Tuning the carburetor and air filter.

The basic principle of driving fast is to burn more gasoline per unit of time, it is suitable for tuning Chinese 4t scooters, Japanese 2t scooters and any other models and types of engines, and the carburetor helps in this, first of all. You can modify the standard unit by installing more efficient jets, but in practice it is better to install more efficient models. Scooter tuning is made easier due to productive models of carburetors produced by DellOrto, a set of pipes and other accessories for them.

A high-performance carburetor will deliver more fuel to the cylinder, and more fuel requires more air. Therefore, the standard filter should be reviewed; it is best to replace the filter element with a new one, while making sure that the entire system is tight. If you are preparing a high-power device, it makes sense to install a minimum resistance filter, but do not forget that it requires constant care, otherwise the filter element will dry out and sand will begin to get into the engine.

Scooter rider

The fuel supply system is necessary for engine operation. Even if there are craftsmen who can ride without a battery, then without a carburetor the scooter will not even start. However, a more modern analogue is becoming increasingly common - an injector. It is common in Europe and Japan, but in our country the owner of an iron horse, as a rule, has to deal with a traditional device. It is important to correctly configure the carburetor on a scooter, otherwise excessive fuel consumption and breakdowns cannot be avoided.

Analogues - engine 1P39QMB

Chinese developers have created an analogue of the Japanese 139QMB engine - a motor labeled 1P39QMB, which in appearance completely replicates the original. Despite all the similarities, you can still find differences: the valve clearances on the 1P39QMB are not adjustable. The situation is similar with the carburetor: before direct operation it requires thorough cleaning and correct adjustment. Chinese copies of 139QMB engines, of course, cope with their task, but their main purpose was to reduce the final cost of motor vehicles. Budget versions of scooters are equipped with exactly the same versions of engines that are good only for short trips at low speeds.

Before starting operation, be sure to carry out a full run-in of the 1P39QMB engine. The optimal operating mode of the engine begins only after 2 thousand kilometers, but after 10 thousand kilometers all its technical characteristics drop, and it loses dynamics and power.

Installing piston rings

Remove the set of piston rings from the box. A piston ring set for a Chinese four-stroke scooter usually consists of five items. Three of which are a single assembled oil scraper ring, the other two: upper and lower compression.

A typical set of piston rings looks something like this

Or so

Carefully unpack the kit with perfectly clean hands.

In the kit you will find two of the thinnest rings and one thick corrugated ring (expander) - this will be an assembled oil scraper ring that needs to be installed on the piston first.

We place an expander in the lowest groove of the piston

We place thin oil scraper rings in the same groove - one under the expander, the second on top of the expander

We find the lower and upper compression rings in the kit and install them, respectively, in the middle and upper grooves of the piston - with marks on the side surface to the cylinder head (cylinder head). The lower compression ring differs from the upper one in color (not always) and the shape of the working edge (always). In most kits, the lower compression ring is painted black, and its working edge has a slight bevel.

Tags

The top compression ring in the vast majority of piston ring sets is a uniform light color. But this is in most cases, but in practice it happens that the kit comes with upper compression rings that are black or even red

By and large, the color is not particularly important to us, something else is important to us: the working edge of the upper compression ring has small roundings (chamfers) on the sides, and the working surface of the edge of the upper compression ring is covered with a shiny protective coating

For example, in this kit both compression rings are black. But the working surface of the upper compression ring is covered with a layer of protective coating, and small chamfers are removed on the edges of the working surface.

The lower compression ring has a matte working surface, and the working edge is beveled at a slight angle. All these moments are clearly visible in the photo.

The compression rings in this kit are red and black. As in the first case, the upper compression ring has chamfers on the working edge and a protective coating, and the lower one has a matte working edge beveled at an angle.

On classic piston ring sets, the upper compression ring has a light color and a rounded working edge. The bottom is dark in color and the working edge is beveled at a slight angle.

When installing the piston rings, do not forget about the marks. The marks on the rings after installation on the piston should be oriented towards the cylinder head (cylinder head).

Tools

Most Chinese four-stroke scooter engines can be divided into two main types

Essentially, these two engines are a copy of the ancient Honda GY6 and differ from each other in displacement, kickstarter design, oil pump drive and electric starter drive. In all other respects, these engines are identical.

Typical 139QMB, in fact JL1P139QMB-2

And this is what a typical 157QMJ looks like, in fact LK162QMK

Cylinder-piston group.

Finally, the most effective improvement for any engine is replacing the CPG. But not just a replacement, but the installation of a new, larger piston. Fortunately, there are now many ready-made kits on the market; you don’t have to sharpen or adjust anything, as with Soviet equipment. Moreover, there is even a lot to choose from. For example, for various models with a volume of 50 cubic meters, they offer kits to increase to 63, 72, 82 and even 90+ cubic cm. In some cases, this is an almost double increase in power.

The situation is similar with larger engines, for example, for 125 cubic meters, sets of 150 or 170 cubic meters are sold. Some, in the process of tuning a scooter, manage to increase 150 cubic meters with their own hands to 225 cubic meters. Choosing the right part is not the most difficult thing, the most difficult thing is installing it. After all, this process involves almost complete disassembly of the engine. You will be faced with the need to have several special removable keys in your arsenal; you can ask them from friends or borrow them for the evening at auto repair shops. We strongly recommend studying the technical component in order to properly disassemble, replace the necessary elements and assemble the motor.

Alas, for some, increased power does not promise anything other than breakdowns or inadequate performance. This is because by significantly increasing power, you inevitably entail work on all other nodes. Let's imagine that we installed a new 92 cc CPG on an old 50 cc engine. The first thing to check is the condition of the connecting rod, crankshaft and bearings. Otherwise, they will fly first, followed by our new system of both cylinder and piston.

Great, we added new bearings to the CPG, an elbow with a connecting rod, now we can be sure of reliability. But the engine does not go faster, and we decide to purchase a new carburetor. Now the mixture is too rich, and we understand that the exhaust needs to be changed. After such modifications, the engine sounds loud, accelerates perfectly, but the maximum speed is slightly higher than before and the variator sounds strange. After installing a high-speed CVT, for example from the Italian manufacturer Polini, the engine will be able to fully realize its new power. The last stage is an inspection of the brake system; you don’t want to find out at a speed of 60 km/h that the brakes are now comparable to bicycle ones.

As a result, after replacing almost all the components, we got a very fast “flea” that can surprise your friends and experts in this technology. Over time, you can make changes to the chassis system, replace shock absorbers, and install more attractive wheels. Often, the modernization process does not stop there, and after tuning a scooter 50, 150 with your own hands, impressive improvements in appearance are made. The moped is repainted, panels are changed, new devices, lighting, and so on appear.

Increasing the volume of a motorcycle engine from 50 cubic meters to 110. From 139FMB to 152FMH. Part 2

In continuation of my previous post.

Yes, I changed the title to include the correct engine model. After all, the work took place more than a year ago, and I simply don’t remember such trifles, and Googling led me to what turned out to be the wrong engine coding. Therefore, I had to crawl down and look at the documents for the model and engine number.

Therefore, this size is for control.

And by the way, from the above fact of possible standardization of crankcases, a second nuance follows: this is the diameter of the seat for the crankshaft.

It fit me just perfectly, as if it was supposed to be there.

Assembly is the opposite of disassembly, with the exception of preparatory, cleaning, and fitting work.

I'm not commenting on this...

One more piece of advice: REMEMBER HOW THIS FUCK STANDED!

I probably took the engine apart two more times because of the kick starter mechanism. I really don’t remember how it should be there and what needs to be done, so remember it and if something doesn’t work out, then look at how it should be on the Internet.

YES! This FUCKING clamp must go behind this FUCKING bracket for the gear to retract, or whatever it is supposed to do there. I took photos, but I don’t remember why, well done of course.

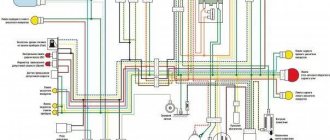

This is the gear indicator switch. I recommend cleaning it and checking the contacts.

And I took this photo apparently to once again remind you that remember the sequence and correctness of the details. For example, cylinder centering bushings (both bottom and top) and a rubber seal for the oil channel. Little dirty tricks that cost me a huge number of nerve cells and disassembly and reassembly of the motor.

But actually, there’s nothing particularly complicated. One cylinder, zero problems.

This is what it looks like assembled.

Knowing what kind of vibrator it was, the fasteners were screwed onto an anaerobic thread lock of medium fixation. Plus pulling all the elements along the second or third circle with a moment.

And this is what it looks like after installation.

By the way, it also fits neatly into the frame)

I didn’t do much running-in, it’s a waste of time to break-in there. I had it heat up and cool down for a couple of cycles, heat up and cool down, I rode from the garage to the stall and back in a calm rhythm, and the next day I rode it quite normally.

And by the way: you can do it with a passenger too. Well, more precisely as a passenger) Of course, it takes away his agility, but he drags himself along quite well and is lucky, you know.

I don’t know about the consumption, I haven’t measured it exactly. He's kind of funny there anyway.

Financial result:

For the entire box that was in the previous post, I spent something like 8-9 thousand or so, I don’t even remember. It took one day of time... And in general, after the purchase, to put it in order, I only spent about 10 thousand: movement with the engine, oil, reinforced front brake hose, normal mirrors and stars. Considering its cost and all the expenses, you actually get much more emotions.

Thanks for reading and interest, peace to all!

Possible duplicates found

Please tell me, here’s my personal selfish interest: I’m lazy to get category A licenses, but I can sit down with my B for 50 cc. Can sellers of striped sticks identify such alterations? Not exactly the subject, but the butt stool.

And now there are a lot of mopeds, with the correct marking 139 something there, but with a 72 and 80 cc piston installed, with the coveted 49.5-49.9 cm3 stamped on board.

PS I myself, too, don’t want to open it yet. But in case it doesn’t work. Buy fifty dollars for now, drive it, and then decide whether it’s worth it, or, what the heck, keep driving the car.

The description says 120kg, about fifty dollars. But it seems to me that there is more CPG there.

Here it is, but it already says 110cc.

But the 1P39 engine is specified

Many stores sell mopeds with a clean CPG of 49.5 cm3, and use a spare CPG of 72-110 cm3 (I don’t know if it’s possible to put a 110 cm engine on the 139), or they immediately install an enlarged one (with 49.5 knocked out) and the original one in the box as a set.

Engines 157QMJ

In addition to the very popular model - the 139QMB engines - Hongling Corporation produces other versions of power units, one of which is the 157QMJ. It is installed on expensive scooter models of famous brands. In terms of its technical parameters and indicators of functionality and reliability, this version is a complete analogue of 139QMB. In addition, the design features of the model are strongly reminiscent of other mass-produced Japanese engines.

The advantage of the 157QMJ is its increased service life - about 25 thousand kilometers. The engine boasts powerful dynamics and a high top speed. However, it also has its downside - the price is too high compared to previous versions of the engines.

Setting the valve timing ch2 (in collective farm style - ignition)

Without knocking the piston off from TDC, we orient the camshaft so that the large hole and marks on its sprocket become as shown in the photo and, while putting on the chain, install the camshaft in bed.

Ideally, the marks on the sprocket should be strictly parallel to the plane of the valve cover connector. In practice, unfortunately, such accuracy is difficult to achieve. And this is mainly due to the stretching of the timing chain. And there’s nothing you can do about it - either change the timing chain to a new one or catch the phase by switching the teeth, but this method of setting the valve timing is not acceptable to me personally.

Opening of the 2021 motorcycle season. Revitalizing the Dnepr

Hi all! The weather has become quite warm in Belarus and I decided to wake up one of my motorcycles, the Dnepr, from winter hibernation. I put it in for the winter in October and have never started the engine since then. Having pulled the motorcycle out of the garage, I checked the oil level, pumped air into the wheels, poured fresh gasoline, connected the battery and. Nevermind. Didn't start. I unscrewed the spark plugs, checked for spark - no. The reason was found quite quickly: the ignition contacts oxidized a little while parked and due to poor contact there was no spark. After cleaning the breaker, I tried to start it again; it started to seize, but it would not start. The reason for this is a frankly weak piston. I plan to replace it a little later, since I have repair pistons. My brother and friend launched it “from the pusher”. It started working smoothly and smoothly, all electrics are working properly, oil pressure is 4 kg/cm. We drove it for a while and put it in the garage to wait for it to warm up and replace the piston. Overall, I'm happy with the motorcycle) Happy spring everyone! Thank you for your attention)

As usual, for those who prefer to watch rather than read, there is also a video:

Air filter

It is not recommended to completely remove the filter element or replace it with a zero-resistance filter - this can lead to contamination of the carburetor. Experts usually recommend removing the plug that is installed at the inlet of the air filter.

Many reviews that affected the assembly of the 139QMB engine after tuning talk about installing a zero-resistance air filter. Despite the fact that this solution is one of the most popular, it is not always appropriate and justified.

The reason lies in the fact that installing such a filter leads to rapid contamination of the carburetor. The main reason for using a zero resistance filter is the need for a richer fuel mixture after installing a larger piston. However, this can be avoided by installing a new camshaft and replacing the jets in the carburetor.

Separately, it is worth noting that a standard carburetor equipped with a 16 mm diffuser is installed together with a 62–72cc piston system, while the 82cc piston system is equipped with a carburetor with an 18 mm diffuser.

For replacement, it is advisable to purchase a set of jets, since several different options may be needed to adjust the carburetor.

Results

Despite all the difficulties and apparent complexity of the device, adjusting the carburetor on a scooter is possible both at home and in the field. It is recommended to carry it out at least once a season, especially during frosts - this will avoid flooding the candle. If your old engine starts to feel bad, adjusting the carburetor can extend its life. Although the moped will lose a little power. And yet, with the help of proper carburetor settings, you can make life much easier for yourself and your iron horse.

Source

Running in the engine

Incorrectly carried out running-in of the 139QMB engine in most cases leads to failure of the piston system. Friction occurs between the parts of the new CPG, which leads to an increase in engine temperature.

Running in the scooter motor is carried out as follows:

- The scooter is placed on the center stand.

- Within 5 minutes the engine starts at idle speed, the field of which cools down during the same time.

- Over the next 10 minutes, the engine also runs, after which it cools down for 15 minutes.

- The engine is restarted for 15 minutes, then turned off and left to cool for 15 minutes.

- The scooter is started again for 30 minutes, after which it is turned off and left for 20 minutes.

After carrying out such manipulations, you can run in the scooter itself. In the first 100 kilometers of the journey, you should not turn the throttle handle more than 1/3 of its full stroke. The maximum speed should not exceed 30 km/h. The speed can be increased by 15–20 km/h for the next 300 kilometers - during this time the engine should more or less reveal its potential.

After this break-in process, the oil must be changed.

Engine valves are adjusted every 500 kilometers.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Installing the timing chain tensioner

If you have a 157QMJ series engine, do the following: unscrew the plug on the tensioner body; We insert a thin flat screwdriver into it and begin to tighten the bolt until the tensioner rod goes inside the body.

Without releasing the screwdriver while simultaneously holding the tensioner body, with your free fingers, insert the tensioner into the cylinder, screw it in with bolts, and only then release the screwdriver and screw the plug into place.

If you have a 139QMB series engine, then do this: unscrew the plug from the tensioner housing and remove the spring; push the rod inside the body; install the tensioner in the cylinder; insert the spring into the housing and screw in the plug.

After installing the piston, do not forget to adjust the thermal clearances of the valves and break in the engine.

Tightening torques for threaded connections

| Tightening torques, Nm | |

| Generator rotor nut | 30-38 |

| Camshaft sprocket bolts | 7-11 |

| Clutch housing fastening nut | 38-45 |

| Footrest attachment | 20-25 |

| Rear shock absorber upper nut | 20-30 |

| Rear shock absorber lower nut | 25-30 |

| Engine, mounting nut M10 | 25-30 |

| Engine, mounting nut M8 | 20-25 |

| Rear footrest attachment | 35-50 |

| Muffler mounting nut | 20-25 |

| Left and right crankcase cover, screws | 5-10 |

| Front fork fastening nut | 18-23 |

| Connection of front fork and shock absorber | 15-20 |

| Seat nut | 6-10 |

| Attaching control handles | 6-10 |

| Steering wheel mount | 5-10 |

| Brake handle | 3-5 |

| Trunk mount | 5-10 |

| Wheel axle nuts: front rear | 50-60 110-120 |

| Crankshaft pulley nut | 80 |

| CVT rear pulley nut | 100 |

| Spark plug | 18-20 |

| Drain and fill plugs | 10 |

| Cylinder head nuts (bolts) | 10-15 |

| Other threaded connections | |

| M6 | 6-8 |

| M8 | 14-18 |

| M10 | 30-35 |

| M12 | 55-60 |

| M14 | 80-100 |

| M16 | 110-140 |

Note

:

These tightening torque values do not apply to fastening plastic parts.

Cleaning the cylinder, boring windows.

Improvement suitable for scooters with two-stroke engines. Their peculiarity is that very often the casting inside the drain and exhaust channels is defective, that is, it has roughness. These shortcomings lead to the fact that the piston is not blown through properly and, accordingly, loses power. Having removed the cylinder and armed with a rolling cutter, you can polish the channels, and then round off the sharp edges on the inside. When tuning scooters, in the photo you can see the differences between the motor before and after polishing. This action will help make the engine work easier at high speeds and potentially add a couple of kilometers to the top speed.

You can go further and increase the diameter of the inlet/outlet windows. For each 2T engine, this parameter is calculated individually. For example, it is enough to bore some 50 cc engines by 1 mm to obtain optimal intake/exhaust parameters. Do-it-yourself tuning of a 150cc scooter and other engine sizes is done in the same way.

Installation of 72cc (47mm) CPG on 50cc 4-stroke Chinese scooters

Those who rode Chinese 4-stroke “fifty dollars” felt that the capabilities of their engines left much to be desired. Horsepower can be added by installing a tuning kit that increases the displacement to 72 cubic meters. Sold in our store: CPG 72cc 139QMB https://www.motochasti.ru/product_info.php?cPath=105&products_id=1786 Remove the side parts of the plastic lining and the seat tank - this is already enough to disassemble the cylinder-piston group. For convenience, we also disconnected the engine-transmission unit from the frame. Disconnect all hoses and throttle cable from the carburetor and remove the carburetor. Remove the muffler by first unscrewing its mounting bolts - they are located near the oil filler neck and on the exhaust pipe. Remove the cooling shroud halves by unscrewing the screws that connect them. That's it, the motor is ready for disassembly. First, unscrew the bolts and remove the cylinder head cover. Before disassembling the engine further, align the marks of the crankshaft and camshaft - otherwise inconsistencies will arise during assembly. Sometimes the crankshaft position mark cannot be found. Then set the piston to TDC as follows: turn the crankshaft with one hand, and with the other control the position of the piston with a piece of copper or aluminum wire inserted into the spark plug hole. At this point both valves should be closed. If at least one of them is open, turn the crankshaft one more turn. In this position, make your marks with a marker - they will help during assembly. And another hint: almost always in this position one or more marks on the camshaft sprocket are aligned with the camshaft bed parting plane. Before removing the timing chain tensioner, unscrew the screw at its end. This will not only weaken the spring, but also disable the plunger locking mechanism. I would like to draw your attention right away: when assembling, first install the tensioner in place and only then screw the bolt into place. Once the tensioner is removed, the timing chain will be loosened and can be removed along with the camshaft sprocket. Be sure to tie it to something with wire - otherwise the insidious piece of iron will slip into the crankcase. If the cylinder has chain guides and a tensioner shoe, remember when disassembling which one is located. For some scooters, these parts are very similar, but they cannot be swapped! Unscrew the four cylinder head nuts. Remove the camshaft from the bed, and then, rocking from side to side, remove the head from the studs. Watch the chain: now is the most treacherous moment when it can be dropped into the crankcase, and to get it out, you will have to disassemble the entire engine! Before removing the cylinder, lower the piston to BDC. Otherwise, the piston, slipping out of the cylinder, may hit the edge of the crankcase and become deformed. Or the connecting rod will hit the crankcase, make a nick on its edge, and the joint under the cylinder will not be airtight. Being at BDC, the piston will simply slip out of the cylinder and “lie” on the crankcase wall. And again, watch the chain... To ensure that the cylinder leaves its place without resistance, take a mallet and lightly tap it. After this, remember in which direction the crankshaft was rotated, and, turning it in the opposite direction, return the piston to TDC. Before removing the pin retaining rings, plug the crankcase neck with a rag. If a ring falls into it, you will have to disassemble the entire engine: it is impossible to shake out the ring, and, as you understand, it is impossible to leave it inside. It is more convenient to work when the piston is at TDC. To remove a finger, as a rule, it is enough to remove one ring. Moreover, not with a screwdriver, as is often done, but with narrow pliers. The rings on some engines have very small antennae, but sometimes there are no antennae at all - then only an awl will help. The piston pin can now be pressed out. As a rule, it comes out with a little force, but try not to put pressure on the side of the connecting rod. Sometimes those who are especially diligent manage to bend this rather strong part. It is impossible to visually notice the resulting bend. You will learn about it only when the new piston gets awry and quickly wears out, and before that, since it will move in the cylinder with difficulty, the engine will never develop the power it is supposed to have. What's in our tuning kit? It includes: a piston with rings (piston and retaining rings), a cylinder and a set of gaskets. When assembling, lubricate all parts with engine oil. Do not skimp on oil: the first minutes of engine operation after assembly are the most critical, and parts should not run dry! The compression rings of a 4-stroke engine should not be pushed into the grooves at random. Due to their shape, they, like scrapers, scrape oil from the cylinder walls into the crankcase - they help the oil scraper ring. There is a designation on the top surface of the rings, usually the letter A, but it happens that something else is stamped into the marking. Make it a rule: any inscription on the ring should be directed towards the cylinder head! Here are the marks (highlighted with a red oval): on the generator rotor, crankcase... ...and camshaft sprocket. The cylinder is ready for dismantling... ...and now the piston. The arrow indicates the tensioner shoe. Feel the difference! The new guy has taken his place. Installing the cylinder is much more convenient with an assistant. Now you need to check the valve adjustment and screw on the cylinder head cover. Now you need to check the valve adjustment and screw on the cylinder head cover. Be sure to move the joints of the rings 120° apart from each other. Moreover, if the oil scraper ring is assembled, the upper and lower of its constituent rings must be moved apart relative to the place where the gap should be by 20 mm in each direction. Exactly how the gaps are located relative to, for example, the plane of rotation of the crankshaft is not important. Install the retaining ring so as not to deform it! Otherwise, it will not fix the finger and may jump out, damaging the cylinder wall. You can check whether the rings fit well in the grooves like this: take them by the tendril with narrow pliers and try to turn them. In the direction towards its gap, the ring should move with little resistance, and in the opposite direction - not move at all. The ends of the ring must be located in the same plane. Check it by placing it on the table, straighten it if necessary - straighten it with pliers. Remove the centering bushings from the old cylinder and install them into the new one. Find the cylinder gasket in the tuning kit and place it on the crankcase studs. In any case, when assembling the motor, use only new gaskets. As a last resort, thoroughly clean the joint between the mating parts and lubricate with silicone sealant. It can be painlessly used (in accordance with the instructions on the tube) in almost all components, except for the joint under the cylinder head and in the carburetor. When you place the cylinder on the piston, compress the piston rings using a simple crimp, such as one made from a beer can. It happens that without such a device the piston cannot be inserted into the cylinder at all. And don’t forget to lubricate the cylinder bore with engine oil first! It is better to work together: while one, squeezing the rings with his fingers, pushes the piston into the cylinder, the other pulls the timing chain. Now slow down the assembly. Since the engine has been disassembled, it makes sense to flush the carburetor, clean the combustion chamber and the exhaust port of the cylinder head. There are special liquids for removing carbon deposits from internal combustion engines. But sometimes mechanics use household liquids designed for cleaning ovens and gas stoves - they are much more effective. But this efficiency may be excessive. Such products, having “eaten” carbon deposits, are capable of “biting” the aluminum of engine parts. If you decide to do a “speed” cleaning, be careful! The recipe is as follows: heat the part with a hairdryer to 60°C, spray the contaminated surface with a household spray bottle and after two or three minutes, as soon as the carbon deposits soften (check the hardness with a wooden stick), immediately clean it off and rinse the part with water. Please note that polished parts will turn matt gray after this cleaning. Make sure the piston is at TDC. Install the cylinder head and the bed with the camshaft. The position of its sprocket for this motor should be as follows: one large hole at the top, two small ones on the sides, parallel to the edge of the cylinder head. There are different recommendations for tightening the head nuts. We follow the instructions of Piaggio. To complete them, you need a lot of patience, but gas breakthrough will not happen. Tighten the nuts crosswise first with a force of 6-7 Nm, then turn each 135°, and then another 90°. Wait a little and tighten again to 6-7 N.m and “walk” through the nuts two more times, tightening them by 90° each time. For those who find all this too complicated, there is advice: tighten all the nuts at once in a crosswise sequence with a force of 20 N.m. If the gaskets are of high quality and the mating surfaces are not damaged, then this is usually sufficient. Check the marks again and install the tensioner. Again, take your time! Once the head is removed, it's worth checking the valve clearances. What should they be? It is best to take information from the scooter manual. If it is not there, do not despair: the vast majority of scooter engines have the following clearances: at the exhaust valve - 0.15 mm, at the intake valve - 0.1 mm. Both should be closed when checking. An article on valve adjustment is here: https://www.motochasti.ru/article_info.php?articles_id=84 And only now screw on the valve cover and assemble everything else in the reverse order of disassembly. Change the oil and oil filter. That's it, engine tuning is complete. The result was not long in coming: already during the running-in, the engine made it clear that it now has more torque. And after running-in, the maximum speed increased by 15 km/h. Scoot easily carries two people. In short, after replacing the cylinder-piston group, the device is unrecognizable. Source: Moto Magazine

Piston installation

Insert a retaining ring into any boss of the piston pin. It is most convenient to insert the ring with small round nose pliers. After installation, check how well and tightly the retaining ring fits.

- If the retaining ring does not cover the entire surface, but only a small part of it, replace it with a new one.

- If the retaining ring does not lie tightly in the groove and dangles, straighten it a little

Lubricate the bearings of the lower and upper connecting rod heads and the piston pin bosses with clean engine oil. We put the piston on the connecting rod, orienting it with the “IN” mark to the inlet port; if there is an “arrow” on the piston instead of the “IN” mark, orient the arrow to the exhaust port. We insert the piston pin into the boss - orient the piston on the connecting rod so that the pin hits the connecting rod - install the pin all the way into the locking ring and secure it from falling out with the second locking ring.

We install the cylinder guide bushings on the studs and put on the gasket. It is advisable to place the gasket on the sealant, but without fanaticism.

YORUMLAR • 32

A good way to unbalance your knee!

Aluminum parts from carbon deposits are very well and quickly eaten away by a mole solution for blockages

And the aluminum will dissolve

Hit the crankshaft with a hammer

Tell me what to do, when I assembled the engine, the piston began to rest against the head

Check if the valve rests on the head, remove the cover and look to see if the camshaft is positioned correctly

turn up the music down

My new oil pump did not pump until I made a cut on the gasket, so it turns out that the gasket is blocking the oil inlet?

Why wasn’t the rear gearbox rebuilt?

I didn’t look carefully, why do you need to PUNCH the ENGINE when replacing a piston?

Shove the music up your ass

Bro, wouldn't it be easier to just buy a Chain Releaser? and press the old chain into the engine and attach the new one to one edge with a wire and then simply turn the impeller so that the new one fits onto the sprocket and fasten the ends of the new one. It will take literally 15 minutes if you have a presser

+Slavyan video was made for those who, for example, need to change the crankshaft

Hello, when you installed this thing, for some reason it took me longer to do what, I don’t know, it’s not installed, that’s the time at which you installed it 20:15

there, in short, where it sticks out there is a regulator higher up, you remove the spring with the nut and push it in

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at [email protected]

MOTO-ARENA.ru

On our motorcycle forum you will find all the answers on the operation, repair, tuning of a moped, scooter, scooter or motorcycle.

- Links Unread Messages

- Unanswered messages

- Active topics

- Search

- our team

- Registration

- Entrance

- Service area

- Repair zone

- Alpha Delta Orion mopeds

- Scooter

- Motorcycles

- Mopeds like Riga Carpathians

- Modifications, alterations, motorcycle tuning

- Alpha Delta Orion mopeds

- Scooter

- Motorcycles

- Do it yourself

- Urgent help

- Other questions

- Educational section

- Literature on motorcycles, articles

- Literature on moped repair

- Literature on scooter repair

- Literature on motorcycle repair

- Other literature

- Road safety

- Moto news

- Miscellaneous

- Our motorcycles

- Traveling by motorcycle

- Moto meetings (Clubs)

- Moto meetings of the city of Snezhnoye (Torez)

- Moto meetings of other cities

- Equipment

- I will sell, buy, accept as a gift, exchange motorcycles

- Selling Moto

- I will buy and exchange a motorcycle

- Other deals

- Motorcycle shops, services, salons, websites, forums, portals

- The shops

- Salons

- Services

- Private entrepreneurs

- Moto sites, forums, portals

- Offtopics

- Moto movies. (online).

- Video

- Music

- Interesting news

- Games

- Computer games

- Mini games

- Games for mobile devices

- Other games

- Hobby

- Flood

- Closed topics!

- Administrative section

- Questions, answers on the forum.

- Suggestions and wishes

- New on the forum

- home

- Service area

- Modifications, alterations, motorcycle tuning

- Motorcycles