Motorcycles with chain drive make up the vast majority of motorcycles around the globe. A chain is the simplest and at the same time reliable system for transmitting torque from the engine shaft to the drive wheel of a motorcycle. Made of metal, it can withstand heavy loads, tolerate sand, dust, dirt and even swimming in water. Unfortunately, on many of the motorcycles we have to buy, the previous owners skimped on such an important spare part. They buy either a cheap chain from China or a low-quality fake (also from China). Chinese motorcycle manufacturers also don’t bother and put a cheap chain of their own making on their equipment.

The enduro motorcycle chain experiences serious stress

To correct these shortcomings, it is worth considering the Japanese DID chain, which is sold in our online store. We sell exclusively the original, which is sent to us from Japanese factories. We are not looking for profit and do not want to deal with cheap chains that will upset their owners. Every customer is our friend, so we wish only the best and offer the best and hassle-free options.

Replace or shorten?

A common problem is stretching, in which case the question arises: to replace the timing chain on a scooter or is it possible to shorten the timing chain. Shortening is a short-term measure that is applicable to products with little wear and will only be useful if the actions are performed correctly.

If the wear is minor, you can carefully remove 1 link and slightly extend the ride life. If the work is performed incorrectly, the spare part can be permanently damaged. In addition, you need to carefully ensure that when removing the link, the pitch matches, otherwise such a part can wear out and damage the camshaft sprocket.

How to tell if replacement is needed

It is clear that the circuit must be changed when there is obvious dysfunction. When the chain wears out a lot, it makes a loud noise. Well, or jumped over the tooth of a star. Or it fell off, which indicates its stretching and wear.

Standard chain lifespans should be close to the lifespan of the scooter engine itself. It's logical. Each owner operates the vehicle differently, but the average chain lifespan is somewhere between 15,000-18,000 km. In a situation where the engine was halved to eliminate other faults, and the chain was immediately replaced after using it for, for example, 9000 km, everything is clear.

There are options for shortening the chain when stretched. But there are some caveats: if the step does not match, the star begins to erase, i.e. the stretched chain eats the camshaft sprocket. If the wear on the star is small, you can isolate the link and ride it a little. You need to do this correctly, adjusting the chain tension with a tensioner, and not forcibly. Otherwise, you will completely damage the chain.

What is typical for a worn chain: A small point: to check, you need to remove it. The degree of wear can be assessed by the angle of horizontal deflection. If it sags downwards, going almost vertically, change it 100%. The new chain deviates approximately 45 degrees from horizontal.

And by laying out the old and new chains on the surface, you will see that the first one will be longer. Also, the wear of the scooter's timing chain can be indirectly judged by the level of extension of the tensioner rod. Critical wear is when the rod extends completely.

Replacing the timing chain on an engine with engine disassembly

For disassembly you will need tools: generator and variator puller, kickstarter puller, 8, 10, 12 and 17 mm sockets, flat and Phillips screwdrivers and a hammer. The principle is simple: sequentially dismantle the covers, bolts and nuts, remove parts that interfere with getting to the chain. Do not forget to thoroughly clean and inspect structural elements and, if necessary, replace damaged ones.

- Remove the engine, drain the oil and thoroughly wipe and clean the parts. Next, remove the cooling casing and muffler. Using a puller, unscrew the bolts from the impeller and remove it from the rotor, fix it with the puller and unscrew the nut. Remove the rotor and remove the cover from the variator. Secure the impeller with a puller, unscrew the nut and remove the variator.

- Using a puller, remove the kickstarter gear, which is located under the variator. Clean all connectors, remove the bolts on the valve covers. Unscrew the bolts on the cylinder head and remove the camshaft bed, this way you will remove the scooter's timing chain tensioner.

- Pull the camshaft out of bed and remove the part. Remove and tidy up the guide bushings. Remove the retaining ring and pin from the upper end of the connecting rod and remove the cylinder head, cylinder and piston in sequence.

- You can get to the chain by following these steps: remove the bolts from the crankcase cover and remove it from the engine, remove the starter intermediate gear. Use a screwdriver or hammer to loosen the overrunning clutch nut and remove the rest.

- Remove the protective screen from the oil pump, place a metal stick under the chain, and remove the oil pump sprocket. Now you can remove and replace the spare part.

- Carry out all engine assembly steps in reverse order.

Chain, belt or cardan?

Transmission. Part 3. Main gear

Text: Artem 'S1LvER' Terekhov

In previous articles, we dealt with the structure of the gearbox and clutch. However, there is one more component, without which the operation of the transmission is simply meaningless. In today's article we will talk about the main gear. We will understand the structure of the mechanism itself, and also estimate when it is best to use one or another design option.

The final drive is needed to transfer power from the transmission driven shaft to the rear wheel. This is the last link in the power transmission chain from the engine to the wheel. It is also the last in the chain of speed reduction and torque enhancement. On motorcycles, the final drive is a separate transmission unit, but on scooters there is no final drive. There it usually consists of a pair of gears, which are considered as an extension of the gearbox, and not as the final drive in its traditional sense. Therefore, further down the article we will talk about motorcycle systems. Modern motorcycles use three types of final drives: chain, belt and cardan. The most common is the chain drive, and is used on machines for a wide variety of purposes, from small bikes like the Yamaha YBR125 to high-performance sportbikes. The cardan is installed on bikes, the main requirements for which are reliability and durability of the main gear, plus long service intervals. Relative to the other two types of final drive, the belt is used the least. All bikes from Harley-Davidson and many devices from the now deceased Buell, as well as some cruisers from Japanese manufacturers, are equipped with it. Now let's talk about each type in more detail.

A funny, but no less revealing model of the Moto Guzzi V8 chain final drive

Chain

Chain drive is the most successful scheme for use on a motorcycle. The chain drive is compact and easily located in most modern designs. A well-adjusted and properly lubricated chain is the most efficient way to transfer power, with power transmission losses of about 5% to the wheel. It has a low unsprung mass (we’ll talk about what this is in the article about bike suspensions) and is quite cheap to produce. An undoubted advantage is the ease of changing the gear ratio of the final drive by replacing the drive and driven sprockets.

An additional element on motorcycles with a chain drive and long-travel suspension is a chain guide, which prevents the chain from jumping off the sprocket (Kawasaki KLX250 2009)

Of course, the chain also has its disadvantages. The chain needs to be serviced frequently, and if this is not done on time, its performance will noticeably decrease. And when the bike is used in difficult conditions such as high humidity or sandy terrain, chain maintenance intervals are sharply reduced. If you completely neglect lubrication/cleaning/adjusting the chain, it will crackle for a thousand or two kilometers as a warning, and then it will burst enchantingly. Maybe even the engine crankcase will get a crack or a dent as a souvenir, and the unlucky owner will forever remember that the condition of the chain needs to be monitored. Chain life can be extended by installing a closed guard or an automatic lubrication system. However, these measures will not save the chain from stretching and sagging. And the more powerful the engine, the shorter the life of the chain.

Please don't forget to maintain your chain!

The development of sealed joint chains (O-ring or X-ring) solved some of the problems associated with standard roller chains by preventing dirt from getting into the rotating bushings and keeping lubricant inside them.

All chains are paired with sprockets, which cost little, but which wear out just as much as the chains. The constant impact of the rotating chain rollers quickly “chews” the sprocket teeth, and eventually the sprocket and chain assembly will need to be replaced. The drive sprocket is attached to the free end of the secondary (driven) shaft of the gearbox. The driven (rear) sprocket is usually installed on the pendulum in which the wheel is mounted, or directly on the hub (in the case of a cantilever pendulum). Now let's take a closer look at how the circuit is constructed.

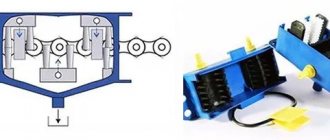

• A standard roller chain consists of inner and outer links. The inner link consists of two side plates, two hollow bushings pressed into the holes of the side plates, and two rollers located on the bushings. The outer links consist of two side plates and two fingers pressed into the holes of the side plates. The chain is made from individual links by inserting the pins of the bushing links into the hollow bushings of the rubber links. The rollers can rotate freely on the bushings, and the bushings can rotate freely on the fingers. The standard roller type chain is the cheapest, perfect for installation on small-capacity motorcycles and inexpensive mid-capacity motorcycles.

Standard roller chain design 1 - roller link, 2 - bushing, 3 - roller, 4 - bushing link, 5 - pin, 6 - side plate

• O-ring . The design is basically the same as discussed above, with the exception of the presence of ring seals (the same O-rings) between the side plates of the roller and bushing links. These seals serve to seal in the grease that is used to lubricate the rollers and bushings during assembly, and to prevent dirt and moisture from getting inside.

Kawasaki KLR650 2008, O-ring chain

• X-ring . They work in the same way as the O-ring, only the O-ring is X-shaped in cross section. This improves sealing and reduces friction losses between the ring and the side plates.

The cost (as well as weight) of the last two types of chains is higher, which is compensated by an increased service life. However, the strength of a chain is ultimately determined by the material it is made from and how the pins are secured into the side plates. In racing bikes, durability is a concern, so the chains for such machines are made thin and light, often using slots in the side plates and hollow pins. There is no question of any sealing, as well as long service life of the chain. In general, all means are good in the fight against excess weight.

If you decide to replace the chain, when buying a new one, you must take into account its size. Its designation uses a three-digit code, for example, 525. The first number indicates the chain pitch (the distance between the centers of two adjacent fingers), and is expressed in eighths of an inch. The next two numbers indicate the width of the rotating rollers, expressed in eightieths of an inch. That is, the number 25 means that the width is 25/80 inches. Sometimes the manufacturer will change the last number to provide a stronger version of the chain, which has the same pitch and width but thicker side plates.

Chain width and pitch

Belting

The belt was used on the very first motorcycles, and it worked satisfactorily, since the power of the engines of that time was low. To give you a little idea of what kind of power we were talking about at the dawn of motorcycle construction, here’s a fun fact: the power of the first motorcycle, built in 1902 by Siegfried Bettman, the founder of the Triumph brand, was as much as 1.75 horsepower! The same as the Triumph Rocket III starter now has...

Oh yes, belt drive. The first belts were made of leather, rubber and fabric, they worked quietly and absorbed shock loads well in transmission, but slipped when wet or stretched. As power increased, the belt drive gave way to a chain drive. This was until, much later, belt technology made it possible to create a belt drive capable of withstanding the high loads found on modern motorcycles.

Belt drive BMW F800ST

A modern belt consists of an inner cord of man-made fiber (most often Kevlar is used) embedded in rubber. On the inner surface of the belt there are teeth that work along the mating surface of the toothed pulleys. The use of teeth eliminates slippage and provides the same efficiency as a chain drive. The pulleys must be larger than the main chain drive sprockets to reduce bending as the belt runs up and down; It also ensures that the gear is distributed over the maximum number of teeth, reducing the load on each tooth.

The belt structure is clearly visible

The efficiency of a timing belt is slightly lower than that of a clean, new chain, but during operation this difference becomes reversed. The belt system is lighter and quieter than a chain, does not require lubrication or adjustment, and lasts longer. However, the use of the belt is still limited by the motor power. The belt drive can cope with a cruiser without problems, but it will not be able to transmit the consistently high power of sportbike engines. So, we sorted out the belts and chains. Now let's move on to the most ponderous, but very reliable main gear mechanism - the cardan.

Cardan shaft

On motorcycles, driveshaft drive has been used for many years, although in terms of preference it has never been ahead of chain drive. Which is better, a chain or a cardan, is the subject of much debate. The advantages of the cardan include rigidity, cleanliness (due to the closed design) and ease of maintenance. In fact, the entire job of the owner of a bike with a driveshaft is to change the oil in the bevel gear housing (aka the gearbox). When talking about the disadvantages, opponents of universal joints on motorcycles perk up and remember the high cost of production and high weight (which leads to an increase in unsprung masses). The main “killer trump card” of cardan fighters is large losses when transferring power to the wheel.

Tetralever driveshaft and suspension, Kawasaki GTR1400 2008

It is best to use a cardan on engines in which the crankshaft is located longitudinally to the line of the motorcycle - that is, when the axis of rotation of the cardan and crankshaft is parallel. To make it clearer - any boxer BMW, Honda Gold Wing, Moto Guzzi bikes with transverse cylinders. If the crankshaft is located transversely in the frame (for example, in-line fours), then the shaft can be connected to the drive only by changing the direction of its rotation at a right angle using a pair of bevel gears. Modern bikes with a cardan drive and a transverse crankshaft prove that this can be done technically and accurately (the same BMW K1300R). It is also necessary to ensure rear suspension travel. For this purpose, a universal joint or constant velocity joint (CV joint) is used at the front end of the shaft. The driveshaft itself rotates inside the control arm, and the final drive housing is bolted to the end of the arm.

There are several side effects associated with using a driveshaft. I’ll immediately make a reservation that the following shortcomings were more obvious in early designs; in modern systems the effect is not so noticeable. The first is the rigidity of the transmission, which is counteracted by the "elasticity" of the chain drives (engineers can combat this effect by installing a damper in the gearbox). The second is the tendency of some cars equipped with a driveshaft to “goat” when accelerating. BMW dealt with this effect by using a “Paralever” type suspension (we will talk about the design of this in the articles on suspension and chassis).

Paralever and driveshaft on BMW R1200GS Adenture

The final reduction in speed and increase in torque occurs in the final drive housing through the use of a small pinion and a large internal gear.

Universal joint Yamaha FJR1300 2004

Small gear and ring gear FJR1300

***************

I hope that after reading this article, you will be able to make an informed judgment about why a particular final drive design is chosen for a particular motorcycle, as well as evaluate future developments in this area. Now your knowledge includes how the engine, intake and exhaust systems, and transmission work (for those who haven’t read, welcome to our “iron shop”!). Our immediate plans are to tell you all the most interesting things about wheels, tires and braking systems. And we will also definitely talk about why the tread pattern on the wheels is directed in different directions. So stay with us, and be sure to leave comments about the article! All the best!

How to replace the timing chain in an engine without disassembling the scooter engine

If the method described above seemed too time-consuming and complicated to you, we will describe an alternative; it will require a puller, pliers, a Phillips screwdriver and a replacement chain.

- Using a puller, partially remove one pin from the new chain and flare it.

- Next, remove the following parts from the engine: cooling casing, cylinder head cover. Remove the chain tensioner, remove the camshaft bed, the shaft itself and remove the sprocket.

- Center the puller with the pin of the old chain and push it out completely, it will not be useful. Match the links of the old and new chain and instead of a pin, stretch a wire to fix the structure.

- Using the cooling impeller, turn the chain counterclockwise to replace the old one with the new one. Remove the wire, unhook the old chain and connect the links of the new one. Check the alignment of the links and carefully fasten them together with pliers, using a shot, finally secure the links and check the mobility and correctness of the pin to avoid jamming.

- Reassembling the engine includes some special features. When installing the camshaft bed, check the valve clearances with a feeler gauge (it should fit freely between the valve and the bolt) after tightening the nuts. When installing the chain tensioner, unscrew the bolt on the tensioner from the top and use a screwdriver to push the rod back.

Scooters and mopeds have many advantages: lightness, maneuverability and convenience. One of the main ones is the ability to repair the scooter yourself. After disassembling the scooter and replacing the timing belt several times, you can perform the actions automatically, but do not forget that incorrect installation or installation can damage the chain and related parts. Therefore, it is necessary to strictly follow the sequence and check each step. You can combine replacement methods or choose a convenient one and use it.

The main disadvantage of lightweight transport is safety; the above advantages make the scooter less noticeable to other road users and complicates movement on dark roads. To increase the safety of movement, we recommend equipping the scooter with factory LED headlights from the Wesem-Light online store catalog.

Why you shouldn't buy cheap chains

Often, motorcycle owners who are faced with the need to replace a chain prefer to save a couple of thousand rubles and choose cheaper chains.

At first glance, saving on a chain seems reasonable, because when replacing it you will also have to spend money on a set of sprockets, a decent amount. But the saying about “the miser pays twice” can actually turn out to be three times or more.

Let's divide inexpensive chains into three categories.

Just inexpensive chains in the store up to 3000-4000 rubles

These chains mean budget JT type chains, as well as Chinese brands. We repeatedly bought these chains for ourselves and got burned. Alas, the JT brand's Japanese pedigree doesn't help. If there are no problems with the stars, they use up their resources, then the chains stretch like chewing gum. JT has to constantly tighten up, and by the end of the season she already sounds like beads. If this chain is not replaced in time, it will eat the drive sprockets of your motorcycle. Complete disappointment.

We won’t talk about the Chinese chains for a long time; those who have contacted them know that it stretches out over several trips. In order not to waste the resource of new stars, in all public pages on social networks dedicated to Chinese motorcycles it is recommended not to save, but to immediately buy a normal chain, for example DID.

Inexpensive chains of good brands

We think that cheap and good is fantastic. If they sell you a DID 520 chain for less than 4,000 rubles, it is most likely an outright fake. When purchasing, check the data and, based on indirect evidence, try to determine what kind of circuit it is. At best, such a chain will stretch, at worst, it will shatter under serious load and destroy your motorcycle. Unfortunately, counterfeits can be found even in famous stores.

We had a case when, for a trip to the mountains, our friend purchased a fresh AFAM SX2 chain from an online enduro store. On the second day of riding in difficult conditions, this chain broke. The motorcycle was dragged on a cable, on the same day a DID VX2 chain was purchased as a replacement in the original KTM packaging, which cost almost 10,000 rubles; there were no other options. But, unfortunately, it turned out that the clutch was lost. Two days of pumping and troubleshooting did not yield results. At the moment of the break, the chain damaged the clutch release cylinder, breaking the channel. Visually, the cylinder was intact and did not show itself in any way.

The initial savings on the chain resulted in a ruined trip (the motorcycle sat until the end), the purchase of a good chain is obviously expensive and the purchase of a new clutch cylinder. If the DID chain had been purchased initially, then there would have been no problems and there would have been no need to overpay several times.

Just a ready-made instruction “what not to do”, so we advise you to buy high-quality Japanese chains such as DID or EK.

Broken chain AFAM (fake)

As it turns out, the purchased AFAM chain is a fake. Please note that the word "JAPAN" is stamped on each link, but AFAM is a French company and has nothing to do with Japan. An uneven rivet also hints at an obvious fake. Unfortunately, these chains were sold in a well-known online store, which we will not name; you can find it yourself using a search in Yandex. This chain is currently out of stock, but oddly enough, there are other types of these same AFAM chains, which are most likely also fake, judging by the photo of the packaging.

Good Japanese chains (DID, EK)

If a chain is sold under the DID brand and in size 520 it costs more than 4,000 rubles for an oil seal chain, most likely it is an original. Apart from the price, these chains have the following advantages:

- Long service life with proper care and lubrication.

- Strength

Once you install a DID circuit, you won't want to try cheaper options. This is an absolutely hassle-free option that will work and not cause headaches. The strength of these chains is so high that you will rarely need to check tension and tighten them, turning it from a routine operation into a rare maintenance task.

For enduro motorcycles we recommend the DID VX3 chain. This is a new Japanese development that replaced the VX2. It easily endures all the hardships and hardships of off-road operation and rolls back its service life, delighting the owner. Also easily fits any motorcycle with a 520 chain size, including road bikes. Withstands engine capacity up to 800 cubic centimeters.