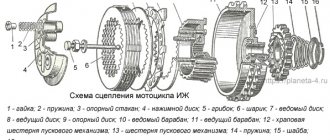

Dnepr motorcycle clutch diagram

Chapter IV.

TRANSMISSION OF MOTORCYCLES “URAL”, “DNEPR” The transmission is designed to transmit torque from the engine crankshaft to the wheel (wheels) of the motorcycle, change it and stop the transmission of rotational force.

The transmission consists of a clutch, gearbox, driveshaft and final drive.

CLUTCH OF MOTORCYCLES “URAL”, “DNEPR”

The clutch is designed to transmit torque from the engine to the gearbox, disconnect the engine from the gearbox during gear changes, and smoothly engage when the motorcycle is moving away. The double-disc dry clutch consists of driven and driven parts and a clutch release mechanism.

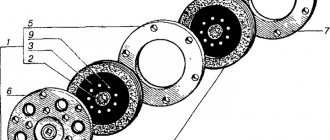

Rice. 4.1. Clutch discs of the motorcycle “Dnerpr-11/16. 1 — disk assembly; 2 - hub; 3, 5, 6, 7 - disks; 4 - spring; 8 - screw; 9 - rivet

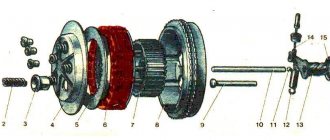

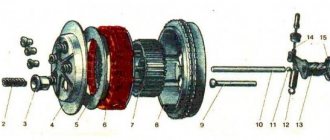

Rice. 4.2. Clutch release mechanism: 1 — cotter pin; 2 — washer: 3 — ring; 4 - slider; 5 - bearing, 6 - tip; d 1 - rod, 8 - oil seal; 9 — rod assembly, 10 — lever; 11 - bolt; 12 - nut; 13-axis

The need to check clutch parts arises if the clutch pins and pin holes in the drive discs wear out, the pin fits in the flywheel become loose, the splines in the hub of the driven discs wear out, the fastening of the disc hubs becomes loose, the friction discs wear out and the elasticity of the springs decreases. If the fingers are worn out by more than 1 mm, they need to be replaced. To do this, press out the worn pins, having previously measured the amount of protrusion of the ends relative to the plane of the flywheel. Press in new fingers (Fig. 4.3), leaving an allowance at the ends for grinding. Then the fingers are polished. After grinding, the ends of the fingers should be in the same plane. The runout of the ends relative to the conical seating surface of the flywheel should be no more than 0.2 mm. If the walls of the holes in the drive disks are damaged, then you need to drill new holes with a diameter of 196 mm between the old ones (hole diameter 12.5 - 12.57 mm). Discs with worn out linings and splines in the hub are replaced with new ones. If rivet connections become loose, they must be riveted or replaced. Clutch springs must have the same stiffness. New parts, when compressed to 21 mm and depending on the load, are marked with paint: 17.5 - 19.0 kgf - gray, 16.0 - 17.5 kgf - black. The free springs are about 45 mm long.

Source

MY MOTORCYCLE

So, the advantages of a driven tavrodisk are the presence of a spring damper. Its (damper) location “before” the gearbox smooths out torsional vibrations on the shafts of the gearbox itself, which is not actually observed if only a rubber damper is installed “after” the gearbox.

I think that with this scheme the box will work a little longer. Well, I emphasized that this is not “nuno”, but “mono”.

But let's take things in order.

Our standard clutch looks something like this (springs and screws are not shown):

Somehow something started ringing in my engine at very low speeds and with the clutch depressed. The book didn’t tell me anything about this, except that you can drive further, and if necessary, check it out. Well, on occasion, on occasion. It turned out that there was nothing catastrophic there. The middle steel drive disc begins to ring when the holes on it become slightly broken. And this happens very soon.

Let's go further. All this talk to me about installing a disk from Tavria... I couldn’t find any proper information, so I decided to draw everything myself.

Let's first consider the disc itself from the brand.

It consists of two plates that hold springs; a central plate that “hangs” on these springs; a splined bushing, which is cleverly pressed into the central disk; disc-bracket for the friction discs themselves; a centering plastic sleeve (purple in the picture); washers with whiskers and a spring washer. All THIS is assembled with rivets.

Let's get started.

The spline bushing is pressed out of the central disk with three blows of a hammer. We give the plate itself to the turner to grind the inner hole (the teeth must be cut off).

Next, we remove the bushings from our original MT driven disks, cutting off eight rivets with a grinder.

These bushings need to be machined. We also give them to the turner, showing the following diagram...

They need to be machined one and a half millimeters, or a little less, from the chamfer side of the holes, and the diameter must be such that they are pressed into the central disk.

The diagram also shows the new centering sleeve. It needs to be made of duralumin or bronze so that it is pressed onto the MT spline bushing.

Then it gets more interesting. The MT bushings must not only be pressed in, but also secured in the central plate. To do this, in the latter we will need to drill eight holes with a diameter of 5 mm. The plate is basically calcined. We take a victorious drill and remove the side cutting edge on it. Next, using our machined bushings as a template and as a guide for the drill, slowly pouring oil on us, we drill the central plate at very low speeds. Because the holes hit the edge of the metal, the drills experience extreme side load. I ruined four pobedit drills :))))…

The photo shows the actual central plate on which we drilled and broke :)), and turned MT bushings.

When you mount the bushings into the central disk, pay attention to the fact that they need to be turned so that the holes of the two bushings and their splines coincide. Drilled? Now remove the chamfers on the bushings for the rivets, and rivet the bushings with the central disk. Next you need to remove a 1x45 degree chamfer from the “inner” side on one of the spring holder plates to install the centering sleeve. All that remains is to press on the centering sleeve itself and put it all together.

Well... We made the driven disk itself.

Let's see in the diagram how this is all installed.

Sectional diagram of the modified clutch, on the right - the standard clutch.

The sequence of discs is: release, intermediate drive from the standard set, driven (already T-type) and drive, which is screwed to the flywheel. The driven disk may rest against the box (as in the case of using the Moskvich one), so you may have to shorten the flywheel pins. Or you can simply put another intermediate drive between the driven (already branded) and the drive, which is screwed to the flywheel. But this will make the whole set heavier, which may affect the dynamics.

I’ll say right away that I sharpened the flywheel. I cut off the outer shell and increased the groove “around” the fastening bolt. This lightened the flywheel by one and a half kilograms.

Before shortening the flywheel pins, ALWAYS make sure that the gearbox drive shaft is long enough for such a disc offset.

If you intend to install a starter, check whether there is room for its crown.

By the way, sometimes there is talk about installing a Moskvich disk (401 or 408), in which the splined bushing matches the teeth one to one with the MTshnoy. But they also say that its damper works “in the wrong direction,” and therefore, with such a disk, the gearbox shafts fly, in the absence of a rubber washer after the box. But it is impossible to turn the disk over due to its specific dimensions. I haven't tested it in metal. That's just what they said.

Sketch of a standard flywheel with some dimensions.

The article is purely informational for those who like to get technical, so don’t be biased. And taken from the first person in a slightly shortened form.

Author: SerDUKE, source: MOTO.kiev.ua

Dnepr motorcycle clutch diagram

MOTORCYCLE GEARBOX “DNEPR”

In models MT9, MT10, MT10-36, (“Dnepr-11”, “Dnepr-12”, “Dnepr-16”), MV-750M MV-650, a two-shaft four-speed gearbox with reverse gear and an automatic clutch release mechanism is installed model MT804 (Fig. 4.11).

The box has been equipped with a reverse gear, a mechanism for power release of the clutch when changing gears, and other components have been changed. The gearbox can be installed on motorcycles of the Kyiv Motorcycle Plant models K-750, K-750M, K-650 and on the latest models of Ural motorcycles. If boxes from previous editions are replaced, some modifications will need to be made. The driveshaft needs to be shortened.

For a shaft designed by the Kyiv Motorcycle Plant, this can be done by rearranging the retaining ring, which is located at the rear end of the propeller shaft. If necessary, cut another groove on the shaft, slightly shortening the cardan fork. The fork and shaft can also be connected with a pin (Fig. 4.12). The shaft is shortened on the cardan joint side by such an amount that the end of the shaft is removed from the oiler by a distance of at least 3 mm.

On motorcycles of the Kyiv Motorcycle Plant models K-750, K-750M, the frame is shorter than on subsequent models, so contact between the spring cardan disc and the frame is possible. In this case, bevels are made on the disk and frame (Fig. 4.13). Unlike the box of previous releases, the neutral of the switching mechanism is set by a foot pedal using a lamp-lamp indicator, which is mounted on the instrument panel. The flashlight switching circuit is shown in Fig. 4.14. Unlike the previous gearbox, the housing consists of a crankcase and one cover. A cardboard gasket is installed between the crankcase and the cover, which is lubricated with grease, for example, Litol-24. The gasket does not stick to metal surfaces and remains on the cover or crankcase during disassembly.

Dnepr motorcycle clutch diagram

POWER TRAIN OF MOTORCYCLE DNEPR-12

The power train of a motorcycle consists of interconnected units designed to transmit torque from the engine crankshaft to the rear wheel and sidecar wheel, as well as to change the traction force on the drive wheels.

The power transmission includes: clutch, gearbox, cardan and final drives, differential mechanism, sidecar wheel gearbox.

Motorcycle clutch Dnepr-12

The clutch (double-disc, dry) is designed to transmit torque from the engine to the gearbox, disconnect the engine from the gearbox during gear changes, and smoothly engage when the motorcycle is moving away.

The clutch consists of driven and driven parts and a mechanism

disengaging the clutch. The leading parts of the clutch include flywheel 7 (Fig. 12) and discs (pressure 8, intermediate 9 and thrust 11) mounted on the flywheel pins.

In the center of the pressure plate there is a square hole into which the clutch release rod fits.

The thrust disk is attached to the ends of the fingers with screws, which are secured by drilling the thrust disk into the slot of the screw head.

The driven parts of the clutch include two driven disks 10, with ring linings made of friction material molded on both sides; the discs engage with the splined part of the input shaft.

The clutch has two control drives: from the clutch control lever located on the steering wheel (manual drive) and from the gear shift pedal (foot drive).

When using a manual drive, disengage the clutch before engaging (shifting) gear and release it smoothly

clutch control lever after engaging (shifting) a gear.

When using a foot drive, the clutch is released automatically during the process of engaging (switching) the next gear without affecting the clutch control lever. In this case, after engaging the gear, the pedal should be held with the toe and heel of the foot, smoothly returning it to its original position, while simultaneously increasing the engine speed.

Rice. 12. Clutch and clutch release mechanism when changing gears: 1 — foot shift pedal; 2 — cam-crank; 3 - roller; 4 — internal lever; 5 — intermediate rod; 6 — adjusting bolt; 7 — engine flywheel; 8—pressure disk; 9 — intermediate disk; 10 — driven disk; —thrust disk; 12 — clutch release rod; 13 — rod tip; 14 — sealing rubber ring; 15 — ball thrust bearing; 16 — slider; 17 — outer clutch release lever; 18 - axis; 19 — cable for manual clutch drive; 20 — clutch cable adjusting screw

Source

A simple way to assemble a clutch

In general, opposition brothers, due to numerous requests, I am laying out the procedure for assembling the clutch using two bolts. Actually, when I was young and stupid, I thought that this system was the first to invent, but when I got to Opposite, and also after talking with comrades, I realized that there is no smell of a patent