Clutch adjustment IZ Jupiter 5

The main reasons why the clutch on an IZH Jupiter motorcycle “leads” or “slips” 5. Troubleshooting and subsequent adjustment and adjustment of the clutch.

In this article we will consider in detail the issues that relate to the correct adjustment of the clutch of the IZH Jupiter 5 motorcycle. The name of this motorcycle unit itself speaks about the main functions it performs, or rather, the crankshaft engages directly with the engine gearbox. Optimally, the clutch should be as smooth as possible without jumps. This is necessary for the movement of the motor vehicle and subsequent switching while driving. The clutch is located on the left side of the crankcase under the installed engine cover. In order to get to the clutch as quickly as possible, you will need to first drain the oil and unscrew the cover. In this case, you will need to unscrew all the necessary mounting bolts and then carefully remove all the levers.

Tips for increasing the life of the Izh motorcycle clutch

The clutch is not intended for long-term operation in the disengaged position, as in this case increased wear of the mechanisms occurs. The control lever must not be released abruptly or very slowly. When turned on abruptly, the power transmission receives maximum load; when turned off slowly, the parts wear out even more than when turned off completely, due to slipping of the disks. If you have a habit of keeping your fingers on the lever, make sure that there is not even the slightest pressure on it. Even with a slight pressure that does not cause the discs to slip, the clutch mechanisms experience significant load. Do not use the clutch to disconnect the engine from the gear when stopping or coasting for a long time. In all these cases, use the gearbox, putting it in neutral. Also, never try to make the engine work easier on climbs and in other difficult situations, causing the discs to slip and, as a result, increase engine speed. In such cases, it is better to switch to a lower gear in advance.

Clutch adjustment IZ Jupiter 5

The clutch is almost always in motion and the discs are compressed by special springs that are tuned to certain parameters. The transmission consists of two sprockets. One of which, the small one, is located directly on the crankshaft, and the larger main star is on the drum. Their connection is carried out using a motor chain. For motorcycles of the IZH Jupiter 5 model, which have one cylinder, the gear ratio is 2.17. Using a specialized mechanism, it turns off when required. This specialized shutdown mechanism is located in the motorcycle engine cover. This is important to take into account, because it is used to adjust the IZ Jupiter 5 clutch.

Features of clutch settings

It is possible to check the correctness of the clutch settings by pressing the pedal in any direction. Moving the first end of the lever 3-5 mm from the neutral position should not affect the pressure plate, that is, it should not move. After completing this procedure, it is possible to adjust the manual squeeze using a specialized screw to make the adjustment. After this, the IZ Jupiter 5 clutch is assembled, during which it is necessary to strictly adhere to the sequence of all necessary actions.

Clutch setting

Adjusting the springs usually does not take much time and is not considered a complicated procedure. To carry out these actions, the motorcycle is placed on the stand, the oil is drained, and then the installed cover can be removed. After this, the special lever will need to be squeezed to the maximum and securely fixed. Then it is recommended to turn on the first or second speed, take the wheel and start rotating. Based on the load, we determine which springs are more tense and which are looser.

Then, when we have figured out which springs need to be tightened, we rotate the wheel to check the result. It is necessary to pay special attention to such a fairly important point that when the load increases, the clutch will not slip. After all of the above steps are completed, the IZH Jupiter 5 clutch basket is assembled. Adjusting the IZH Jupiter 5 clutch is important for stable and safe riding on this popular motor vehicle. Therefore, when you feel that it is necessary to carry out these actions, then you should not delay it.

Basic clutch malfunctions

One of the most common problems that occurs with the IZH Jupiter 5 motorcycle is clutch slipping. Almost all owners who use this model for quite a long time face this problem. This kind of malfunction indicates that the discs are not pressed together well enough and the IZ Jupiter 5 clutch needs to be adjusted.

The main reasons why this can happen:

- The IZ Jupiter 5 clutch was adjusted incorrectly.

- The installed springs have lost the required elasticity.

- The discs have lost their thickness due to significant wear.

- The drive elements are significantly worn.

Sometimes it feels like the clutch is dragging . A similar problem usually occurs when the lever is clamped to the maximum, but the clutch is not disengaged. In this case, the installed disks in some places touch slightly, and in others they fit tightly to each other. Adjustment of the clutch basket on IZ Jupiter 5 must be carried out in full compliance with the specified recommendations.

We examined the main issues that are directly related to clutch adjustment. These actions must be performed when you have the above malfunctions, otherwise riding the IZH Jupiter 5 motorcycle will not be comfortable and safe.

Why does the clutch “drive” on the Izh-Jupiter motorcycle, how to adjust?

The clutch on the Izh-Jupiter motorcycle may fail for the following reasons: 1. In winter, thicker oil is used 2. The pressure springs have weakened 3. The clutch discs have worn out 4. The parts of the clutch control mechanism have worn out

The clutch rod does not reach the required level on the Izh Jupiter 5, what should I do?

The clutch adjustment process itself is not very complicated if you follow some rules:

Eliminate distortions in the pressure plate (to do this, secure the lever to the steering wheel with wire).

Turn on first speed.

Start turning the rear wheel in one direction.

Malfunctions and clutch adjustment of Izh motorcycles

There are two possible types of clutch malfunction: incomplete disengagement of the discs and slipping. If the motorcycle is slipping, it will not develop speed as the crankshaft speed increases. The reasons for this malfunction may include: wear of the discs, insufficient spring pressure due to loss of elasticity or loose adjusting nuts, incorrect adjustment of the clutch mechanism. When the clutch is not fully disengaged, the motorcycle wheel continues to rotate while the control lever is fully pressed. This may also be due to incorrect adjustment, or this malfunction may occur when thick oil is used, especially in cold weather. First of all, if you discover one of the clutch malfunctions, try to eliminate it by correct adjustment. First, you need to adjust the gap in the shutdown mechanism; this is done using the adjusting screw located on the right engine cover. To do this you will need a screwdriver and a 13 mm wrench. Using a wrench, loosen the locknut and use a screwdriver to tighten the screw until it stops, and then turn it in the opposite direction half a turn - one turn. Tighten the locknut with a wrench. Secondly, after this, adjust the free play of the lever using the cable adjusting screw on the left handlebar handle. It should be within 5-10 millimeters. The correct clutch adjustment can be checked in this way: place the motorcycle on a stand, engage first gear and try to manually turn the rear wheel with force. If the adjustment is correct, you will not be able to do this. Now you need to perform one more check: to completely disengage the clutch. To do this, in the same position (motorcycle on a stand, rear wheel not touching the ground), start the engine and engage first gear. Then fully depress the clutch control lever and apply the rear brake, the wheel should stop. Release the brake, the clutch is depressed, and the wheel should remain stationary if adjusted correctly. If it starts to rotate when the lever is pressed, you need to loosen the adjusting bolt on the right side of the engine.

Functional purpose of the gearshift clutch

Before you adjust the clutch on the Izh-Jupiter 5 motorcycle, it’s a good idea to understand its purpose and principle of operation. The essence of the transmission clutch:

- Ensuring the transmission of torque from the large gear of the motor transmission to the gearbox input shaft.

- Short-term separation and smooth connection of transmission elements to each other.

Izh motorcycles were equipped with a mechanical clutch, the operation of which is based on the friction force between the driven and driving disks. It is a multi-disc design operating in an oil bath - a classic arrangement that the Izhevsk Machine Plant used until 2008. Working in tandem, the main chain drive and four-speed gearbox are reliable and proven by many generations of motorcyclists.

CLUTCH OF MOTORCYCLE “IZH”

If we consider the motorcycle transmission in order, then the first article should appear on the motor transmission - the first link of the transmission. But for various reasons we were forced to change our plan. And let's start this cycle with the second link - the clutch .

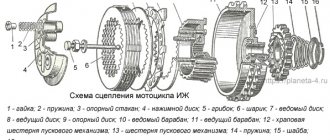

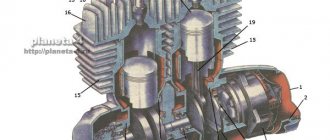

The clutch (Fig. 1) ensures the transmission of torque from the large gear of the motor transmission to the input shaft of the gearbox, short-term separation and smooth connection between them. IZh motorcycles use a friction multi-plate clutch operating in an oil bath. Let's consider the operation of the clutch using the example of the IZH Planet power unit.

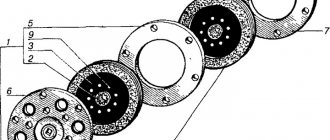

The large driven gear of the motor transmission is made integral with the drive drum 8 of the clutch (Fig. 2). The driving plastic disks 6 fit with their protrusions into the grooves of the large drum 8. Between the driving disks, driven steel 5 are installed, which are connected in the same way to the small, driven clutch drum 7, mounted on the splines of the input shaft of the gearbox.

The package of disks in working condition is compressed by five cylindrical springs 2, which rest on cups 3, fixed in the outer pressure steel disk 4. The force of the springs can be changed using shaped nuts 1: during operation, this has to be done when replacing the package in order to move it evenly in the grooves drums The normal position of the clutch is constantly closed, the discs are pressed tightly and with great force against each other. To disengage the clutch, you need to separate the discs and move them away from each other.

This is accomplished by a shutdown mechanism mounted on the right engine crankcase cover and a drive. The clutch release lever is located on the left side of the steering wheel. A cable 14 is fixed in it. When you press the lever, the force is transmitted through the cable to the worm 13; the latter turns, moves along the three-start thread and presses on the ball 11, the thrust rod 10 and the pusher 9 and moves the pressure disk 4, overcoming the force of the springs.

At the same time, the clutch discs are released from the force compressing them and are separated, the clutch is disengaged. As soon as you release the lever on the steering wheel, the release mechanism returns to its original position under the action of springs 2 and 12. Normal operation of the clutch mechanism is ensured only if there is sufficient clearance in the drive (free play on the release lever), and the springs are preloaded so that the disks move without distortion and over a sufficient distance.

Approximately, the spring force can be considered normal if the nuts protrude above the caps by approximately 4.5-5 mm. The clearance in the clutch release mechanism is, first of all, ensured by the adjusting screw 17. First, this screw must be screwed in until it reaches a noticeable stop (without, however, allowing the discs to move), and then loosened 1/2-3/4 of a turn and secured with a nut 16. Then use the adjusting screw on the steering wheel to set the free play of the clutch cable: it should be 5 mm at the end of the lever.

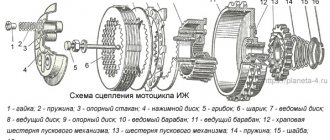

The clutch release mechanism of the IZH Jupiter engine (Fig. 3) differs significantly from that previously described in that it is interlocked with the gear shift mechanism. This allows you to disengage the clutch using both the lever on the steering wheel and the pedal, and gear shifting occurs more smoothly and quickly. The shutdown mechanism is also mounted on the right engine crankcase cover.

As in the previous case, it is connected to the lever on the steering wheel by a cable drive, the operation of which requires no explanation. As for semi-automatic clutch release, we need to talk about it in more detail. The gear shift pedal is mounted on the left end of the shift shaft; At the right end of this shaft 14 there is a cam 15 of the automatic clutch release.* The cam has a complex shape; in constant contact with its working surface there is a roller mounted on the end of a double-armed lever 19.

In the normal position of the shift lever, the roller is located in the cavity of the cam 15. When the lever moves down or up (this or that gear is engaged), the cam 15 with its protrusion runs onto the roller, through it presses on the shoulder of the lever 19; the second arm acts on the pusher 13, the ball 12 and the thrust rod 11 and moves the pressure plate 6. The springs 2 are compressed and release the disks, the clutch is disengaged. The working surface of the cam 15 is designed so that the clutch disengages earlier; what switches on this or that gear; It turns on only after the transmission is detected. You have to pay for convenience - in this case, with more complex adjustments.

If in the IZh Planeta clutch release mechanism it was necessary to adjust only the free play of the lever on the steering wheel, then on the Jupiter it is also necessary to adjust the free play of the shift pedal. Moreover, the sequence of adjustments is also important. Start, as in the first case, with the clutch springs. They should protrude above the cups by approximately 3.5-4 mm and ensure uniform, distortion-free movement of the discs when the clutch is disengaged. After this, screw 4 must be screwed into the pressure plate until it stops and unscrew it 1/4-1/2 turn. This may not work right away; for insurance purposes, it is better to perform this operation several times to be absolutely sure of the result. Then lock screw 4 with nut 5.

When is it necessary to repair and adjust the gear clutch on an Izh motorcycle?

Regardless of the amount of experience the motorcyclist has, the feelings regarding gearbox malfunctions are almost the same:

- At first it seems that the clutch is slipping slightly. After two or three days, confidence appears - yes, it is slipping, because as soon as you add speed, the acceleration rate lags behind the engine speed level. The breakdown is especially obvious when moving uphill.

- The clutch “leads” or the clutch is incompletely disengaged when the control lever is depressed. In such a situation, the disks of the assembly remain pressed against each other and do not stop transmitting torque to the gearbox. You can finally verify such a breakdown after lifting the rear wheel - it continues to rotate in this situation.

If you want to know how to adjust the clutch on a motorcycle Izh-Jupiter 5 , then information about the reasons causing the listed factors would be useful:

- Use thicker oil in winter.

- Weakening of pressure springs.

- Worn clutch discs.

- Wear of clutch control mechanism elements.

In most cases, if signs of slipping or incomplete disengagement of the clutch are detected, a simple adjustment of the mechanism is required. To do this, it is enough to have a “13” key and a slotted screwdriver.

CLUTCH OF MOTORCYCLE “IZH”

If we consider the motorcycle transmission in order, then the first article should appear on the motor transmission - the first link of the transmission. But for various reasons we were forced to change our plan. And let's start this cycle with the second link - the clutch .

The clutch (Fig. 1) ensures the transmission of torque from the large gear of the motor transmission to the input shaft of the gearbox, short-term separation and smooth connection between them. IZh motorcycles use a friction multi-plate clutch operating in an oil bath. Let's consider the operation of the clutch using the example of the IZH Planet power unit.

The large driven gear of the motor transmission is made integral with the drive drum 8 of the clutch (Fig. 2). The driving plastic disks 6 fit with their protrusions into the grooves of the large drum 8. Between the driving disks, driven steel 5 are installed, which are connected in the same way to the small, driven clutch drum 7, mounted on the splines of the input shaft of the gearbox.

The package of disks in working condition is compressed by five cylindrical springs 2, which rest on cups 3, fixed in the outer pressure steel disk 4. The force of the springs can be changed using shaped nuts 1: during operation, this has to be done when replacing the package in order to move it evenly in the grooves drums The normal position of the clutch is constantly closed, the discs are pressed tightly and with great force against each other. To disengage the clutch, you need to separate the discs and move them away from each other.

This is accomplished by a shutdown mechanism mounted on the right engine crankcase cover and a drive. The clutch release lever is located on the left side of the steering wheel. A cable 14 is fixed in it. When you press the lever, the force is transmitted through the cable to the worm 13; the latter turns, moves along the three-start thread and presses on the ball 11, the thrust rod 10 and the pusher 9 and moves the pressure disk 4, overcoming the force of the springs.

At the same time, the clutch discs are released from the force compressing them and are separated, the clutch is disengaged. As soon as you release the lever on the steering wheel, the release mechanism returns to its original position under the action of springs 2 and 12. Normal operation of the clutch mechanism is ensured only if there is sufficient clearance in the drive (free play on the release lever), and the springs are preloaded so that the disks move without distortion and over a sufficient distance.

Approximately, the spring force can be considered normal if the nuts protrude above the caps by approximately 4.5-5 mm. The clearance in the clutch release mechanism is, first of all, ensured by the adjusting screw 17. First, this screw must be screwed in until it reaches a noticeable stop (without, however, allowing the discs to move), and then loosened 1/2-3/4 of a turn and secured with a nut 16. Then use the adjusting screw on the steering wheel to set the free play of the clutch cable: it should be 5 mm at the end of the lever.

The clutch release mechanism of the IZH Jupiter engine (Fig. 3) differs significantly from that previously described in that it is interlocked with the gear shift mechanism. This allows you to disengage the clutch using both the lever on the steering wheel and the pedal, and gear shifting occurs more smoothly and quickly. The shutdown mechanism is also mounted on the right engine crankcase cover.

As in the previous case, it is connected to the lever on the steering wheel by a cable drive, the operation of which requires no explanation. As for semi-automatic clutch release, we need to talk about it in more detail. The gear shift pedal is mounted on the left end of the shift shaft; At the right end of this shaft 14 there is a cam 15 of the automatic clutch release.* The cam has a complex shape; in constant contact with its working surface there is a roller mounted on the end of a double-armed lever 19.

In the normal position of the shift lever, the roller is located in the cavity of the cam 15. When the lever moves down or up (this or that gear is engaged), the cam 15 with its protrusion runs onto the roller, through it presses on the shoulder of the lever 19; the second arm acts on the pusher 13, the ball 12 and the thrust rod 11 and moves the pressure plate 6. The springs 2 are compressed and release the disks, the clutch is disengaged. The working surface of the cam 15 is designed so that the clutch disengages earlier; what switches on this or that gear; It turns on only after the transmission is detected. You have to pay for convenience - in this case, with more complex adjustments.

If in the IZh Planeta clutch release mechanism it was necessary to adjust only the free play of the lever on the steering wheel, then on the Jupiter it is also necessary to adjust the free play of the shift pedal. Moreover, the sequence of adjustments is also important. Start, as in the first case, with the clutch springs. They should protrude above the cups by approximately 3.5-4 mm and ensure uniform, distortion-free movement of the discs when the clutch is disengaged. After this, screw 4 must be screwed into the pressure plate until it stops and unscrew it 1/4-1/2 turn. This may not work right away; for insurance purposes, it is better to perform this operation several times to be absolutely sure of the result. Then lock screw 4 with nut 5.

Life hack: how to adjust the clutch on an Izh-Jupiter 5 motorcycle yourself?

The adjustment procedure depends on the design features of Izhevsk motorcycles. The fifth generation is equipped with a shutdown mechanism, which is combined with a gear shift device. Adjusting the clutch control should begin by centering the machine's cam relative to the roller with the lever, which are mounted on the body of the right crankcase cover.

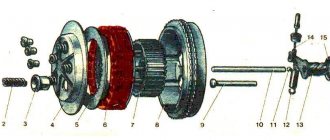

First of all, the distortions of the pressure plate (No. 1 in the photo) are removed, for which the lever on the steering wheel is secured with wire or rope in the squeezed position. Next, turn on 1st speed and rotate the rear wheel, while observing the axial runout between the pressure plates and the end of the drum. The nuts (No. 2 in the photo) that are closer to the point of maximum deflection need to be tightened, and the tightening force should be determined experimentally. Repeat the operation until the runout becomes minimal.

The following operation is performed when the gear shift unit has been disassembled for repair, or after replacing the right crankcase cover. Motorcycle owners interested in how to properly adjust the clutch on an Izh-Jupiter 5 should definitely familiarize themselves with the work technology:

- Disconnect the cable end from the clutch control lever on the steering wheel.

- Between the end of the weakened fastening of the machine cam and its cotter pin, install such a number of washers so that the gap between them and the cotter pin is no more than 0.4 mm.

- Tighten the cam bolt with enough force to prevent the cam from turning.

- Place the right crankcase cover in its original place and secure it with screws.

- Remove the hatch on the left crankcase cover, loosen the locknut and tighten the adjusting screw until it touches the thrust rod, then tighten it another 2-3 turns.

- Move the gear selector pedal up and down by 20-25 mm, then carefully remove the right crankcase cover.

- Without changing the position of the cam on the shaft, tighten the bolt securing it with a force of 2-2.5 kgm .

- Replace the right crankcase cover and remove the adjustment screw.

- Screw the adjusting bolt until it touches the thrust rod, then unscrew it half a turn and secure it with a locknut.

How many clutch discs on Izh Jupiter 5

Motorcycle IZH-Planet. Operation, maintenance and repair. >> Motor transmission, clutch, trigger mechanism. Clutch - disc replacement

LLC "World of Autobooks"

Clutch - disc replacement

Before replacing the clutch discs, motor chain or drive sprocket, it is necessary to remove the left muffler from the left driver's footrest (with a two-pipe exhaust system), drain the oil from the power unit crankcase, or (for repairs on the road) place the motorcycle on its right side. If the fuel tank is full, the fuel must be drained or the tank removed.

The work is shown on a removed power unit.

Removing the clutch discs

1. Using a 12 mm wrench, loosen the pinch bolt of the gear shift lever.

2. Remove the lever.

3. Remove the washer.

4. Remove the O-ring.

4. Use a 14 mm wrench to loosen the pinch bolt of the kick starter lever.

5. Remove the lever.

6. Using a slotted screwdriver, unscrew the eight screws securing the left crankcase cover. If necessary, you can use an impact screwdriver.

Please note that the screws vary in length and some have aluminum sealing washers underneath.

7. Remove the cover along with the paronite gasket. Be careful not to tear the gasket.

8. Using a large slotted screwdriver, unscrew the five nuts of the clutch pressure springs.

9. Remove the five springs along with the caps from the inner clutch drum.

10. Remove the pressure plate.

11. We take out the driven and driving disks.

12. We lay out the disks in the order of removal, so that (in case of assembly without replacement) install them in their original places.

13. Inspect the clutch discs. The driven (steel) discs must not be deformed as a result of overheating, and the driving (plastic) discs must be free of cracks, burns and visible wear of the contact surfaces. The outer protrusions of the discs must not be damaged. If defective disks are found, we replace the entire set.

Installing clutch discs

We install the clutch discs in the reverse order.

Uniform compression of the springs is ensured by equal protrusion of the ends of the nuts above the ends of the studs. It should be equal to 4.0-4.5 mm (for new disks) and is measured with a caliper depth gauge.

The pressure plate should move without distortion or jamming. Otherwise, it is necessary to eliminate the distortions by additional adjustment with nuts.

Before installing the crankcase cover, it is recommended to degrease its seating surface and the crankcase seating surface, and apply a thin layer of sealant to them or to the oil-free gasket (on both sides).

The holes in the cover for the screws should also be degreased, and sealant should also be applied to the back of the screw heads.

Attention!

After installing all the removed parts, you should adjust the clutch drive (see below), and, in addition, repeat this adjustment after several hundred kilometers of the motorcycle, when the clutch discs have become accustomed to each other.

An important detail - the cable

Owners of used motorcycles do not always take into account the essential role of the cable in the clutch control system. The cable itself is practically not subject to stretching, but the sheath loses its qualities. Its frame is a spiral under a layer of PVC.

After prolonged use, the frame becomes pliable and excessively springy, which affects the useful stroke of the lever. If the cable sheath is worn out, the clutch will not operate normally, so it is important not to miss the moment and replace the cable in a timely manner.