How the suspension works

If you are not making a trike out of a scooter with your own hands and are counting on a powerful and impressive model rather than a children's tricycle with a motor, then you need to seriously think about the action of your front wheel suspension. What are helicopter or airplane reasons for? The fact is that the movement of the wheel along the vertical axis will occur with much greater force than on a motorcycle, so you need to install stiff and durable springs - at least in the lower part of the suspension, which compensates for movement along the vertical axis. To compensate for movement along the horizontal axis, you can use softer springs - for example, from the Izh motorcycle. As you can see, assembling a tricycle with your own hands is quite difficult, but if you follow all the instructions, have a clear drawing and all the necessary materials, you should be able to cope.

The process of disassembling the transmission cassette

First, a little theory. On the rear wheel there may be two options for parts related to gear shifting.

- Transmission cassette. This product is modern and features innovative spline fasteners that attach to the hub axle.

- Ratchet. A somewhat outdated model, typical for inexpensive bicycles with speeds. There are no more than seven gears in a set. As for the fastening, it has a thread with external installation parameters.

Let's immediately focus on the ratchet. Changing the rear sprocket on a bicycle with a freewheel is not possible.

Just change the entire component completely.

Therefore, the topic of the article will be a problem describing the situation when a bicycle cassette sprocket needs to be replaced. As for the set of sprockets in the transmission, there are options for up to 11 pieces, depending on the bike model.

Photo 1. Elements of the ratchet and cassette

So how do you change the rear sprocket on a fast bike? Let's consider the algorithm of actions.

- Taking a bicycle wrench for the rear wheel, we dismantle it. We consistently open the levers and loosen the nut.

- Now it's the turn for the axle nuts. Using another key, unscrew the fastener.

- The next step involves unscrewing the bearing cone and pulling it out.

- We take out the axle with all the elements.

Photo 2. The process of removing the sleeve.

- We take a special tool - a cassette puller. We insert it into the slots.

- The whip is placed on the star that is the largest. We make rotational movements in a clockwise direction.

- At the same time, using an adjustable wrench, the puller rotates in the opposite direction.

The preliminary stage is over. Such simple actions are possible in normal home conditions.

We emphasize that if not one sprocket is worn out, but several, then it is better to replace the entire cassette at once. This option is also desirable if the largest star is damaged.

And one more recommendation. We put all the small parts, washers and nuts in a certain place so that later we don’t have to look all over the room

Homemade tricycle assembled from Soviet motorcycles

Dear visitors of the site “”, from the material presented by the author, you will learn how to independently assemble a tricycle from spare parts from old Soviet motorcycles with your own hands. This trike was assembled by Viktor Bryukhanov and was based on the Voskhod motorcycle frame, front fork with wheel, tank and seat, single-cylinder internal combustion engine borrowed from the Minsk motorcycle. The rear part (gearbox, axle shafts, wheels) is from the Ant cargo scooter. IZh “Planet” shock absorbers; by the way, the tricycle has a reverse speed and an additional towbar for a trailer. Rear brakes, no front brakes)

Assembly algorithm

If you have a frame ready, then the following sequence of actions will help you:

- Find a suitable rear axle from Moskvich or Zaporozhets.

- Mount the engine, exhaust system, filters, and oil cooler on this axis.

- The frame must perfectly connect the rear axle, engine and front fork. This is a very important stage. It is easier to install everything on a lift or jacks for better access to parts during the assembly process. All ferrous metal structures must be carefully primed and painted before installing parts.

- In order for the trike to be fixed on the ground, a front fork with a shock absorber is installed.

- When fixing each element, eliminate any play or clatter; if the part may come loose over time due to vibration, use locknuts.

- It is better to use fastening of metal elements by welding, where possible, for example, with cross members, rear axle and frame.

- Once the trike is on its three wheels, it's time to install the fuel tank, rack, seat, and additional accessories.

Even by investing a small amount of money and working with passion, you can get a trike no worse than its foreign counterparts. At the same time, the driving characteristics will be at their best, and will allow you not only to show off beautiful equipment in the garage, but also to show off at high speed on the highways. Stylish accessories such as leather fringe, chrome details, a specific helmet shape and the characteristic roar of the engine will allow you to recognize an ardent biker on a tricycle, which was made with his own hands in the garage.

Fork

The length of the fork is determined by your project. If you want to make a long front fork, this trike is suitable for flat roads and long rides. A more aggressive driving style will require a shorter length. A tricycle from Izh, photos of various mods of which can be found on amateur forums, may even have a trunk located above the front wheel. Of course, in terms of cross-country ability, trikes are not competitors to ATVs, but for trips to the country, garden or fishing, the work invested will more than pay off.

Purpose of all-terrain vehicle x

The vehicle in question is designed to overcome any off-road conditions. The tricycle will go through forest paths, sand, mud, ice, shallow water and shallow snow.

ATVs are popular among hunters and fishermen.

Owners appreciate the increased cross-country ability, compactness, and maneuverability of the unit.

Such modifications are of interest to residents of the outback and villages. All-terrain vehicles will confidently overcome country roads, reaching speeds of up to 60 km/h. Moreover, the price of such a vehicle (especially a home-made one) is an order of magnitude lower than its automobile counterpart or ATV.

All-terrain vehicle based on the Urals

At the preparatory stage, drawings and a diagram of the future tricycle are being worked out. In the variant under consideration, chain transmission is not provided.

The unit is suitable for 15-inch alloy wheels, which are heavier than homemade analogues, but more reliable and have a beautiful appearance.

After choosing the final concept, they move on to turning the parts of the all-terrain vehicle.

Tools and Supplies

The frame from the Ural motorcycle, converted to accommodate the installation of a car rear axle, was chosen as the base. You will also need the following items:

- ICE type Lifan (6.5 hp);

- variator from a scooter;

- tarred fiberglass;

- moped generator;

- muffler with wide cross-section;

- metal corner 32 mm;

- tires out the Shishiga wheels;

- conveyor belt.

The instrument is traditional. You will need a lathe, yews, a set of keys, screwdrivers, a gas welding machine, and measuring devices.

Main stages of rework

The process of creating a three-wheeled all-terrain vehicle can be divided into several stages:

- Preparing a variator from a 4-stroke 150 cc scooter. This part is convenient because it is easy to adjust working and coupling speeds. These modifications are mounted on motors with power up to 14 hp.

- They begin to create the rear axle of the all-terrain vehicle, including preparing the site for the automobile bridge, manufacturing cones and flanges.

- The front fork is widened and adjusted to fit a wide rim.

- The seat is made of plastic, lubricating the prepared mold with wax and then laying fiberglass in several layers.

Making odorishi

On a light three-wheeled carakat they put “strippings” from the tires of a GAZ-66 or Ural (Lapot) car, as well as medium-sized tractors. The tires become lighter, while a new tread is cut onto the old rubber, which is responsible for reliable grip when driving on snow and mud.

It’s not difficult to make wheels for an all-terrain vehicle with your own hands. Process steps:

- Using a construction knife, a cut is made around the perimeter of the tire to remove the wire.

- Mark rectangles for the future tread and cut them out.

- The wire is removed with a hook and a hand winch or a screwdriver.

- The peeled rubber is peeled off.

- Remove unnecessary layers until the frame remains.

- The discs are welded to the plates, and the surfaces are sanded.

- Put the headband on the frame.

Engine and transmission

The wheeled all-terrain vehicle in question was equipped with a Lifan engine, modified for installation on a tricycle. A moped generator and a larger cross-section muffler were also installed. The standard carburetor did not perform well, which is why a tractor starter was installed.

This approach made it possible to increase the power of the karakat by almost 2 times.

The variator works great, in the 2nd range it makes it possible to slip and drift. In mode 4, the unit starts off smoothly, accelerates to 50 km/h, and at high speeds loses stable control. A unit from Honda City, Oka, Zhiguli is suitable as a transmission box. The gearbox is mounted on the vehicle frame and is coupled to the rear axle using a cardan drive.

Final improvements

At the final stage, the reliability of the assembly and the operation of all components are checked. The seat and body are painted, oil and fuel are added. If desired, fenders, mudguards, light and signal elements are mounted.

English Wheel - the best machine for old-school body customization

When you hear the phrase old-school style tuning, which translates as old school, you should understand that this is not only the final appearance in the old school style, but precisely the tuning technology itself. In tuning of past years, carbon, fiberglass and other modern materials were not common and everything had to be made of metal. The parts turned out to be heavy, reliable, and beautiful, especially if everything was done wisely and with soul.

The auto giants produced all the parts by stamping from sheet metal, but such equipment was not available to garage “customizers” and tuning studios. But fortunately, a machine for rolling sheet metal, invented since the time of King Pea, came to the rescue - the English wheel. Thanks to it, it is possible to produce body parts for cars and motorcycles. It is necessary to make swollen wheel arches - please, a sports hood with nostrils - no problem, a teardrop gas tank for a chopper or fenders - just go. With such a machine, the imagination for turning an ordinary flat metal sheet into the necessary geometric shapes is unlimited.

Of course, many parts can be made from plastic and other modern materials, but this will no longer be the style of the old school, and besides, plastic elements may not be suitable for the specifics of your car or motorcycle. For example, you are making a retro rod - plastic has no place here, or you are restoring a car from the 30s-40s of the last century, there should only be metal. And since you can’t find original spare parts during the day, you’ll have to make them by hand. This is where the English wheel comes in handy.

What is an English wheel?

As a result, we already have a part that does not require additional processing or straightening. This is very convenient, considering that we can carry out all manipulations in an ordinary garage, without industrial equipment. Many craftsmen, in order to expand (inflate) the wheel arches, cut out sheet metal and, bending it into an arc, stupidly weld it to the supporting body. The view is, frankly speaking, not so hot. In an attempt to correct the situation, they apply tons of polymer putty, trying to smooth out the sharp corners. Some people even do pretty well. In addition, the rollers of the English wheel, of various shapes, allow us to make convexities, stiffeners and chamfer our parts.

What is the English wheel? This machine has the shape of a round or rectangular metal bracket with thick walls, mounted on a powerful platform that does not allow the device to tip over. There are metal rollers on the ends of the bracket. The upper roller is fixed on a fixed axis, the lower one is equipped with a hydraulic or mechanical pressing mechanism, depending on the machine model. The upper roller (main) is vertically stationary and rotates only around its axis, the lower pressure roller is removable. The lower rollers can be changed depending on how much area needs to be rolled or what kind of bend to make.

DIY English wheel

The frame is ready, you need to take care of the main elements of the rolling machine - the rollers. Any large bearing from agricultural machinery or a locomotive can be used as the upper roller. Everything is simple here. We weld the bearing mount and install it on the end end of our machine. Bottom rollers. It's more complicated here. Initially, a couple of rollers of different sizes will be enough. If you plan to roll metal to customize motorcycles, then a couple of rollers 30-50 mm wide will be enough.

Due to the small rolling area. To process sheets of a larger area, rollers with a width of 60-80 mm or more are required. Let me make a reservation right away: it’s not easy to get rollers; companies selling English machines don’t sell them; you can either order them from abroad or from local turners. Fortunately, the Internet is now full of drawings, in different variations. The cost of a set of videos from ebay sites is about 10-15 thousand rubles. How many turners will they take? How do you agree? The clamping mechanism can be borrowed from other machines, for example a mechanical pusher or vice.

To further minimize costs, you can use an old truck beam as material for the bracket. The metal on them is powerful and, moreover, you can buy them at scrap metal collection points for pennies.

Homemade tricycle based on IZ Jupiter: photo, video

A tricycle built on the basis of the Izh Jupiter motorcycle: photo and description of the homemade product, as well as a video review of the trike’s design.

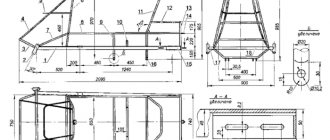

The craftsman assembled a homemade tricycle with his own hands, using Izh Jupiter as a donor. Below are photos and drawings of the trike.

The design of the tricycle is quite simple: a rear axle is installed, torque is transmitted via a chain drive to the driven axle sprocket.

Rear wheels from VAZ.

The figure shows the dimensions of the rear axle of the tricycle.

The rear axle is made of a thick-walled pipe with an outer diameter of 42 mm, machined axle shafts from a VAZ are installed.

How to make a three-wheeled scooter with your own hands. Blueprints

The practicality of a trike is higher compared to the classic scooter layout. It’s true that its price is steep, so we suggest taking a used Honda scooter or any other used scooter as a basis and remodeling it yourself.

Drifting on a bike. All about custom trikes for serpentine roads

What does a normal person think of when they hear the word “drift”?

Perhaps cars with the appropriate surroundings around them. What does a cyclist mean by drifting...

A good downward slope, an asphalt winding path, three wheels, two pedals, low seating, speed, a good and “fragile” angle and of course - a generous pinch of real custom! – all this is bicycle drift.

Many people have heard about tricycles for drifting, and perhaps many have seen these toys in cool foreign videos, but, of course, this trend cannot be called popular in our country. Trike is an exclusively fun phenomenon, supported until recently by the desire to do something with your own hands.

Now tricycles for drifting are beginning to actively appear on sale. The starting price is $200, the cost of advanced models exceeds the level of $1000 or more. But it is custom trikes that are the coolest component of this unusual cycling phenomenon!

How to make a drift bike

To create a drift trike, an old and broken BMX, or a children's bike on 20-inch wheels, is most suitable.

The bike will need the front part - a wheel, fork, handlebars, stem and a piece of frame with the lower tube of the front triangle, and the rear part - a cart with a beam and two wheels wrapped in plywood cylinders, will be assembled separately and welded to the front part of the future trike.

Pedals on a drift bike are optional - you can do without them by installing pegs on the front of the bike to hold your feet.

If you decide to install pedals, then you will have to solve the issue with idle speed, which will require a “Kulibin” approach to adapting the rear bushing and connecting rods to the frame fork, or searching for specialized parts rarely found in nature.

Some people install a controlled electric drive on a drift trike. We have already written about electric motors on sports equipment, telling you about longboards with a power plant

.

But the pinnacle of custom is installing an internal combustion engine on a trike!

Drift trike with engine. Video assembly instructions from a Russian master

The three-wheeled monster with an internal combustion engine also lives in Russia. It was assembled by the famous Ufa customizer Maxim Klyuch, who recorded the entire assembly process in the form of a series of interesting videos.

Rides

Even in those places on the planet where the number of tricycles for drifting is more than one for the whole city, nothing larger than local mini-competitions or fun rides usually happens.

But its rarity, of course, doesn’t make this entertainment any worse!

Bicycle rear hub and its structure

One of the important spare parts of a bicycle is its wheel. In particular, the rear wheel is much more loaded than the front, since it is on it that the ratchet (freewheel mechanism) and cassette (sprocket block) are installed.

The wheel is the main focus when riding, so it is important to understand the design of its hub in order to be able to properly maintain it. A hub is an element of the wheel mounted on a bicycle frame, namely on dropouts. This is the central part of the wheel, ensuring its free rotation

The bushing consists of the following elements:

Types of rear bicycle hubs, their differences from each other

One of the reasons for dividing rear bushings into varieties is their design. Depending on it, rear bushings are divided into:

- Without brakes.

- With built-in brakes.

According to the method of fixation, the bushings can be fixed on two nuts, which is much cheaper, or they can be secured using an eccentric. The second method is more expensive, but much more convenient, since the nuts need to be removed with a wrench, and to remove the wheel on the eccentric, you just need to press its handle. It will only take a couple of seconds. The material of manufacture also matters. The bushings are:

- Aluminum (lightweight and non-corrosive).

- Steel (strong, but heavy and very susceptible to corrosion).

The bushings also differ in the size of the axle; the standards vary - from 9mm to 15mm. Keep in mind that the larger the bushing, the heavier it is.

How to properly design a mini-tractor?

The conversion of a walk-behind tractor into a mini-tractor is carried out in several stages. First you need to take care of the frame. It is made of durable metal, which is cut into pieces of the required length and then welded together. When the frame is ready, you can start assembling the chassis.

If the motor is placed in the front part, then the width for the wheels can be left the same as in the walk-behind tractor. In order to attach the wheels to the rear, you will need an additional axle. It is made to the required length; an ordinary piece of pipe is suitable for this, the main thing is that the width is suitable. Bushings and bearings must be installed at the ends of the pipe. You can then install wheels on them.

If you decide to place the engine at the rear, then the width of the wheels must be increased, otherwise the minitractor will not have the necessary balancing. So, you need to remove its wheels from the walk-behind tractor, after which you need to make the bridge a little wider.

To control the mini tractor, you can take the handles from the walk-behind tractor. However, this will make the converted tractor look like a motorcycle and will be a little awkward to drive. For convenience, it is better to install a regular steering column.

The driver's seat can be made from a sled frame that needs to be welded. In addition, you need to remember to install the headlights, as well as the dimensions. After fully assembling the mini tractor, you must definitely lubricate all the parts and also run it in.

From all this it follows that almost every person who is at least a little familiar with technology can convert a walk-behind tractor into a mini tractor.

When to remove the rear wheel

It is unlikely that the idea of unscrewing the chassis from a bicycle frame will just come to mind, unless, of course, a person specializes in bicycle disassembly. But this is a completely different case. Rear wheel removal will be required if the following problems occur:

- noticeable damage to the rim;

- complete wear when the wheel needs to be replaced;

- the tube has gone flat or the tire has burst;

- bushing bulkhead.

This includes the planned replacement of the rear sprocket system and chain.

Before removal, the bike must be turned over and installed on the saddle and handlebars. It is better to remove canopies in the form of a mirror, a bell and a lantern in advance so as not to damage them under the weight of the frame. V-brake brakes are first released and removed, otherwise they will not allow the wheel to be pulled out freely. With disc models everything is simpler - you can immediately remove the wheel.

It must be said that the removal process itself consists only of unscrewing the eccentric or unscrewing the fastening nuts from the bushing axis, depending on what it is. If the mount is an eccentric, simply unscrew the handles and twist the wheel. The nut is loosened with one or two keys.

Usually one wrench of the appropriate size is enough, which is used to remove the nuts one by one. If the bushing axle rotates, then the nuts unscrew simultaneously in different directions. It is recommended to use open-end or box-end wrenches. The adjustable version is undesirable, since its thick horns “eat up” the corners of the nut due to loose fit and sliding.

General technical specifications

Homemade tricycles are mainly made on motorcycle frames or structures hand-welded from a metal profile. Wheels from trucks or tractors are used as wheels. The transmission, brakes, steering rod are formed from spare parts of domestic and foreign cars or motorcycles.

For comparison, the table shows the parameters of 2 serial domestic tricycles.

| Characteristic | TMZ-5.971 | ZID-200 (Farmer) |

| Engine capacity (cc) | 199 | 196,9 |

| Power (hp) | 13,6 | 13,0 |

| Dimensions (m) | 2.3x1.35x1.25 | 2.2x1.5x1.2 |

| Weight, kg) | 250 | 210 |

| Wheel base (m) | 1,52 | 1,5 |

| Ground clearance (cm) | 16,0 | 13,0 |

| Maximum speed (km/h) | 70,0 | 50,0 |

Power unit

Naturally, when you think about making a tricycle with your own hands, you will need to choose a suitable engine. In this case, you do not have to take a power unit from another motorcycle - an engine from a car will also work. The main thing is that it fits properly between the rear wheels. This way you can improve the performance of your vehicle. In some cases, you won’t even have to make any changes or improvements; in others, you won’t even have to replace the radiator or some other part. It is also recommended to install other mufflers, and increase their number by installing one on each cylinder. Naturally, there are other options - it all depends on which power unit you decide to choose. For example, if you make a tricycle from the Ural with your own hands, then it is better to replace the engine completely.

Design Features

If you don’t know how to assemble a tricycle from the Urals, strictly follow the drawings. Typically, the upper beam is used to secure the rear shock absorbers. Glasses welded to it will allow you to achieve a good level of comfort. Car-like shock absorbers will respond reliably to changing road surfaces. Simply welding a square or round pipe into the end will not be enough. It is necessary to use reinforcing kerchiefs made of ferrous metal, scalding them well. A do-it-yourself trike from the Urals can be used not only to satisfy your love for a hobby, but also as a workhorse on the farm. If you set a goal, such a trike can have a carrying capacity of several hundred kilograms . It will be necessary to install not only the engine, but also prepare the site for installing the gearbox. Looking ahead, there will be the most problems with it, since there is nowhere to remove the finished structure, and making the box itself, the body, is very difficult.

It is also important to remember that the tricycle from the Urals with your own hands has a shifted center of gravity back. This occurs due to the installation of the power unit. A common problem is that at high speeds and abrupt release of the clutch, the motorcycle can rear up. Therefore, if there is an opportunity to shift the balance to the front wheel, it is better to take advantage of it.

The engine mounted on the frame requires virtually no modification. The main thing is to prepare the engine from the ZAZ-968 so that it works flawlessly. The exhaust system will also have to be made to order. Firstly, all bikers are simply delighted with the large and bright chrome parts, and secondly, you may not like the sound of the engine. A tricycle from the Urals can have an oil cooler or water cooling.

Examples of homemade all-terrain vehicles

A craftsman from the Moscow region built a two-wheeled all-terrain vehicle almost from scratch. The frame was welded from a rectangular steel profile. The wheels are Chinese, for light ATVs. The driving force is a 6.5 liter Lifan type engine. The clutch was purchased along with the engine. A special feature is a one-piece gearbox with reduction gear. The brakes are scooter discs, the chainrings are 520 motorcycle ones. Steering wheel, wings, seat - from scrap materials.

Another interesting all-terrain vehicle based on the Oka car. Main components:

- steering column - from the Urals;

- CV joints, wheel gearboxes - from Zhiguli;

- wheels front and rear 15 inches - Niva Chevrolet;

- fuel tank - from a 20 liter canister;

- the engine, gearbox, clutch, headrest, part of the “tidy” are from Oka.

The result was an ATV with a mass of 430 kg, ground clearance of 30 cm, and top speed of 65 km/h. Dimensions - 2.3 x 1.25 x 0.9 m.