| Place | Name | Characteristics in the rating |

| The best drag sled for a motorized towing vehicle |

| 1 | Forza | Best Capacity |

| 2 | Norfin Taiga | Highest quality |

| 3 | Polymer sheet SVP-150 | The most passable trails on loose snow |

| 4 | Master Pro 150 | Optimal combination of price and quality |

| 5 | Solar | Best price |

| The best sled drag for a snowmobile |

| 1 | Safari polymer sheet | Better maneuverability and stability |

| 2 | Yaman Tundra No. 4 | A light weight |

| 3 | G.L.Q. | Choice of hunters (fishermen) |

| 4 | Polymer Group Rex | The most durable |

| 5 | Station wagon - Comfort 220 | High level of comfort |

Dragging sleds significantly increase the practical capabilities of snowmobiles and motorized dogs for transporting goods. In winter conditions, this is the best solution for fishermen and hunters, and also allows residents of remote villages to solve various problems.

The rating includes drag sleds that can serve as a trailer for motorized towing vehicles or snowmobiles. The best models were selected based on characteristics such as load capacity, reliability of fastenings, and strength. The selection also took into account customer preferences and the cost of the sled.

Materials

The body of the drag sled is made of high-strength, frost-resistant plastic.

Passenger trailers are usually made of high-quality plastic material or plywood. The body is connected to metal runners.

As for the third version of the trailer (cargo), its body can be made of plastic, but it can also be made of wood.

Sleds can also be inflatable. This type is inconvenient because they have to be pumped up each time before use. In addition, they are not particularly durable due to the fact that they can be damaged by hummocks or elements of equipment.

Do it yourself

Everyone decides for themselves whether to buy drags or make them with their own hands. If you have the opportunity to easily spend about 10-15 thousand rubles on a fairly good sled, there is no point in messing around with homemade products.

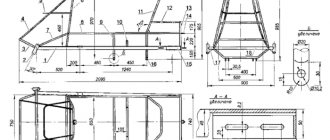

But if you think this cost is unreasonably high, you can make a variation of the drags with your own hands. A similar thing for a snowmobile will consist of:

- metal profile pipe (size about 20×20 mm with walls 2-3 mm thick);

- metal sheet;

- round plastic pipes;

- sheet of plywood (thickness not less than 10 mm);

- additional design elements;

- inserts for a comfortable fit (optional);

- sides (if needed), etc.

It is better to take good metal as a material for the frame. This is a guarantee of the reliability and durability of the structure. Although the drags will be heavier than those made on the basis of plastic pipes, there will be no problems with service life.

You just have to change your plastic skis occasionally. After all, over time they will wear out, break and collapse. The process is natural, nothing to worry about.

Assembly procedure

The procedure for making a simple version of drags looks something like this:

- Using 4 pieces of pipe, a metal frame is made for a rectangular base. Set the dimensions yourself;

- If the design will be used for cargo transportation, it is better to supplement the base frame with special cross members;

- Vertically located racks are mounted to the base;

- The number of racks used depends on the length of the drag itself;

- Basically, 2-4 racks are used on each side;

- Skis are made from pipes, this time plastic. I advise you to level them so that you get flat-shaped skis;

- The pipe, cut in half lengthwise, is straightened with a construction hairdryer;

- The heated plastic is pressed with something heavy to fix the new shape. Wait for the plastic to cool;

- Skids are mounted on the frame;

- It is desirable that the upper part of the ski runners be at the level of the frame and mounted to the edge of the base. Otherwise you will bury yourself in the snow;

- A drawbar and a lock for coupling with a snowmobile are mounted in the front part;

- A sheet of plywood is laid on top of the frame as a flooring.

Then equip and decorate this variation of drags at your discretion. You can look for ideas on the Internet, or just use your imagination. Nobody limits you here.

I think I managed to answer many questions. If I missed something, comments are open. Write, ask or just share your opinion.

And I have everything

Thank you all for your attention! Subscribe, tell your friends about us and stay with us!. Watch this video on YouTube

Watch this video on YouTube

Case dimensions

The body or, as it is also called, the trough is a load-bearing element.

The performance properties of the drag directly depend on its size. The dimensions of the housing are the first thing you need to decide on at the design stage. Everything is simple here - the more things you plan to carry, the larger the trough should be. There should be enough space for the fisherman and his equipment. But there is one more nuance. To prevent the failure of a motorized towing vehicle from turning into a disaster for you, it is necessary to provide for the possibility of transporting it in a housing. Pulling a broken motorized towing vehicle is much easier than carrying it on your back. Depending on individual needs, the length of the trough can reach two or three meters, and the width - a meter. The height of the sides does not play a significant role. Everything is similar here - the more things there are, the higher the sides. You also need to take into account the height of the snow. The thicker the snow cover in your region, the higher the height of the sides you need to make. But if you have a wide motorized towing vehicle and narrow skids, then this indicator can be ignored, since the structure will slide on already compacted snow. The height of the sides ranges from 30 to 50 centimeters.

Advantages

Fishing sleds allow you to stow all your equipment - a winter box, an ice auger or an ice pick, tackle, and other equipment. You can store caught fish in them. If necessary, they will act as a shield, covering the hole from the wind, which is especially important when fishing with a jig.

Plastic sleds have the following advantages:

- light weight;

- compact dimensions;

- stability on ice;

- simplicity of design;

- reliability and durability;

- practicality;

- ease of use;

- capacity;

- low cost.

Modern drag sleds are made from durable and hard polyethylene, which does not lose its properties at low temperatures. It is not afraid of corrosion and can withstand many impacts and collisions with obstacles.

Design

There may be a snow bumper on the front part of the drag sled design - this depends on the modification of the product. And also, at the buyer’s request, the sled is equipped with a plastic cover, which is quite convenient when transporting various cargoes.

Cargo products have a different design - it is much more complex than that of drags, but simpler than that of the version for passengers. They usually consist of elements such as a frame, runners and decking. It should be noted that the stability of this design is much better than that of drag nets. This is achieved by the fact that the skis on these sleds are located at a considerable distance from each other.

Photo gallery

In our photo selection, we invite you to familiarize yourself with the varieties of drags, which are intended not only for passenger raids, but also for transporting various types of cargo.

Manufacturers

Among the huge selection of sleds, it is worth focusing on the best options, whose characteristics were largely liked by consumers. Below is a rating of the highest quality sleds.

Otter sleigh ride. The US manufacturer made it clear who the market leader is.

This attribute is intended for transporting any cargo and has the following indicators:

- sled material – impact-resistant frost-resistant polyethylene;

- operation possible down to -30 degrees Celsius;

- the design has a low center of gravity, making it reliable when trying to overturn;

- deep snow is not a hindrance, because the sled has a wide supporting surface;

- the presence of a high bumper side protects from snow;

- the high side helps to securely place the cargo being transported on the sled;

- the possibility of installing special skids that will ensure low slip and protection of the lower part of the structure.

It is worth noting that the American manufacturer, at the request of the buyer, can improve the design and additionally install a drawbar with a shock absorber, which is equipped with a coupling bracket.

"Polymerlist" Safari. The drags from this manufacturer are also loved by consumers. The sled design is used as a trailer for a snowmobile. The dimensions of the trailer are impressive - 2400x870x400 mm. This amount of free space is enough to transport a huge amount of luggage. The sliding area is quite large, which ensures the required stability and maneuverability of the trailer. The plastic is resistant to low temperatures, and the black color does not fade in the sun. Thanks to improved strapping, the strength and reliability of the trailer is ensured.

At the buyer's request, the seller can equip the trailer with a hood that will protect from snow and gusty winds. Buyers appreciated this product. They liked the maneuverability, stability and reliability of the trailer. The only drawback, in their opinion, is the price, which is somewhat overpriced.

"Snowstorm". This is a cargo-passenger trailer. The body of this unit is made of fiberglass. Inside the hull there is a reclining seat for two passengers. The seat has a cushion. In the event that a cargo space is needed, the backrest folds, creating an empty space for carrying cargo. The front part of the case is equipped with a visor made of polycarbonate. The top of the trailer is covered with a cordura awning, which is stretched over aluminum arches and attached to the visor using Velcro and a button. The awning is equipped with zippers and ventilation valves. It is worth noting that it has windows.

The body and steel frame are rigidly fastened. The front part of the frame is equipped with a drawbar with dampers and a ring, with which the sled and snowmobile are fastened.

Kettu. Finnish drag sleds quickly fell in love with buyers from the Russian Federation. The Finns make sleds using seamless casting technology. The material is polyethylene, which is elastic and light. At the same time, the plastic retains its properties at -45 degrees Celsius. If you do not give the sleds more than normal load, then they can be operated at lower temperatures.

Snowcoach sled. These Canadian-made trailers are enclosed and made from impact-resistant polyethylene. The cabin glazing is made of polycarbonate, thanks to which passengers will be pleased with the opening landscapes. The design of the sled includes a suspension with spring mechanisms and shock absorbers. Thanks to a combination of additional elements, the start of driving and braking become less noticeable.

In terms of equipment, the Snowcoach sled has side reflectors and brake lights. For the safety of passengers while driving, the manufacturer has provided seat belts.

Flaws

It is difficult to find flaws in a sled of such a simple design, since it fully copes with the tasks assigned to it. An angler may be dissatisfied with a particular model. For example:

- big size;

- small capacity;

- inconvenient to fix equipment;

- low sides or front.

Some anglers complain that it is inconvenient to move with drags on high, loose cover. The sleigh, loaded with all the property, sinks into the snow, making movement difficult. You have to put in extra effort, which quickly wears you out on long treks.