(2

ratings, average:

4.50

out of 5)

Ant is a three-wheeled cargo moped that was produced by the Tula plant. The Ant gained popularity due to its versatility of use and cost. A working motorcycle was a way out of the situation of not being able to purchase a car during Soviet times. A load capacity of 250 kg, with a weight of 240 kg, made this transport indispensable in agriculture.

The scooter is distinguished by high maneuverability and maneuverability, as well as small dimensions. In the garage it will take up as much space as a heavy motorcycle with a sidecar.

The Soviet scooter "Ant", which is still popular, has the following technical characteristics:

- Length – 2.68 m.

- Width – 1.25 m.

- Height – 1.07 m.

- Dry weight – 240 kg.

- Load capacity – 250 kg.

- Speed – about 30 km/h.

- Gasoline engine, two-stroke, 11 hp.

- 4-speed gearbox + reverse.

- Drum brakes with mechanical drive on each wheel.

Among fans of this brand, there is an opinion that the scooter is not inferior in performance properties to its Western counterparts.

Among the advantages of a moped it is worth noting:

- Small turning radius – 3.5 m.

- The lightness of the Ant scooter; motorcycles significantly predominate in weight.

- Low cost - only used devices are available on the market.

There are also disadvantages:

- There are a lot of used equipment on the market.

- The engine has high fuel consumption - from 8 liters. per 100 km. But more often this figure is closer to 10 - 11 liters. per 100 km. due to increased wear.

- Frequent breakdowns due to low reliability, especially of the engine.

Ant owners have the most questions about the engine. After all, I want to moderate my appetite for fuel consumption.

The Ant was equipped with a motor that was different from others produced by the industry of the Soviet Union. Innovations in its design fueled interest in technology among then ordinary people. And now they are warming up restorers and collectors. The differences are as follows:

- Availability of electric starter.

- Forced cooling.

The main difference is the presence of an electric starter. This made it possible to start a moped in the same way as a car.

The cooling system fan moves air through the engine casing, removing heat from it. It is worth noting that such a scheme works tolerably.

The motor design is simple. But even this does not protect it from breakdowns, which are often associated with age. You shouldn’t just disassemble the engine, but if the following symptoms appear, you should take up the tools:

- Startup problems.

- Oil leak.

- Lack of traction.

- Increased background noise.

- The winding lever does not return to its place.

Possible breakdowns:

- Worn seals.

- Poor quality assembly after previous repair.

- CPG failure.

- Worn bearings.

- The return spring in the kickstarter has broken.

Note! Before overhauling the power plant, it is not necessary to wash it. Just drain the oil and remove it from the frame.

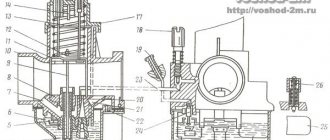

Cylinder block

After unscrewing several bolts, you need to remove the cylinder head. Pay attention to the worn cylinder head gasket. Opposite the outlet window, you should probe the so-called excavation. If a characteristic wave or step is felt, then such a cylinder needs to be changed or bored.

Burnout occurs where the piston rings contact the cylinder. Where they work, the metal wears out, so a transition is formed at the border of the two zones, which reflects the degree of wear.

The piston should be examined for wear. Some “Kulibins” manage to refine it with sandpaper.

Clutch

- Removing the clutch cover and kickstarter shaft. Pay attention to the return spring - it often breaks and the kickstarter does not return to its place. Also at this point you can check the timing chain tension.

- Clutch disassembly. To do this, you will need to unscrew the nuts and remove the pressure plate from the basket.

- The lock washer must be bent and a stick must be inserted under the tooth of the main gear sprocket. Please note that the threads on the crankshaft journal nut are right-handed. The nut needs to be unscrewed.

- There will be another lock washer that needs to be straightened. We take a puller and fix the clutch drum. The clutch nut has a left-hand thread.

- The disc and drum are removed, as well as the clutch basket is removed from the shaft along with the chain and drive sprocket.

Dinostarter

Remove the following elements:

- Cooling casing.

- Ignition chopper cam, but provided that the power plant was not converted to a magneto. In this case, it is necessary to fix the dyno starter rotor. This can be done using the cooling fan or by fixing the crankshaft with improvised means.

- The rotor is dismantled using a puller - standard or homemade.

As a result, the rotor was removed.

Characteristics of the Ant scooter

The scooter is distinguished by high maneuverability and maneuverability, as well as small dimensions. In the garage it will take up as much space as a heavy motorcycle with a sidecar. The Soviet scooter "Ant", which is still popular, has the following technical characteristics:

Among fans of this brand, there is an opinion that the scooter is not inferior in performance properties to its Western counterparts.

Among the advantages of a moped it is worth noting:

There are also disadvantages:

Ant owners have the most questions about the engine. After all, I want to moderate my appetite for fuel consumption.

Installing a Lifan engine on an Ant scooter. Motor scooter "ant" with Lifan engine

The three-wheeled ZiD cargo motorcycle with an onboard dump body is designed for delivering various types of cargo over short distances. The LF200ZH-3 trike is economically beneficial not only for private owners and farmers. Such a vehicle is often used by public utilities and large industrial enterprises where prompt transportation of equipment is required.

The ZiD Lifan cargo tricycle is equally practical in rural areas and in urban environments. Like the Soviet motor scooter Ant, a modern motorcycle with a body is convenient to use for moving on paved roads, for example, welding or any other equipment for repair, and for residents of villages and small towns it is simply an irreplaceable and faithful assistant.

The ZID LF200ZH-3 model is equipped with a Chinese Lifan 163 FML-2 engine with a maximum power of 17.5 hp. or 12.5 kW. The volume of one cylinder located vertically is 200 cm³. Fuel is supplied through a Sheng Wey carburetor. The four-stroke gasoline engine starts with an electric or kick starter, has an air cooling system and runs on AI-92 gasoline.

The five-speed manual gearbox is located in the same block with the power unit, and the multi-plate clutch is in an oil bath. The driver shifts gears with his foot, and the clutch control is located on the steering wheel. The motor transmission is gear. For efficient maneuvering in confined spaces, reverse gear is provided.

The front suspension is made in the form of a telescopic fork with two spring-hydraulic shock absorbers, the rear suspension is a spring suspension in which hydraulic shock absorbers are not used. The front and rear wheel discs use drum-type brake mechanisms with a mechanical foot drive. The emergency and parking brakes are operated by a mechanical hand drive.

To watch online, click on the video ⤵

Motor scooter ant engine IZH-planet 3. Read more

Moto scooter with Planet 5 engine. Read more

ant with planet sport engine 28 liters Read more

Ant mountings for installing an IZH engine Read more

Izh with an ant engine. More details

Review of the Ant scooter, a dump truck with a lifting mechanism. More details

Motorcycle pickup truck based on IZH P5 and Ant. More details

Ant 2m01 with IZH Planet 3 engine Read more

Ignition from a chainsaw on a tula Read more

Tricycle from Izh Planet MurIZh Read more

Ride on Ant. with engine IZH Planet 3 Read more

Motor scooter Ant (TGA-200) with an engine from a disabled woman. A short review. More details

How to increase engine power of an Izh motorcycle Read more

Review of Homemade mini tractor with IZH Engine Read more

Vehicle Upgrades

If your old bicycle, scooter or motorcycle breaks down, you should not sell the equipment for scrap. There is also no need to rush into buying a new motor. It can be replaced with a power unit from a light motor cultivator. There is only one restriction: such a car cannot be driven on public roads. But the Ant scooter with a walk-behind tractor engine can be used in the country for trips to a field or river. 5-6 hp engine quite enough to accelerate the moped to a speed of 50-60 km/h. Before installing the engine on a bicycle, it is necessary to install reinforced wheels on this vehicle that can withstand a weight of up to 100 kg.

In order to assemble a scooter with a walk-behind tractor engine, you will need the following tools and materials:

In order to install the power unit on the Ant, you will need to create a frame for it.

This is done in the following sequence:

If you have experience in handling household tools and knowledge in electrical engineering, you can assemble an electric excavator with your own hands. This will require channels, hinges, cables and a working electric motor. The bucket is made of sheet steel, which can be purchased inexpensively at scrap metal collection points.

Ant engine

The Ant was equipped with a motor that was different from others produced by the industry of the Soviet Union. Innovations in its design fueled interest in technology among then ordinary people. And now they are warming up restorers and collectors. The differences are as follows:

The main difference is the presence of an electric starter. This made it possible to start a moped in the same way as a car.

The cooling system fan moves air through the engine casing, removing heat from it. It is worth noting that such a scheme works tolerably.

Engine

The Ant engine is somewhat different from Soviet engines of that time. The most significant difference is in the starting system: here it can be done using an electric starter (this was very cool in the 50s) or using a manual kickstarter. There was no trace of an electric starter on any Soviet motorcycle of those years.

The engine is started with the starter just like a regular car: insert the key into the ignition, turn the key all the way to the right and the engine starts.

The second difference is the forced cooling of the engine

The fan drives air through the casings, cooling the cylinder and cylinder head. The cooling system works tolerably

Mechanical clutch with cable drive from a lever on the steering wheel

The gearbox is manual, the shift lever is located on the left directly under the driver’s foot. The switching algorithm is as follows: first, second, third and fourth gears are switched up. Neutral gear is at the very beginning and to engage it you need to push the gear lever down. Controversial decision, but that's how it's done here

Twin-shaft gearbox with constant gear meshing

How to disassemble and reassemble the engine of the Ant scooter?

The motor design is simple. But even this does not protect it from breakdowns, which are often associated with age. You shouldn’t just disassemble the engine, but if the following symptoms appear, you should take up the tools:

Possible breakdowns:

Note! Before overhauling the power plant, it is not necessary to wash it. Just drain the oil and remove it from the frame.

Cylinder block

After unscrewing several bolts, you need to remove the cylinder head. Pay attention to the worn cylinder head gasket. Opposite the outlet window, you should probe the so-called excavation. If a characteristic wave or step is felt, then such a cylinder needs to be changed or bored.

Burnout occurs where the piston rings contact the cylinder. Where they work, the metal wears out, so a transition is formed at the border of the two zones, which reflects the degree of wear.

The piston should be examined for wear. Some “Kulibins” manage to refine it with sandpaper.

Clutch

Dinostarter

Remove the following elements:

As a result, the rotor was removed.

Music on the road: how to connect speakers to an amplifier in a car, and which ones are better to choose?

How to fill out the European Protocol in case of an accident, how long is the document valid? Find further information.

Motor "Green Ant" - a unique Russian development

Designers from Russia invented a motor, the distinctive feature of which was the absence of a crankshaft in the design.

A distinctive feature of the development is a new method for converting the translational energy of the pistons into rotational energy. Theoretically, such a motor should operate at lower speeds, developing a greater degree of torque, and being one third more economical than an internal combustion engine.

Work in theory. The design of the device, designed to take power from a power plant in the form of an internal combustion engine, does not allow violation of the existing laws of nature and the basic principles of science. During the implementation of the project, a completely new design of the internal combustion engine was implemented, which did not change the principles of its operation and did not affect the fundamentals of the theory of internal combustion engines. The difference will be in the method of transmitting force during operation, and it lies in physical laws, and not in motor theory.

Using the existing motor theory, the processes that occur in inertial machines, which are almost all existing design options, are determined. The fact is that the direction of the inertia forces in the structure in almost all places is the same as the direction in which the force is applied for work, as a result of which all actions will be converted into rotation in one direction. This makes it fair to indicate in theoretical information about the motor the fact that almost all the efficiency of the device is concentrated in the cylinder, and represents the quality of the work process, but its efficiency does not significantly depend on the design option used. But the application of such a theory is not possible for inertia-free machines.

It is no secret that the basis for the operation of any type of motor is the basic physical laws, which makes it possible to explain the difference using the law of the addition of forces. The reason that the motor can develop high torque from the very beginning of operation is the fact that the electromagnetic field seems to “pull” the rotor along with it, without the formation of inertial forces. The result is the formation of a direct transmission, like a gearbox. The question arises: why can’t a conventional internal combustion engine produce the same level of torque? The answer is that the piston has to push the crankshaft, which causes the formation of inertial forces acting in the same direction. It is precisely the presence of its own inertial forces in the mechanism for performing work that becomes the reason for the absorption of most of the available effort. In other words, the work is transferred to the execution mechanism, which then moves independently.

The process of power distribution. For a crank mechanism, two forces participate in the process of work - the work process and the inertia process. Due to the fact that the action of these forces is carried out in the same direction, then, according to the law of the addition of forces in the same direction, with different points of application, only one of them can perform useful work. The higher the engine rotation speed, the greater the inertial force of the entire structure will become, while the value of the work force remains unchanged. Despite the increase in the number of cycles, the efficiency of the motor remains at the same level. Increasing the load on the output shaft will have no effect other than increasing fuel consumption.

Fuel system

The power system consists of a fuel tank, carburetor and air filter

Fuel supply by gravity, supply control by mechanical fuel tap

The latest scooters were equipped with a more advanced K-65G carburetor. In general, the carburetor is very good, if only because it has two systems that make starting easier in cold weather: a manual enricher on the steering wheel and a float suppressor. All these systems together ensure reliable engine starting in any frost

To increase low-end thrust, a reed valve was added to the engine design. The valve is installed in the cylinder and blocks the reverse emission of fuel from the crank chamber

The cylinder is purged with three channels. Three-channel purge ensures better cylinder filling

The cylinder head has a displacer. The displacer itself is useless, but in combination with a three-channel purge and a reed valve it significantly adds traction at the bottom

Spare parts price

Despite the fact that the production of the device stopped long ago, you can still find new spare parts for it that are produced by the industry. Some parts are imported, some come assembled. Supplied in sets:

The necessary parts can be found on the Internet using store catalogs. Prices for spare parts for the Ant scooter are fair. Here are some examples:

Judging by the prices, the device is more than cheap to repair. This is an important operational property for people in rural areas.

Analogues - engine 1P39QMB

Chinese developers have created an analogue of the Japanese 139QMB engine - a motor labeled 1P39QMB, which in appearance completely replicates the original. Despite all the similarities, you can still find differences: the valve clearances on the 1P39QMB are not adjustable. The situation is similar with the carburetor: before direct operation it requires thorough cleaning and correct adjustment. Chinese copies of 139QMB engines, of course, cope with their task, but their main purpose was to reduce the final cost of motor vehicles. Budget versions of scooters are equipped with exactly the same versions of engines that are good only for short trips at low speeds.

see also

Comments 36

Hello, tell me how the Bright engine has proven itself? I want to install a similar one on a homemade product, but I haven’t found any information on it on the Internet.

Has it become quiet (in terms of noise) and economical? But it’s a cool idea to convert both two-wheeled electrons and tourists

The noise is probably the same, it all depends on the muffler, mine is homemade. But the exhaust sound is more pleasant, you can immediately hear that the powerful engine is working, reminiscent of powerful Japanese motorcycles.

Thank you very much for your experience... it will be very useful to me)))

I installed 125 cc 4-stroke on my ant, I had to assemble the gearbox in a mirror image so that the star would be on the other side, gear shifting under the original foot, a home-made exhaust for it, now you can quietly sneak up on a person on an ant and you can’t hear him, it starts with just a push and I don’t bother with spark plugs, I only need Akum to start from the button, it works without Akum,

Source

Ant + lifan 188f

We solve all issues that arise during the construction of all-terrain vehicles

Moderator: User buggy

Vasilev Adept Messages: 279 Registered: Sun Nov 11, 2012 9:23 pm

Ant + lifan 188f

Post by Vasilev » Wed Jul 08, 2015 5:12 pm

In the meantime, I took Ant for repairs and installed a Lifan 188f engine (400 cm3, 13 hp)

Yes, does anyone know why the steering wheel chatters at any speed? The bushings seem to be alive, there are no backlashes...

Vasilev Adept Messages: 279 Registered: Sun Nov 11, 2012 9:23 pm

Re: Shket-2 or bierkisten in Russian

Post by Vasilev » Wed Jul 08, 2015 11:57 pm

When disassembling the fork, I found a spring inside, as it turned out it was a standard steering damper. And the spring tension knob was missing. I found it in spare parts, I'll check it tomorrow))

ilya38 Super technician Posts: 528 Registered: Mon Oct 24, 2011 8:34 am

Re: Shket-2 or bierkisten in Russian

Post by ilya38 » Thu Jul 09, 2015 4:47 am

Of course it’s interesting, instead of a CVT gearbox.

Vasilev Adept Messages: 279 Registered: Sun Nov 11, 2012 9:23 pm

Re: Shket-2 or bierkisten in Russian

Post by Vasilev » Thu Jul 09, 2015 11:22 am

Without CVT and gearbox. They asked me to drive 30 km per hour. The scooter will be used to transport small loads such as potatoes from the field)

In general, it all started with the fact that a man bought an ant for 6,000, supposedly after capital, and he just needed to install a magneto and connect the electrics.

An autopsy showed that there was nothing to start there; the engine was simply washed.

We decided to install another motor, but the person is very worried about its warranty, so the alterations must be reversible)

To begin with, I went through the gearbox and moved the star to the other side. I sawed off all the excess from the frame to mark the engine.

Intermediate shaft and exhaust manifold:

I moved the reverse to the other side. I made the handle longer:

Re: Shket-2 or bierkisten in Russian

Post by Old Man » Mon Jul 13, 2015 12:51 pm

It’s right that they didn’t bother with the original engine; it can’t hold a candle to this Chinese. This “Ant” doesn’t need speed, so you can do without a variator, the only thing that wasn’t worth saving on was an electric starter; it would be more convenient with it. My “scotch-mobile” is built exactly on the basis of the rear part of the “ant”; the engine costs 9 l/s. trailer with cabbage 200-250kg. takes it out of the field. I replaced the wheels on my car with “Zhiguli” ones and I advise you to do the same: a wider wheel with a larger diameter goes better and easier on bad roads. I’ll tell you how to install wheels without turning if you decide and you don’t need to change the gearbox with Zhiguli wheels it will run faster.

Vasilev Adept Messages: 279 Registered: Sun Nov 11, 2012 9:23 pm

Re: Shket-2 or bierkisten in Russian

Post by Vasilev » Mon Jul 13, 2015 4:34 pm

At first I also advised them to buy a motor with an electric starter, but as it turned out, it starts just fine. Almost always without getting off the ant the first time. Yesterday I already managed to burn out the clutch))) I went to test the cross-country ability. I came across an area between a field and a forest with a firebreak... My wheels got into a 20-30 cm rut with solid boulders and I drove for about 100 meters until I realized that the clutch was stinking, and there was nowhere to go I had to drive to a more or less level place. I think it would be difficult even for a tractor there. But the ant still made it home. And this is with a “high-speed” frequency converter (9:1), I’ll change it to 11:1 and calm down at that, the speed is at

25 km/h will be enough, you still can’t go on the road...

I temporarily secured the clutch disc from an ant, welding its joint to the machined disc)):

Vasilev Adept Messages: 279 Registered: Sun Nov 11, 2012 9:23 pm

Re: Shket-2 or bierkisten in Russian

Post by Vasilev » Tue Jul 14, 2015 10:19 am

The star on the motor is 15 teeth from an ant. I ground it inside and placed it on a tube with a welded key.

They are sold ready-made for a 428 chain, but it was easier for me to do than to go to the city to look for them.

The chain does not fly off, but now, just in case, I am installing a tensioner-calculator.

Vasilev Adept Messages: 279 Registered: Sun Nov 11, 2012 9:23 pm

Re: Shket-2 or bierkisten in Russian

Post by Vasilev » Tue Jul 14, 2015 4:45 pm

Well, I hope the last finishing touches are completed.

A damper from a chain tensioner shoe like a Niva and a broken furniture gas elevator. I shortened everything, inserted a spring into the gas elevator, and instead of hinges, a piece of chain)):

I replaced the throttle handle with a bike trigger, otherwise it was due to the rev limiter spring and vibration of the throttle handle at 2800-3300 rpm. the hand gets tired). Of course, it was necessary to immediately make a frame for the engine with dampers... Vibration is annoying only on the gas handle.

Making a homemade walk-behind tractor from a motorcycle engine

For successful operation of the walk-behind tractor, a multi-stage kinematic transmission scheme was developed, which increases the additional ratio, as well as traction and torque. Together with the adapter gearbox, the kinematic diagram includes a main gearbox. When a gearbox is combined with a wheelset and main gear, a highly efficient propulsion unit is obtained.

A special mechanism tensions the drive chains. It is attached with pins to the sliders, which are made of steel angle. The latter are also capable of moving by tightening or loosening the drive chain. For this purpose, grooves are provided in the sliders and there are two adjusting screws and M10 mounting bolts.

The most labor-intensive design is the main gearbox. It is made from pre-prepared steel plates (10 mm). Reinforcement discs are placed where the bearings are installed. The welds are continuous to prevent oil leakage. A bracket-bracket is welded to the rear wall of the gearbox, allowing you to attach a cargo trolley or trailed agricultural implement. If you use a cargo trolley, the walk-behind tractor becomes a mini tractor.

A steel plate (5 mm) is used to make the gearbox cover. It is attached to the body with M6 screws. Spur gears and shafts are taken from agricultural machinery. It must be remembered that the purpose of the intermediate shaft is power take-off, so it is better to make new shafts than to use old ones. The differential of the main gearbox on the walk-behind tractor was part of a decommissioned electric car.

Locking the wheels of a walk-behind tractor with a motorcycle engine

Wheel locking is a necessary technical solution for a walk-behind tractor, from a design point of view. On the right axle shaft, where the spline end is, a cylindrical neck is machined, which should be slightly deeper than the spline groove. A threaded hole is made at the opposite end of the axle shaft.

When the M12 adjusting screw rotates, the axle shaft is displaced due to the action of the coil spring. Further inside the differential, the axle shaft moves away from engagement with the “native” gear and engages with the adjacent one, thereby blocking the wheels.

The impellers of the walk-behind tractor are made from the wheels of a decommissioned electric car. For each disk, 16 grooves are cut in the rim, and steel plates are welded in, which will serve as the basis for the lugs. After that, jumpers are welded to them, and the rims of plow wheels are obtained.

Plow for walk-behind tractor

The unit that regulates the entry of the plow into the soil is very effectively made. It consists of a welded U-shaped body, with installation and limiting protrusions. The heel of the plow's hailstone is inserted into them, which is capable of rotating in a vertical plane using a bushing-axial hinge. The required angle of rotation is set by an M16 pin. The beam channel is welded to the rotary heel. Thanks to a slight turn to the side where the soil falls off from the plow, correct installation of the latter becomes possible.

The walk-behind tractor is controlled by two rods from the walk-behind mower with handles. The reverse and speed switch knobs are also used for this.

The productivity of the walk-behind tractor is three to five hundred square meters of land per hour. Ordinary soil can be plowed in second gear. For heavy soils, work on the first one.

see also

Comments 36

Hello, tell me how the Bright engine has proven itself? I want to install a similar one on a homemade product, but I haven’t found any information on it on the Internet.

Has it become quiet (in terms of noise) and economical? But it’s a cool idea to convert both two-wheeled electrons and tourists

The noise is probably the same, it all depends on the muffler, mine is homemade. But the exhaust sound is more pleasant, you can immediately hear that the powerful engine is working, reminiscent of powerful Japanese motorcycles.

Thank you very much for your experience... it will be very useful to me)))

I installed 125 cc 4-stroke on my ant, I had to assemble the gearbox in a mirror image so that the star would be on the other side, gear shifting under the original foot, a home-made exhaust for it, now you can quietly sneak up on a person on an ant and you can’t hear him, it starts with just a push and I don’t bother with spark plugs, I only need Akum to start from the button, it works without Akum,

( 1 rating, average 4 out of 5 )

Snowmobile from a walk-behind tractor

In winter, moving around the terrain becomes much more difficult, and buying even a used snowmobile involves significant financial costs. The solution to the problem is to convert the walk-behind tractor into a snowmobile. Everything you need for this can be found at the nearest landfill or scrap metal collection point. If you have enough money, modular tracks are purchased, installed instead of wheels on the axle shaft.

If we take an already manufactured tractor as a basis, then for work you will need:

You can make a snowmobile in different ways. The choice depends on the skill of the vehicle owners and the availability of available materials.

Rework can be carried out in the following areas:

A homemade snowmobile made from a walk-behind tractor will not set a speed record. But for a trip to the forest for firewood or for winter fishing, its capabilities will be quite sufficient.

Characteristics of the Ant scooter

The scooter is distinguished by high maneuverability and maneuverability, as well as small dimensions. In the garage it will take up as much space as a heavy motorcycle with a sidecar. The Soviet scooter "Ant", which is still popular, has the following technical characteristics:

Among fans of this brand, there is an opinion that the scooter is not inferior in performance properties to its Western counterparts.

Among the advantages of a moped it is worth noting:

There are also disadvantages:

Ant owners have the most questions about the engine. After all, I want to moderate my appetite for fuel consumption.

Engines 157QMJ

In addition to the very popular model - the 139QMB engines - Hongling Corporation produces other versions of power units, one of which is the 157QMJ. It is installed on expensive scooter models of famous brands. In terms of its technical parameters and indicators of functionality and reliability, this version is a complete analogue of 139QMB. In addition, the design features of the model are strongly reminiscent of other mass-produced Japanese engines.

The advantage of the 157QMJ is its increased service life - about 25 thousand kilometers. The engine boasts powerful dynamics and a high top speed. However, it also has its downside - the price is too high compared to previous versions of the engines.

Materials used:

I started installing the new engine by dismantling the old engine and then washing, cleaning and reassembling it, so in the future I planned to use it as a gearbox for the new engine.

This is the condition the scooter was in before the repair.

Dismantling the old engine.

Next, I tried on the new engine in place of the original one, since it was larger in size and had to cut off the tubes on which the seat and trim are installed.

To connect the engine and gearbox, I decided to use a belt drive. To do this, I bought 2 identical pulleys from a walk-behind tractor, but with the original mounting diameter of 25 mm for the internal combustion engine and 19 mm for the gearbox shaft, which I ordered from a turner. Instead of a crankshaft to reduce vibration, because cutting the connecting rod will upset the balancing of the crankshaft, and this is not a buzz. All dimensions were removed from the crankshaft with only the change to the pulley.

Next, a piece of plywood (template) was cut out, which I used to cut a 10 mm slab from the slab for mounting the internal combustion engine.

I bought a longer clutch cable and carried out the first “test drive” which showed that this system would exist. I began a complete disassembly of this scooter with replacement of bearings and much more for subsequent cleaning of dirt and old paint and subsequent painting and assembly.

To summarize: the engine power is enough for the eyes. The gear ratio of the internal combustion engine and gearbox is 1:1. The maximum speed is 45-50 km/h, which is quite enough on rural roads.

The process of replacing the internal combustion engine on an Ant scooter can also be seen in this video:

Homemade author: Alexey Kochnev.

The feasibility of installing a magneto

It’s none of my business, of course, but I have an extremely negative attitude towards this kind of collective farm tuning. Moreover, the magneto does not solve the problem with the reliability of the standard ignition system, but only replaces it with another problem. And this, in my opinion, is complete stupidity: convert the engine to a magneto, and then suffer even more with it...

Yes, the dyno starter is not an ideal device. Which also needs to be constantly monitored and, if necessary, serviced. So what? Well, I cleaned the collector and breaker contacts at the beginning of the season and that’s it. Are there fewer problems with the magneto? More than a hundred times!

- Firstly, due to the fact that the rubber coupling constantly breaks, the ignition timing is lost, and this entails detonation, loss of power, overheating and increased fuel consumption.

- Secondly, after installing the magneto, they usually stop monitoring the dyno starter, deprive it of its battery, and it eventually dies completely... Accordingly, the on-board network of the scooter is deprived of its power source. And this means that “there is no light - there will be no cinema”...

- Thirdly, due to the fact that this whole alteration is a complete collective farm - the axes in which the magneto rotor and the dynostarter rotate diverge within significant limits. And this leads to the fact that the parts of these two devices begin to work with a large axial misalignment relative to each other, which is why the magneto’s output shaft of the rotor constantly breaks off and its support bearings fall apart.

- Fourthly, the magneto was not initially designed for long-term operation, much less to work with such a horse-like misalignment along the axes, which leads to an increased radial load on the rotor, which is not typical for a magneto.

- Fourthly, a magneto is very expensive - plus you need to buy a spacer and a coupling.

How to Connect an Ant Engine and a Motoblock Engine

Nowadays, the development of agricultural machinery has reached its best development. It’s hard to imagine a modern farmer without a cultivator or walk-behind tractor.

For convenient and comfortable use of the walk-behind tractor, it is made from an old Ant scooter. With such equipment it will be comfortable to move around the cultivated area, transport harvested crops, humus, agricultural tools, even firewood, garbage and everything else.

Branded walk-behind tractor Ant

First of all, you need to find an old scooter and decide what size areas will be processed. This affects the power of the walk-behind tractor motor. The Ant scooter with an engine from a walk-behind tractor is converted into a real walk-behind tractor according to the standard classical scheme:

Secondary parts are attached to the vehicle walk-behind tractor which of course will be very necessary for further use of the device:

Following from the above, the necessary elements for the production of a walk-behind tractor are a frame, engine, wheels, steering wheel, seat and electrical equipment.

The elements of the walk-behind tractor are placed on the frame for our client. The frame design consists of two spars, which are made of an inch and a quarter metal pipe. The front and rear ends of the side members are bent upward, the rear ends need to be bent towards each other and later connected by welding. At the control control production stage, the Izh bike and its spare parts are used.

Homemade walk-behind tractor with a motor from Ant

Related Posts

The control structure from the bike is welded to the rear ends of the side members. To tension the chain of the first stage of the box, you need to connect the side members lengthwise with several cross members. The platform for the battery and other parts also serve as cross members. The gearbox housing, which is part of the frame assembly, in addition to its own functions, also functions as a rack between the chassis and the power unit. For transporting cargo with a trailer, you can hook up a two-axle cart to one of the rear parts of the crankcase.

Dynastarter

However, it is not only the engine that can make a motorcyclist clearly see all the components of his motorcycle. The most common problem is a problem with the dynastarter . The engineers of the Tula plant installed it in Muravya, instead of a conventional alternating current generator.

Why is it so important? If you notice a red light on the instrument panel while the moped is running, it means you are running out of charge. This happens because the generator is not producing alternating current. To begin with, in such a situation, it is necessary to check the integrity of the wires connected to the dynastarter and the relay regulator. If everything is in order, then the problem lies directly in the dynastarter. There may be three main causes of problems:

Running in the engine

Incorrectly carried out running-in of the 139QMB engine in most cases leads to failure of the piston system. Friction occurs between the parts of the new CPG, which leads to an increase in engine temperature.

Running in the scooter motor is carried out as follows:

After carrying out such manipulations, you can run in the scooter itself. In the first 100 kilometers of the journey, you should not turn the throttle handle more than 1/3 of its full stroke. The maximum speed should not exceed 30 km/h. The speed can be increased by 15–20 km/h for the next 300 kilometers - during this time the engine should more or less reveal its potential.

After this break-in process, the oil must be changed.

Engine valves are adjusted every 500 kilometers.

To watch online, click on the video ⤵

Motor scooter ant engine IZH-planet 3. Read more

Moto scooter with Planet 5 engine. Read more

ant with planet sport engine 28 liters Read more

Ant mountings for installing an IZH engine Read more

Izh with an ant engine. More details

Review of the Ant scooter, a dump truck with a lifting mechanism. More details

Motorcycle pickup truck based on IZH P5 and Ant. More details

Ant 2m01 with IZH Planet 3 engine Read more

Ignition from a chainsaw on a tula Read more

Tricycle from Izh Planet MurIZh Read more

Ride on Ant. with engine IZH Planet 3 Read more

Motor scooter Ant (TGA-200) with an engine from a disabled woman. A short review. More details

How to increase engine power of an Izh motorcycle Read more

Review of Homemade mini tractor with IZH Engine Read more

Engine tuning

The first thing they try to change when tuning the 139QMB engine is the cubic capacity. For this purpose, the standard piston system is replaced with an 82cc one. At the same time, a new cylinder head with enlarged valves is installed. The piston system changes along with the camshaft, since a larger amount of fuel-air mixture is required for its correct operation. A new camshaft will help increase the volume of the incoming fuel mixture, but the carburetor will still need to be replaced.

How to Install an Engine from a Motoblock to an Ant

Branded and homemade walk-behind tractor "Ant"

Today, the Motoblock "Ant" can be a pretty serious builder for the brand. With its help, you can perform various agricultural work on the site, avoiding long and exhausting manual labor. At the same time, its weight is less than 100 kg, which allows the device to be transported in the trunk of a car. Its dimensions are quite compact, do not require special storage conditions, and can be easily placed both in a utility room and in a residential building in a high-rise building in the city. However, since the price for it starts at 25 thousand rubles, it makes obvious sense to make such a walk-behind tractor with your own hands from an old scooter. Especially popular are homemade walk-behind tractors with the engine and gearbox from the Ant

", which in its characteristics is close to similar parts of the installation kit.

How to make a walk-behind tractor with your own hands

The work began with the Ant, or rather the engine from a T-200 scooter. First, let's sort it out. Then we make the frame - we weld an iron sheet 4 mm thick with pipes 4 cm in diameter. The frame is rigidly attached to the engine with three supports. The next stage of assembly was the installation of a carburetor, magneto, air filter, and muffler. In order to protect the engine from overheating, we had to come up with a cover on top for forced cooling. The chain drive was made to be driven from the engine to shafts with flanges (they came from a conventional combine). The important point is that the rotation speed of the shafts can be excellent with the correct selection of gears, but you still need to carefully calculate the size of the lower crankcase on the frame. If you get carried away by one frequency, the frame will simply go on top and not reach the ground. Gear ratio: motor-gearbox 4:1, in gearbox 2.5:1

Everything inside should be lubricated with oil - drain and fill hatches are made for this.

The steering wheel is an ordinary metal pipe (to adjust the height, you can take a telescopic pipe from an old vacuum cleaner). The unit operates in first gear, although there are already three gearboxes. The carburetor damper is controlled manually. There is a wheel in front of the walk-behind tractor; its installation determines how deep the soil needs to be plowed, and it is not particularly difficult to control. The weight of the structure turned out to be decent - a little less than 90 kg.

Based on the test results, it turned out that the engine adequately withstands passage through virgin soil, you can plow a field with a shovel bayonet, passing through the field 2-3 times; on previously processed soil, a second pass is not required. Due to its heavy weight, it is not particularly agile, but it works great in a garden where there are no bushes. When a homemade walk-behind tractor needs to be moved, I insert wheels that are secured with through bolts.

For the same unit, I planned to make a special body stand for transportation in the back; I also plan to reduce the size of the wheels and make plows, a hiller and a potato digger.

I understand that both walk-behind tractors are Chinese.

Just a limited budget

Eduard Better than the GT 700, it's faster and has more power

Ant engine

The Ant was equipped with a motor that was different from others produced by the industry of the Soviet Union. Innovations in its design fueled interest in technology among then ordinary people. And now they are warming up restorers and collectors. The differences are as follows:

The main difference is the presence of an electric starter. This made it possible to start a moped in the same way as a car.

The cooling system fan moves air through the engine casing, removing heat from it. It is worth noting that such a scheme works tolerably.

Engine D1E41QMB

The D1E41QMB motor is the only two-stroke engine model made in China. A distinctive feature of this engine from other representatives of the category of power units is the presence of a chain reverse gear in the design. The uninterrupted operation of such an engine is ensured by mixing gasoline and oil in proportions of 40 to 1. The working life of the engine is about 10 thousand kilometers, after which the need for repairs arises. The disadvantage of the engine is the forced speed limit - no more than 50 km/h.

Factory installed

It is produced by domestic industry at agricultural machinery enterprises. This is a gasoline engine on a two-wheeled platform, capable of both rotating the wheels of the chassis and working cutters for cultivating the soil. "Ant" is capable of processing hard and virgin soil. In addition to the cutters, you can install a plow or holner. Four-stroke gasoline engine

is 7 horsepower.

This allows you to plow the soil to a depth of 30 cm. The fuel tank holds up to 3.6 liters of gasoline, the crankcase volume is 0.6 liters. The transmission is a belt drive and chain reducer with a cast iron pulley. While forward speeds can be switched, reverse provides only one speed. The engine has a manual starting system. Motoblock can provide plowing widths of up to 80 cm. The steering column can be adjusted both vertically and horizontally. The result is a fairly powerful and user-friendly device. The only drawback can be considered the relatively high cost, which makes most owners of summer cottages and playgrounds prefer to make their own copy. A homemade walk-behind tractor will cost several times less, and the consumer quality of the mechanism is not much different from its assembled counterpart.

Making a homemade gearbox for a walk-behind tractor

To make a homemade gearbox for a walk-behind tractor, parts were taken from the V-150 M engine: crankcase, gears, chain sprockets, as well as an additional gearbox shaft. The crankcase must be cut into two halves and the kickstarter, gearshift mechanism and crank chamber removed from it. You need to install a plug at the kickstarter exit point and weld it using argon welding.

We install the bearing axle box of the right running wheel of the walk-behind tractor into the left half of the crankcase. A spare crankcase of the same engine is used as an axle box.

A part of the V-150 M engine crankcase is also used as the left cover, which is supplemented with one part - a duralumin bushing. The bushing is pressed into the crank chamber and has a hole corresponding to the diameter of the engine output shaft shank.

Walk-behind tractor chassis

Walk-behind tractor drive shaft

The motor and gearbox are fixed relative to each other using an M10 screw.