The Ural 4320 is a popular truck that is excellent for use on rough terrain and in forestry. This is facilitated by high ground clearance and a powerful engine. This machine is equipped with YaMZ diesel engines. Power can exceed 300 horsepower. The gear shift scheme is competently designed by the manufacturer of this equipment. Approximately 30 liters of fuel are consumed per 100 km. If this indicator has increased, it is necessary to carry out premature diagnostics of the automotive system.

The winch for the Ural-4320 is necessary for self-pulling vehicles or pulling out other vehicles. Maintenance of the winch consists of directly checking and tightening all fasteners.

How does the checkpoint work?

The KPP-141 device, installed on some Ural models, includes the following elements:

- Coupling mechanism. It helps temporarily separate the engine and transmission. This allows you to change gears without reducing the speed of the power unit.

- Driven gears and shafts. The drive, intermediate and secondary shafts are installed here.

- Synchronizer. It ensures silent operation of the mechanism and equalization of gear speeds.

The gears rotate freely when the neutral mode is engaged, at which time all clutches and synchronizers are in the open position. When the driver begins to squeeze the clutch mechanism and shifts the handle to some other gear, a special fork device begins to move the clutch into the engagement position with the corresponding pair at the end of the gear.

The gear mechanism is rigidly fixed to the shaft and stops spinning on it. The clutch in this position facilitates the transmission of rotational motion and traction force.

While the vehicle is moving, the gearbox is activated by the gear shift knob. It moves sliders equipped with forks, which begin to move the synchronizers at the required speed. A color diagram of gear shifting is in the Ural user manual.

Gear ratios of the Ural box:

- first stage - 5.26;

- second stage - 2.90;

- third stage - 1.52;

- fourth stage - 1.00;

- fifth stage - 0.664;

- reverse gear - 5.48.

Operating principle and troubleshooting of the Ural gearbox

Beginners, just learning the basics of driving and controlling a motorcycle, look with admiration at how motorcyclists skillfully and silently change gears on a motorcycle. And they have an irresistible desire to learn the same impeccable technique for driving their vehicles. But they shouldn’t think that it’s so difficult.

Ural gear shift scheme can be different depending on the model of the Ural car. If we look at a car of the Ural brand, or Ural with their modifications, we will see that a YaMZ U gearbox is installed there. It is three-way and has five forward gears and one reverse. The gear drive installed in the box switches first gear and reverse gear.

Malfunctions and repairs

Basic malfunctions and repairs of the box:

- Extraneous noise in the mechanism. In this case, it is recommended to conduct an external inspection of the system and replace damaged and worn parts.

- The shafts move along the axis. It is necessary to replace the parts that secure the bearing, or replace failed bearings.

- Unstable operation of the gearbox. This problem may be due to wear on the reverse spline shaft bushings. Damaged mechanisms should be replaced.

- The clutch does not engage fully. In this case, it is recommended to conduct an external inspection of the coupling mechanism for damage and defects, check the level of lubricating fluid in the system and replace damaged elements.

- The fork rods are difficult to move. This malfunction can be caused by damage to the locking pins and synchronizers. It is necessary to replace the mechanisms with new ones.

- If the gearbox switches off spontaneously, it is necessary to adjust the gap between the valves, replace worn synchronizer rings, install new springs, and tighten fasteners.

- If the switching is unclear, you need to remove the cover of the locking device and inspect the main components for wear, replace the clutch and gears.

Gearbox repairs are carried out only with the power unit turned off.

How to adjust

The gearbox is adjusted as follows:

- The vehicle is installed on a special platform.

- Using a jack, slightly raise the front part of the car body and fix it in this position.

- On the transmission control rod, loosen the fastening nuts of the clamp bolt. The nut is loosened 4.5 turns.

- Using a screwdriver, expand the grooves at the end of the traction device and the clamp.

- Move the rod to the neutral position.

- Unscrew the special fasteners.

- Remove the gearbox cover from the control handle. The cover is lowered to the very bottom of the case, and the handle itself is placed in a vertical position with the end up.

- Loosen the clamp mechanism.

- Engage reverse gear when the power unit is not working.

- Install the prepared template into the trim window, as well as the reverse locking bracket.

- The stop of the axial mechanism is inserted into the groove of the template and pressed against the system body.

- Set the required gap between the elements. Tighten the fasteners and clamp.

- Start the engine and check the serviceability of the adjusted gearbox.

How much oil to fill

Oil must be added in accordance with the user instructions. For Ural cars, the sufficient oil fluid level is 3.5-4 liters.

Ural-4320 – EcuRed

R) 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 Tipo

| Ural-4320 | |

| Ural-4320 6×6 military, Ukraine | |

| Manufacturer | |

| Periodo | 1976-Presente |

| Fabricas | UralAZ-de-Miass, Russia |

| Predecessor | Ural-375D |

| Camion Militaryar | |

| Configuration | Engine YaMZ-236M2 (diesel v6), YaMZ-238M2 (version 8 diesel) |

| Largo / anchor / alto / battalion | 7.366 mm (29169.3066 mm).0 inch) / 2500 mm (98.4 inch) / 2715 mm (106.9 inch) o 3.005 mm (118.3 inch) (con la tienda) |

| pesos | in vacuum: 8,500 kg; peso a plena carga: 14,500 kg |

| Transmission | manual, cinco velocidades y de dos en reversa |

| Model manual | Neumáticos |

| Like 000000000000000000000000000000000000000000000000000000000000000000000000000000000000000R ВeD 2 | |

| Asientos | 3 |

se basa en el Ural-375D y es bastante, similar to este. Fundamental differences between the Ural-4320 and automotive and household appliances.

Historia

The Ural 4320 series, released in 1978, combined with an engine similar to gasoline, similar to the engine, including equipment for the engine and diesel in 1973.

Model range of 4320 serial production engines with the YaMZ-740.10-20 diesel engine at the KAMAZ manufacturing plant.

Series 4320 Continued development and actual cost of 150 variants including 4x4 case. Serecen muchos modelos para applicaciones comerciales.

How to remove and disassemble

In order to dismantle and disassemble the gearbox, you must:

- Place the vehicle on a lifting device or inspection pit.

- Remove the batteries, air filter element and mudguards. They are located at the bottom of the engine compartment, in the center and along the edges.

- Remove the front suspension cross member and the front drive wheel drives.

- Drain the transmission fluid from the box.

- Disconnect the wires of the sensor responsible for speed indicators. To do this, you need to pry up the wires with a screwdriver and carefully remove the spring retaining device.

- Remove the vehicle reverse switch.

- Remove the engine harness holder.

- Remove the mounting bolts from the gearbox and the hydraulic clutch release bracket.

- Remove the bolts from the working cylindrical block, clutch housing, amplifier.

- Remove the crankcase.

- Place a support under the dismantled box.

- Disconnect the front and rear supports from the bracket.

- Move the gearbox back and place it on a hard surface.

- Unscrew the fasteners and disassemble.

Dismantling the transfer case

It is more convenient to remove the transfer case if the car is installed on an inspection ditch in a room equipped with a lifting device.

Remove the driveshaft of the middle axle drive, disconnect the flanges of the driveshafts of the intermediate, front axle drive and front winch drive from the flanges of the transfer case and the additional power collection box.

Disconnect the wires from the speedometer sensor.

Undo the cotter pins and remove the pins, disconnect the rear ends of the control rods for the transfer box, auxiliary power take-off box and parking brake.

How to assemble and install

Box assembly procedure:

- compress the bearing;

- insert a chisel into the gap between the end part of the inner bearing ring and the differential box;

- install the bearing and axial mechanism of the satellites;

- insert the support ring into place;

- install drive gears and differential box;

- tighten the fasteners;

- install the synchronizer blocking ring;

- install the sliding clutch and retaining ring of the synchronizing device hub;

- install the driven gear and thrust washer;

- adjust the gap between the front bearing ring and the drive gear.

Installation of the gearbox in the Urals is carried out as follows:

- install a support under the gearbox;

- screw the fasteners to the block of cylindrical elements;

- install the left engine mount using 4 mounting nuts;

- place the rear support and attach it to the body;

- connect the gearbox bracket and the front engine mount;

- install the clutch housing, connect the cables with brackets;

- connect the lever cables and support washers;

- install the exhaust gas neutralizer, replace the cover;

- connect the amplifier to the cylinder block;

- screw the engine harness holder;

- install a retainer, block, spring mechanism;

- connect the front drive wheels, mudguards, air filter and batteries.

VESKO-TRANS.RU

AutoNews / Reviews / Tests

How to Remove a Gearbox in the Urals 4320

As a take off gearbox on the Ural 4320

gearbox, the car's gears are tightly intertwined with the type of engine. For Ural vehicles, the gearbox versions were changed in combination with the engines.

Checkpoint compliance schedule

Ural 4320, Ural 5557 until 1994. A KAMAZ 141 gearbox was installed, which was installed on the KAMAZ 740 engine. Since 1994, the Ural has been equipped with YaMZ 236 engines with a corresponding YaMZ 236 gearbox, YaMZ 2361 gearbox

Today, most Ural cars are equipped with YaMZ 206 gearboxes and modifications. YaMZ 206 is a mechanical, three-speed, five-speed, 2 and 3, 4 and 5 synchronizer.

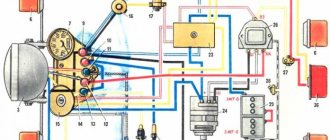

Rice. 1. Transmission of cars Ural-4320, 5557 (YaMZ-236) 1. clutch; 2. input shaft; 3, 15. bearing caps; 4. clutch housing; 5, 10. synchronizers; 7. clamping ball; 8, 22. fifth gear; 9, 21. third gears; 11, 19. 2nd gear gears; 12. first gear and reverse gear; 13. top cover; 14. secondary shaft; 16. flange; 17. intermediate shaft with first gear gear; 18. Transmission ; 20. oil pump with magnet; 23. gear; 24. intermediate drive shaft gear; 25. oil pump; 26. axis of the caliper gear block; 27. support gear block; 28. four-wheel drive speedometer.

Ural It operates in difficult conditions, so components such as the gearbox fail very quickly if maintenance and repairs are not carried out in a timely manner. It is important to choose a high-quality gearbox repair with Ural auto parts, because if you start installing Chinese spare parts for the Ural, then most likely the gearbox will break at the most inopportune moment (usually with a heavy load).

TO YaMZ KPP 236

Maintenance begins with checking the fastening of the Ural-4320 gearbox to the engine, checking the status of the suspension, and checking the normal oil level. Also follow the oil change instructions according to the table.

The YaMZ 236 gearbox has a mixed lubrication system: the plain bearings of the secondary shaft gears are lubricated under pressure. The gear shift mechanism, gears, and rolling bearings are spray lubricated. To pump oil from the oil bath into the air duct system, there is an oil gear pump, which is located on the front wall of the crankcase. The pump is equipped with a safety valve set to a pressure of 80 ± 10 kPa.

Ural YaMZ-238. Replacing the rear crankshaft oil seal. Dismantling

Ural

lumber carrier, Yamz-238.

Crankshaft seal seal, disassembly, gearbox removal

, clutch removal,

breeding,

fly on.

Ural 4320 part 17. Repair, replacement of input shaft, cufflinks.

Oil is poured into the Ural 4320 transmission through a hole in the top cover of the box, which is closed with a plug. To avoid oil overflow, keep an eye on the inspection hole on the left side of the crankcase. The Ural-4320 gearbox lubricates 5.5 liters. lubricating fluid. The oil level in the gearbox housing should not be below the lower edge of inspection hole 3 (Fig. 3).

Changing the oil begins by lowering the old oil while hot through the drain hole, closed by plug 4. After draining, clean the drain plug magnet, remove the intake pump cover and wash the screen, and then install everything.

Carefully install the lid so that it does not cover the oil.

Rice. 3. Transmission plugs Ural-4320, 5557 (YaMZ-236) 1. hole for filling oil; 2. oil inlet pump cover; 3. oil level control hole; 4. drain hole

Industrial oil I-12A or I-20A according to GOST 20199. 88 is recommended for flushing gearboxes; 2.5. 3 l. To flush the oil, pour the gear shift lever into the neutral position and start the engine for 7-8 minutes. Then the flushing oil is drained and fresh is refilled.

Do not flush the gearbox with other liquids: kerosene, diesel fuel, as this may damage the oil pump.

If you are assembling a transmission, the newly installed oil pump must be lubricated with pre-used transmission oil to allow fluid to be drawn into the pump before starting.

Features of towing a car with an idle engine.

1. Move the gearshift lever into 4 gears forward or disconnect the gearbox from the gearbox.

2. Towing is allowed for no more than 20 km without disengaging the clutch with direct transmission engaged or without disengaging the drive shaft.

Why should you follow these towing rules?

When the engine is turned off, the input and intermediate shafts in the box do not rotate, so the oil pump does not work and does not supply lubricant to the bearings or to the conical surfaces of the synchronizer. As a result, the sliding surfaces lift and wear the synchronizer rings. This wear causes the transmission to malfunction.

Cold start

If the ambient temperature. 30C, the gearbox must be warmed up before starting. If it is not possible to warm up, then the oil is drained from the crankcase for a long stop, and before it starts, it is heated, and the heated oil flows through the top cover. It is important to adjust the clutch correctly to prevent it from malfunctioning and transmitting information.

Engine

Engine type – four-stroke two-cylinder. Brand – M-72M. Cylinder diameter, mm – 78. Piston stroke, mm – 78. Working volume, cm³ – 746. Compression ratio – 5.5 ± 0.2. Maximum power, l. With. – 22. Maximum torque, kg m – 4.0. The block head material is aluminum alloy. Head gasket – asbestos metal 0.6 mm. The piston material is aluminum alloy.

Valve distribution phases (according to the angle of rotation of the crank), degrees: – beginning of intake to c. m.t. – 76; – end of inlet after n. m.t. – 92; – beginning of release BC m.t. – 116; – end of release after c. m.t. – 52.

Carburetor – Two K-37.

Transmission system components

Ural vehicles are valued for their high power characteristics, excellent load capacity, and driving dynamics. The performance indicators of this vehicle are largely influenced by the installed gearbox. This device affects power gain.

The Ural-4320 is equipped with a five-speed gearbox. It has a long service life and can withstand the loads placed on it well. The Ural gearbox housing is attached to the clutch housing. The manual transmission on the Ural car has fixed shaft axles. The upper crankcase cover is equipped with a gear shift mechanism.

Gearbox diagram

The transmission system includes lockable cross-wheel and center differentials. On the truck there is a dependent power take-off box or KZOM.

It should be noted that there is a transfer case on the Ural 4320. It is 2-stage and affects the fuel consumption for each kilometer traveled. This box is securely fixed to the frame with several special rubber pads.

Power take-off box

The Ural transfer box is an additional gearbox. It ensures stable movement of the machine at low speed. The installed Ural power take-off is single-stage. It is necessary to drive auxiliary units.

Gearbox Power Line Gear Shift Mechanism

Dismantling the transfer case

It is more convenient to remove the transfer case if the car is installed on an inspection ditch in a room equipped with a lifting device.

Remove the driveshaft of the middle axle drive, disconnect the flanges of the driveshafts of the intermediate, front axle drive and front winch drive from the flanges of the transfer case and the additional power collection box.

Disconnect the wires from the speedometer sensor.

Undo the cotter pins and remove the pins, disconnect the rear ends of the control rods for the transfer box, auxiliary power take-off box and parking brake.

Unscrew the sealing tube from fitting 11. Move the disconnected ends of the cardan shafts and control rods of the transfer case, additional power take-off and parking brake to the side and secure them to the vehicle frame.

Fasten the load-lifting device to the bracket on cover 4 of the top hatch of the transfer case and lightly tighten the slings of the lifting device.

Undo the cotter pins and unscrew the nuts of the studs securing the transfer case to the brackets, remove the cushions and washers, carefully lower the box onto the trolley and remove it from under the car frame.

Source