A mixture is formed in the carburetor, which then enters the engine; it must be periodically adjusted. The composition comes in three types: normal (ratio 1:15), enriched and depleted. The quality of the connection is determined by the fuel to air ratio. An increase in the amount of air leads to a leaner mixture .

As a result of this, consumption can be minimized, but maximum power cannot be achieved. Reducing the amount of air leads to a richer mixture. With a ratio of 1:12.5 or 1:13, the engine is able to operate at maximum efficiency, but gasoline consumption increases significantly.

The delta moped carburetor is adjusted in the following order:

- The engine is pre-warmed. You can make adjustments after a trip, when the engine is already well warmed up.

- Before making adjustments, it is advisable to replace the spark plug, clean the air filter, look at the exhaust system and clean it. The carburetor channels must be washed and blown with air.

- The screw that regulates the quality of the mixture is tightened all the way and returned 1/2 turn back.

- The minimum stable rotation of the crankshaft is set by turning the idle screw. By turning the quality screw, the air ratio is increased until interruptions in engine operation begin.

- Using the idle screw, stable engine operation is restored.

- The quality screw is turned again. This reduces the rotation speed. The previous steps are repeated until a minimum stable crankshaft speed is obtained.

- The result of regulation is checked by closing the throttle. If the engine stops, the mixture must be leaner, and if it stalls, it must be enriched. Most often, the quality screw needs to be turned 1/4 or 1/2 turn.

It is also necessary to periodically check the condition of the damper to ensure there is no deformation. To do this, check the condition of the damper in the open and closed positions. In normal condition, the damper should be at an angle of 60°-70°.

Not only the performance of the engine, but also its power and fuel consumption depend on the correctly adjusted operation of the carburetor. Both rich and lean mixtures negatively affect engine wear, the frequency of replacing spark plugs, and the condition of the exhaust system. Correct carburetor regulation can be monitored by the condition of the spark plug.

If the candle is brown, then the mixture is normal, if it is black, the mixture is enriched and needs to be depleted to normal, if white, the mixture is lean and needs enrichment. A properly adjusted carburetor ensures minimal gasoline consumption without loss of engine power.

Carburetor adjustments should not be made indoors. During operation, exhaust gases will be released, which are very poisonous to the body. Garage doors must be open, otherwise serious poisoning can occur.

Sometimes it happens that the carburetor starts to malfunction on a faithful iron horse and it becomes necessary to clean it and adjust it correctly. Symptoms of this problem most often include: difficulty starting the engine after long periods of standstill (1 day or more), power failures when switching from idle to load, and unstable engine operation at high speeds. And, as a rule, there is not always time or opportunity to roll the moped to a workshop where it could be repaired. Therefore, you have to take on this painstaking work yourself.

Alfa moped carburetor overhaul

Before starting any work with the carburetor, you should know that any speck that gets into or is not washed out of the bowels of the unit can cause it to malfunction. Therefore, the workplace must be thoroughly cleaned. An important point is that all dismantling work is carried out only with the engine cooled down.

There should be no problems when dismantling the carburetor. You need to disconnect all the pipes from the unit (before disconnecting the fuel pipe, you need to turn off the fuel supply valve) and the throttle cable. Next, the assembly should be thoroughly washed from the outside using a brush and gasoline. As a “cleaning” agent, you can use gasoline, diesel fuel, kerosene, VD 40 or aviation alcohol of your choice.

Once all dirt has been removed from the carburetor body, you can begin disassembling it. It should immediately be clarified the purpose of the three (usually brass) flat-head screws located on the carburetor body (all three are on the left side).

- Located in the area of the air supply pipe and serves to adjust the quality of the mixture when the engine is idling

- Located near the throttle valve and is responsible for adjusting the idle speed

- Serves to dump sludge from the float chamber and is located at the very bottom of it

For people who do not have experience disassembling carburetors, it is recommended that they lay out the parts in a line in the order in which they were removed. This will greatly facilitate the process of assembling the unit and eliminate the appearance of “extra parts”.

When disassembling, the following is removed from the carburetor:

- float together with axle;

- locking needle;

- fuel jet (integrated with the idle emulsion tube);

- main fuel jet;

- emulsion tube of the main dosing system;

- float chamber cover gasket.

When disassembling the unit is completed, all internal parts should also be thoroughly washed. After this, the integrity of the parts is inspected, and if a defect is detected, the part is replaced. If the carburetor parts do not have defects and are not clogged with debris, then carburetor tattoos are not suitable for this engine.

Mopeds of the Brize Delta Dingo series.

A little about repair and operation. >> Carburetor repair Kovrov 2008

Contents :: Next >>

The carburetor serves to prepare a working mixture of gasoline and air in the most favorable proportion for various engine operating modes. The working properties (quality) of the mixture are determined by the proportion of gasoline and air in it. The ease of starting and stability of the engine depends on how well the mixture is prepared and fed into the cylinder.

Mainly, the quality of the mixture is determined by the design of the carburetor (it depends on how good the fuel is). Carburetor metering elements are selected for each engine type first by calculation, and then they are adjusted based on test results.

Before you start disassembling the carburetor, you need to stock up on reliable tools: screwdrivers with the appropriate pH...+...-, a sheet of white paper, and you also cannot do without a pump with a tip for inflating balls or a compressor with a tip for purging, and ideally a blowing gun with flushing. The procedure for removing the carburetor is as follows:

1. Unscrew the side closures

2. Clean the connection between the inlet pipe and the cylinder

3. Unscrew the bolts securing the inlet pipe from the cylinder (attention, there is a sealing gasket in this connection), then, pressing the lock ring, remove the carburetor diffuser air filter

4. Unscrew the throttle cover and remove it

5. close the intake manifold hole with a clean rag (to prevent sand and other mechanical particles from entering)

6. Disconnect the inlet pipe from the carburetor. Before disassembling, wash the outside of the carburetor. Unscrew the two bolts on the float chamber cover and remove it.

The axis on which the float swings is inserted without tension; remove the axis and place the float on a white sheet of paper. The toroidal shape of the float allows, with its minimal dimensions, to maintain a constant fuel level at different inclinations of the moped.

The locking needle, as in many (on some modern carburetors, the conical part of the locking needle has a rubber coating) carburetors, has the cone part precision-ground and fine-tuned, and the rod is spring-mounted on the rear.

A small part of resinous deposits or mechanical particles trapped between the seat and the conical part of the locking needle can cause the float chamber to overflow (needle retraction). The fuel will enter the intake manifold and from there into the combustion chamber. This can cause a lot of troubles, including water hammer (when there is only gasoline in the combustion chamber). To prevent such troubles, there is an overflow tube in the float chamber. When the fuel level reaches her level, she pours the excess into the drain fitting.

Unscrew the jets of the main dosing system, blow them and other channels of the dosing system. (It is strictly forbidden to clean channels and holes with toothpicks, matches, or metal objects).

Screw back the jets and insert the shut-off needle, then check the float level

The alloy line on the float should be parallel to the plane of the float chamber connector; if this is not the case, bend the tongue on the float (the float should not recess the spring rod of the locking needle).

Turn the carburetor over, the alloy line should be ~30-45 degrees relative to the float bowl connector.

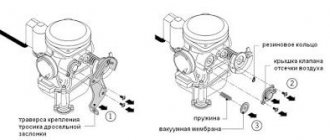

At the top of the carburetor there is a throttle valve, a return spring, and a spool rod.

The spool has grooves for adjusting the quality of the mixture (the lower the locking ring, the poorer the working mixture).

Contents :: Next >>

How to adjust the carburetor on an alpha moped

Beginning motorcycle enthusiasts often encounter the problem of incorrect carburetor calibration. This happens after replacing a unit or after long-term use. The usual setup can be done with your own hands in literally 10 - 15 minutes. While upgrading an incorrectly selected unit and increasing its performance (this often happens when buying a new carburetor happens at random), the matter is not simple and requires certain knowledge and skill.

And so, setting up a correctly selected or original carburetor occurs in several steps:

- The air filter is cleaned from dust and, if necessary, the spark plug is replaced, and you also need to check the integrity of all tubes and the reliability of their fastenings.

- The engine warms up to operating temperature and the quality of the combustible mixture is adjusted. In this case, screw the mixture quality screw to the maximum and unscrew it back about 1 turn. Next, you need to turn the idle speed screw until the engine begins to stably maintain speed at a normal level.

- Next you need to force the mixture to lean. To do this, the quality adjustment screw is unscrewed until the engine begins to operate intermittently. It is then screwed back in again until the motor runs normally and the motor is tuned.

- Checking the setting is done by sharply rotating the throttle. If the motor runs without interruption, then everything is done well. If, when you sharply press the gas, the engine begins to choke or stall, you will need to enrich the mixture a little more by rotating the corresponding screw.

Increasing carburetor performance on an alpha moped

Increasing carburetor performance is a whole complex of measures and everything happens approximately as follows:

- For better air supply, the factory air filter is replaced with a more efficient one. Next, you will need to bore the flow area of the diffuser using its boring tool.

- The main fuel jet is being replaced. For carburetors of this type, jets from a Solex car carburetor are ideally suited, and they are selected with a large bore. Note. Under no circumstances is it permissible to independently bore the nozzle holes to a larger diameter. Increasing productivity should only be done by replacing the part.

- Adjusting the position of the dosing needle. To improve performance, you can replace the metering needle with a more efficient one, allowing you to more accurately adjust the fuel supply at different speeds. But as a rule, replacing the needle on such carburetors is not very cost-effective. Therefore, it is enough to set it in a different position.

- Under ideal conditions, the idle jet must also be replaced with a more efficient one. But due to the fact that it is not always possible to find it. You can achieve the desired effect by adjusting the mixture quality screw.

- Increasing the diffuser passage opening. To better fill the cylinder at high speeds, you can slightly increase the cross-section of the unit. However, this procedure should be performed very carefully - if the hole is enlarged too much, the mixture formation rate in the low speed range may decrease.

It is worth mentioning right away that the factory carburetor settings assume maximum fuel efficiency. That is why, with standard settings, the consumption of a 110 cc engine does not exceed 2.5 liters per hundred. But such settings do not allow the engine to operate at full power (when driving at high speeds, the engine does not operate stably).

To treat some of the problems inherent in this type of technology, you can do the following:

To neutralize the “plug” effect on the tops, you can install a high-performance fuel jet. Together with an increase in the cross-section of the diffuser and a more efficient air filter, this will give a good effect.

Next, to dampen the dip in transition modes, you need to adjust the position of the metering needle relative to the throttle. You can raise the needle a little to get more fuel.

The final calibration is performed by working with the quality screw. Initially, you should unscrew it about 1.5 turns and start the engine. After warming up the engine, using the speed control screw, you need to adjust the rotation speed at 900 - 920 rpm. Then, by unscrewing the quality control, you need to get the maximum possible engine speed, after this speed adjustment screw you again need to bring the engine to 900 - 920 rpm.

Next, a test drive is made for approximately 5 - 7 km. And if necessary, adjustments are made.

A mixture is formed in the carburetor, which then enters the engine; it must be periodically adjusted. The composition comes in three types: normal (ratio 1:15), enriched and depleted. The quality of the connection is determined by the fuel to air ratio. An increase in the amount of air leads to a leaner mixture .

As a result of this, consumption can be minimized, but maximum power cannot be achieved. Reducing the amount of air leads to a richer mixture. With a ratio of 1:12.5 or 1:13, the engine is able to operate at maximum efficiency, but gasoline consumption increases significantly.

The delta moped carburetor is adjusted in the following order:

- The engine is pre-warmed. You can make adjustments after a trip, when the engine is already well warmed up.

- Before making adjustments, it is advisable to replace the spark plug, clean the air filter, look at the exhaust system and clean it. The carburetor channels must be washed and blown with air.

- The screw that regulates the quality of the mixture is tightened all the way and returned 1/2 turn back.

- The minimum stable rotation of the crankshaft is set by turning the idle screw. By turning the quality screw, the air ratio is increased until interruptions in engine operation begin.

- Using the idle screw, stable engine operation is restored.

- The quality screw is turned again. This reduces the rotation speed. The previous steps are repeated until a minimum stable crankshaft speed is obtained.

- The result of regulation is checked by closing the throttle. If the engine stops, the mixture must be leaner, and if it stalls, it must be enriched. Most often, the quality screw needs to be turned 1/4 or 1/2 turn.

It is also necessary to periodically check the condition of the damper to ensure there is no deformation. To do this, check the condition of the damper in the open and closed positions. In normal condition, the damper should be at an angle of 60°-70°.

Not only the performance of the engine, but also its power and fuel consumption depend on the correctly adjusted operation of the carburetor. Both rich and lean mixtures negatively affect engine wear, the frequency of replacing spark plugs, and the condition of the exhaust system. Correct carburetor regulation can be monitored by the condition of the spark plug.

If the candle is brown, then the mixture is normal, if it is black, the mixture is enriched and needs to be depleted to normal, if white, the mixture is lean and needs enrichment. A properly adjusted carburetor ensures minimal gasoline consumption without loss of engine power.

Carburetor for scooters/scooters/scooters/mopeds

The starting enricher is essentially an additional small carburetor standing parallel to the main one. It is connected to the main carburetor by three channels - air, emulsion and fuel, drilled in its body. The air is taken in before the throttle valve, the emulsion (mixture) is supplied after it, directly into the carburetor outlet pipe. Gasoline is taken from a common float chamber. Thus, with some stretch, the enrichment can be considered an independent device. It’s a stretch, because it is, nevertheless, structurally inseparable from the carburetor. Let's consider the design diagram of the starting enrichment plant (Figure 8).

Rice. 8

The carburetor has a small additional fuel chamber (7), which is connected to the main float chamber (8) through the start jet (9). The tube from the chamber (7) leads into the mixing chamber, into which air is supplied and from which the air-gasoline mixture flows into the engine. A flap (6) can move in the mixing chamber, similar to a carburetor throttle valve, only much smaller in size. Just like the throttle valve, the starting valve contains a spring-loaded needle that closes the fuel passage when the throttle is lowered.

When starting a cold engine, the throttle is raised (open). At the first engine revolutions, a vacuum is created in the emulsion channel and the gasoline in the chamber (7) is sucked into the engine, causing a strong enrichment of the mixture and facilitating the first flashes in the engine. After the engine has started, but has not yet warmed up, it needs a rich mixture. The enricher works like a parallel carburetor; gasoline enters it through a nozzle (9), mixes with air and enters the engine. When the engine is running, alternating current from the generator is always supplied to the contacts of the ceramic heater (2) of the thermoelectric valve of the starting system. The heater warms up the drive (3). Inside it, obviously, there is a gas or liquid boiling at a low temperature and a piston connected to a rod (4). When the actuator heats up, the rod gradually extends by 3-4 mm and, through the pusher (5), sets the damper in motion. The valve body (1) is wrapped in thermal insulation (polyethylene foam) and covered with a rubber boot. Thus, the engine warms up along with the thermoelectric valve and the mixture gradually becomes leaner. After 3-5 minutes, the damper closes completely and the degree of enrichment of the mixture on a hot engine is set only by the carburetor idle system. When the engine stops, heating of the valve stops, the damper drive cools down and, under the action of the spring (10), the pusher (5), rod (4) and damper (6) return to their original position, opening the channels for subsequent start-up. Cooling down and returning to its original position also occurs within a few minutes.

This enricher design is used on almost all modern scooters. Older models may use a design without an electric heater; heat is transferred to the drive through a copper heat-conducting cylinder directly from the engine cylinder. Sometimes, there is also a manual drive of the damper through a cable from the handle on the steering wheel (“Choke”).

Now let’s look at the “diseases” of this system.

1. The air channel may be clogged with dirt. In this case, the mixture becomes very rich, even after the engine has warmed up.

2. The jet (9) may be clogged with dirt. It is very thin and this happens quite often. In this case, the enricher works in the opposite way - it leans the mixture, making starting difficult.

3. Contact with the “thermoelectric valve” (2) of the heater is broken. The valve does not heat up and does not close. The engine runs all the time on an over-enriched mixture and does not develop the required power. The resistance at the valve contacts is easy to measure; it should be in the region of several ohms.

4. The antennae on the pusher (5) are broken, usually due to careless handling when removing the valve, and although the pusher moves, the valve is always closed, since it does not rest on it. Symptoms - as in point 3.

5. The drive (3) has failed. When heated, the rod does not extend or almost does not extend. Symptoms - the same as in point 3. Checked by heating the actuator assembled with the valve or separately, for example with boiling water. The drive cannot be repaired.

Spool

It is sometimes called an air damper. Its purpose is to maintain a constant vacuum in the mixing chamber (diffuser) at various engine speeds and loads. It consists of the spool itself with a membrane and a metering needle, see photo 9.

Photo 9

It works like this. The membrane divides the space under the spool cover (screwed with two screws on top of the carburetor) into two parts: the upper one, connected by a special channel to the diffuser, and the lower one, located at the carburetor inlet. When the motor is running, a vacuum begins to form in the diffuser. While it is small, nothing happens. When it reaches a threshold value sufficient to overcome the weight of the spool and the force of the spring pressing it, the spool goes up, opening a wider path for air entering the carburetor, which reduces the vacuum in the diffuser. So it (the vacuum) balances around the value that is best for engine operation, and the spool moves up and down, ensuring its constancy.

The dosing needle, mounted on the spool, with its sharp end looks into the emulsion tube of the main dosing system, partially blocking it. The higher the needle is currently located, the less this overlap, the more gasoline flows and the richer the mixture, i.e. the needle enriches the mixture the more, the higher the spool is raised. Within small limits, the composition of the mixture can be adjusted by moving the needle locking ring along the grooves. The lower it is, the richer the mixture.

Acceleration pump.

As the name suggests, this is a regular pump with a check valve, like a bicycle or car pump, only very small. When you turn the throttle valve connected to the gas handle, a special lever presses on the pump rod. The pump does not respond to slow presses (like a bicycle pump, for example, if you do each pump for five minutes), but when pressed sharply, it spits out an additional portion of gasoline into the diffuser, which makes it easier to accelerate the engine and, accordingly, improves the dynamics of the scooter.

Debriefing, or Adjusting the carburetor unit of the Alpha moped

After the moped has been run-in, a full cycle of technical inspection is carried out, which includes changing the oil in the transmission and engine, as well as adjusting the valve clearance. In addition, the manufacturer recommends replacing the air filter element. During operation, disturbances in dynamics are possible, requiring individual adjustment of the carburetor on an Alpha moped. Qualified adjustment of this unit will improve driving performance and help reduce fuel costs. This operation is similar to adjusting the carburetor on a scooter and will not cause much trouble for both beginners and experienced motorcyclists.

Causes of malfunction

You can determine that the carburetor is overflowing by several signs:

- Condition of the candle. A dirty spark plug indicates a rich fuel mixture, which means high gasoline content. Even a serviceable or new spark plug may not be able to cope with the flow of fuel entering the cylinder and over time it will become covered with soot, will be constantly wet and the engine will stop starting.

- Gasoline leaks through the air filter. Signs of fuel may be found in the air filter housing.

- Gasoline leaks through the float chamber gasket.

It is worth noting that these signs can appear either on their own or after repairs. For what reasons can the carb overflow?

Failure of the fuel valve

The tanks are equipped with vacuum fuel taps with three outlets. One of them is taking fuel from the tank, the other is supplying fuel to the carburetor. The third outlet is intended for supplying a vacuum hose. When a vacuum is created in the engine, the valve membrane begins to pump fuel.

Advice! If the engine does not start after a long period of inactivity (fuel is not pumped in), in order not to wait for the engine to pump it in, you can remove the vacuum hose on the other side of the tap and create a vacuum with your mouth until the carburetor is filled.

Clogged air filter

Air filter on a scooter

If there is insufficient air supply, the scooter may also overflow fuel. You can diagnose the filter for air permeability as follows. Simply disconnect the air filter. If the engine now starts to work correctly, then it is necessary to change the air filter. When the carburetor on a scooter without a filter still floods, “dig deeper”!

Signs that require an urgent check of the carburetor

Most motorists know the principle of operation of the carburetor unit and the necessary conditions for its stable operation. The main indicator for the full functioning of the engine is the composition of the combustible mixture, which should consist of 15 parts air and 1 part gasoline. Violation of the ratio leads to enrichment or, conversely, to depletion of the composition.

The main signs of a lean mixture:

- instability XX;

- difficult starting;

- popping sounds in the carburetor;

- the engine does not gain momentum;

- white carbon deposits on the candle.

Signs of over-enrichment of the combustible mixture:

- increased fuel consumption;

- candle covered in soot;

- popping sounds in the exhaust pipe;

- slow acceleration.

What is the need?

In order to prevent parts from wearing out too quickly, it is important to select the correct mixture at idle, at full throttle and in modes when the throttle is not fully open. What should make the owner think about adjusting the carburetor of the Alpha moped in these modes? Violation of the ratio of air and gasoline. Ideally, it should correspond to 1:15, where there is only 1 part of gasoline. Signs of a violation may include:

- Difficulty starting the engine.

- Any instability in idle speed can be heard as irregular engine operation.

- When you turn the throttle all the way, the engine does not rev up and accelerates slowly.

- Popping sounds in the carburetor or exhaust pipe.

- Candle color is white or black.

Adjustment procedure

Proper engine operation depends on compliance with operating rules and strict compliance with technical inspection requirements. Before you start setting up the carburetor on the Alpha moped, you need to first carry out a number of works:

- Clean the carburetor body.

- Replace the spark plug.

- Replace the air filter.

- Make sure the connections are tight.

Now you need to accurately set the gasoline level in the float chamber by bending the float tongue. By connecting a transparent hose to the drain fitting, it is possible to determine the absolute fuel level. To do this, the hose is lifted up. Typically the height is at the junction of the carburetor caps.

The next step is to adjust the idle speed system using quantity and quality screws. The whole process takes place on a warm engine. The quality screw is screwed in until it stops and then unscrewed two turns. Start the engine and, by rotating this screw in both directions, achieve maximum speed. Then use the quantity screw to reduce the speed to the minimum stable speed. It is possible that the procedure may need to be repeated several times until the desired result is achieved.

Adjustment of the middle speed range occurs by raising or lowering the needle. To do this, you need to unscrew the throttle nut, remove the needle and move the corkscrew into one of the grooves: above the middle division to lean the mixture and below to enrich it.

High-quality engine operation at high speeds is ensured by the size of the main jet

. Therefore, setting up the carburetor on an Alpha moped will be completed only after selecting the appropriate jet number. If the carburetor produced a lean composition, then it is worth installing a part with a higher throughput. To lean the mixture, you need to do exactly the opposite - set a lower number.

You can check the accuracy of the settings by inspecting the spark plug insulator. If it is light or brown in color without carbon deposits, then the system is adjusted normally. If the threads and insulator of the spark plug are smoked with black soot, the mixture should be adjusted to medium speed.

How to adjust the carburetor on an Alpha moped

Most mopeds have a very simple carburetor design; it is also located in a convenient location, which makes it possible to quickly adjust. And if you are the owner of an Alfa moped and the like, this guide is about how to set up a carburetor on an Alfa moped for you.

Carburetor adjustment is necessary for most mopeds, because over time, precise settings are lost, and it becomes necessary to improve idle speed or fuel consumption. This need may arise when the Alpha moped begins to function incorrectly, producing a completely different fuel mixture. The standard ratio of gasoline to air should be 1 to 15. Deviation from the norm leads to the mixture becoming richer or leaner.

When a rich mixture forms, you will experience the following symptoms:

- frequent popping noises in the exhaust pipe;

- weak acceleration dynamics;

- high fuel consumption.

Signs of a lean mixture include:

- the presence of white carbon deposits on the candle;

- difficulty starting the engine;

- poor idle speed;

- inability to increase speed.

If you do not know how to adjust the carburetor on an alpha 50 or 110 cc moped, perform all the steps in sequence, but before doing this, make sure that the engine is properly warmed up. After this, you will have to perform the following steps to fine-tune the carburetor:

- replace or clean the air filter;

- check the spark plug;

- clean the surface of the carburetor from dirt;

- Check all hoses and connections for leaks.

How to properly adjust the carburetor on an alpha moped

Step 1. Setting the mixture quality. The Alpha moped has a special screw for this, which must first be fully tightened and unscrewed a maximum of 1 turn. Next, we find the idle speed screw and rotate it until the moped begins to operate stably at normal speeds. The next stage is to lean the mixture; after idling, you will have to slightly unscrew the mixture quality screw until the engine begins to work poorly intermittently.

Step 2. We made the mixture lean, but we need to fix this; to do this, we enrich the mixture with the idle screw, tightening it. The adjustment continues until the motor starts working normally and without interruption. You can check that the carburetor of the Alpha moped is adjusted by pressing the gas handle. If, when it is opened abruptly, the engine immediately stalls or choke, you will have to enrich the mixture by slightly unscrewing the mixture quality screw.

Soot contamination

Type of spark plug: dry soft soot of intense black color on the insulator, electrodes and spark plug body.

Consequences: poor start of the scooter engine; poor operation of a cold scooter engine; interruptions in ignition of the air-fuel mixture; bad reaction to gas.

Probable causes: excessively rich air-fuel mixture; The scooter's air filter is very clogged; The thermal range is incorrectly selected - the candle is too “cold”.

Remedy: adjust the working mixture; adjust the cold start system of the scooter engine; change the scooter air filter; clean the spark plugs or replace them with new ones - with the correct heat rating.

Overheat.

Plug Type: Extremely white insulator with small black flecks and premature electrode erosion.

Consequences: loss of scooter power at high speed or under load.

Probable causes: the spark plug is not screwed in enough; The scooter's engine cooling system is not working properly; ignition of the scooter too early; The thermal range is incorrectly selected - the candle is too “hot”.

Remedy: check the torque of the scooter's spark plug; operation of the scooter engine cooling system; adjust the ignition timing; select the correct spark plug heat rating.

Type of spark plug: melted and burned central and grounding electrodes (or one of the electrodes) of the scooter spark plug; bubbling insulator with metal deposits on it.

Consequences: significant loss of scooter engine power; ignition interruptions. Continued use of such spark plugs may cause serious damage to the scooter engine.

Probable causes: thermal overload; significant overheating of spark plug parts due to glow ignition - combustion begins before a proper ignition spark appears; use of low-quality fuel; burning out of the remaining air-fuel mixture in the combustion chamber due to an incorrectly adjusted fuel system of the scooter or the ignition timing of the scooter; The thermal range is incorrectly selected - the spark plug is too “hot”.

Remedy: check the scooter engine, ignition system and fuel system, as well as the quality of the working mixture and the ignition timing of the scooter. Install new spark plugs with the correct heat rating.

Trouble-shooting

What to do if you had to face such problems? Let's go in order. You need to start with the air filter - if there are no problems with it, then proceed to the next steps.

Fuel tap problem?

If gasoline constantly flows from the fuel supply hose, even when the vacuum hose is removed, then the valve is faulty. It simply does not work, but is always in the open position. In this case, the tap must be replaced with a new one.

If, when you remove the vacuum hose, gasoline stops flowing, then the reason is a constant vacuum - you need to climb into the cylinder head.

Locking needle

Provided the faucet is in good working order, you can play the shut-off game. How to get to the needle of a scooter or moped?

- To remove the carburetor, you need to disconnect the air filter; hoses suitable for it; unscrew it from the intake manifold and remove the throttle cable.

- Next, use a Phillips screwdriver to remove the float chamber housing.

- Assess the condition of the shut-off needle and float antennae.

- If necessary, replace the needle and bend the float antennae. If the needle is in good condition, then its seat should be thoroughly washed and blown out.

- Reassemble everything and install it on the engine.

This is what the carburetor looks like with the cover removed

To remove the locking needle, you need to unscrew it

Carburetor purging

Vacuum accelerator (if all else fails)

In addition to the locking needle, Chinese scooters are also equipped with a vacuum needle (vacuum accelerator). This device also works from a vacuum hose connected to the “carb”. This needle has 5 (usually) adjustment positions. When the scooter accelerates, the vacuum opens this needle and more fuel is supplied to the combustion chamber.

Vacuum accelerator in a Chinese scooter

The system is correct, however, everything breaks down. Over time, none of the needle positions produces results. This problem can be solved simply by removing or cutting the vacuum hose (not the one to the fuel tap)! And the engine no longer overflows - miracle of miracles.

Oil contamination

Type of spark plug: wet oily black deposits on the insulator, black oil deposits on the insulator, electrodes and spark plug body.

Consequences: poor start of the scooter engine, interruptions in ignition.

Probable causes: too much oil in the fuel mixture (for two-stroke engines); wear of the rings and/or piston liner - wastes oil.

Remedy: mix gasoline and oil in the correct proportion, install new spark plugs for the scooter (for two-stroke engines); inspect the condition of the scooter engine, if necessary, repair the engine, CPG; .

How to adjust the carburetor on an Alpha moped

Most mopeds have a very simple carburetor design; it is also located in a convenient location, which makes it possible to quickly adjust. And if you are the owner of an Alfa moped and the like, this guide is about how to set up a carburetor on an Alfa moped for you.

Carburetor adjustment is necessary for most mopeds, because over time, precise settings are lost, and it becomes necessary to improve idle speed or fuel consumption. This need may arise when the Alpha moped begins to function incorrectly, producing a completely different fuel mixture. The standard ratio of gasoline to air should be 1 to 15. Deviation from the norm leads to the mixture becoming richer or leaner.

When a rich mixture forms, you will experience the following symptoms:

- frequent popping noises in the exhaust pipe;

- weak acceleration dynamics;

- high fuel consumption.

Signs of a lean mixture include:

- the presence of white carbon deposits on the candle;

- difficulty starting the engine;

- poor idle speed;

- inability to increase speed.

If you do not know how to adjust the carburetor on an alpha 50 or 110 cc moped, perform all the steps in sequence, but before doing this, make sure that the engine is properly warmed up. After this, you will have to perform the following steps to fine-tune the carburetor:

- replace or clean the air filter;

- check the spark plug;

- clean the surface of the carburetor from dirt;

- Check all hoses and connections for leaks.

How to properly adjust the carburetor on an alpha moped

Step 1. Setting the mixture quality. The Alpha moped has a special screw for this, which must first be fully tightened and unscrewed a maximum of 1 turn. Next, we find the idle speed screw and rotate it until the moped begins to operate stably at normal speeds. The next stage is to lean the mixture; after idling, you will have to slightly unscrew the mixture quality screw until the engine begins to work poorly intermittently.

Step 2. We made the mixture lean, but we need to fix this; to do this, we enrich the mixture with the idle screw, tightening it. The adjustment continues until the motor starts working normally and without interruption. You can check that the carburetor of the Alpha moped is adjusted by pressing the gas handle. If, when it is opened abruptly, the engine immediately stalls or choke, you will have to enrich the mixture by slightly unscrewing the mixture quality screw.

Adjusting the carburetor of a 4T moped

The article discusses the procedure for adjusting the carburetor of a 4T moped.

Let's consider the adjustment using the example of a KEIHIN carburetor, which is often installed on Chinese-made 4T mopeds with a 139FMB engine and similar ones. It should be noted that this technique is suitable for adjusting most carburetors used on scooters and mopeds.

A little theory before we start

The fuel mixture is a mixture of gasoline and air composed in a certain proportion. The fuel mixture is divided into normal, enriched, rich, lean and lean. The given types of mixture, as mentioned, are determined by the proportions (weight ratio) of gasoline and air. A lean and rich fuel mixture is a composition in which the ratio of components is such that this mixture is ineffective.

Normal is a mixture in which gasoline and air are bound in a weight ratio of 1:15. When the engine operates on such a mixture, the power is 4-5% lower than the maximum, and fuel consumption is approximately the same amount higher than the minimum possible.

The engine develops the greatest power when running on a rich mixture, in which this ratio varies from 1:12.5 to 1:13. In the case when it is necessary to achieve the greatest efficiency, the amount of air increases to 16-16.5 kg per 1 kg of gasoline (lean mixture).

With a further increase in the air content in the mixture, it becomes increasingly leaner and soon becomes ineffective. If the air content in the mixture is reduced, then at a ratio from 1:12.5 to 1:6.5 (rich mixture), the engine “pulls poorly” due to a large loss of power and does not operate economically.

Carburetor adjustment

Let's move directly to adjusting the carburetor.

Carburetor adjustment is performed with the engine fully warmed up. Adjustments should be made either outdoors or in a well-ventilated area.

Before making adjustments, you must make sure that the carburetor is in good working order, not clogged, and that the fuel level in the float chamber is acceptable. The fuel needle is usually set to the middle mark.

The carburetor, on the example of which we will carry out adjustments, has two adjusting screws - “Quality Screw” and “Quantity Screw”. The first is to regulate the composition of the mixture, the second is the engine speed at idle.

1. The “mixture quality” screw is turned clockwise all the way until it stops and then turned out 1/2 or 1 turn counterclockwise.

2. Using the “quantity” screw (idle speed screw), we achieve the minimum engine speed at which it operates stably.

3. By rotating the “quality” screw counterclockwise, we find the position at which the engine begins to operate intermittently.

4. Using the “idle speed” screw, we again achieve the minimum speed at which the engine runs stably.

Operations 3 and 4 should be repeated several times.

You can determine whether the adjustment is correct by sharply opening and closing the throttle (rotating the throttle). If the engine stalls when the handle is sharply unscrewed, then the “quality” screw should be turned clockwise 1/4 - 1/2 turn, enriching the mixture. If the engine stalls when the throttle is suddenly closed, then the “quality” screw should be turned counterclockwise by 1/4 - 1/2 turn, leaving the mixture lean.

Checking the correct carburetor settings

You can check the correct carburetor adjustment by looking at engine operation and a number of signs, including the condition of the spark plug.