioner back to the engine. But before this, it is necessary to recess the pusher, and to do this, unscrew the spring support cover, then remove the spring, and only after that can you remove the wedge that prevents the tensioner rod from moving back into the body. Having installed the chain tensioner in its place on the engine, now calmly insert the wedge and spring into place, and then screw on the cap, which will tighten the spring and wedge.

Hydraulic motor timing chain tensioner mounted on the engine. A tube from the oil system of this engine is connected to it.

Hydraulic tensioner . They are also called oil tensioners, since they work from the pressure of oil entering the inside of the hydraulic cylinder from the engine lubrication system. Such tensioners have long been used on many cars, but they began to be used on motorcycles in recent years, and even then not so often. They are mainly used on quiet engines, since on forced engines the oil pressure can vary widely, and this will cause the chain tension to change, naturally this is not good. Moreover, for the normal and smooth operation of such a system, the engine must Very clean and high-quality engine oil is always present, since inside the tensioner there is a plunger manufactured with high precision and with a very small clearance in the hydraulic tensioner cylinder.

And if even the slightest speck gets into this pair (plunger and cylinder) with oil, then the plunger with the tensioner rod will simply jam. The consequences are very sad, since no matter how much oil pressure is in the system, it will no longer be able to push out the jammed plunger and chain tensioner rod. This will weaken the chain and the timing will no longer operate normally.

Therefore, the purity of the oil and its timely replacement play a huge role here. The hydraulic timing chain tensioner is removed from the engine. The polished pusher rod is visible. Moreover, in cold weather, or after a long stay (when the oil drains into the sump), engines with a hydraulic tensioner rattle the chain for several seconds of engine operation (until the oil fills the hydraulic cylinder to the required pressure). At this point, the main thing is not to increase the speed of your engine until the sound goes away. However, I do not recommend increasing the speed on any engine until it warms up. Two automatic tensioners (rack and pinion on the right), which must be cocked before installation on the engine.

There is also an automatic tensioner, as in the photo on the left, in which, before installing it on the engine, you just need to cock the spring-loaded handwheel (turn the wheel) and at the same time sink the tensioner pusher rod. After installing such a tensioner on your engine, turn the wheel back, and the pusher rod will move out freely and tension the chain.

Remember that if, on any type of tensioner, the pushrod is pushed outward as much as possible, then your bike's timing chain is completely stretched (worn out). Wear of parts such as friction material (slides) of dampers is usually visible visually. Naturally worn or loose parts must be replaced with new ones. We cock this tensioner by turning the wheel and at the same time pressing on the pusher rod. If you repaired the engine (you can read about the correct repair of a Japanese four-stroke engine here), then after assembling it, install the motor chain tensioner last, and as described above - with a completely recessed pusher.

After installing the tensioner on the engine, rotate the crankshaft of the assembled engine 4-5 revolutions in the direction of rotation (by the crankshaft bolt), and at the same time make sure that the tensioner friction shoe takes its working position.

Don’t even think about performing the same operation, rotating the camshaft instead of the crankshaft. I hope now you will be able to more competently service the timing belt of an imported motorcycle, and most importantly, diagnose this unit and modify the parts yourself, because high-quality motorcycle service, especially in the outback, requires just dream for now. Good luck everyone!.

Replacing the timing chain on a 139qmb engine the easy way

How I replaced the timing chain on a 139qmb engine of a Chinese scooter, and at the same time checked the possibility of shortening the timing chain

When I first opened the valve cover on the 139qmb engine, shortly after purchasing a used scooter, it was discovered that the timing chain was stretched to the limit and even more. The tensioner was pulled all the way out, but the chain was still loose. with spare parts for scooters in our area, and trying to find them in stores led nowhere. I've been driving like this so far. But soon there were two instances of the chain slipping on the camshaft or crankshaft sprocket, but in any case in such a situation, having turned off the engine, it was impossible to start it again until the camshaft was installed according to the marks. Since there is still no timing chain Under the cylinder from thick (2 mm) cardboard, under the head - from metal asbestos, also about 2 mm thick. The chain no longer jumped on the teeth, but it was still rather weak. You won't be able to travel like this for long. There was an idea - to shorten the chain by throwing out one link, but then on one site I found an acceptable option for me to purchase a chain through an online store by mail with cash on delivery - honlingzakaz.ru - Timing chain 50cc (139QMB). Simple registration, the only thing is that the minimum order price was no less than 400 rubles and in addition I ordered head and cylinder gaskets. Placed an order by registering on the website (you need a valid e-mail and phone number). After some time they contacted me and I confirmed the order. A week later I received the parcel at the post office.

to change the timing chain without completely disassembling the engine. To begin with, I removed the valve cover and installed the camshaft according to the marks (large hole at the top, small holes at the edges of the head). Next, I removed the chain tensioner, unscrewed the 4 nuts on the cylinder studs and removed the bed with the camshaft. I secured the chain with wire to prevent it from falling into the engine crankcase. Using a bicycle chain squeezer, I disconnected the timing chain .

Here I could not resist and decided to check whether it was possible or not to throw out one link on an elongated chain. After removing the link, I connected the chain using ordinary pliers

and put it on the camshaft sprocket. It turned out that the shaft does not fit into the head bed.

But this is not surprising because the engine has thick gaskets under the head and cylinder. And so this option (as a temporary one) also has a right to exist. At least it's better than driving with a fully extended chain. But after shortening, the chain replacement must still be carried out as soon as possible. A stretched chain causes accelerated wear on the sprockets. Warning: everyone carries out this option of replacing or shortening the chain at their own peril and risk. If the chain suddenly breaks while the engine is running, the consequences can be dire...

Then I disconnected the circuit again. Then he disconnected the new chain, connected it to the old one from the bottom edge and began to turn the crankshaft with a kickstarter, holding both chains with his hand. Slowly the new chain fell into place. Connected the chain. I tried to put it on the sprocket and it turned out that with thick spacers the new chain does not fit close. We'll have to change the gaskets, which took another hour and a half. After that, I installed the chain, observing the marks on the camshaft and the generator flywheel. The timing chain fit just right and, in theory, even a tensioner was not required yet. New is new... I installed the tensioner - having first reduced the retractable rod to a minimum, and then screwed on the body, inserted the spring and the fixing nut. Put the valve cover on and started the engine. I immediately noticed that the engine began to run smoothly and less noisily.

It will be useful: Engine jammed: reasons

At this point, I completed the timing chain on the 139qmb engine

VIDEO:

Setting the timing belt at 139qmb

CHECKING THE TIMING MARKS____________________Many people call this adjustment incorrectly! This is not an ignition setting, but rather an INSTALLATION OF TIMING MARKS! The generator will produce a spark even without a CPG.

There are several marks on the rotor, we need “T” (Top or TDC), it should be located strictly in the middle of the inspection hatch in the upper part of the crankcase. Not the letter itself, but its mark (mark next to the letter) on the rotor! The second pair of marks will be visible if you remove the characteristic round cover on the head (by unscrewing the bolt whose head is located on the opposite side - there are two more bolt heads, but the one needed is closer to the spark plug). At the camshaft drive sprocket, the stamped recess should be located opposite a small hole oriented forward in a horizontal plane. Since the gear ratio in the timing drive is 1:2, not every position of the piston at TDC (mark T) will correspond to the desired valve timing, but every other revolution. If the mark is not visible, the crankshaft will have to be turned one more revolution. If the marks do not match, unscrew the 3 screws securing the camshaft sprocket, pull out two and leave one in place. It is needed so that the star does not jump to the side. Next, pry the edge of the star with a screwdriver and, holding the star and chain, one link at a time, move the chain along the star in the desired direction. Having moved the chain, use a screwdriver to pry the sprocket from the side of the 2 protrusions in the head hole under the locking protrusion of the cover and insert it with your fingers onto the end of the camshaft. 3 bolt prevents the holes on the camshaft and sprocket from becoming misaligned. We tighten the remaining bolts and tighten them, locking them with a screwdriver between the same protrusions and the star.

Mark F - is intended for checking the ignition timing with a strobe light, just like the other marks without letters.

Source

How to tell if replacement is needed

It is clear that the circuit must be changed when there is obvious dysfunction. When the chain wears out a lot, it makes a loud noise. Well, or jumped over the tooth of a star. Or it fell off, which indicates its stretching and wear.

Standard chain lifespans should be close to the lifespan of the scooter engine itself. It's logical. Each owner operates the vehicle differently, but the average chain lifespan is somewhere between 15,000-18,000 km. In a situation where the engine was halved to eliminate other faults, and the chain was immediately replaced after using it for, for example, 9000 km, everything is clear.

There are options for shortening the chain when stretched. But there are some caveats: if the step does not match, the star begins to erase, i.e. the stretched chain eats the camshaft sprocket. If the wear on the star is small, you can isolate the link and ride it a little. You need to do this correctly, adjusting the chain tension with a tensioner, and not forcibly. Otherwise, you will completely damage the chain.

What is typical for a worn chain: A small point: to check, you need to remove it.

The degree of wear can be assessed by the angle of horizontal deflection. If it sags downwards, going almost vertically, change it 100%. The new chain deviates approximately 45 degrees from horizontal. And by laying out the old and new chains on the surface, you will see that the first one will be longer.

Also, the wear of the scooter's timing chain can be indirectly judged by the level of extension of the tensioner rod. Critical wear is when the rod extends completely.

How to replace the timing chain in an engine

Having decided on such an action as replacing the timing chain of a scooter, you need to decide on how to implement your plan.

There are two replacement options:

- With a thorough disassembly of the scooter engine

- No engine disassembly.

How to change, everyone decides for themselves. Both methods, advantages and disadvantages are described in detail below.

With disassembly

You should choose the right tools - generator and variator pullers (you can make them yourself), a kickstarter sprocket puller, 8, 10, 12 and 17 mm sockets, a hammer, two screwdrivers (flat, Phillips).

The engine is removed from its place, the oil is poured out, all parts are wiped and cleaned. Next, remove the muffler and cooling casing. We remove the generator only with a puller. To do this, unscrew the bolts from the impeller and remove it from the rotor. It is necessary to fix the rotor with a puller and unscrew the nut. Then we tear the rotor off the crankshaft journal. Remove the variator cover. Also, secure the impeller with a puller, unscrew the nut, and remove the variator from the axle.

Below the variator is the kickstarter gear. Likewise, a puller is required for it. Then we clean the cylinder connector, valve covers and cylinder head. After unscrewing the bolts on the valve covers, remove it. Next, remove the scooter's timing chain tensioner. After unscrewing the bolts on the cylinder head, we pull out the camshaft bed.

Next, remove the chain from the camshaft and pull it out of bed. To avoid losing the guide bushings that center the parts relative to each other, you need to remove them and put them away. We remove the cylinder head, the cylinder itself, and the piston (to do this, remove the retaining ring and pin from the upper connecting rod head).

After unscrewing the bolts on the crankcase cover, tapping it a little, remove it from the engine. We take out the starter intermediate gear, use a screwdriver and a hammer to unscrew the overrunning clutch nut (clockwise) and remove the gear and housing from the trunnion. We reached the chain!

Remove the protective shield from the oil pump. Place a metal stick under the chain, twist the nut on the oil pump sprocket, remove it and remove the chain.

No disassembly

We take the following tools: a Phillips screwdriver, pliers, a new chain and a special puller. More details about it will be below. We flare the new chain - to do this, use a puller to press the pin out of the joint of the links, but not completely.

A little about the puller

It is called a timing chain puller. It can be made by a turner by turning a threaded extruding pin and rolling a strong pin into it with a diameter similar to that of a chain pin. You can purchase a ready-made bicycle one. Just narrow the pin a little to the desired size.

Remove the cooling casing from the scooter engine, then the cylinder head cover. Next you need to remove the chain tensioner. We remove the camshaft bed, take out the shaft, remove the star.

We take the puller, center it with the pin, and gradually press out the pin. You can press it out completely, it will not be useful. We compare the links of the new and old chains, thread the wire into the seat of the pin and fix the ends of both chains. We turn the cooling impeller counterclockwise, gradually replacing the old chain with a new one.

Then we separate the ends of the chains, throw out the old one, and combine the new links from the ends. We check the alignment, install the pin, and use pliers to carefully press the pin in so as not to damage the new chain. We first check the mobility of the links. We finalize the pin with a puller. Again we control mobility. This point is very important: if you install the pin unevenly and miss it, it will begin to rest against one of the links and squeeze out the next one.

As a result, the subsequent pin or link bends, causing it to jam and become immobile.

Next, we assemble the engine in reverse order, placing marks on the rotor. When installing the camshaft bed, after tightening the nuts, you need to check the valve clearances with a feeler gauge. Upper valve – inlet: 0.05mm, lower – exhaust: – 0.1. The feeler gauge should fit freely between the valve and the adjusting bolt.

Then install the chain tensioner. We unscrew the bolt on the top of the tensioner, install a screwdriver in the groove, and, turning it, push the rod back. We fix everything else back according to the diagram.

Replacing the timing chain of a scooter with a detailed description

Sooner or later, during the operation of the scooter, the owner is faced with the need to replace any parts. We are not talking about standard consumables such as spark plugs or seals. Replacing the timing chain of a scooter is quite within the capabilities of its owner, this article will help. How to understand whether a replacement is needed It is clear that the chain needs to be changed when there is obvious dysfunction. When the chain wears out a lot, it makes a loud noise. Well, or jumped over the tooth of a star. Or it has fallen off, which indicates its stretching and wear. The standard service life of the chain should be close to the service life of the scooter engine itself. It's logical.

Each owner operates the vehicle differently, but the average chain lifespan is somewhere between 15,000-18,000 km.

In a situation where the engine was halved to eliminate other faults, and the chain was immediately replaced after using it for, for example, 9000 km, everything is clear. There are options for shortening the chain when stretched. But there are some caveats: if the step does not match, the star begins to erase, i.e. the stretched chain eats the camshaft sprocket. If the wear on the star is small, you can isolate the link and ride it a little. You need to do this correctly, adjusting the chain tension with a tensioner, and not forcibly. Otherwise, you will completely damage the chain. What is typical for a worn chain ? A small point: to check, you need to remove it. The degree of wear can be assessed by the angle of horizontal deflection. If it sags downwards, going almost vertically, change it 100%. The new chain deviates approximately 45 degrees from the horizontal. And by placing the old and new chains on the surface, you will see that the first one will be longer. Also, the wear of the scooter's timing chain can be indirectly judged by the level of extension of the tensioner rod. Critical wear is when the rod extends completely.

How to replace the timing chain in an engine

Having decided on such an action as replacing the timing chain of a scooter, you need to decide on how to implement your plan. There are two replacement options:

- With a thorough disassembly of the scooter engine

- No engine disassembly.

How to change, everyone decides for themselves. Both methods, advantages and disadvantages are described in detail below.

With disassembly

You should choose the right tools - generator and variator pullers (you can make them yourself), a kickstarter sprocket puller, 8, 10, 12 and 17 mm heads, a hammer, two screwdrivers (flat, Phillips). The engine is removed from its place, oil poured out, wiped and cleaned all parts. Next, remove the muffler and cooling casing. We remove the generator only with a puller. To do this, unscrew the bolts from the impeller and remove it from the rotor. It is necessary to fix the rotor with a puller and unscrew the nut. Then we tear the rotor off the crankshaft journal. Remove the variator cover. Also, secure the impeller with a puller, unscrew the nut, and remove the variator from the axle.

Below the variator is the kickstarter gear. Likewise, a puller is required for it. Then we clean the cylinder connector, valve covers and cylinder head. After unscrewing the bolts on the valve covers, remove it. Next, remove the scooter's timing chain tensioner. After unscrewing the bolts on the cylinder head, we pull out the camshaft bed.

Next, remove the chain from the camshaft and pull it out of bed. To avoid losing the guide bushings that center the parts relative to each other, you need to remove them and put them away. We remove the cylinder head, the cylinder itself, the piston (to do this you need to pull out the retaining ring and the pin from the upper head of the connecting rod). Unscrew the bolts on the crankcase cover, tap it a little, and remove it from the engine. We take out the starter intermediate gear, use a screwdriver and a hammer to unscrew the overrunning clutch nut (clockwise) and remove the gear and housing from the trunnion. We got to the chain! Remove the protective screen from the oil pump. Place a metal stick under the chain, twist the nut on the oil pump sprocket, remove it and remove the chain.

No disassembly

We take the following tools: a Phillips screwdriver, pliers, a new chain and a special puller. More details about it will be below. We flare the new chain - to do this, use a puller to press the pin out of the link joint, but not completely. We remove the cooling casing from the scooter engine, then the cylinder head cover. Next you need to remove the chain tensioner. We remove the camshaft bed, take out the shaft, remove the sprocket. We take the puller, center it with the pin, and gradually squeeze out the pin. You can press it out completely, it will not be useful. We compare the links of the new and old chains, thread the wire into the seat of the pin and fix the ends of both chains. We turn the cooling impeller counterclockwise, gradually replacing the old chain with a new one.

Then we separate the ends of the chains, throw out the old one, and combine the new links from the ends. We check the alignment, install the pin, and use pliers to carefully press the pin in so as not to damage the new chain.

We first check the mobility of the links. We finalize the pin with a puller. Again we control mobility. This point is very important: if you install the pin unevenly and miss it, it will begin to rest against one of the links and squeeze out the next one. As a result, the next pin or link bends, leading to it jamming and immobility. Next, we assemble the engine in the reverse order, placing marks on the rotor . When installing the camshaft bed, after tightening the nuts, you need to check the valve clearances with a feeler gauge. Upper valve – inlet: 0.05mm, lower – exhaust: – 0.1. The feeler gauge should pass freely between the valve and the adjusting bolt. Then install the chain tensioner. We unscrew the bolt on the top of the tensioner, install a screwdriver in the groove, and, turning it, push the rod back. We fix everything else back according to the diagram.

Which method is preferable?

It is logical that the first option with complete disassembly of the scooter engine is more complicated and takes more time and effort. But, as you can see, it is more reliable. Firstly, the factory integrity of the circuit is not compromised; secondly, by disassembling the scooter engine, you can see any defects, such as cracks, wear, change the seals, clean the parts. The second option is more simplified, can be used when you only need to replace the chain. And you are confident in the quality of your work.

Final word

The scooter is a fairly popular vehicle and is in increasing demand. Because it leaves traffic jams behind, has low operating costs and is economical in terms of fuel and lubricants. Many people prefer to do scooter repairs on their own, especially since four-stroke engines are simple and reliable to use. Timely technical inspections, careful operation and the above article will allow you to enjoy riding this miracle of the Asian motorcycle industry for a long time.

Which method is preferable?

It is logical that the first option with complete disassembly of the scooter engine is more complicated and takes more time and effort. But, as you can see, it is more reliable. Firstly, the factory integrity of the circuit is not compromised; secondly, when disassembling the scooter engine, you can see any defects, such as cracks, wear, change the seals, clean the parts.

The second option is more simplified and can be used when you only need to replace the chain. And you are confident in the quality of your work.

Final word

The scooter is a fairly popular vehicle and is in increasing demand. Because it leaves traffic jams behind, has low operating costs and is economical in terms of fuel and lubricants. Many people prefer to do scooter repairs on their own, especially since four-stroke engines are simple and reliable to use. Timely technical inspections, careful operation and the above article will allow you to enjoy riding this miracle of the Asian motorcycle industry for a long time.

It will be useful: Tips on which battery to choose and how to install it on a Renault (Logan and other models)

Photo report: How to check the timing chain of a scooter?

It’s always like this in life: one thing is good, the other is bad. Exactly the same principle applies to various types of mechanical torque transmissions. Chain transmission was no exception here. On the one hand, there is nothing simpler, more reliable, lighter, more compact and cheaper than a chain drive.

On the other hand, we get eternal “hemorrhage” with stretching of the chain, wear of the sprockets, endless cleaning and lubrication, maintenance and tension of this very chain. But there is nothing to be done, the chain transmission has a lot of advantages over other types of mechanical transmissions, so these types of transmissions are used almost everywhere.

However, today we will not talk about the chain drive as such, but about a method for diagnosing the timing chain driving the camshaft of a scooter engine.

Consequences of a broken timing chain

A broken timing chain has become a real horror story for drivers. This is especially common for beginners. It's no secret that the timing belt, like most car parts, has a finite lifespan. After the timing life has been exhausted, it must be replaced.

As for the consequences of a broken timing chain, it all depends on the design of the power unit. When an engine is running, its pistons continuously move up or down from one dead center to another. During the fuel and air intake stroke, the piston moves to bottom dead center and opens the intake valve. When release occurs, the piston is already moving towards top dead center. And when he reaches it, all valves must be completely closed.

When the timing chain breaks, the camshaft stops rotating and the valves stop in the position in which the chain broke. The crankshaft in the engine continues to rotate, and the pistons are directed towards the open valves. Some engines provide the ability to avoid contact of the pistons with the valves through special recesses. In this case, the consequences will be limited to immobilization of the car. But there are situations much worse.

Modern engines often have multiple valves. They were designed to develop maximum power, so piston recesses are not provided. When the pistons meet the valves, the latter bend and fail. You can avoid breaking all the valves at once if the timing chain breaks at idle. When driving at high speed, the entire set will need to be replaced after a break. At high speeds, the valve guides may also burst, which may even lead to the replacement of the cylinder block. Twin-shaft engines are generally more susceptible to such severe damage.

So, as a result of a broken timing chain, we have a domino effect. First, the valves are bent, then the camshaft along with the bearings is destroyed, then the cylinder head fails, and finally the connecting rods and pushers are bent.

To change or not to change?

Suppose you “overhaul” your engine: you change the seals, crankshaft, gaskets and other devices, but you doubt whether to replace the timing chain with a new one or not. If you doubt it in vain, change it for a new one at the first opportunity. And now I will explain why.

See for yourself: a chain has an average service life of approximately 18,000-20,000 km of a scooter (personal experience), approximately the same as the average service life of the engine itself. And for example, after driving 6,000 km, the crankshaft jammed or the engine leaked, or something else happened that requires complete disassembly of the engine. Naturally, you disassemble the engine, replace the crankshaft with a new one, and leave the chain, which by that time has exhausted a third of its service life.

And what happens? The chain, after 12,000 km, will exhaust its service life and become unusable, but the crankshaft and other parts will be in good order and you, like it or not, will have to again, because of the chain alone, half the engine. Is it necessary? The chain is a consumable item. Never skimp on it!

Replacing the timing chain

The time has come to change the timing chain, and along with it, I would also recommend changing the chain guide, tensioner and camshaft sprocket, which will save you a lot of time in the future.

To replace the timing chain if it is overstretched, you need to:

- Remove the cylinder head (the cylinder itself does not need to be removed)

- Remove the crankcase cover

- Remove the generator rotor and crankshaft chain drive parts from the electric starter (the electric starter itself does not need to be removed.)

- Remove the cover of the left crankcase half (it is not necessary to separate the crankcase halves)

To access the timing chain, use a Phillips screwdriver to unscrew the two screws securing the cover of the left half of the crankcase (it is advisable to perform this operation with an impact screwdriver)

The cover contains the crankshaft oil seal, which can be replaced if necessary.

We use a key to unscrew the pin of the timing drive guide pulley, which is located on the left side of the cylinder. We remove the pin with the washer and remove the timing chain guide roller towards the cylinder head.

We remove the movable timing belt tensioner wheel and remove the chain through the crankcase cavity.

After installing a new chain, as well as when removing the crankshaft, it is necessary to align the marks in the timing drive

- The “T” mark on the generator rotor should be in the middle of the inspection hole in the generator cover.

- The mark on the camshaft sprocket must be in the prescribed position.

The matching marks are checked after engine assembly.

It should be borne in mind that attempts to turn the crankshaft with mismatched marks can lead to damage to engine parts.

There is also a way to replace the chain, which involves less disassembly of the engine. Having gained access to the timing chain, the old one is disconnected, which is also done with the new one... then both chains are connected... the chains are pulled through... the new chain is connected....

It seems like a simple method, but look what can happen. Replacing the chain, and a week later you suddenly have to change the tensioner. And a week later, a sedative... and then an asterisk. So it turns out that it is better to replace everything at once.

Examination

Personally, I never check timing chains. I simply throw them in the trash, no matter how awesome they seem to me. For me, a chain is a consumable, just like a spark plug, oil or oil seal. But if you are important, or money is tight, you can use the old fashioned way.

We stretch the chain along its length, hold it with our fingers and try to position it in a horizontal position

- If the chain describes an arc that looks very much like a 90-degree angle, then feel free to throw it in the trash.

- If the chain bends slightly and describes a small arc, then such a chain is quite suitable for further use

For clarity, I took a new and heavily worn chain, put them together and checked for horizontal deflection. As you can see: the new chain (above) described a barely noticeable arc, while the worn and useless chain sagged like snot, almost at an angle of 90 degrees.

The worn chain turned out to be almost a centimeter longer compared to the new one.

How to replace the timing chain of a scooter engine?

It’s very simple, my friends: you remove the engine from the frame, disassemble it and replace the chain with a new one. There are no special secrets in this matter, just as there are no special ways to “cheat fate” and replace the chain without disassembling the engine. The chain can only be replaced by completely disassembling the engine.

There is, of course, one guy on YouTube who rivets an old chain, then rivets a new one, connects both chains, pulls out the old one, starts a new one, and then rivets the whole thing back, but that’s porn. I don’t suffer from such crap, since the result of such “repairs” is not always predictable.

The timing chain is in no way designed to be riveted or riveted. During the riveting process, it can easily be pulled or twisted, and this is a sure way for the chain to fly off the sprocket while the engine is running, and then, depending on your luck... Maybe everything will work out, or maybe the valves will bend. And one more point: a beginner will not be able to rivet a chain efficiently. This work is not as simple as it might seem at first glance. Therefore, don’t suffer from bullshit and disassemble the engine.

Photo report: Adjusting valves on a Chinese scooter (139QMB, 157QMJ)

During operation of a four-stroke air-cooled engine (such engines are found on most Chinese scooters and motorcycles), the cylinder head (hereinafter referred to as the cylinder head) can heat up to 260 degrees. This is, of course, not the operating temperature, but this is often the peak temperature.

The valves that are located directly in the cylinder head itself heat up in the same way as the head, with the only difference that the intake valve heats up a little less since it is cooled by the working mixture, and it is ordinary atmospheric air saturated with gasoline vapors, and the exhaust valve heats up much more. Since a flow of exhaust gases passes through the exhaust valve, the temperature can reach 600 degrees.

The problem is that metal parts expand when heated. Valves are no exception: during operation, the valve heats up and becomes a little longer. And when the valve becomes longer, it simply rests against the gas distribution mechanism and opens a little, or rather does not close completely (squeezed), due to which gases under high pressure seeping through leaks melt the working edges of the valve and its seats.

The edges of burnt valves look something like this.

By the way, not only the valves burn out, but also the sockets in which they sit

And this is what the working edges of valves and seats look like after repair.

As you can see, there is little point in regulating something that has already gone bankrupt for a long time. A burnt-out valve will no longer hold compression. And if you find that one of the valves has been jammed, then feel free to remove the head and grind the valves, otherwise there will be no point.

How to adjust and tension the chain?

There’s no way you can tighten it or adjust it, and you don’t bother Google or Yandex search with such queries. The chain in the scooter engine is tensioned automatically. And if it has already stretched to such an extent that it begins to fly off or jump over the teeth, feel free to disassemble the engine and replace it with a new one. There are no miracles.

And I will prove this to you now. The chain in the engine is tensioned using a special tensioner, which operates in a fully automatic mode. As the chain stretches, the tensioner rod, under the action of an internal spring, comes out of the housing and tightens the chain. And the more the chain stretches, the more the rod will come out. But! The rod has a limited stroke: on a completely new chain it comes out about a third of its stroke and then, as it stretches, it comes out completely and then it won’t come out anymore. Therefore, the chain will no longer be tensioned! And all your attempts to correct the situation will lead to nothing.

How to set the ignition on a scooter

The ignition system plays an important role: without it, not a single vehicle with a gasoline or diesel engine will move. The quality of engine operation, whether it will start in cold weather, and whether it will work correctly depends on how it is configured. Depending on how the ignition is set and what spark plugs are selected on the scooter, it depends on whether it will go or not. From this material you will learn how to set the ignition on a scooter yourself, what you will need for this, and how to set up a contactless system.

How to set the ignition on a scooter - an eternal question and a simple answer

Operating a scooter and enjoying its ownership brings a lot of positive emotions to the owner. In general, a scooter is a truly unique motor scooter, which is an almost universal transport. The scooter is great for driving around the city and for traveling outside of it. And everything would be fine, but sooner or later the moment comes when it has to be repaired and maintained, something that motorcyclists like to do much less of. Also, you often have to adjust and set the ignition, which few people know how to do correctly. It’s exactly how to set the ignition on a scooter that will be discussed in today’s article.

The principle of operation of ignition in a 4-stroke scooter engine

Modern scooters are equipped with contactless systems. They are considered the most reliable and easy to use, do not require complex connections, and provide a constant good spark on time. However, the setting is still important; even the presence of a spark does not always allow the fuel mixture to ignite, since its power also plays a role.

The main reasons for the operation of the ignition system are quite simple: its task is to create a spark to detonate the fuel mixture. If this does not happen, you need to carefully examine each node and find out why the spark disappeared.

- In order to check whether there is a spark at all, you need to unscrew the spark plug and apply it to the engine ground; this can be done using metal objects that are not covered with paint. You cannot hold it with your hand: if there is a spark, it can give you an electric shock, and the discharge reaches 40,000 volts, which the coil creates.

Broken ignition is the cause of engine failure

An incorrectly configured or faulty ignition often causes engine failure. It would be wrong to immediately climb into the cylinder and examine the insides of the scooter, especially since this will not solve the problem. Before touching the ignition system, you need to check for other reasons why the scooter may not work.

- The simplest thing is the lack of gasoline in the tank. Quite often, owners forget to refuel their vehicle, and such a trivial reason can be overlooked.

- The carburetor may be clogged, which prevents the formation of a mixture suitable for driving.

- The carburetor needs to be cleaned regularly, so it doesn't hurt to check whether fuel is flowing from it into the cylinder. It is possible that the fuel pipe is clogged. The jets and other parts of the device may become clogged with debris, which causes little fuel to flow or, conversely, the engine does not have enough air, and therefore it does not start.

- The scooter may also refuse to start if the fault is caused by spark plugs. They may be wet or not produce a normal spark. It is advisable to have a spare set and check with it. In any case, the spark plug needs to be unscrewed and inspected.

How to set the ignition on a scooter

With minimal experience, but good theoretical knowledge, you can set the ignition yourself. To do this, you just need to strictly follow the instructions below.

The most important part of tuning is to find the correct position for the timing sprocket to sit. In order to find it, they use special marks that are applied at the factory during engine assembly. The desired mark looks like the letter "T". In this position, the piston is at dead center. This is the extreme position after which the piston will return back. You need to rotate the rotor until the protrusion on the crankcase and the letter “T” coincide. This can be done using your hands or a kick starter. An electric starter does not need to be used.

If the piston has only moved down minimally, turn it further until the marks line up. It's not always possible to get the right position the first time. After they match, you need to study the other marks: they are located on the timing star. Usually these are three points or holes that are located on the outside of the star. They form a triangular shape if you connect them visually. Notice that one point is larger than the others. After adjusting the ignition, it should be on top, and the other two marks should remain opposite each other. They must stand horizontally.

If the ignition is contactless, it is adjusted as follows. In order for the engine to run smoothly and correctly, you need to adjust the ignition of the mixture at the right moment. To do this, after all the tags are installed in the right places, you need to understand how the contactless principle works in general.

A special feature of the BZS is the presence of special sensors, a switch, and two types of ignition coil winding. When the sensor is closed using a rotor equipped with a magnet, a pulse is generated that enters the commutator, it pumps up the current coming from the generator and directs it to the primary winding of the coil. After this, the charge enters the secondary winding, where a high voltage is generated, with the help of which a spark appears, used to detonate the gasoline mixture. Adjusting the ignition is the alignment of the marks on the crankcase and the star. Usually you have to remove the valve cover.

After this you need to do the following:

- Labels are set in the manner described above.

- In order to set the ignition angle, you can release the stator mount and adjust it in accordance with the technical requirements of your vehicle.

- Make sure that the marks or holes are in the correct position.

What is advance ignition

The quality of the mixture supplied to the engine cylinder determines the behavior of the scooter in cold weather, as well as how high the wear of the cylinder itself will be. For example, with a rich mixture, the engine starts better, but carbon deposits form; with a lean mixture, the cylinder quickly wears out and traction is lost.

In order to facilitate the process of starting the engine, you can set the ignition to advance, this will make it easier to start the engine regardless of the weather outside, slightly increase engine power, and significantly increase traction. The peculiarities of such settings are that a charge is formed in the spark plug before the piston reaches the dead center. This makes it easier to start the engine and increases engine power. However, it is worth remembering that cylinder wear may increase.

The procedure is carried out in approximately the same way as a regular ignition adjustment, but has its own nuances. To do this, all the same actions are carried out, only the tags are not completely connected. The discrepancy should be approximately half a centimeter. This is enough to get the desired effect.

How to set the lead angle (video)

About adjusting the ignition of a 4t scooter

Knowing how to set up the ignition of a 4T scooter on your own, you can save time and money, since you will not need to contact a motorcycle repair shop. The procedure is simple, even if you have no experience it takes a little time, but you will need to be patient. Regardless of the type of ignition, an important role is played by how the marks are set.

Correct adjustment is a guarantee of stable and smooth engine operation even in cold weather conditions. Often, in used vehicles, the ignition is broken: this can happen for various reasons, ranging from elementary shaking when driving to improper handling of the equipment. In order for the scooter not to let you down and for you to be able to start it whenever you want, you will need to learn how to carry out this procedure yourself. To do this, you will need to have several keys that allow you to remove the valve cover if the engine is four-stroke.

Setting up the Vision scooter ignition system

If the ignition is knocked out, this may be the reason the scooter does not work. Restoring it is not difficult if you understand how it is done.

Advice: before starting work, carefully check and clean the carburetor: this may be the reason. Adjust the quality of the mixture. In addition, it doesn't hurt to check the spark plugs.

You need to start adjusting by setting the timing belt in the desired position. As a rule, there are marks on it for this purpose; they are set at the factory. The cylinder must be installed at dead center. The mark may be indicated by the letter T or another symbol. Now make sure that the mark installed on the rotor matches the mark found on the magneto. To do this, you need to gently press the kickstarter. The rotor can also be turned using your hands, but this is more difficult.

There are also marks on the timing star in the form of holes or dots; they must be set so that the largest hole is on top and located exactly in the center. The remaining points should be below and located horizontally opposite each other. Setting the ignition advance makes sense if you want to increase the engine's power a little and make it start easily. The adjustment will help make the spark plug produce a spark earlier than the standard time. That is, a spark will appear even before the piston reaches the dead center. In cold weather, a moped configured in this way will start better.

In order to configure the scooter in this way, you will need to repeat the procedure described above. However, there is a difference: the marks should not coincide clearly, and not reach each other by about 0.5 cm. The main difficulty lies in connecting the marks.

Scooters Maintenance and repair

On a four-stroke scooter, one of the main problems is the operation of the carburetor and misalignment of the valve settings. This unit constantly requires adjustment and checking, and if your scooter suddenly loses power, starts up poorly and picks up speed very slowly, and at the same time you hear a weak clatter from the engine, you definitely need to check and take further action. On Chinese four-stroke bikes, why does the gap setting often go wrong? Perhaps this is due to the quality of the metals and workmanship

maybe with something else, but this is no longer important to us, the main thing is to adjust everything correctly and on time

First, you need to remove the plastic that prevents you from getting to the cylinder head, then remove the cooling casing and unscrew the head itself. This is what the cylinder looks like with the head removed. You will see two valves, as well as a sprocket with a tensioned timing chain. The star has holes and engraved stripes. In our case, to check the clearance, we first need to set the piston to “Top Dead Center”. To do this, remove the cooling impeller casing and fix the nut with a wrench so that you can turn the crankshaft. We turn it until the two small holes with stripes are parallel to the cylinder, and the large hole is on top.

The mark is indicated. To determine whether the “dead center” has really been found, lightly turn it with a wrench in two directions, the valve rocker arms must be motionless. Now we proceed directly to the adjustment, for this you will need this set of feeler gauges. To adjust the valves, such a set is required. We need this set You will need 0.05mm and 0.1mm probes. First we take the first one, we will use it to adjust the intake valve.

The dipstick should fit tightly in the gap, and you should not create any effort to pull it out. After adjustment, tighten the locknut. We do the same action with the exhaust valves, only we take the feeler gauge by 0.1 mm. Adjusting the intake valve with a feeler gauge by 0.05 mm The intake valve is at the top, the exhaust valve is at the bottom. The clearances are indicated. After fixing the settings, we assemble everything in the reverse order, cylinder head, casing, plastic. Check the clearance regularly, during intensive use of the scooter, keep the carburetor clean, and most problems with repairs will be on your side.