Among the three types of drive trains on a motorcycle, there are two that have one thing in common: they require no maintenance. If the chain needs to be washed and lubricated every 500 km, then the belt and cardan will serve you for tens of thousands without any maintenance.

MY MOTORCYCLE

Of course, for many guys I won’t say anything particularly new, but I also want to make my contribution and “put in my two cents” on the topic of belt drives on a motorcycle. Nowadays, there are no problems at all when encountering a motorcycle with a belt instead of a chain or cardan. Some motorcycle manufacturers are returning to this topic and producing bikes with this type of drive. For those who don’t know, belt drive of the rear wheel on a motorcycle arose along with two-wheeled horses.

Their history begins in the first half of the 20th century, when the first motorcycles appeared: leather belts were placed on them - most often they were smooth, and due to friction and tension they rotated two absolutely round disks. But over time, the belts began to show their shortcomings. It slipped when wet, quickly stretched, and limited the designers in the amount of transmitted torque. And the first motorcycles were not particularly powerful: the power of the first motorcycle, built in 1902 by Siegfried Bettman, founder of the Triumph brand, was as much as 1.75 horsepower! The same amount as the Triumph Rocket III starter now has... The power of the motors grew, and the belt was quickly replaced by the chain. But the story of the belt drive still did not end there.

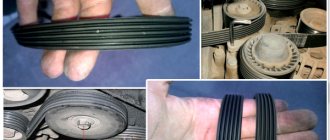

But why did belt drives return to motorcycles and why does it attract attention? With the advent of timing belt manufacturing technology (with a good cord made of artificial fibers), it became possible to return to this type of transmission again. Over these hundred years or so, belts have evolved greatly: they began to be made from high-quality rubber, super-strong Kevlar threads and other components. Firstly, it requires almost no maintenance: install a belt and for 50,000 kilometers you won’t think about anything. This does not work with a chain: it requires maintenance, and you need to look after it very carefully; in addition, over time it stretches, and the motorcycle begins to make a lot of noise. As already mentioned, the belt life on most motorcycles ranges from 40 to 70 thousand kilometers. The clear advantages of the belt include the absence of losses when transmitting torque from the engine to the wheel and unsurpassed smoothness. It absorbs shock loads well and is quieter than a chain, which has a positive effect on comfort. A belt with pulleys is lighter in total than a chain with stars. At the same time, it requires virtually no maintenance and lasts longer than the chain. You just need to monitor its condition for cracks and tears. Manufacturers do not regulate the service life of a belt, and it is definitely (and significantly) longer than that of a chain.

But nothing is ideal in our world! The same thing happens with the belt - it also has disadvantages:

The biggest disadvantage is that it cannot be used on all motorcycles. Mainly on choppers and even those. That they only ride on asphalt. Why? — The belt drive can only operate in relative cleanliness; dirt is not removed when the belt runs onto the pulley. Therefore, protective covers around the belt are mandatory, and such motorcycles should only be driven on asphalt, so belts are installed mainly on choppers. If the belt is not protected enough. A foreign object may get into it, and the belt will inevitably break.

Also, modern belts are toothed, and the rear drum along which the belt runs is made of aluminum coated with more durable chrome. The chrome, although durable, is gradually worn down by the belt, sand and water that hits it, leaving bare aluminum. When this happens, the belt teeth begin to wear down and eventually they pull out and the belt breaks.

Therefore, when replacing a belt, it is also necessary to change the driven pulley, which is located on the rear wheel - these pulleys are made of aluminum, while the drive pulleys are made of steel. The pulley diameters must be large enough to reduce belt bending. And if this is not critical for the driven pulley on the wheel, then there may simply not be enough space on the engine for the driving one. Its width is greater than that of the chain, which also causes difficulties for designers. I want to put a wider wheel, a belt has to go next to it, the frame has to be made wider, and so on. The lack of slack in the belt and limited ability to stretch makes it impossible for the rear suspension to travel much.

Another problem with the belt can be a manufacturing defect. Although all belts are made using the latest technology and equipment, they are also made entirely by hand. Defects are inevitable in any production. You can try to return the belt, but, to be honest, it’s easier to buy another belt than to prove that the previous one broke due to a defect. Most often, of course, manufacturers refuse defects, claiming that incorrect installation or the entry of a foreign object is to blame for belt damage, and the manufacturer is not responsible for such incidents.

Usually belts actually break due to improper installation. If the axle is uneven, even less than a millimeter, the belt will constantly break. Moreover, the quality of the installation may, unfortunately, not depend on the eminence of the master or workshop, since the mechanic may get distracted during the installation process and do something incorrectly.

The belt must be at a certain tension all the time: not too tight, because then it will break even faster, but not loose. To evenly tension the belt, you need a special device, which is available in any motorcycle workshop. To assess the sag, look at the protective cover, which should be present on any belt motorcycle: there is a slot with divisions. When you press the belt in this place, you can tell by the divisions. how much the belt can sag. Usually this is 1-2 centimeters, but you can’t rely on this figure, because each motorcycle and each belt has its own tension: to find out the exact number, you need to open the manual and read about your motorcycle and its belt. Don't overlook belt slack because it can ruin your entire season.

WHEN DO YOU NEED TO CHANGE THE BELT DRIVE?

The instruction manual for each specific motorcycle states after how many kilometers the belt needs to be replaced. If it says that the belt drive needs to be changed after 50,000 kilometers, but in your opinion it looks great, change it anyway. At least to know that you did everything right and not to expose yourself to danger on long trips. Belts are divided into cheap, original and expensive. Cheap ones, of course, may not be of very good quality, original ones are usually much better, and expensive ones, which cost more than original ones, can be an order of magnitude better than original ones. It makes sense to overpay for a belt while you are in the city, rather than spend fabulous money on evacuation from somewhere on the highway. Of course, this is also an adventure, but an unplanned one, and experience shows that nothing is better than planned adventures.

CAN I REPLACE THE BELT MYSELF?

You must answer this question yourself. For some, changing the spool (for example) is a problem, for others it’s not even a problem, it’s easy to change the engine and frame or change everything to suit yourself. So if you are not afraid and there are manuals, etc. then go ahead guys!)))))) Changing the belt is not difficult if you follow the instructions and study additional materials that are freely available on the Internet. But I will repeat. that replacement must be carried out especially carefully, therefore

FIRST , strictly follow the flow chart for the sequence of disassembling, assembling, removing and replacing the belt.

SECOND , put all the bolts that you removed in one place, and if there is any bolt left after you put everything back together, you will know that you did not tighten something.

THIRD , if you take a bolt or nut and place it where it should be, tighten it immediately. You can get a bolt on and then get distracted and come back and see that the bolt or nut seems to be in place, which means you can move on to the next one. And it turns out that you have one bolt left loose, which is dangerous for you and for the motorcycle.

NEXT ADVICE . After you have tightened all the bolts exactly, you take it and tighten it again. Then you will be 100 percent sure that nothing will go wrong along the way. When you remove the bolts, you may notice that some of them are treated with thread sealant. When screwing them back in, try to use the same sealant that was on those screws: blue, red or clear. You need to buy sealants in exactly the same colors and use them in the right place and at the right time. You should not lubricate generously, but in small droplets. If the screws do not come out, it means they have thread sealant on them. And screws with thread sealant only unscrew if they are heated.

THE NEXT NUANCE is alignment. Once you have the wheel and rear pulley in place, you should tighten everything 70% and then tighten the belt. It needs to be pulled onto a rigid structure, and not when everything is dangling. After you have tightened all the screws with a torque wrench, you need to check the tension - it should remain the same.

When assembling and disassembling, pay attention to the pulley: it must be smooth, it should not dangle, and you must be sure that the pulley from previous accidents or tire fittings is not damaged, not moved or dangling, it must have edges in its “primeval” state that hold the belt.

In addition, you must keep an eye on the bearings. There are rear pulleys with and without bearings, tightly screwed. If your pulley has a bearing, pay attention to its durability: if it is dead, naturally it needs to be replaced. If your pulley is screwed tightly, then usually all its bolts are treated with thread sealant, it itself is very wide and the belt is also wide. If the belt with the pulley and damping insides does not hit hard, then it is made thin - then all the shocks are smoothed out, since they pass through the rubber dampers. This belt has no peak loads. Thinner belts are found on more modern motorcycles, and wider belts are found on older motorcycles...

good luck on the roads!)))))))))

Hydraulic drive

Yamaha's design in collaboration with the Swedish company Öhlins is a real breakthrough in creating a simple and reliable drive.

The work scheme turned out to be the most optimal:

- minimum production costs

- easy to maintain

- reliability of design

- optimal distribution of torque between the wheels

Yamaha WR450F 2-Trac - production model with hydraulic drive

The WR450F 2-Trac bike appeared in 2004. 20% of the power is supplied to the front wheel, which is enough to overcome difficult obstacles. However, the cost of the bike turned out to be expensive for the buyer, so Yamaha did not produce all-wheel drive motorcycles for long.

Toothed belt

It transmits rotation not only due to friction, but also due to the engagement of the teeth with the geometry of the pulley wheel. This achieves high transmission rigidity, synchronization of shaft rotation, high transmission efficiency and reduced load on the bearings of both the drive and driven shafts. The use of a timing belt allows greater power to be transmitted at significant speeds, but the design requires complex and precise adjustment. This is due to the fact that its service life depends on the degree of tension of the belt, and since it is expensive, frequent replacements will lead to significant expenses.