Hi all! In this article I will talk about the main stages of building a homemade motorized towing vehicle on a standard Buranovsk track, 380 mm wide, with a Lifan engine with 8 hp. So, straight to the point:

Assembly video:

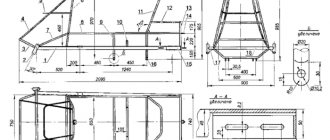

First of all, you need to weld the base of the frame, which is a simple rectangle, from 20x40 mm profile pipes.

Next, we prepare and weld the steering wheel mounting posts from the same profile, but with a larger wall thickness, in our case 2 mm.

The next step is to start making the steering wheel from a 20×20 mm profile and a round pipe with a diameter of about 22 mm. We further strengthen the place where the steering wheel is attached to the frame by welding washers, because this node experiences quite high loads.

After this, he begins to manufacture the drive shaft mounts from an iron sheet, 3 mm thick.

Now we return to the base of the frame. For engine mounting and general rigidity, it is necessary to supplement it with transverse sections from the same profile.

Next, we weld the drive shaft mounts flush to the front of the frame.

Then we proceed to the manufacture of the engine protective frame. In our case, a homemade pipe bender was used for this, but you can do without it by simply welding the pipes into a structure of the desired shape.

Next, we make the engine mount from a 40x4 mm corner. We cut 8 pieces of equal length and weld them into the front of the frame.

The next step is preparing the fastenings for the suspension bogies of the motorized towing vehicle, which are sections cut from a 40×4 mm steel strip with drilled holes. And immediately weld them.

Now that the frame is almost ready, we weld the previously prepared engine protective frame and the sections connecting this frame with the steering wheel mounting posts.

The frame is ready, we clean the welds and sharp edges, and prepare the structure for painting.

After the paint has completely dried, we fasten the pre-cut galvanized sheet using rivets, and then cut out holes for the engine mounting bolts.

The design is ready, you can begin final assembly. First, we install the track with the drive and driven shafts. Then 3 suspension rollers, a mudguard, a driven sprocket and, finally, an engine with a drive sprocket and chain.

Let's move on to preliminary tests. It is clear that without snow it will not be possible to fully test the structure, but I don’t see any particular need for this. Now I will explain why.

In general terms, this design repeats our previous motorized towing vehicle, created at the end of last fall and which has proven itself well over several months of operation. All of its shortcomings and weak points were eliminated in the new design, which is also quite primitive in itself and there is nothing special to break there.

Structural differences

The tracks for the Neva walk-behind tractor make it a couple of times easier to transport cargo and move the equipment itself. The tracked module covers a significant surface, the walk-behind tractor drives more smoothly, provides the least pressure on the road and does not even slip on difficult soils. The device on tracks can work even in bad weather; in sunny weather it is distinguished by excellent maneuverability.

It is not difficult to care for and use the module on tracks, and there is an option to construct it without the help of others. The main thing to remember is that when a walk-behind tractor is equipped with tracks, its speed will be lower, but not significantly.

Motoblocks on caterpillar tracks are not one hundred percent different from standard walk-behind tractors:

- The engine is a 4-stroke engine with the ability to automatically lock the axis so that the technical device can turn around, without turning around in a circle.

- Naturally there is also a requirement for the inevitable arrangement of water cooling, which can cope with overloads, due to which the engine gets very hot.

- This type of track module is more efficient than an air-cooled one.

- The coupling system, gearbox and gearbox are similar to the design of the standard model. It is necessary to control when using the handle.

A mower for a walk-behind tractor will help you quickly and efficiently remove not only grass from your site, but also weeds, and sometimes small ones...

When making tracks for a walk-behind tractor in handicraft conditions, you need to know that if you design them very high, the center of gravity of the walk-behind tractor will change, and it will begin to have difficulties when turning, and even bending to the side. It is necessary to make the second driven axle longer by 2.4 cm. Also, by using a bushing, it will be possible to expand the wheelbase that is already available in the walk-behind design.

Motorized towing vehicle - how they make it at the factory from A to Z

The designer drew the whole thing, measured every hole, every bolt, and attached everything. The assemblers are competent, professional, and assembled. The CMK shop welded the whole thing, painted it, did everything beautifully - appearance, design. They sold it to you and gave you a year of warranty, someone else gave it 2 years of warranty.

You drive, don’t worry. Something rustled, you dragged it to the dealer and said: Guys, fix it. Everything was done for you under warranty, and you can continue riding. And you no longer worry that you need to go to the garage, cut up this towing vehicle, and reassemble it, because something is wrong, something doesn’t work.

Anyone steps on their rake, even a professional welder. He cannot be a professional welder, he cannot be a mechanic, a person cannot absorb everything perfectly. Every person has mistakes, and he will make them in any profession.

Therefore, you can spend time, so to speak, when you assemble the towing vehicle yourself, there will certainly be savings. You will save some money, because the manufacturer has collected and needs to earn money, he needs to pay wages, rent, etc. He appraised it, gave it to the dealer, and the dealer appraised it. Well, how much will you save? Dealer delta. You won’t be able to beat the factory price, because the plant has its own capacity, components, which it produces 70 percent of itself, rather than buying from someone else, so it’s easier for him. He already has it set up on a conveyor belt and goes in a chain.

He collects from 30 to a hundred a day, and people understand how to do it. The more you collect, the lower the cost. You take a kilogram of metal for 200 rubles, and if you take a ton, then the cost will already be 120 rubles. That is, the manufacturer will always be cheaper.

When you want to drink coffee, you don’t invent a coffee maker. You just go and buy it, because you know that it has been thought through to the smallest detail and that it will grind your coffee and make a really delicious cappuccino. If you start collecting it yourself, you will first get poisoned, then something will go wrong with you. That's true anyway. Having saved 10 thousand, you will spend a lot of nerves, time, money again. It's not worth it.

How to make homemade tracks on a walk-behind tractor with your own hands

Owners of walk-behind tractors often go for home-made gadget production for a bulky unit. The crawler walk-behind tractor is maneuverable and is comfortable when cultivating the garden and other work. And the caterpillars themselves, given the availability of material and experience, are made without the help of others. You just need to follow a certain technique and sequence.

Two more methods

Walk-behind tractors on tracks are often made using V-belts. They are fastened with lugs. The belts are secured with rivets. A popular method is to introduce chains of similar size. You can always find them in the garage; they are often left over from other equipment. The work is phased:

- Take 3.2 equivalent chains.

- Break the last links and connect the chains into a single ring.

- Brew.

- Use hooks to fasten the chains together and make a strong fastener. They can be made from steel plates of suitable thickness. They are connected with bolts.

The caterpillar drive for the walk-behind tractor requires the ability to work with equipment and a welding machine.

Conveyor belt

The technique is easier. In addition to the transport tape, you need to take a bushing roller chain. The ease lies in the fact that creation will not require a lot of additional materials and tools. To increase the period of implementation of the machine tape in the module, it is necessary to circle it along the edge with fishing line. Be sure to provide a step of 1 cm.

Particular attention is paid to the height of the material. For this reason, it is 100 percent dependent on how long the device can withstand. It is normal to take a tape with a height of 0.7 cm more. One more wheel on both sides needs to be taken care of. It will fit from an old car, but it is important that the size matches the type of wheel on the walk-behind tractor.

Car wheel

Crawler attachments to a walk-behind tractor made from car tires are a popular solution. Craftsmen say that the design will be more reliable with tracks made from tires. In order for the made device to be comfortable, it is necessary to take care of the quality of the tires. Tractor tires are what you need. The tread pattern plays a role as it is a lug. The process is step by step:

- When the tires are prepared, the path is cut there.

- This is a difficult job that requires attention. Use a well-sharpened knife for cutting. It is correct to take the one that shoemakers use. Periodically it must be moistened in a soap solution. This makes the rubber surface easier to cut.

- Both sidewalls are trimmed from tires. To make the process easier, use a jigsaw with small teeth. Cut off excess parts inside the tire, if necessary. If the track is hard inside, trimming can be done again.

The operation of gardening equipment begins with its startup. A walk-behind tractor is actually a design in which...

The main advantage of the gaming slots technique is that you will not connect with a ring. The tire is already round. Therefore, it turns out to improve the strength properties of the module, which is important in circumstances of severe overloads. And yet such structures turn out to be quite compact. The length will be according to the size of the tire used.

Additional Tips

Before making a caterpillar drive for a walk-behind tractor, you need to make drawings and find the dimensions. They do this in order to feel that for which the design of the production of a very high homemade caterpillar for a walk-behind tractor is intended, it will be necessary to change the center of gravity of the walk-behind tractor. This will inevitably cause problems when turning, as the equipment will fall to one side. To avoid this, the second driven axis must be made longer.

Apart from the rules regarding engine power, they look at the cooling system:

- Air cooling is ineffective under important overloads, which will damage the engine.

- It is correct to use aqua cooling, which has proven to work evenly.

Attached attachments to the walk-behind tractor can significantly improve the vehicle's cross-country ability. Therefore, there is an option to diversify the range of implemented operations that a homemade device can handle. To put it another way, a manufactured base in some situations outperforms standard wheels. But reworking walk-behind tractors may not be suitable for owners of these technical devices. It talks about special requirements for the engine.

The motor comes with good traction. Homemade production is suitable for execution in the presence of a garage. It is for this reason that a block made in a garage is not a bad replacement for tracked monoblock blocks that are available in the trade.

Replacing the variator belt

The surest way to increase the speed of a motorized towing vehicle is to install a 33 variator belt

Initially, all manufacturers try to install a 30th belt (30 is the width of the belt), so that there is no self-propelling. The speed with a 30 belt is a little less, but there is no such wild self-propelled gun.

As a rule, some clients, when buying a motorized towing vehicle, do not know anything about it. They didn’t have this technology before - they just saw a bunch of men driving by while fishing. A man got the idea to buy a motorized towing vehicle. He buys and receives a high-speed motorized towing vehicle, which has a 13-tooth sprocket and a 33-tooth belt. He turns it on, pulls it, and he, almost tearing his hand off, begins to run away from him. This, by the way, is a common problem with 33 belts.

What materials are required

To convert wheel modules into tracks, a powerful engine is required. It must have an axle block. Power is important, since the walk-behind tractor will be driven on difficult roads. Without improvement, it is impossible to achieve good maneuverability. Basic building materials required:

- Motoblock machine with gearbox, 4-stroke engine, axle block option.

- A few extra wheels to put the caterpillar on there.

- The track attachments themselves.

READ Do-It-Yourself Potato Digger for Motoblock

Based on the building materials used in the production process, you will need two tires of good diameter and a transport belt. If you include a platform here, you get a compact tractor.

When selecting building materials to make tracks for a walk-behind tractor in a homemade environment, it is important to take into account that it should not be heavy. The walk-behind tractor is not equipped with a powerful engine; it simply cannot cope with a heavy load and will break. Tracked modules are made from:

- Motorcycle tires.

- Chains.

- Tubes.

- Belts.

- Conveyor belt in symbiosis with a bushing and roller chain.

Usually, attachments for walk-behind tractors are made from car tires - these elements can be easily transformed naturally. It is correct to choose tires for large trucks, taking into account the existing tread pattern and shape, because the pattern will improve traction with the road. Tractor tires or elements from other huge machines are perfect.

Do-it-yourself ski module for a motorized towing vehicle Part No. 1

The tread pattern provides real contact with wet soil, icy roads, and snowy roads. Not counting the materials for the tracked module, to create a real device you need a walk-behind tractor with a gearbox, as well as several auto wheels. If necessary, secure the cart if desired, even on skids, in order to carry important weights through the snowdrifts.

Man K2 - 18.5M

The “heart” of this axlebox is a 4-stroke engine with 15 horsepower. The unit is equipped with a 2-bearing transmission and a safari variator. A metal hood is used to protect the engine compartment. The frame material is durable 3mm steel. The drive shaft maintains a constant horizontal position thanks to self-aligning, serviceable bearings.

The length of the motorized dog is optimal for products of this kind and is 1450 mm. Track width – 500 mm. Thanks to the increased angle of attack, the pressure on the snow is reduced. This allows the motorized towing vehicle to pass through even 1.5-meter snowdrifts without problems.

Advantages:

- high level of load capacity – up to 0.75 t;

- thoughtful design (all units are reliably protected from external contamination);

- good lighting;

- increased angle of attack.

The disadvantage of the design is that it is somewhat prone to collapse.

Pomor 500 S15 (1450 mm)

The best option for multifunctional use. In addition to the standard functionality, the kit is rich in additional accessories: mounts for snowboards/skis, a removable rack, hand protection from the wind. The manufacturer did not focus on the design of the towing vehicle, devoting more effort to ergonomics and convenience. But this did not in any way affect the maneuverability of the vehicle.

The choice of roller or skid suspension smoothes out uneven terrain in wilderness areas, preventing rollovers. Deep snow is no problem for a motorized towing vehicle. The wide 50 cm double-sided caterpillar will prevent you from digging in or falling through.

Advantages:

- Heated handles;

- Storage case;

- High quality brakes;

- Navigation materials;

- Engine noise insulation;

- Develops a speed of 50 km/h.

Flaws:

Weight 120 kg.

When transporting large quantities of cargo, the steering wheel is adjusted to a vertical position. This allows the driver to drive while standing and have a better view of the road. For these purposes, users are advised to give preference to AI-95 gasoline.

Trolley device

Motoblocks and motor-cultivators on trailers consist of the following main parts:

- frame;

- body;

- hitch, also called drawbar;

- driver's seat;

- control mechanism;

- chassis.

To withstand heavy loads, a homemade cart for a walk-behind tractor is reinforced with special elements.

For a 1-axle trailer, a manual type device is sufficient. A 2-axle dump truck with a large load capacity must be equipped with a hydraulic drive to prevent it from tipping over.

With a load capacity above 350 kg, for safety, the self-propelled cart is equipped with braking parts. Mechanical brakes are made by yourself. If these details are not taken into account, then if it is overloaded while descending from a hill, the cart for the walk-behind tractor at home will not be able to brake and will tip over. If you set the goal to remain in the working position after disconnecting from the walk-behind tractor, install stops.

How does the variator and fuel affect speed?

If the variator is not made in a factory, but somewhere in a garage from Chinese casting, unprocessed, unfinished (weights, bushings, movement - everything must be modified) - yes, it can have an effect. It all depends on how well the variator is made. If the variator is made clumsily, this will affect the speed, the belt wear, and the ride quality.

Fuel. All manufacturers use Chinese engines and 92 gasoline. These are air cooled engines. Cooling is minimal, there is a cover plus a hood on the engine. And since the walls of the cylinder mirror heat up to 220 degrees during operation, when using 98 gasoline with a higher octane number, the heating increases, and you can overheat the engine with such fuel much faster than with 92. There will be no difference in speed, but you can overheat the engine . In order not to overheat the engine, you need to install temperature sensors and monitor the temperature.

Making a trolley

To find out how to make a cart for a walk-behind tractor in a homemade way, you need to perform the following procedure:

- To produce a load-bearing welded rigid frame, take 5 pipe blanks and trim the ends with a grinder.

- Press the clamps onto the chipboard sheet and weld the junction of 3 longitudinal pieces with 3.5 perpendicular pieces so that they form a mesh frame.

- Check the geometry of the structure using an ordinary construction square. The angles of the connected ribs must be 90°.

- Install spacers between the tacked workpieces in the corners of the bottom and in the center, and tack them by welding.

- Use a welding electrode to tack 4 vertical posts in the corners to the longitudinal pipes of the bottom.

- Check the perpendicularity of the corners, check the dimensions of the sides of the structure with the dimensions on the drawing of the cart for the walk-behind tractor.

- Completely weld what remains to be done for our client to make the workpieces together, grind the welding seams, clean them from sagging and formations.

- The body will be made of plywood or wood planks; in this case the corner joints are secured with steel corners.

- The boards are installed on the frame and attached using bolted connections.

- Craftsmen make stronger sides from steel sheets. The sides are either folding or fixed. The folding sides of the body are considered better, because... Unloading large volumes of cargo is easier. The sides are also made from steel pipes of square or rectangular cross-section. They are made in the same way as the frame, they are clamped, the geometry is checked for strength and to avoid braces and deviations, they are completely welded, and they are rigidly attached to the frame. The tailgate is secured with ordinary door hinges and equipped with latches.

- Take a metal rod with a diameter of 30 mm and a length of about 1050 mm to produce an axle for the wheels, connect it to a longitudinal hinge and corner supports. The length should be chosen so that the axle does not extend beyond the boundaries of the wheels. Sharpen it to the required diameters of the bearings in the hubs.

- As a chassis, there is an option to take the wheelbase from a scooter, stroller, wheelbarrow, or other agricultural equipment. Heavy trailer wheels with hubs are not recommended for installation.

- To produce a drawbar, take 4.5 profile pipes with a diameter of 25x50 mm and a length of about 1.85 m, weld them to the frame support so that a triangular structure emerges. For reinforcement, steel gussets 4 mm wide are attached by welding at the corners, and a plate 8 mm wide is attached in front of the trolley.

- The tipper design provides for the installation of door hinges attached below to the support and to the bottom struts.

- The frame of the constructed structure is covered with wood boards, plastic or metal.

- The driver's seat is installed on a walk-behind tractor with a trolley ready-made, in other words, like homemade boxes made from a piece of chipboard and foam rubber covered with dermantine. Such boxes are necessary for covering equipment and materials.

- The parking brake drive of the unit is used as a brake. Fix the brake pedal, made of a 6 mm wide plate, on the footrest under the seat, weld 4.5 corners. Install a pedal in the front part, and a plate with 2.7 holes for fastening brake cables in the rear part, the ends of which are connected to a T-shaped plate with a rod.

In this way it is natural to make a cart for a walk-behind tractor at home.

Do-it-yourself trolley for a motorized towing vehicle

A motorized towing vehicle (motorized dog) is a device for transporting goods and traveling through snow and wetlands. The towing vehicle itself has a caterpillar track and is complemented by a sleigh. A trailer in the shape of a sleigh is comfortable in winter, when there is a huge snow cover, but in summer or in snowless winters, the implementation of such a trailer is problematic.

Manufacturers of Russian agricultural equipment offer a wide selection of trailers, adapters and carts, including those for motorized towing vehicles. Some owners of such equipment make a cart at home. Its device is practically no different from a trolley for a walk-behind tractor .

The main feature of a motorized towing vehicle, which dictates the design of trailers, is the caterpillar track. Such vehicles are perfect for off-road use, so the trailer must meet the same requirements.

Two types of trailers are recommended for motorized dogs: a cargo platform and a skidder. Both options are difficult to implement, so it is better to adapt a ready-made trolley for a walk-behind tractor. The drawings and dimensions for the motorized towing vehicle and the walk-behind tractor will be almost similar, so any can be used.

The main feature of a trailer for this type of equipment is low-pressure wheels. They have a high shock-absorbing effect and are excellent for off-road use. A cart with such wheels is used throughout the year. This modification requires the trolley to strengthen the axle and additionally secure the wheels. What remains for our client to do other parts of the cart there are options to remain without configurations.

READ Which Adapter Is Better For Rear Motoblock

Criteria for choosing a motorized towing vehicle from experienced fishermen

Users who have been able to test a purchased motorized dog can provide useful recommendations. The tips below will help you approach the purchase of a car wisely:

- The most favorable power is considered to be 6.5 hp. This unit is suitable for transporting small loads, as well as several people. For driving through difficult terrain and transporting large loads, experts recommend buying a motorized towing vehicle with a power of 10 horsepower or more.

- Even before purchasing a machine, you need to determine what kind of drive is needed. Models with front-wheel drive differ from cars with rear-wheel drive in having better cross-country ability and, on the contrary, motorized towing vehicles with rear-wheel drive are faster than their “brothers”.

- Experts advise conducting a thorough inspection of the motorized dog to ensure that the main components are protected from corrosion. It would also be useful for the seller to consider the level of strength of the case.

- To drive at night, you need to buy a car with a powerful headlight.

- The heated grip option allows you to drive long distances.

Materials and tools

To perform the work you need the following tools:

- grinder for cutting parts;

- apparatus;

- welding electrodes;

- jigsaw;

- screwdriver;

- an ordinary construction square for measuring angles.

At the production stage of the trailer structure, the following materials and parts will be needed:

- steel profile pipes of square or rectangular section;

- wheels and springs;

- duralumin sheets 2.7 mm wide;

- steel sheets;

- channel;

- steel corners;

- metal rod;

- fasteners.

Our client receives the parts, especially if they are remnants of old metal products, which are carefully inspected for damage, cracks, cleaned of rust, and cut.

We test and fix bugs

Any manufacturer at the development stage stumbles upon its own mistakes. Only the manufacturer has a central steelworks - a welding shop that is prepared, and the people are already professionals in this matter. There is an assembly area, there is a designer who creates everything in the program, there are facilities that allow you to make some parts.

At the same time, the manufacturer tests the equipment, encountering some errors and problems of its own, although, it would seem, everything is perfect, but... Take, for example, the automotive industry. They made a car for 10 million Range Rover, went for a test drive, the electronics unit failed, the air fell and something else, and they are guessing. And the reason is that the wiring engineer forgot to connect the yellow wire!

And it's the same here. The manufacturer tests, reworks, looks and brings it to mind. You leave the garage in your self-garden. Bang, the bearings on the drive shaft have fallen apart. You go to the garage, drag it for 5 kilometers, take it apart and realize that you have a crooked frame. You start to think: well, we need to redo it. You start doing things, collective farming. In the end, everything seems to have turned out great again.

You drive further and your belt starts to eat. Accordingly, the transmission needs to be redone. Or the vibration is such that you get Parkinson's from it. It's pounding because you didn't install mounts on the engine, or didn't install a sub-frame, or some kind of buffer that would dampen the vibration.

Basic information

Before carrying out work on the manufacture of a trailer, it is necessary to make a detailed action plan and adhere to it.

The work plan for the manufacture of a trailer for a walk-behind tractor looks like this:

- At the preparatory step, it is necessary to find out everything about the structure of the mechanism, analyze its functionality based on the power of the walk-behind tractor.

- Make a drawing of the structure. A trailer diagram compiled independently will greatly simplify the work.

- Calculate the dimensions of the cart for the walk-behind tractor.

- Design a drawing of the cart, showing the main components, properties and dimensions of the parts.

- Plan the operating principle of the main and additional devices, think about how to connect all the components and parts, and their functioning.

- Prepare a list of suitable materials and tools.

- Start the assembly and finishing process.

Depending on the ability to transport cargo, trailers are divided into 3 types:

- An ordinary 1-axle device for walk-behind tractors with a lifting capacity of up to 70 kg. Its design is ordinary and affordable.

- Universal cart with a carrying capacity of up to 110-120 kg. Often used in households.

- Trolleys for walk-behind tractors with a carrying capacity above 120 kg. Such mechanisms are designed to move heavy loads, therefore they have a more complex design, and accordingly, the costs of materials for the frame and cladding increase. The functionality of this technology is expanding.

Based on these features, they select a material based on strength for the frame and finishing of the mechanism.

How to make a cart for a walk-behind tractor with your own hands: drawings and dimensions, photos, videos

A trolley for a walk-behind tractor is a towed equipment for universal agricultural motor vehicles for transporting goods on personal plots and land plots. With the help of such a mechanism, garbage, animal feed, construction materials, fertilizer, grain, and equipment are transported.

The trailer and adapter for the walk-behind tractor are types of homemade products made by skilled mechanics. The adapter is actually a longitudinal support with its own chassis, driver's seat and footrest. This module allows you to cultivate the soil in a sitting position, in addition to attaching 3.5 equipment at once - in front and behind.

A trolley is a type of adapter with a difference in the design of the chassis.

A purchased cart for a walk-behind tractor is expensive. To save money, craftsmen make it without the help of others, design design drawings, and select the necessary materials. The process of creating such a useful vehicle does not take a long period and is not very difficult. Even a beginner with at least a little knowledge of technology can handle it.

A laconic review will help you understand the question of how to make a trolley for a walk-behind tractor without the help of others with good performance characteristics.

DIY wheelbarrow for walk-behind tractor

A wheelbarrow for a walk-behind tractor is your irreplaceable assistant in the household. Such a device allows you to transport cargo (collection, garbage, building materials, etc.). You can make a cart for a walk-behind tractor in a handicraft way from auto parts or from individual materials. In any case, welding and certain design capabilities will be required. The wheelbarrow requires a better simple design; any drawing of a trailer for walk-behind tractors will be suitable for its creation.

For the Neva MB-2 walk-behind tractor, a mounted wheelbarrow with an H-shaped hitch is suitable. This type of connection is universal and easy to make. The coupling point between the wheelbarrow and the walk-behind tractor is one of the most important units that receives a huge load, so the materials for its creation need to be strong, and checking for defects (cracks, rust) is imperative.

A wheelbarrow for a walk-behind tractor consists of a frame, sides and wheels. If you add a seat and a control column to it, you get an analogue of a mini-tractor. Any version of a wheelbarrow for a walk-behind tractor can be made from improvised means; there are many photos and videos on the Internet showing the process of assembling the devices.

Do you use trailers, adapters and wheelbarrows for walk-behind tractors?

How to do it yourself?

This part of the article will examine how to make a homemade ski module.

Manufacturing scheme

The main part of the design of the ski module is the frame-frame; it is recommended to start assembly from it, in accordance with the previously selected drawing. The main design feature is the distance between the skis (about 90 cm).

The control system for the motorized towing vehicle will be transferred to the steering wheel of the future module. The last step will be to attach the seat and spring skis.

Support frame

This is the frame, or the supporting system, of a motorized towing vehicle. The main structural components are left to our client to attach to it. Narrow metal is not allowed during the production process, since the frame experiences severe loads during movement, and due to its deformation, the machine will become unusable at work. Experts say that the thickness of the steel can be as thick as in a cinema hall, 3 mm.

How to choose?

The first thing you should pay attention to when choosing a motorized towing vehicle and its components is the dimensions. Compact models can be placed in a car, while standard-sized units are transported in a trailer.

Goose and its cross-country ability

Considering the size, we should not forget that the larger the tracked transporter of a motorized towing vehicle, the better.

Engine and its power. The more people ride a motorized dog, the more horsepower the engine should have. It is worth remembering that Chinese manufacturers actually have “horses” that are not as powerful as those of the Americans. That is, the American engine is 13 liters. With. will work more productively than the Chinese 15 hp. With.

Workmanship. You must immediately carefully examine the accuracy and evenness of the seams, the uniformity of the coating of the parts.

Drive - front or rear. With rear-wheel drive, driving a loaded motorized towing vehicle is easier, since the center of gravity is located near the steering wheel, but an empty unit will rear up or bury itself in the snow instead of moving. In front-wheel drive vehicles, the track contact with the surface is better and maneuverability does not depend on the load.

CVT or gearbox, as well as suspension type.

Ease of system adjustment. Any motorized towing vehicle requires periodic inspection of its structural components; an important criterion is the simplicity and convenience of these operations. When choosing, you should pay attention to the casing - it can be plastic and can be easily removed or made of a special material with fastening flaps.

Accessories. Here you can do without restrictions, according to the principle “the more, the better” thanks to all kinds of modules, ski track builders, and wheeled carts. The motorized towing vehicle will become an indispensable assistant with many options for any time of year.

Modules for motorized towing vehicles

- Description

- What are they?

- Dimensions

- Popular brands

- How to choose?

- How to do it without the help of others?

- Fastenings

A motorized towing vehicle is a rather unusual vehicle, similar to a docked snowmobile, designed for transporting people and cargo off-road. Such a device will be very useful for skiers and fishermen.

HOMEMADE SKI MODULE Deep snow...can't be overcome

Control systems and electrical equipment

The basic kit provides manual start, but if necessary, you can equip it with an electric starter and a headlight.

Tools and materials

- profile pipe;

- saddle;

- plastic skis;

- steering wheel;

- springs.

Tools:

- apparatus;

- Bulgarian;

- drill;

- spanners;

- small consumables (fastening elements).

Description

The motorized towing vehicle also has a second name – “motorized dog”. He received it for his resemblance to a dog sled. Its transport module and sled, or sled-drag, are located separately. Operation of this vehicle almost always takes place on icy rivers and lakes or in snowy areas, which is why the motorized dog is so popular among fishermen, tourists and hunters.

A motorized towing vehicle has a lot in common with a snowmobile, no matter how annoying it may sound, and their most important difference is that the driver is located on a sled, and not on a transport module. Thanks to this modification, a motorized towing dog has low weight and enormous cross-country ability. Lightweight design and low price are two more main advantages. Without much effort, this car can be placed in almost any passenger car. The volume of the gasoline tank is 5-6 liters, and in one hour the device spends about 1-2 liters. fuel.

READ How to Make a Tile Cutter with Your Own Hands

A good and high-quality motorized dog should not only ride on a knurled track, but also through fairly deep snow. It copes with transporting cargo through the forest or through terrain with ups and downs. Since the motorized towing vehicle was made mainly for the winter, its performance decreases in the summer. Rocky surfaces quickly deteriorate the rubber track with which it is required to move. In the summer, it is better to move through swamps, fields or forest paths.

Let's take a closer look at the design features.

Gasoline or diesel engine

A single-cylinder, four-stroke DSV (internal combustion engine) is almost always used, the power of which ranges from 6 to 15 horsepower. This is a common design of a piston engine with one working cylinder. It has a high efficiency factor (efficiency) and little heat loss, but on the other hand , parts of the motor experience thermal and mechanical stress. If you look at the traction properties, 6 horses are designed to transport 1 person, and 9 - for 2.

What to look for when choosing

Suspension

The greatest load during off-road driving falls on this element. The suspension distributes the weight of the equipment and cargo onto the track, while the force can change dramatically. The suspension is:

- roller (this type is considered to be all-season) - the tracks move on rotating rollers: not suitable for driving on melted or loose snow;

- slick - an ideal option for moving on snow, since the design features involve the sliding of the caterpillar track along the slicks (skis), in addition, heating occurs due to friction, and the main components cool under the influence of snow;

Important! Vehicles with this type of suspension stand out from the rest due to their excellent cross-country ability and economical fuel consumption, however, it is not recommended to operate such motorized towing vehicles without snow. Certain types of equipment are equipped with springs for better comfort during movement.

pneumatic - made specifically to overcome swampy terrain (units with such a suspension are characterized by a smooth ride, which makes the ride as comfortable as possible).

Motor

The latest generation of motorized towing vehicles, as a rule, have 4-stroke gasoline engines with a power of 5-15 horsepower. Honda (Japan) and Briggs&Stratton (USA) have proven themselves to be excellent. Their worthy rivals are Lifan and MTR from China. Experts advise giving preference to high-power models, because only such a motorized dog can cope with the most difficult tasks.

Transmission

For ease of controllability, manufacturers equip their units with an automatic clutch or a CVT. The most favorable solution, according to experts and buyers, is a transmission with a Safari variator, which has proven itself excellent in the harsh Russian climate.

Application area

The equipment is selected taking into account the specifics of the territory, the cargo that is planned to be transported, as well as the type of road surface. For fans of winter fishing and hunters, a small-sized device that perfectly overcomes ice and snow would be an excellent option.

To operate motorized dogs in the fall and spring, experts advise taking a closer look at units that are capable of crossing swampy terrain.

Helpful information! Motorized towing vehicles with roller suspension ride well on grass and mud.

Load capacity

To have a pleasant time outdoors with friends, you should focus your attention on the traction capabilities of a particular model. If the user loves speed, then it is worth giving preference to lightweight and high-speed equipment

A sled's carrying capacity of about 200 kg is enough for one fisherman, and if a group of several people gathers to hunt, then it is worth purchasing a model that can handle 500-700 kg of cargo in a hitch.

Manufacturer

The final criterion is the manufacturer, since the Internet presents a large number of primitive equipment assembled by amateurs.

Advantages and disadvantages of a ski module for a motorized towing vehicle

Purchasing and servicing motorized towing vehicles is cheaper than repairing a snowmobile. That is why they are so popular among hunters and fishermen. But driving a motorized dog with a drag sled is not a very comfortable experience. It is natural to try installing a seat on a sled, but such driving creates some discomfort: a homemade chair is inconvenient to remove, and drag sleds quickly wear out at the attachment points due to the introduction of uneven weight distribution. Therefore, it is even more practical and convenient to use a ski module that can be made at home.

The ski module is a steel frame with a seat, steering wheel and sprung skis, which is attached to the motorized towing vehicle with 4 bolts. Installing a ski module allows you to transform the towing vehicle into, in a certain sense, a mini snowmobile. The design weighs about 10 kg and does not even take up much space during transportation. To control the mini-snowmobile, our client installs the necessary switches on the steering wheel: ignition, gas lever, etc.

Among the advantages of installing a ski module, it is natural to list the following: increased capacity of the sled, acceleration of the motorized towing vehicle, ease of control, better contact of the skis and tracks with the surface and reduction of fuel consumption due to the introduction of correct weight distribution. By using the wide arrangement of skis, the stability of the structure increases, which prevents the towing vehicle from turning over.

The main design advantage, of course, is the versatility of the ski module. Thanks to its simple design, it will be attached to almost any Russian or imported motorized towing vehicle.

The disadvantages of the additional module include the following:

- the need to have a license to drive a newly formed vehicle, since the coupling module -towing vehicle is equivalent to a mini snowmobile;

- poor passage of a motorized towing vehicle in the deepest and loosest snow;

- additional load on the towing vehicle frame, its chassis and suspension, which can lead to frequent breakdowns (in contrast to the ski module, in mini-snowmobiles the creators do not simply take such loads into account).

Tselina MB-509VB

Powerful and reliable engine Country: Russia (manufactured in China) Average price: 71,500 rubles.

Rating (2020): 4.2 The powerful motorized towing vehicle TSELINA MB-509VB takes a worthy place in the list of the best low-speed models of motorized dogs. The device is perfect for both household needs and for recreation and entertainment. One of the features of this model is that a drag sled is supplied with it. The weight of the motorized dog is 105 kg, which is relatively small. The total permissible load on the equipment is no more than 150 kg, including the driver. At the same time, the highest speed that the motorized towing vehicle will develop will be 20 km/h. The manual starting system will make starting the engine much easier, even in severe frosts.

The main advantages of using this model in customer reviews include convenient controls, a robust body and a reliable engine. A 4-stroke single-cylinder unit with a capacity of 9 liters is installed here. pp., which is powered by AI-92 or AI-95 gasoline. Maximum fuel consumption is 2.8 l/hour. A distinctive feature of this model is the presence of heated handles, which is especially important for winter use. The steering wheel folds, making storing equipment much more convenient. A strong LED headlight is installed at the front. Weaknesses include high cost and low carrying capacity.

When purchasing a motorized towing vehicle, we recommend paying attention to the following important characteristics:

Engine. The more powerful it is, the faster the motorized dog will move, and the larger the load can be placed on the drag sled. As a rule, single-cylinder four-stroke units with a power of up to 15 hp are installed. It should be remembered that greater engine power implies increased consumption and requires a larger fuel supply. Load capacity. Most motorized dogs have their own trunk, which is most often used to transport tools and an additional canister of fuel. In addition, the motorized towing vehicle is capable of pulling sleds with a load of 150 to 500 kg, depending on the design and engine power. Transmission. There are 2 types: automatic and CVT. The first type provides the greatest traction force, but is less reliable due to the large number of parts in the assembly. The CVT is somewhat more expensive than the automatic, but it lasts an order of magnitude longer. Track and chassis design. Here it is necessary to take into account the surface on which you plan to move on a motorized dog. For snow, devices with large hooks are better suited, but on hard ground they will only get in the way. In addition, some motorized towing vehicles can be equipped with replaceable ski and wheel modules. Frame. This is the main power element of a motorized towing vehicle.

It is necessary to pay attention to the profile of the frame and the thickness of the steel sheet from which it is made. Recommended thickness – at least 3 mm

This thickness will ensure that shock loads are received harmlessly for the overall structure and will not allow deformation. Fuel tank volume. It should be selected based on how voracious the motorized towing vehicle is. Optimally, it will be 2-2.5 hours of constant work. It should be remembered that carrying a large supply of fuel with you is not always convenient.

How to make a ski module with your own hands

To be able to make a ski module, you need to most fundamentally understand its structure. For this purpose, you can view a photo or drawing of your favorite models on the Internet. As you can see, there are no difficulties in its design. If you have all the necessary parts, tools and capabilities, then it is better to make the module yourself. This will cost even less, and with reasonable management the structure should be stronger.

The main thing is not to forget about this fact - these are the design features of the frame itself. The skis should be located about 90 cm apart from each other - this will give the structure stability, and there will be places on the frame for attaching the module to the towing vehicle (usually four nuts).

So, there is an option to simply transform your motorized towing vehicle into a mini snowmobile. As we have seen, there is nothing complicated in resolving this issue.

How a drag can affect speed

It all depends on the type of terrain. A motorized towing vehicle is needed to get through where there is a lot of snow. If the drag is wide, wider than the caterpillar, it will cut its trail. For example, a sled is 800 mm wide, and the caterpillar is 500. That is, the sled digs its own path. Power is lost, fuel consumption increases, the motorized towing vehicle begins to operate at maximum speed, because you have to pull yourself, the passenger and the sled. Thus, the sled should have a track close to that of the motorized towing vehicle. If the width of the sled is in the wake of the motorized towing vehicle, the speed will be good; if it is wider, the speed will decrease.

Advantages and disadvantages of a ski module for a motorized towing vehicle

Purchasing and servicing motorized towing vehicles is cheaper than repairing a snowmobile. That is why they are so popular among hunters and fishermen. But to control a motorized dog with a drag sled? not a completely comfortable experience. Naturally, you can try installing a seat on a sled, but such driving creates some discomfort: a homemade chair is inconvenient to remove, and drag sleds quickly wear out at the attachment points due to uneven weight distribution. Therefore, it is even more practical and convenient to use a ski module, which is also made at home.

Ski module? This is a steel frame with a seat, steering wheel and sprung skis, which is attached to the motorized towing vehicle with 4 bolts. Installing a ski module allows you to transform the towing vehicle into, in a certain sense, a mini snowmobile. The design weighs about 10 kg and does not take up much space during transportation. To control the mini-snowmobile, the necessary switches are installed on the steering wheel, which remains for our client to make: ignition, gas lever, etc.

The main design advantage, of course, is the versatility of the ski module. Thanks to a simple device, it can be attached to almost any Russian or imported motorized towing vehicle.

The disadvantages of the additional module include the following:

- the need to have a license to drive a newly formed vehicle, since the module-towing hitch is equivalent to a mini snowmobile;

- poor passage of a motorized towing vehicle in the deepest and loosest snow;

- additional load on the towing vehicle frame, its chassis and suspension, which can lead to frequent breakdowns (in contrast to the ski module, in mini-snowmobiles the creators do not simply take such loads into account).

Comfort and safety

The more a manufacturer thinks about the ergonomics of the equipment they produce, the more convenient it will be for you to subsequently own and use it. These are the “little things” that you can do without, but which will ultimately determine how happy you will be with your purchase. The steering wheel should be folding. This simple idea has not yet been picked up by all manufacturers - but in vain: screwing or unscrewing the steering wheel in the cold is a very dubious pleasure (otherwise you won’t be able to load the motorized towing vehicle into a vehicle). The correct folding steering wheel, among other things, has a height lock. It will not fall under the driver’s feet, is adjusted to the driver’s height, and most importantly, it will be convenient to press on it in order to lift the front part of the track and quickly move over an obstacle. Gas handles and control unit. Here, manufacturers use different options, from cheap Chinese crafts to serious ATV designs. You will have to pay extra for quality, but the ride will be more pleasant and there will be fewer breakdowns. An electric starter is a nice thing, but by and large it is not very necessary. It’s a matter of taste and wallet: if you want to start a motorized towing vehicle with a button on the steering wheel, sitting comfortably in a sleigh, take an electric starter; ready to pull the manual starter and get into the sled a little later - you can save money. Reverse gearbox, or reverse gearbox. You can do without it, but it is a useful thing, especially if you drive through the forest and periodically climb into impenetrable windfalls. Turning a motorized dog around on a narrow spot is not an easy task; the included reverse gear will allow you to easily drive back along the already laid track. Ideally, the reverse gear is activated on the steering wheel, and not on the motorized towing vehicle itself. The safety check is a very important element; wear it every time you ride your motorcycle dog. An accidental stump under the snow, an awkward movement - and now you are already lying in the snow, and your motorcycle friend is cheerfully trotting away from you across the snow field at a speed of 30-40 km/h. The check is designed to prevent such situations: it breaks when the driver falls, which instantly stops the engine

Some manufacturers offer it as an additional option; In our opinion, every motorized towing vehicle should be equipped with this device, so pay attention to whether this part comes “stock”. Headlight, socket, electrical accessories. You can't drive in the dark without a headlight; Without a cigarette lighter socket you won’t be able to recharge your navigator away from home

On high-quality motorized dogs, an “electrical package” with a relay-voltage regulator, which allows the use of various electrical devices, is included immediately, as well as a headlight. The brake with parking mode is a very useful thing: you can safely warm up the motorized towing vehicle without fear that it will drive away from you across the field. Not available in all models and not all manufacturers, so please pay attention.

Sources

- https://zuzako.com/reyting-luchshih-motobuksirovschikov-motosobak/

- https://markakachestva.ru/rating-of/409-luchshie-motobuksirovschiki.html

- https://gadgetok.ru/top-12-luchshih-motobuksirovshhikov.html

- https://brakonyerov.net/ohota/ekipirovka/motobuksirovshhiki.html

- https://expertology.ru/17-luchshikh-motobuksirovshchikov/

- https://VseObzornik.com/5-luchshih-motobuksirovshchikov/

- https://TechnoSova.ru/ratings/rejting-motobuksirovshhikov-po-nadezhnosti-i-prihodimosti/

- https://bagorik.ru/aksessuari/motobuksirovshhik-dlya-rybalki.html

- https://fermersadovod.ru/otdyh-i-dosug/tehnika/luchshie-motobuksirovshhiki-dlya-ohoty-i-rybalki/

- https://navigatorfh.ru/novinki/mototekhnika/2156-11-lajfkhakov-dlya-vybora-motobuksirovshchika

How to make a ski module with your own hands

To be able to make a ski module, you must first understand its structure. For this purpose, it is natural to look at a photo or drawing of favorite models on the Internet. As you can see, there are no difficulties in its design. If you have all the necessary parts, tools and capabilities, then it is better to make the module at home. This will cost even less, and with reasonable management the structure should be stronger.

The main thing is, don’t forget about this fact? these are design features of the frame itself. Skis are made to be located about 90 cm far from their native land? this will give the structure stability, and there should be places on the frame for attaching the module to the towing vehicle (usually four nuts).

This is how you can simply transform your motorized towing vehicle into a mini snowmobile. As we have seen, there is nothing complicated here.

One comment on ““Advantages and disadvantages of a ski module for a motorized towing vehicle””

Is there an option to purchase the drawings from you? How much will they cost? And how much will the finished module cost?

Sources:

https://specmahina.ru/motoblok/telezhka-dlya-motobloka.html https://stroy-podskazka.ru/kvadrocikly/moduli-dlya-motobuksirovshchikov/ https://motoli.ru/2337-preimuschestva-i-nedostatki -lyzhnogo-modulya-dlya-motobuksirovschika.html https://motoaria.ru/snegohody/preimushhestva-i-nedostatki-lyzhnogo-modulya-dlya-motobuksirovshhika.html

Mukhtar 15

Innovative 2021 model. The new product is positioned as a towing vehicle that can be used all year round in a variety of conditions, including complete off-road conditions. The motorized dog is equipped with a 15-horsepower Zongshen unit with a capacity of 420 cm3. A special feature of the model is wide 500 mm tracks. Thanks to the snow hooks, the structure moves through loose snow without any problems. The equipment set includes:

- rollers with seals made of rubberized material;

- towbar;

- Ruben belt 3.3x1.4x112 cm;

- roller-slide suspension;

- skis measuring 1010x150 mm;

- disc brakes;

- powerful LED headlight that allows you to move in the dark.

Such a rich supply set makes it possible to assemble different modifications of the axle box. The optional ski module turns the classic tug into a snowmobile. When equipped with wheels, you get an all-terrain vehicle with increased cross-country ability.

Advantages:

- versatility due to modular design;

- good level of traction;

- headlight included;

- reliable durable bearings.

The disadvantage is the high price. However, it is more than compensated for by its versatility.