For the proper operation of any engine based on the principle of internal combustion, optimal dosing of the air-fuel mixture (FA) is important. If the balance of the ratio is disturbed, the equipment begins to malfunction.

Even the most precise mechanisms require periodic adjustments. Adjusting the carburetor on a Chinese scooter is not a frequent procedure, but it is necessary for the proper functioning of the equipment.

Purpose and principle of operation of the carburetor

The carburetor is an important component of an internal combustion engine, responsible for preparing the air-fuel mixture and supplying it to the working cylinder in the required ratio. A scooter engine with an unadjusted carburetor cannot function properly. The stability of speed, the power developed by the engine, gasoline consumption, response to turning the throttle, as well as ease of starting in the cold season depend on the correct settings of the engine power supply.

An important component of an internal combustion engine is the carburetor.

This unit is responsible for preparing the air-gasoline mixture, the concentration of the components of which affects the nature of the operation of the power plant. The standard ratio is 1:15. Leaning the mixture to a ratio of 1:13 ensures stable engine operation at idle. Sometimes it also becomes necessary to enrich the mixture by maintaining a ratio of 1:17.

Knowing the structure of the carburetor and knowing how to adjust it, you can ensure stable operation of the engine on two-stroke and four-stroke scooters.

Thanks to a properly configured carburetor, easy and quick starting of the vehicle engine is ensured, as well as stable operation of the engine, regardless of the ambient temperature. Any carburetor is equipped with jets with calibrated holes, a float chamber, a needle that regulates the cross-section of the fuel channel, as well as special adjusting screws.

The adjustment process involves specially rotating the screw in a clockwise direction or in the opposite direction, which causes, respectively, the enrichment or depletion of the working mixture. Adjustment measures are carried out on a warmed-up engine. In this case, the carburetor unit must first be thoroughly washed and cleared of blockages.

Results

Despite all the difficulties and apparent complexity of the device, adjusting the carburetor on a scooter is possible both at home and in the field. It is recommended to carry it out at least once a season, especially during frosts - this will avoid flooding the candle. If your old engine starts to feel bad, adjusting the carburetor can extend its life. Although the moped will lose a little power. And yet, with the help of proper carburetor settings, you can make life much easier for yourself and your iron horse.

Most mopeds have a very simple carburetor design; it is also located in a convenient location, which makes it possible to quickly adjust. And if you are the owner of an Alfa moped and the like, this guide is about how to set up a carburetor on an Alfa moped for you.

Carburetor adjustment is necessary for most mopeds, because over time, precise settings are lost, and it becomes necessary to improve idle speed or fuel consumption. This need may arise when the Alpha moped begins to function incorrectly, producing a completely different fuel mixture. The standard ratio of gasoline to air should be 1 to 15. Deviation from the norm leads to the mixture becoming richer or leaner.

When a rich mixture forms, you will experience the following symptoms:

- frequent popping noises in the exhaust pipe;

- weak acceleration dynamics;

- high fuel consumption.

Signs of a lean mixture include:

- the presence of white carbon deposits on the candle;

- difficulty starting the engine;

- poor idle speed;

- inability to increase speed.

If you do not know how to adjust the carburetor on an alpha 50 or 110 cc moped, perform all the steps in sequence, but before doing this, make sure that the engine is properly warmed up. After this, you will have to perform the following steps to fine-tune the carburetor:

- replace or clean the air filter;

- check the spark plug;

- clean the surface of the carburetor from dirt;

- Check all hoses and connections for leaks.

How to properly adjust the carburetor on an alpha moped

Step 1. Setting the mixture quality. The Alpha moped has a special screw for this, which must first be fully tightened and unscrewed a maximum of 1 turn. Next, we find the idle speed screw and rotate it until the moped begins to operate stably at normal speeds. The next stage is to lean the mixture; after idling, you will have to slightly unscrew the mixture quality screw until the engine begins to work poorly intermittently.

Step 2. We made the mixture lean, but we need to fix this; to do this, we enrich the mixture with the idle screw, tightening it. The adjustment continues until the motor starts working normally and without interruption. You can check that the carburetor of the Alpha moped is adjusted by pressing the gas handle. If, when it is opened abruptly, the engine immediately stalls or choke, you will have to enrich the mixture by slightly unscrewing the mixture quality screw.

This way we will get a properly tuned carburetor. In turn, this affects fuel consumption, engine power and smooth operation. If the carburetor is stable, the engine will be able to produce full power. In some cases, it is impossible to adjust the carburetor of an Alpha moped yourself, but specialists do the procedure in 10-20 minutes.

—> Sources used:

- https://topkarting.ru/kak-nastroit-i-otregulirovat-karbjurator-na-skutere.html

- https://scoteram.ru/obsluzhivanie/kak-otregulirovat-karbyurator-na-skutere.html

- https://avtomoto-best.ru/kak-nastroit-karbjurator-na-mopede-alfa.html

Why do you need to regulate?

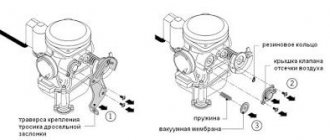

During the adjustment process, the scooter carburetor needle is adjusted, the position of which affects the proportions of the air-fuel mixture, as well as a number of other adjustments.

Adjusting the scooter carburetor needle is done during the adjustment process

Each tuning operation has a different effect on engine operation and fuel preparation:

- adjusting the idle speed ensures stable operation of a running engine when the transmission is turned off;

- changing the quality of the air-gasoline mixture using a special screw allows you to deplete or enrich it;

- adjusting the position of the carburetor needle affects the change in the quality of the fuel mixture;

- Ensuring a stable level of gasoline inside the float chamber avoids flooding of spark plugs.

A power unit with an adjusted carburetor operates stably in any conditions, is economical, throttle response, develops rated power and maintains speed, and does not cause problems for its owner.

Lifehacks for the last time

- — Before adjusting, you need to check that the air filter is clean and soaked in engine oil. How to clean the air filter, read the article: Scooter maintenance.

- — If the rubber cuff on the quality screw is torn, then it can be replaced with a cuff from the quality screw of the classic Lada carburetor.

- — On Suzuki Sepia models, lets 2,

In the latest models of Honda Dio 34 everything is simpler. The carburetor has only one large screw, which is used to regulate the XO. The small one on dio 34 is located under the plug.

The first time the setup will take 15 - 20 minutes, and then everything will be automatic. Feel free to get down to business and share your experience in the comments.

Subscribe and see you for new articles!

Signs that adjustment is needed

Based on certain signs that appear in abnormal engine operation, we can conclude that the carburetor needs adjustment.

The list of deviations is quite wide:

- the power plant does not develop the required power under load;

- when the scooter accelerates sharply, failures in engine operation are felt;

- a cold engine is difficult to start with the starter after a long period of parking;

- the scooter's power unit consumes fuel in increased quantities;

- there is no quick response of the engine to a sharp turn of the accelerator handle;

- The engine may suddenly stop due to insufficient fuel mixture.

The carburetor should be adjusted if there are signs that adjustment is necessary.

If one or more of these symptoms is present, you should adjust the carburetor, and then diagnose its condition and check the operation of the engine.

How to adjust engine idle speed

Work on setting up the power system is carried out after the engine has warmed up to operating temperature. All types of carburetors installed on scooters are equipped with a screw designed to regulate idle speed. Changing the position of the adjusting element allows you to ensure that the engine operates at stable speeds during idling.

Depending on the vehicle model, the adjusting elements are located in different places, so you need to carefully study the instructions and determine where the idle speed adjustment screw is located on the scooter.

Rotating the screw in a clockwise direction allows you to increase the crankshaft speed. Turning in the opposite direction, accordingly, ensures a decrease in speed. To perform adjustment operations, it is necessary to warm up the power unit of the scooter for a quarter of an hour.

Setting the engine idle

Then the screw is screwed in or unscrewed until a stable and precise speed of rotation of the vehicle engine is achieved. The adjustment is made in small increments by smooth rotation. After each manipulation, the engine should be run for several minutes to stabilize the speed.

Ural chainsaw carburetor: design, adjustment, repair, modification

All Ural chainsaws had standard KMP-100 carburetors and its modifications with minor changes. And this was the only carburetor for chainsaws produced in the USSR. Later, with the advent of the newest and last model in the USSR, the Ural 2t Electron, the KMP-100U carburetor began to be used. And it was the only one for chainsaws produced in the USSR, which was also used on Druzhba petrol chain saws.

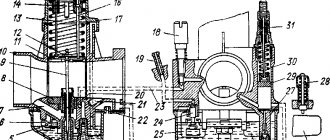

Design and principle of operation

The Ural KMP-100U chainsaw carburetor is a membrane type. It does not have a float chamber and a floating float with a needle that cuts off the flow of fuel when the chamber fills, as on older carburetors. This gives the advantage that the Ural 2t Electron chainsaw engine can operate in any position, even upside down. A float carburetor cannot operate in an inverted position.

The design of the KMP-100U is fundamentally the same as that of all carburetors of two-stroke engines. Its function is to prepare a gasoline-air mixture and supply it to the combustion chamber.

The KMP-100U carburetor system can be considered complex, because it must ensure engine operation in three modes:

- Launch.

- Idling.

- Maximum speed.

For each mode, special channels for the supply of fuel, air and the position of the dampers are used.

Appearance of the new KMP-100U carburetor used on the Ural 2T Electron chainsaw

When starting a cold engine, the conditions for the formation of a working air-fuel mixture in the combustion chamber are very unfavorable for the following reasons:

- low crankshaft speeds when the starter is pulled manually, weak compression of the fuel mixture in the combustion chamber;

- some of the fuel is lost on the cylinder walls;

- low temperature makes ignition difficult.

Therefore, to facilitate starting, an enriched mixture is required - more gasoline, less air. The air supply damper from the air filter is closed in the cold engine starting mode, and the gasoline supply is increased due to pumping (suction) with a primer.

After starting the engine, a vacuum is created in the combustion chamber during the stroke of the piston, so the fuel mixture from the carburetor begins to be sucked into it. More air is required for oxygen supply and complete combustion of fuel. The air damper opens.

When you press the gas handle, the throttle valve opens completely, gasoline and air flow in full flow, the engine runs at full speed.

The flow of gasoline at this moment is regulated only by the calibrated nozzle hole in the carburetor.

In addition to the position of the air and throttle valves, calibrated nozzle holes, the fuel supply is also regulated by a membrane. When the carburetor is filled with gasoline, the membrane presses on the rocker arm with the needle and cuts off the supply of excess fuel from the gas tank to the carburetor.

How to adjust the carburetor on a Ural chainsaw

Adjustment of the KMP-100U is simple and accessible to every user. The carburetor has two adjusting screws (analogues of the H and L screws on some modern imported chainsaws) for adjusting the average and maximum speed. They are accessible from the outside; adjustment does not require disassembling the housing.

At the top you can see 2 screws with springs, these are the adjusting screws

Adjusting the carburetor of the Ural chainsaw is carried out on a warm engine. Initial tuning should be carried out with the engine warmed up but turned off.

- Both screws are tightened completely, but without excessive force. The screws have sharp, thin tips that can become deformed if over-tightened.

- Then the first screw, which is closer to the cylinder, is unscrewed 1 turn. The second screw is unscrewed 0.5 turns.

- The chainsaw is started and given full speed. If the speed drops, you can unscrew the screws another 1/3 or 1/4 turn, listening to the engine and finding the optimal mode.

It is impossible to know the exact number of revolutions. This is individual for each chainsaw and depends on the characteristics of the carburetor, the condition of the piston system, fuel quality, outside temperature, etc.

To adjust, just remove the cover; there is no need to remove the carburetor itself from the chainsaw

Adjusting the idle speed

The idle speed of the carburetor on the Ural chainsaw is adjusted using a screw located on the gas handle. Its rotation changes the position of the throttle valve (opens it slightly) and, as a result, the idle speed parameters change.

All screws may need to be adjusted regularly.

This video shows the maintenance of the KMP-100U, and at the end - a simple and understandable adjustment algorithm.

Repair: main faults and their elimination

Most often, problems with fuel supply arise when the tiny holes of the jets become clogged and when the membrane-rocker arm pair fails. The brass cross of the rocker arm can bend or jump out of its seat and shut off the fuel supply at the wrong time. The soft membrane can dry out over time, lose elasticity, warp and also incorrectly shut off the fuel supply.

This is what the new membrane looks like (right)

How to change the quality of the fuel mixture

For all scooter engines, it is important to receive fuel with an adjusted ratio of gasoline to air. A lean mixture leads to improper operation of the engine, a drop in power and overheating of the engine, while a rich mixture leads to an increase in consumption and the formation of soot.

Adjustment operations are performed by changing the position of the quality screw and moving the throttle needle.

Turning the screw to the right causes the mixture to become richer, and unscrewing in the opposite direction causes it to become leaner. The same happens with the needle: when the needle is raised, the mixture becomes richer, and when lowered, it becomes poorer. The integrated use of both methods allows you to achieve optimal results during setup. However, not all carburetors have this feature, so, as a rule, one of two options is used.

Final setup

Next, without turning off the scooter, we adjust the quality of the mixture. To do this, we lean or enrich the mixture. Slowly tighten or unscrew the small screw (quality) to set the maximum XO.

Then tighten the large screw again and reduce the CO to medium stable.

Setting the gasoline level and the correct position of the float in the chamber

A correctly adjusted fuel level in the float chamber does not allow the spark plugs to get wet and the engine to stall. In the chamber where the floats and jets are located, there is a valve that provides fuel supply. The correct position of the floats determines the closing or opening phase of the valve and prevents fuel overflow in the carburetor. The position of the floats is changed by slightly bending the fastening bar.

The closing or opening phase of the valve is determined by the correct position of the floats

Gasoline level is monitored with the engine running using a tube made of transparent material attached to the drain point and raised up. The gasoline level should be a few millimeters below the flange mounting of the cover. If the level is insufficient, remove the cover and adjust the needle firing phase by slightly bending the metal antennae.

Carburetor value

Today, there are several ways to supply fuel to the engine. They differ in their principle of operation, but all devices are united by a common parameter - preparing the exact amount of working mixture.

The carburetor is a simple but effective device for optimal dosing of fuel assemblies into the cylinders. The idea of its operation is simple - mix the required amount of fuel and air, and then feed the finished proportion into the engine.

The advantages of using a carburetor set it apart from other methods of preparing the mixture. The engine itself controls how much fuel it needs to receive.

Medium and high speed tuning

Using the quality adjustment screw, the fuel proportions at idle speed are ensured. For medium and high rotation speeds, the engine operating mode is adjusted using a different method. After turning the gas handle, the fuel nozzle starts working, supplying gasoline to the diffuser. An incorrectly selected jet cross-section causes a deviation in the fuel composition, and the engine may stall when gaining power.

To ensure uninterrupted operation of the motor at a higher frequency, it is necessary to perform a number of operations:

- remove debris from internal cavities;

- set the gasoline level in the carburetor;

- adjust the operation of the fuel valve;

- check the cross-section of the jet.

The correct operation of the engine is indicated by its quick response when turning the throttle.

A quick response when turning the throttle indicates proper engine operation.

Intermediate setup

Adjusting the carburetor of a 2t scooter is carried out after installing the air filter in its place.

Start the engine and let it run for about five minutes to warm up.

Adjust the idle speed (ISR) with the quantity screw: by tightening it, the throttle rises and the idle speed increases; and when unscrewing, the throttle is lowered and the CO is reduced.

Set the speed so that the scooter operates at a lower speed.

How to set up a carburetor on a scooter - features for the 2t model

Adjusting the carburetor of a two-stroke scooter differs from adjusting the power system of four-stroke engines. Most two-stroke engines are equipped with a simple carburetor with a mechanical enricher, the trigger of which is pulled before starting the device. Scooter owners call the starting enrichment a choke; it is closed after the engine warms up. To adjust, the power system is disassembled, the needle is pulled out and mechanical intervention is carried out in the fuel chamber. Further adjustment is carried out in the same way as for four-stroke engines.

How to check the quality of adjustment of the carburetor of an Alpha moped?

At this stage, you need to adjust the quality of the mixture on the go. To do this, you need to start the moped and go for a ride with the throttle turned half way. After this, you can look at the condition of the spark plug: black - too much gasoline while driving, white - air. How to be in this case? You can pull out the needle and grooves that regulate the amount of gasoline. When moving the locking ring upward, less fuel will be supplied and more air will be supplied, and vice versa. After this, the check is performed again, and if the engine does not stall when turned to full throttle, then this is a sign that everything is fine.

In addition, the problem may be in the main jet, which is responsible for the “full throttle” mode: in this case, it should be replaced with a smaller or larger one. The following steps will serve as a test: when driving at full throttle, you need to slow down a little. If popping noises are heard, a smaller jet is needed.

Setting up the carburetor on a 4t scooter - important points

Setting up the carburetor on a four-stroke scooter is easy to do on your own and is not difficult for motorcyclists. Setting up the carburetor of a 4t 50cc scooter (China) requires certain skills and patience and is performed according to the above algorithm. It is possible that the manipulations will have to be repeated many times until the desired result is achieved. If the carburetor setting on a 4t 139 qmb scooter or a similar model with a different engine is done correctly, the engine will operate stably.

It will be able to start regardless of the ambient temperature and the piston group in the engine will wear out less.

Maintenance Procedure

Scooter motors are manufactured in different volumes. The most common are 50 and 150 cubic meters. The gas distribution system has both 2t and 4t options. The differences between the models are minimal, so maintenance of 2 and 4 stroke 50cc mopeds is carried out according to the same principle.

The technique includes:

- Carburetor adjustment at idle speed. The scooter starts and its operation without load is analyzed. The assessment is carried out based on the evenness of the strokes and the stability of the engine speed.

- The position of the screws for the quantity and quality of the mixture is adjusted.

Due to the relative lightness of the structure, adjustment is made with two control bolts. If stable operation cannot be achieved, it is necessary to remove the unit and carry out deep cleaning and adjustment.

Important: before servicing the carburetor on a 4t and 2t scooter, you should make sure that the piston group and ignition system are in good condition. Otherwise, the adjustment will have no effect.

Removal

Because of the way it works, the carburetor is attached directly to the intake manifold. The fuel line and air duct are connected to it. All removable hoses are removed from the body and the part is exposed.

The starting enrichment is switched off. The fastening bolts are unscrewed with a spanner wrench, and the entire assembly is pulled out.

Installation is in the reverse order.

Carburetor cleaning

An excellent cleaning method is to blow out the internal channels with compressed air from a compressor. For this, a special gun with a pointed tip is used.

During operation, plaque forms on the surfaces of the carburetor. This is due to the quality of gasoline. Most of the dirt stops in the fuel filter, but some gets into the intake tract.

To remove deposits, you can use either a solvent or a special liquid for cleaning carburetors. It is also suitable for scooters. The advantage of using it is that the cleaning agent is under pressure and is able to penetrate into the most inaccessible channels.

The scooter carburetor has rubber gaskets. To avoid exposing them to cleaning mixtures, it is recommended to insulate these parts in advance.

When cleaning the intake mechanism of a scooter, it is not recommended to use fluffy rags. Their threads can get stuck in the carburetor components, which will lead to additional difficulties.

Idle speed adjustment

An indicator of proper operation of the carburetor on a scooter is a stable idle. The absence of “floating” speeds and confident operation indicate a prepared mixture inside the combustion chamber.

Regardless of 2 or 4 stroke engine options, you should start tuning by adjusting the idle speed. The number of cubes also does not matter.

For this purpose, there is a screw on the device that is responsible for dosing fuel when the scooter is operating without load.

Some carburetors do not have adjustment bolts. In this case, you need to adjust the idle mode using a needle and floats in the fuel chamber.

The scooter is started and allowed to run for a few minutes. This is necessary for better evaporation of gasoline inside the intake manifold and its mixing with air.

After warming up, turn the idle screw until the engine becomes stable. The criteria for correct adjustment are:

- the scooter maintains stable speed indicators;

- there is no engine tremors or failures in operation;

- the carburetor confidently switches to power gain mode (when over-throttled) and back.

Sometimes the scooter refuses to respond to idle adjustment. This behavior indicates additional problems in the intake system.

Mix quality

The two main components in the operation of any internal combustion engine are air and fuel. The force from their combustion pushes the pistons and forces the vehicle to move.

But simply mixing these substances is not enough. You can achieve maximum energy output only by maintaining the correct proportion of components. In a carburetor, this procedure is called adjusting the quality of the mixture and the entire operation of the 50cc scooter depends on it.

There are three types of air-fuel mass:

- poor;

- rich;

- optimal.

Maintaining the correct mixture ratio in the carburetor is vital for reliable engine operation.

Mixture control diagram

First, you need to start the scooter and warm it up. After setting the temperature, you should proceed according to the following algorithm:

- The mixture quality screw is tightened until it stops.

- Loosen the adjusting bolt one and a half turns counterclockwise.

- Start the scooter, tighten the screw a third.

- If the speed increases, turn it a quarter.

- We adjust until the speed stops falling.

This scheme allows you to configure all types of motorcycles.