Every motor vehicle is equipped with a clutch. A clutch is a mechanism whose operation is based on the action of sliding friction. This mechanism plays a fairly significant role in the functioning of the vehicle as a whole, since thanks to the clutch, torque is transmitted from the engine to the wheels, and gears are changed, torsional vibrations are damped, and the transmission is disconnected from the engine flywheel for a short period of time. Typically, the clutch is part of the transmission of vehicles. The transmission has the responsible mission of connecting or disconnecting the connection between the engine and the transmission. The author of the development of the first clutch in the automotive world is Karl Benz.

When to adjust the clutch

In general, there are two cases when you need to think about adjusting the scooter clutch:

Clutch leads

When you press the clutch lever and engage the gear, the moped starts moving (with the clutch depressed).

The clutch is slipping

When the gear is engaged and the clutch lever is completely released, the engine runs at high speeds, and the moped moves slowly or hardly moves at all.

All these problems are the result of a less than ideal design of the clutch release and engagement drive, as well as the fact that the parts of the clutch itself wear out after some mileage, which together leads to such troubles.

Types of clutch

The clutches of absolutely all vehicles work on the same principle - a friction force acts on several driving or driven disks, which allows the vehicle to move.

So, the moped clutch is divided into two types:

- dry.

- wet, i.e. those that require an oil bath to operate.

In addition, clutches are also divided by the number of driven discs:

- single-disc or double-disc;

- multi-disc.

As a rule, the first version of the disc clutch is always dry. But for the multi-plate clutch to operate, an oil bath is required, which is also common to the gearbox.

How to adjust the clutch on an Alpha

In order to eliminate all these problems, we need a minimum amount of tools, time and experience, that is, virtually any beginner can perform the adjustment of the moped clutch.

You need to place the moped on the central stand and unscrew the chrome cover on the right side of the motor (marked with an arrow), behind which the clutch adjustment mechanism .

When the lining was thrown off, the clutch device appeared in front of us. We see the adjusting screw and the locking nut. Insert a screwdriver into the screw slot and use a 10mm wrench to unscrew the fixing nut (lock nut).

After unscrewing the locknut, you need to unscrew the adjusting screw a few turns. Then we tighten the adjusting screw back until you feel that the screw has rested somewhere and then turns with some tension, this will be the position of the adjusting screw we need. After you have found the required position of the adjusting screw, secure it from turning with a screwdriver and tighten the locknut.

We screw the tire into place, find the adjustment bolt on the clutch cable, loosen the lock nut and tighten and unscrew the adjusting bolt until the free play on the clutch lever is 5 ... 10 mm .

All Chinese mopeds are equipped with almost identical 4-stroke engines. Let's look at the disassembly and assembly of the clutch using the example of a Lifan engine, which is an analogue of the Honda Super Cub engine.

Look for the clutch mechanism and motor transmission under the right engine cover.

Semi-automatic clutch: 1 - lever that controls the operation of the semi-automatic device; 2 — figured plate with a thrust bearing; 3 — thrust bearing with three balls; 4 - spring that eliminates backlash; 5 - adjusting screw; 6 — figured plate of the engine cover with a stopper; 7 — damper springs; 8 — clutch drive drum; 9 — gear shift shaft.

Disassembly.

To get to the clutch, disconnect the kickstart lever, unscrew the bolts holding the right engine cover, and remove it. Underneath you will see a thrust bearing with three balls. Remove it and the spring underneath it from the seating surface. A lever with a cam at the end is mounted on the splines of the shaft connected to the gear shift pedal. The cam fits into the groove of a shaped plate installed in the bearing of the clutch drive drum cover. Remove the lever from the shaft, and remove the plate along with the thrust bearing and spring-loaded cylinder from the bearing. Unscrew the screws securing the drum cover and remove it. Underneath is a nut that secures the entire clutch mechanism to the crankshaft journal. Bend the tabs of the lock washer and unscrew the nut. But don't use a chisel - you'll ruin the part! Use a special key. The fact that it is difficult to find for sale is no excuse. As a last resort, such a tool can be made in a matter of minutes using a grinder (or hacksaw) and a file from a pipe of a suitable size.

Remove the clutch mechanism from the crankshaft journal. On the reverse side you will see a retaining ring. Press the discs with your hand and remove the ring from the groove using pliers with narrow jaws. You can also pry it off with a thin screwdriver (but then watch your fingers!).

Clutch operating principle

Thus, the main structural elements of the clutch include drive and driven discs, springs, and drive mechanisms. Dry single-disc or double-disc clutches have drive discs connected to the flywheel. For proper operation of the second type of clutch discs, a moped clutch basket is required, into which the discs are placed. The basket is also called a casing, which is driven by a primary transmission. In order to increase the friction of the discs, a special friction material is applied to their working parts. It often happens that high-strength plastic is used to make several disks of the same type.

The role of the crankshaft

The crankshaft transmits torque to the gearbox through the operation of the engaged clutch. This is due to the fact that in this case the clutch discs, both driving and driven, are tightly pressed to each other using springs.

If the pilot exerts force on the moped lever located on the handlebar, which disengages the clutch, then he thereby influences the drive (mechanical or hydraulic). The operation of this drive is as follows - it moves the clutch release rod or bearing, which separates the clutch discs from each other. Thus, the discs stop rubbing strongly against each other, as a result of which torque stops being transmitted from the crankshaft to the gearbox.

Most mopeds are equipped with a clutch, which is controlled manually by operating a lever located on the left handlebar. However, there are also models that are equipped with an automatic clutch. In the case of the latter, there is no lever on the steering wheel; the engine and transmission are connected and disconnected through the operation of a centrifugal machine. In such designs, the engine crankshaft speed acts as a setting parameter. It is worth noting that mopeds, as well as scooters in combination with a V-belt variator, are very often equipped with an automatic transmission.

Thus, the clutch performs an extremely important function in the operation and movement of the vehicle. It requires, like all other parts, careful care and timely adjustment and replacement. However, no matter how good the clutch care is, there still comes a time when it becomes necessary to adjust it or even change it altogether. The clutch is replaced in cases where there are very specific indications for this or when the adjustment did not help.

Engine Features

The engine of the Chinese Alpha moped has characteristic features, thanks to which fans of motorcycle technology prefer this particular model.

Engine for Alpha moped

Engine capacity - 72 cc. With the right approach, it can be upgraded to 110 cc. Also, if desired, you can increase the speed by 10 kilometers.

The weak point of the engine is the gearbox, which requires close attention and a delicate approach . When repairing the “heart” of a moped, you need to know how to correctly disassemble and reassemble this part of the motorcycle “organism”.

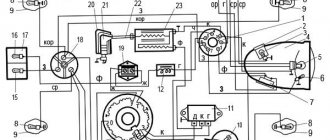

Alpha is equipped with a powerful engine, the circuit of which is complex. If you can’t figure it out on your own, it is recommended to contact an experienced specialist. The price of repairs is quite affordable.

Clutch faults

So, what clutch malfunctions can happen is when the clutch slips, or when the clutch drives.

Let's look at situations when the clutch slips:

- The kickstarter foot slips and the moped does not start;

- When you engage first gear and the moped does not move. It starts to grab at the very end of the clutch handle being depressed;

- When you are riding a moped and give it a sharp gas, the engine speed increases, but the moped does not pick up speed.

Now let's look at the situation when the clutch drives:

The moped starts well, but when the clutch handle is depressed and first gear is engaged, the moped jerks and starts to move;

Gears are difficult to engage and disengage. While driving, there are difficulties with switching to another gear.

Causes of malfunction

The Chinese Alpha moped, whose price is affordable, does not cause owners many problems. Interruptions in a moped engine have several causes, and once you understand them, you can quickly fix the breakdown.

Disassembling the moped engine

So, if the engine starts with great difficulty, the muffler “shoots”, and smoke comes out of the chimney, it means that the moped is “capricious” due to problems with the carburetor. In order to solve this problem with the Alpha moped, you need to:

- clean the carburetor;

- thoroughly clean the moped's air filter;

- tighten the screws;

- adjust the moped carburetor.

If the Alpha slowly picks up speed, and its engine is not able to develop the declared power, then the reason is the incorrect operation of the moped valves. It can also “get sick” due to gaps and incorrect timing. In order to make the Alpha moped function normally, it is necessary to replace the used valves with new ones.

If the Alpha moped is not able to reach the required speed, despite the roar of the engine and solid revolutions, it is impossible to stop the spinning wheel, and gear shifting occurs intermittently, then the cause of the malfunction is clutch wear.

Moped clutch parts

To eliminate the breakdown, you must perform the following manipulations:

- remove the engine;

- remove the plastic cover;

- unscrew the tightening screw;

- Unscrew the adjustment mechanism and tighten the screw tightly;

- start a moped;

- turn on first gear and drive a few meters.

Another cause of moped engine malfunction may be wear on the drive sprockets. If they are very worn, they must be replaced with new ones.

You may encounter the problem of engine overheating. The situation can be corrected after adding oil. If oil leaks, you must urgently contact a professional service .

Alpha moped engine overheating

Engine disassembly

Disassembling the Alpha engine is quite simple. To do this you need:

- “arm yourself” with a key;

- Unscrew the bolts on the intake manifold (by 10);

- unscrew the cylinder covers and the bolts located there (4 pieces);

- remove the cylinder head.

After performing the necessary manipulations, you need to properly assemble the engine, installing all the parts in place.

A diagram can help you understand the nuances. Also, a lot of useful tips regarding repairing the most important “organ” of the Alpha moped are contained in the training video.

Adjustment

If the situation demands it, we will do it. You don’t have to disassemble anything, because this process can be performed even by a beginner who does not have much experience in car repairs.

The setup process is as follows:

- Arm yourself first with a pair of simple keys for 13.

- Open the hood and locate the clutch cable lug in the engine compartment.

- There is a lock nut on it.

- Using the first wrench, slightly loosen the locknut, and with the second, turn the adjusting nut.

- If you turn it closer to the tip, the total pedal travel will increase, and if you move it in the opposite direction, the pedal travel will decrease.

- Tighten the nut and check how the manipulations affect the clutch pedal inside the cabin.

- Having reached the desired mark of 13 centimeters, sharply press the clutch pedal about 5 times and release. If the distance is less or more than required, repeat the operation.

- Having completed the adjustment, tighten the lock nut back, and therefore slide the rubber stopper sleeve as far as it will go.

Gearbox disassembly

It is necessary to disassemble the gearbox in order to replace used parts. This is done after the following parts have been dismantled:

Gearbox disassembly

Repair of this part of the engine is carried out as follows:

- Using a screwdriver or blade, remove the retaining ring and the drive gear;

- Carefully unscrew the gear fixing bolt and remove the gear shift mechanism;

- remove the gear shift fork and shaft;

- remove the crankshaft and drum (including the core);

- After replacing the worn part with a new one, reassemble (in reverse order).

Alfa moped clutch adjustment

In this article we will look at a fairly common problem for almost any Alfa moped owner. This moped is in high demand, but this does not mean that it will not break down.

Often the owners of this moped notice that the clutch is not working properly; it either slips or does not engage completely. Let's find out! If your moped has similar malfunctions, then you have a problem with clutch adjustment. Basically, there are several reasons why you need to look into your Alfa clutch and adjust it.

- Clutch slipping. This can happen in the following way: you engage a gear and release the clutch, but your vehicle does not gain the required revolutions and, accordingly, speed. This means adjustment is needed.

- Over-tightened clutch. This often happens, because if you press the clutch and engage a gear, your moped begins to move spontaneously. At the same time, the clutch is depressed, which should not happen.

But let's move on to the main topic - clutch adjustment.

Place the moped in a position convenient for you and find the clutch cover (pictured). This is the clutch, and in order to get to it, you need to remove this cover. Once you have removed the cover, you will see a nut securing the clutch and an adjusting screw. First of all, you need to unscrew the fixing nut; for this you will need a 10 mm wrench.

Clutch adjustment

How to adjust the semi-automatic clutch on a Delta moped? This is a simple procedure that requires a minimum of tools and experience. The clutch design of the Delta moped is quite simple.

To make adjustments, you need to place the two-wheeler on the stand. The motor cover is unscrewed on the right. A screwdriver is inserted into the adjusting screw, and the lock nut is unscrewed with a 10mm wrench. Now you can unscrew the screw a little and screw it back until it stops. Then the locknut is tightened.

Adjusting the travel of the clutch release handle

Adjusting the clutch handle release on the Alpha moped is adjusted by the tensioner on the clutch cable.

Tensioner on the clutch cable of the Alpha RX moped

We need to start the moped and engage first gear, but before starting the moped, it must be placed on the service stand.

We achieve a point where the rear wheel can be stopped with a little effort. For example, take the same screwdriver or wrench in your hands and bring it to the rear tire.

We check the clutch adjustment by applying slight force to the rear wheel.

We adjust by turning the tension bolt and checking the clutch. Before adjusting, the tensioner must be unlocked with a lock nut.

After we have achieved the desired adjustment, we tighten the tension bolt with a locknut and screw on the clutch cover.

After this adjustment, we check again how the rear wheel rotates when the clutch is depressed. We make sure that the settings are correct.

The clutch adjustment on the Alpha moped is completed.