Purpose of the clutch IZ Planet and IZ Jupiter

Clutch - the name speaks volumes about the job it does. In our case, the crankshaft engages the gearbox of the IZH Planet and IZH Jupiter engines. The connection should occur smoothly without jerking, this is necessary to start moving and smoothly change gears. In case of heavy loads, it protects engine parts from damage.

The clutch is located in the left half of the crankcase, under the left engine cover.

To get to the clutch, you need to drain the oil and remove the cover with the gasket, first remove the levers and unscrew the mounting bolts.

The basket is constantly in working condition, the discs are tightly compressed by springs.

The motor transmission consists of two sprockets. The small drive is located on the crankshaft. A large star driven on a drum. The connection is made by a motor chain.

The engine gear ratio is 2.17 for all single-cylinder IZh models. For IZ Jupiter, the gear ratio is 2.57.

When assembling the motor transmission, the planar arrangement of the stars is controlled. No more than 0.4 millimeters are allowed.

Switching off occurs using a special device. The shutdown mechanism is installed in the right engine cover. This mechanism is used to make adjustments.

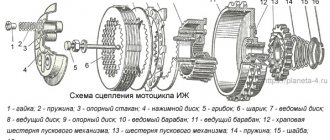

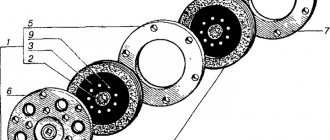

Clutch device of the IZH Planet 5 motorcycle

For those who are not good at technology, it is worth recalling that the clutch acts as a connecting element between the crankshaft and the gearbox. The large clutch gear is connected to the small crankshaft sprocket by a chain transmission, which is how torque is transmitted. In the normal state, the system ensures constant communication between the gearbox and the crankshaft and only when the clutch lever is pressed, the drive mechanisms increase the gaps between the elements in the multi-disc clutch system, thereby disconnecting the box from the crankshaft.

Owners of the IZH Planet 5 motorcycle are lucky; their clutch release system is simpler in comparison with the similar 5th Jupiter, which means it is unpretentious and easier to set up with your own hands. It looks like this:

- Shaped nuts;

- Springs;

- Cups;

- Pressure disk;

- Driven (steel) disk;

- Drive (plastic) disk;

- Driven drum;

- Large drum with large gear motor transmission;

- Clutch release pusher;

- Kernel;

- Ball;

- Spring;

- Worm;

- Cable;

- Washer;

- Screw;

- Screw.

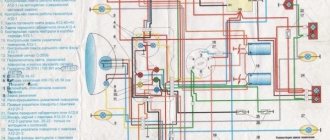

Clutch adjustment IZH Planet

To adjust the clutch control mechanism of motorcycles IZH Planet 5, IZH Planet 4, IZH-56, IZH-49, use adjusting screw 1 and locknut 2. By loosening the locknut by turning the screw clockwise, reduce the free play of the control lever. When turning the screw counterclockwise, the free play increases. After completing the adjustment, tighten the locknut. The normal free play value is determined by the free movement of the end of the clutch lever by 5..10 mm.

The normal amount of free play is determined by the free movement of the end of the clutch lever by 5..10 mm.

Motorcycle IZH-Planet.

Operation, maintenance and repair. >> Motor transmission, clutch, trigger mechanism. Clutch - disc replacement LLC "World of Autobooks"

Clutch - disc replacement

Before replacing the clutch discs, motor chain or drive sprocket, it is necessary to remove the left muffler from the left driver's footrest (with a two-pipe exhaust system), drain the oil from the power unit crankcase, or (for repairs on the road) place the motorcycle on its right side. If the fuel tank is full, the fuel must be drained or the tank removed.

The work is shown on a removed power unit.

Removing the clutch discs

1. Using a 12 mm wrench, loosen the pinch bolt of the gear shift lever.

2. Remove the lever.

3. Remove the washer.

4. Remove the O-ring.

4. Use a 14 mm wrench to loosen the pinch bolt of the kick starter lever.

5. Remove the lever.

6. Using a slotted screwdriver, unscrew the eight screws securing the left crankcase cover. If necessary, you can use an impact screwdriver.

Please note that the screws vary in length and some have aluminum sealing washers underneath.

7. Remove the cover along with the paronite gasket. Be careful not to tear the gasket.

8. Using a large slotted screwdriver, unscrew the five nuts of the clutch pressure springs.

9. Remove the five springs along with the caps from the inner clutch drum.

10. Remove the pressure plate.

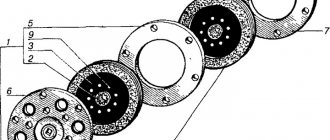

11. We take out the driven and driving disks.

12. We lay out the disks in the order of removal, so that (in case of assembly without replacement) install them in their original places.

13. Inspect the clutch discs. The driven (steel) discs must not be deformed as a result of overheating, and the driving (plastic) discs must be free of cracks, burns and visible wear of the contact surfaces. The outer protrusions of the discs must not be damaged. If defective disks are found, we replace the entire set.

Installing clutch discs

We install the clutch discs in the reverse order.

Uniform compression of the springs is ensured by equal protrusion of the ends of the nuts above the ends of the studs. It should be equal to 4.0-4.5 mm (for new disks) and is measured with a caliper depth gauge.

The pressure plate should move without distortion or jamming. Otherwise, it is necessary to eliminate the distortions by additional adjustment with nuts.

Before installing the crankcase cover, it is recommended to degrease its seating surface and the crankcase seating surface, and apply a thin layer of sealant to them or to the oil-free gasket (on both sides).

The holes in the cover for the screws should also be degreased, and sealant should also be applied to the back of the screw heads.

Attention!

After installing all the removed parts, you should adjust the clutch drive (see below), and, in addition, repeat this adjustment after several hundred kilometers of the motorcycle, when the clutch discs have become accustomed to each other.

Contents :: Next >>

Clutch adjustment IZ Jupiter

On motorcycles IZH Yu and IZH Yu K, adjustment of the clutch release mechanism begins with the release mechanism, for which the adjusting screw is screwed in all the way and released 1/4 -1/2 turn, after which the lock nut is tightened.

The correct installation is checked by pressing the shift pedal in one direction or another. Moving the front end of the shift pedal 5-5.5 mm from the neutral position should not lead to movement of the pressure plate. After this, the manual release is adjusted using the adjusting screw located in the left post of the clutch lever on the steering wheel (the free play is 5-10 mm).

Tips for increasing the life of the Izh motorcycle clutch

The clutch is not intended for long-term operation in the disengaged position, as in this case increased wear of the mechanisms occurs. The control lever must not be released abruptly or very slowly. When turned on abruptly, the power transmission receives maximum load; when turned off slowly, the parts wear out even more than when turned off completely, due to slipping of the disks. If you have a habit of keeping your fingers on the lever, make sure that there is not even the slightest pressure on it. Even with a slight pressure that does not cause the discs to slip, the clutch mechanisms experience significant load. Do not use the clutch to disconnect the engine from the gear when stopping or coasting for a long time. In all these cases, use the gearbox, putting it in neutral. Also, never try to make the engine work easier on climbs and in other difficult situations, causing the discs to slip and, as a result, increase engine speed. In such cases, it is better to switch to a lower gear in advance.

Adjusting the clutch springs

Adjusting the springs is not difficult, the main thing is to get it right. We start by placing the motorcycle on the center stand. Then remove the lid, draining the oil in advance. We squeeze the lever on the steering wheel to the limit and make sure to fix it. Next we turn on the speed, preferably the first one. We take the wheel and begin to rotate. We try to determine by touch how much effort we are applying. We look at the coupling as it rotates and determine which springs are loosely tightened. We mark them with chalk, then tighten them. We begin to rotate the wheel again and if you feel that the wheel has become easier to spin, then everything has been done correctly. The process must be repeated to achieve a better result. After this, we check the result obtained while moving. If, as the load increases, the clutch begins to slip. All springs must be tightened using nuts. In this case, all nuts must be turned the same number of turns.

Clutch faults

Possible malfunctions that may appear during operation of IZ motorcycles.

The clutch of IZH Jupiter IZH Planet is slipping reasons

The malfunction is noticeable during sudden acceleration. We increase the speed, but the motorcycle does not accelerate. The same thing happens when driving on a steep hill as the load increases. The motorcycle cannot overcome the obstacle and stops, although the crankshaft speed does not drop. The discs get very hot and wear out quickly. It is impossible to operate the equipment in this condition; the cause must be found and eliminated.

This malfunction indicates that the disks are poorly pressed against each other.

There may be several reasons:

- The adjustment was not carried out correctly

- The springs have lost their former elasticity

- The discs have worn out and become thinner.

- Wear of drive parts

A serious problem could be a jammed control cable. The reason is damage to the shell and the resulting rust underneath. Gentle cleaning and lubrication, better replacement.

Check and wash the adjustment mechanism itself located in the right engine cover. Small particles of road sand that get into the mechanism with water can slow down the operation. After squeezing the lever, the parts do not return to their original position.

Drives clutch IZ Planet IZ Jupiter reasons

The clutch is driving - this is when the lever is squeezed all the way, and when the speed is turned on, the motorcycle immediately starts moving and cannot be stopped. You press the brake, the engine stalls. This indicates that the clutch is not completely disengaged.

The main reason is the springs that compress the discs. The discs are not evenly weakened and in some places are in strong contact with each other. The springs need to be adjusted correctly.

There is too much free play in the control lever on the steering wheel. If adjustment is not possible, replace worn control parts.

You need to check the pusher, which is located inside the input shaft of the gearbox. Perhaps the rod has become shorter.

Be sure to check the presence of the ball. Often during disassembly it rolls out and gets lost.

The ball is located inside the input shaft of a two-cylinder engine between the pusher and the thrust rod.

For a single-cylinder unit, the ball is located in the right cover between the screw with a control nut and the thrust rod in the input shaft of the box.