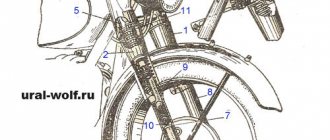

Voskhod clutch device

A motorcycle clutch is a mechanism designed to temporarily disconnect the rotation transmission from the crankshaft to the gearbox and further along the chain to the wheel. By squeezing the lever on the left half of the steering wheel, we break the connection of this chain. By releasing, the reverse action of connection occurs. It is desirable that the work be carried out without sudden jerks. This helps to start the movement smoothly. It is also necessary for changing gears, braking, and stopping the motorcycle.

Return to content☝

Motorcycle bearings "Voskhod" 3, 3M, 3M-1, 3M-2

Brief information. Voskhod-3 (1979) - differs from its predecessor in a different gas tank (holds 2 liters more fuel), intake system, rear shock absorbers with increased energy capacity (located at an angle of 12° to the vertical, providing a wheel travel of 105 mm). Modernized brakes were used (the diameter of the brake drums was increased from 125 to 160 mm), wheels, a G-427 generator (rated voltage 7V), and an improved saddle. Maximum speed 105 km/h, dry weight 125 kg.

Voskhod-3M (1983-1993) The cylinder fins have an increased cooling surface. Some engines were equipped with Czechoslovak-made carburetors. 12-volt electrical equipment was installed, an FG-137B headlight with a “European beam” diffuser, and a new rear light with side reflectors. Above the headlight there is a block of control devices made of plastic: ignition switch, speedometer, indicator lamps for direction indicators, low and high beams. In addition, an anti-theft lock was installed. The front shock absorbers received corrugated rubber covers. "Voskhod-ZM" was equipped with a wear indicator for the brake linings of both wheels. The motorcycle received a new profiled front wheel guard, a kickstarter lever with a folding pedal instead of a solid one, folding driver's footrests, and two rear-view mirrors. Maximum speed 105 km/h, dry weight 122 kg. On the basis of this model, the production of the Voskhod-3M Krokha tricycle was organized; the body had a load capacity of 200 kg. Speed 80 km/h, rear gearbox borrowed from the Ant scooter

Voskhod-3M -tourist (1985) - The motorcycle received a new sports-type steering wheel with a jumper, roll bars, two rear-view mirrors, tourist equipment (rear trunk with side sections, side bags made of artificial leather, a tablet bag on the fuel tank). The motorcycle has new inscriptions on the tank and tool box lids, stickers are made of lavsan film. Maximum speed 105 km/h, dry weight 125 kg.

Voskhod-3M-01 (1989) A new engine with a reed valve was installed on the old chassis. The modernized engine featured a cylinder with a five-channel scavenging and one exhaust port (the Voskhod-ZM model has two channels). An intake reed valve reduced fuel consumption to 4.2 l/100 km. Power increased to 15 hp. at 6000 rpm, maximum torque up to 1.7 kgf m at 5500 rpm. The engine has one muffler. The motorcycle's handlebars became wider and received a crossbar. The piston skirt is enlarged.

Bearing table

| Installation location | Number | Bearing type | Size | Qty |

| Engine, crankshaft | 204 | Ball radial single row | 20x47x14 | 2 |

| Rear wheel sprocket | 60304 | Ball radial single row | 20x52x15 | 1 |

| Rear wheel | 60204 | Ball radial single row | 20x47x14 | 2 |

| Front wheel | 60204 | Ball radial single row | 20x47x14 | 2 |

| Gearbox, primary shaft | 203 | Ball radial single row | 17x40x12 | 1 |

| Gearbox, intermediate shaft | 202 | Ball radial single row | 15x30x11 | 2 |

See also:

- Bearings VITALS CM 125C-2G

- Bearings VAZ 2105 LADA

- Bearings Gas-3301

- Bearings Izh-Planet 3, Planet 4, Planet 5.

- Bearings VTZ-2427

- Bearings IZH-6.113-05 "Junker"

- Bearings T-25A

- Bearings Zil-130

- Bearings VAZ 1111 "Oka"

Kickstarter Sunrise

This unit performs another important job - starting the engine. By pressing the kickstarter to start the engine, the sector engages with a gear mounted on the drum on the side of the box. The gear, in turn, begins to rotate the drum and then the chain transmits force to the crankshaft. The engine starts.

The location of the clutch is in the left half of the engine crankcase, on the input shaft of the box. It is closed with a lid with holes for fastening bolts.

At the top of the cover there is a threaded hole and a plug - a dipstick for filling and monitoring the oil level. In the center of the lid there is a threaded plug for adjustment.

Return to content☝

Technical characteristics sunrise 3m.

| Name | Index |

| General indicators | |

| Load limit, kg | 165 |

| Dry weight, kg | 125 |

| Number of gears | 4 |

| Dimensions | |

| Distance between wheels/width/height from ground to seat, mm | 2000/ 761/ 1090 |

| Ground clearance, m | 1,25 |

| Turning radius, m | 2,5 |

| Performance indicators | |

| Maximum acceleration, km/year | 105 |

| Gasoline consumption per 100 km | 4.4 l |

| Engine | |

| Type | Two-stroke, single-cylinder, carburetor |

| Volume | 173,7 |

| Power at 5500 - 5800 rpm | 4 l. s./ 10 kW |

| Clutch | Multi-disc in oil bath |

| Cooling system | Air |

| Electronics | |

| Voltage | 12 V |

| Ignition system | Electronic, contactless |

| Alternator | 65 W |

| Chassis | |

| Frame | Tubular, welded, single |

| Wheels | Spoked, tube tires, 3.25 - 16 inches |

| Brake mechanism | Drum with mechanical drive |

| Suspension | |

| Front | Telescopic, wheel travel 160 mm |

| Rear | Pendulum, wheel travel 80 mm |

Disassembling the clutch and kickstarter Voskhod

We repeat all removal work exactly as described below: - remove the ends of the spring from engagement with the pressure plate; — dismantle the pressure disk with the adjusting bolt and lock nut, driven and driven; - remove the squeeze fungus; — bend the lock washer securing the inner drum, use a 22 by 17 socket wrench to unscrew the nut and remove the inner drum.

It is easier and more convenient to unscrew the fastening nut by fixing the drum using a homemade device as in the photo. Don't forget the thread is left-handed.

— Unscrew the nut securing the crankshaft sprocket, remove the washer; - pull off the drive gear from the crankshaft along with the chain and outer drum; — remove the key from the groove of the left crankshaft journal; — remove the spacer sleeve with the washer from the input shaft; — remove the trigger mechanism.

Why put the trigger lever on the splined end of the roller? Slowly turning it clockwise, lift the trigger mechanism upward so that it goes beyond the plane of the crankcase. Then, slowly releasing it, take it out.

Return to content☝

Parts of the cylinder-piston group

Tuning sunrise 3m begins with improving performance characteristics. The maximum speed of the Voskhod 3M motorcycle can be increased by lightening the CPG parts. To do this, we use a milling machine to bore those places that do not affect the strength.

We lighten the connecting rod in the same way. To play it safe, you can find foreign analogues. Next, you need to bore the purge, inlet and outlet channels. This is done in order to better mix and ignite the air-fuel mixture.

Tips for assembling the Voskhod clutch

This work should be carried out in the reverse order, and the following tips should be taken into account: - the tension of the trigger spring should be such that the pedal freely returns to its original position; — under the screws securing the crankcase cover, except for the rear point, it is necessary to place copper-asbestos gaskets; — securely fasten the start and shift control levers to the rollers (without rolling), ensuring their free rotation relative to each other and the crankcase cover; — fill 500 cm3 of motor-tractor oil (the lower oil level in the crankcase should be 1.5 mm above the end of the dipstick, and the upper oil level in the crankcase should be at the dipstick mark).

After installing the coupling, we check its functionality. If during inspection it turns out that the clutch does not engage or disengage properly, adjustment must be made.

Return to content☝

Removal and installation of crankshaft, bearings and oil seals Voskhod

To remove the crankshaft, ball bearings and crankshaft seals of the Voskhod-2m motorcycle, you must:

- remove the clutch release rod and ball

- press the guide bushings out of the upper holes in the right half of the crankcase, unscrew 13 screws;

- using a special device attached to the right half of the crankcase at the mounting points of the generator stator, separate the crankcase halves, making sure that there is no distortion of the crankcase halves, so that the roller bearing rollers of the main gear do not fall apart;

- Press out the bearing, remove the adjusting washers, locking ring, and then press out the oil seal.

- Install a special device on the left half of the crankcase and press out the crankshaft. When pressing out, it is strictly forbidden to hit the trunnions with any object;

- Press out the ball bearing, remove the washer and locking ring, and then press out the oil seal.

Wash the removed parts thoroughly in clean gasoline and carefully inspect, paying attention to:

- on the working edge of the oil seal, reliable locking of the spring lock;

- crankshaft ball bearing rings. They should rotate freely relative to each other without jamming (there should be no play);

- the radial play of the roller bearing of the lower head of the crankshaft connecting rod should be no more than 0.3 mm, and the connecting rod rod should not touch the flywheels;

- The piston pin must fit freely into the upper head of the connecting rod and have no radial (transverse) play.

Install the crankshaft, bearings and oil seals in the reverse order, using tools and having previously performed the following operations:

- place the locking ring in the left half of the crankcase, pull the crankshaft into it until it stops;

- install the right half of the crankcase. Press in the bearings. Fill the resulting space between the bearing and the annular groove with adjusting washers and install a locking ring;

- Place shaped washers on the right and left sides, press in the seals.

Before installing series 204 bearings, fill the cage cavity with CIATIM 202 GOST 11110-75 or US-1, US-2 GOST 1033-73 lubricant. Press the 204 series bearing onto the crankshaft after connecting the crankcase halves on the control bushings. In order to protect the crank from damage, a wedge must be placed between the flywheels. In the assembled engine, the crankshaft should rotate freely, without jamming.

>

Similar articles:

- Complete disassembly of the Voskhod motorcycle engine

Modern look

Along with the increase in power characteristics, there is a need to improve the appearance of the unit: installing a new panel, nickel-plated arches, fairings. One of the popular options for tuning a 3m sunrise among drivers is to convert the sunrise to a cross.

The advantages of this option are that the cross bike moves well off-road, is easy to control and does not require fundamental design changes.

Cross version of the motorcycle.

A few simple instructions on how to convey sunrise, tuning for cross.

- When creating a cross bike, wheels play a very important role, since they take the main load. The wheels should be able to absorb strong impacts well. Spoke-based wheels can handle this task. You should select a tire based on the following dimensions: 120/70-17 at the front and 160/60-17 at the rear.

- The front suspension meets more stringent requirements. Unfortunately, a compromise solution is not possible here, since the original fork may not withstand the load. You will have to buy a fork from a motocross bike as a kit.

- The rear suspension is being converted to a single shock absorber. For this purpose, the fork needs to be welded or selected to the required size at a motor disassembly shop. The spring for the shock absorber is selected based on the weight of the bike and the driver. Next, the suspension is adjusted so that the rear wheel travel does not exceed 250 mm.

Previous entry Tuning IZH Jupiter-5 - do it yourself

Next entry Ural motorcycle - valve adjustment