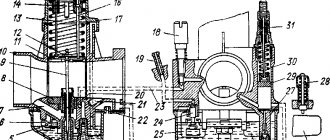

The design of a scooter carburetor is quite simple; Once you understand it, you will be able to understand how to properly configure the carburetor so that the vehicle does not let you down in bad weather, how you can tune it and improve the performance of the engine. You will be able to control the quality of the mixture and many other processes that affect the operation and operation of the device.

Purpose and principle of operation of the carburetor

The carburetor is an important component of an internal combustion engine, responsible for preparing the air-fuel mixture and supplying it to the working cylinder in the required ratio. A scooter engine with an unadjusted carburetor cannot function properly. The stability of speed, the power developed by the engine, gasoline consumption, response to turning the throttle, as well as ease of starting in the cold season depend on the correct settings of the engine power supply.

An important component of an internal combustion engine is the carburetor.

This unit is responsible for preparing the air-gasoline mixture, the concentration of the components of which affects the nature of the operation of the power plant. The standard ratio is 1:15. Leaning the mixture to a ratio of 1:13 ensures stable engine operation at idle. Sometimes it also becomes necessary to enrich the mixture by maintaining a ratio of 1:17.

Knowing the structure of the carburetor and knowing how to adjust it, you can ensure stable operation of the engine on two-stroke and four-stroke scooters.

Thanks to a properly configured carburetor, easy and quick starting of the vehicle engine is ensured, as well as stable operation of the engine, regardless of the ambient temperature. Any carburetor is equipped with jets with calibrated holes, a float chamber, a needle that regulates the cross-section of the fuel channel, as well as special adjusting screws.

The adjustment process involves specially rotating the screw in a clockwise direction or in the opposite direction, which causes, respectively, the enrichment or depletion of the working mixture. Adjustment measures are carried out on a warmed-up engine. In this case, the carburetor unit must first be thoroughly washed and cleared of blockages.

How to check for leaks?

The fuel supply hose is placed on the inlet channel of the measuring device. Then the tap opens, if there is one. Next, a certain amount of air is pumped into the carburetor cavity using a bulb. In this case, the pressure gauge should show at least 0.4 bar. If after a while the pressure remains the same, then you have a working Walbro carburetor. Repair is necessary if the pressure drops. There could be several reasons for this.

This is a faulty fuel pump diaphragm. It may be damaged. Holes or tears appear on it. The malfunction is eliminated by replacing the membrane with a new one from the repair kit.

Why do you need to regulate?

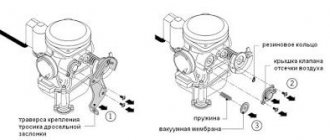

During the adjustment process, the scooter carburetor needle is adjusted, the position of which affects the proportions of the air-fuel mixture, as well as a number of other adjustments.

Adjusting the scooter carburetor needle is done during the adjustment process

Each tuning operation has a different effect on engine operation and fuel preparation:

- adjusting the idle speed ensures stable operation of a running engine when the transmission is turned off;

- changing the quality of the air-gasoline mixture using a special screw allows you to deplete or enrich it;

- adjusting the position of the carburetor needle affects the change in the quality of the fuel mixture;

- Ensuring a stable level of gasoline inside the float chamber avoids flooding of spark plugs.

A power unit with an adjusted carburetor operates stably in any conditions, is economical, throttle response, develops rated power and maintains speed, and does not cause problems for its owner.

Signs that adjustment is needed

Based on certain signs that appear in abnormal engine operation, we can conclude that the carburetor needs adjustment.

The list of deviations is quite wide:

- the power plant does not develop the required power under load;

- when the scooter accelerates sharply, failures in engine operation are felt;

- a cold engine is difficult to start with the starter after a long period of parking;

- the scooter's power unit consumes fuel in increased quantities;

- there is no quick response of the engine to a sharp turn of the accelerator handle;

- The engine may suddenly stop due to insufficient fuel mixture.

The carburetor should be adjusted if there are signs that adjustment is necessary.

If one or more of these symptoms is present, you should adjust the carburetor, and then diagnose its condition and check the operation of the engine.

Inlet and outlet valve

This problem may occur in the fuel pump.

The fact is that the valve petals lose their “flatness”. They no longer press against their supporting planes, and the tightness is broken. The result is a loss of pump performance. It no longer pumps fuel in the required quantity. Why does this happen? Everything is very simple. The owner used the saw for a long time with a fuel other than that recommended by the manufacturer Walbro. Because of this, the carburetor often overheated. As a result of such a malfunction, the mixture is prepared too lean and the engine is poorly lubricated. This can lead to more serious problems. These are scuffing in the cylinders, problems with starting, unstable operation of the unit in all modes. Also among the problems with the fuel pump are deformation of the membrane in the area of the pulse chamber, contamination and slag. Many carburetor symptoms are often associated with clogs. Cleaning and rinsing can restore the device's functionality. There is a special spray for this.

How to adjust engine idle speed

Work on setting up the power system is carried out after the engine has warmed up to operating temperature. All types of carburetors installed on scooters are equipped with a screw designed to regulate idle speed. Changing the position of the adjusting element allows you to ensure that the engine operates at stable speeds during idling.

Depending on the vehicle model, the adjusting elements are located in different places, so you need to carefully study the instructions and determine where the idle speed adjustment screw is located on the scooter.

Rotating the screw in a clockwise direction allows you to increase the crankshaft speed. Turning in the opposite direction, accordingly, ensures a decrease in speed. To perform adjustment operations, it is necessary to warm up the power unit of the scooter for a quarter of an hour.

Setting the engine idle

Then the screw is screwed in or unscrewed until a stable and precise speed of rotation of the vehicle engine is achieved. The adjustment is made in small increments by smooth rotation. After each manipulation, the engine should be run for several minutes to stabilize the speed.

The principle of operation of the carburetor

The carburetor can be either purely mechanical or incorporating electronics, but the operating principle does not change. When the engine is running, a reduced pressure is created in the combustion chamber, and air is drawn into the engine, cleaned by the air filter. Gasoline is sprayed into this air stream, turning into something similar to an aerosol. The fuel mixture enters the combustion chamber, where it is ignited by a spark and moves the piston. The cycle repeats.

For smooth engine operation, the fuel mixture must be optimal. It is important to consider not only the model of your two-wheeled friend, but also climatic conditions and engine wear. The carburetor installed on a moped always supplies the same portion of fuel, regardless of the speed gained and the time of year. You will have to adjust the device manually.

There is no need to do this often. But if you are lazy, the consequences can be unpleasant: increased fuel consumption, faulty spark plug, engine wear due to overheating. To prevent this from happening, you need to monitor the condition of the scooter. If the engine begins to “overeat”, it is difficult to start, and black smoke comes out of the exhaust pipe, it is worth checking. It may be time to properly tune the carburetor, although other systems may be the problem.

Idle speed adjustment

When idling, the engine runs normally but does not use fuel to keep the wheels spinning. When you press the throttle, a choke in the carburetor rises, preventing the fuel mixture from flowing. The higher the damper, the more fuel will have time to enter the combustion chamber. Accordingly, at idle speed, the fuel mixture entering the chamber is only enough to prevent the scooter from stalling. If the adjustment does not work correctly, then at idle speed the engine will consume more gasoline than necessary. But gasoline still costs money. In addition, this causes the engine to overheat.

There is an idle air adjustment screw on every carburetor; all you have to do is find it and select the appropriate screwdriver. The exact location of the screw for your model can always be found on the Internet. For example, adjusting the carburetor on a Honda Dio scooter takes place without any problems. In its original carburetor, the idle speed adjustment screw is in the center, and the mixture quality screw is on the left. But on a Chinese moped, most likely, there is a carburetor with a single screw, which is responsible for adjusting the idle speed. The sequence of actions will not cause difficulties:

Adjusting the mixture quality

When the fuel mixture in the cylinder burns, the ratio of gasoline to oxygen must be strictly 1/15. Unfortunately, the carburetor cannot know exactly how much oxygen is in the air. For example, there is much more of it in cold, winter air, and if the carburetor was adjusted in the summer, the spark plug may be flooded.

Anyone can tell a rich mixture from a poor one. If the spark plug electrodes are white and slightly melted, then it is a lean mixture. It burns completely, but produces too high a temperature. The rich fuel mixture does not burn completely, the chamber and exhaust become clogged with carbon deposits. Black smoke is coming from the chimney. In addition, there is excessive consumption of gasoline.

To adjust the mixture quality:

This may not be enough. In this case, adjusting the carburetor needle will help.

Adjusting the fuel level in the float chamber

Let's say we want to adjust the carburetor on an alpha moped because it floods the spark plug. Let's figure out what's going on. From the float chamber, gasoline is supplied to the air flow, where it is mixed with oxygen. If the fuel level in the chamber is higher than required, the fuel mixture may flood the spark plug. Gasoline will get onto the contacts of the electrodes, ignition will not occur and our Alpha 72 cube will stall.

The fuel level is automatically adjusted by a float in the chamber. When gasoline decreases, the float lowers and opens the valve from which new fuel flows. To check if it is working correctly, you need to take the jet coming from the bottom and bring it to the top. If the gasoline continues to flow, it means that the carburetor is overflowing fuel.

The reasons may be different:

Speed blocks in the carburetor

There may be another, even stranger problem. Since many manufacturers strive to limit the speed of their scooters in order to comply with environmental laws in Europe and Japan, interesting modifications can be found in the design of scooters. Interestingly, this mostly applies to expensive brands, but Orion is also found on Chinese mopeds, for example.

Mechanics find a “bump stop” in the float chamber. It shuts off the fuel supply when the pressure reaches the limit set by the manufacturer. Thus, the scooter cannot accelerate to its maximum speeds. The bump stop will need to be removed.

In another case, the throttle valve may be slightly longer than necessary. It blocks the air flow even when raised up. The scooter again cannot accelerate. The damper can be ground off, but if you overdo it, your two-wheeled friend will lose idle speed. However, this kind of trick is typical mainly for Chinese mopeds. It is much more likely to find such a plug in 139 gmb than in an expensive Japanese brand, where the block is installed in the electronics, and a carburetor is not used.

How to change the quality of the fuel mixture

For all scooter engines, it is important to receive fuel with an adjusted ratio of gasoline to air. A lean mixture leads to improper operation of the engine, a drop in power and overheating of the engine, while a rich mixture leads to an increase in consumption and the formation of soot.

Adjustment operations are performed by changing the position of the quality screw and moving the throttle needle.

Turning the screw to the right causes the mixture to become richer, and unscrewing in the opposite direction causes it to become leaner. The same happens with the needle: when the needle is raised, the mixture becomes richer, and when lowered, it becomes poorer. The integrated use of both methods allows you to achieve optimal results during setup. However, not all carburetors have this feature, so, as a rule, one of two options is used.

Setting the gasoline level and the correct position of the float in the chamber

A correctly adjusted fuel level in the float chamber does not allow the spark plugs to get wet and the engine to stall. In the chamber where the floats and jets are located, there is a valve that provides fuel supply. The correct position of the floats determines the closing or opening phase of the valve and prevents fuel overflow in the carburetor. The position of the floats is changed by slightly bending the fastening bar.

The closing or opening phase of the valve is determined by the correct position of the floats

Gasoline level is monitored with the engine running using a tube made of transparent material attached to the drain point and raised up. The gasoline level should be a few millimeters below the flange mounting of the cover. If the level is insufficient, remove the cover and adjust the needle firing phase by slightly bending the metal antennae.

Medium and high speed tuning

Using the quality adjustment screw, the fuel proportions at idle speed are ensured. For medium and high rotation speeds, the engine operating mode is adjusted using a different method. After turning the gas handle, the fuel nozzle starts working, supplying gasoline to the diffuser. An incorrectly selected jet cross-section causes a deviation in the fuel composition, and the engine may stall when gaining power.

To ensure uninterrupted operation of the motor at a higher frequency, it is necessary to perform a number of operations:

- remove debris from internal cavities;

- set the gasoline level in the carburetor;

- adjust the operation of the fuel valve;

- check the cross-section of the jet.

The correct operation of the engine is indicated by its quick response when turning the throttle.

A quick response when turning the throttle indicates proper engine operation.

How to set up a carburetor on a scooter - features for the 2t model

Adjusting the carburetor of a two-stroke scooter differs from adjusting the power system of four-stroke engines. Most two-stroke engines are equipped with a simple carburetor with a mechanical enricher, the trigger of which is pulled before starting the device. Scooter owners call the starting enrichment a choke; it is closed after the engine warms up. To adjust, the power system is disassembled, the needle is pulled out and mechanical intervention is carried out in the fuel chamber. Further adjustment is carried out in the same way as for four-stroke engines.

Testing operation after setup

It is necessary to check how the Walbro carburetor works. The adjustment may not give the desired result. For testing, start the engine, warm it up and gently press the accelerator. If as a result the revolutions increase to the maximum, then everything is working correctly. If this does not happen, screw L is turned counterclockwise 1/8 turn. The maximum engine speed of a chainsaw is approximately 11.5 thousand revolutions per minute. If their number is higher, this may cause problems in the ignition system. In case of malfunctions, screw H is turned counterclockwise, thereby reducing the maximum speed.

Setting up the carburetor on a 4t scooter - important points

Setting up the carburetor on a four-stroke scooter is easy to do on your own and is not difficult for motorcyclists. Setting up the carburetor of a 4t 50cc scooter (China) requires certain skills and patience and is performed according to the above algorithm. It is possible that the manipulations will have to be repeated many times until the desired result is achieved. If the carburetor setting on a 4t 139 qmb scooter or a similar model with a different engine is done correctly, the engine will operate stably.

It will be able to start regardless of the ambient temperature and the piston group in the engine will wear out less.

What is the carburetor of a Chinese scooter and its capabilities, disadvantages, tuning

The carburetor circuit of a Chinese scooter is, in principle, standard and suitable for both 2t and 4t engines. The design of the carburetor allows certain actions to be taken to improve its performance, however, if the engine is two-stroke, the efforts will not make sense.

The simplest approach is to replace the carburetor with a more advanced one, for example, with an accelerator motor, if you have a fairly old version without it. Most often, simple tuning is limited to replacing the main fuel jet, this is especially true for engines with low power. Replacing the nozzle helps to increase the fuel channel and, due to this, add a little power to the engine.

Quite often, more serious tuning involves the use of a 150 cc scooter carburetor. Interesting models with a diffuser diameter of 17.5 mm. It is great for 70cc piston. Less often you come across a large diameter of 19-24 mm, it is just ideal for a bored 150 cc piston engine. However, the diameter must be selected correctly, otherwise the motor will begin to choke.