How to set the timing belt on a scooter

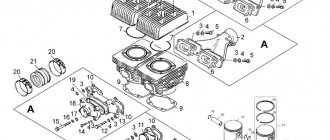

1. Install a new cylinder head gasket.

ATTENTION!

The cylinder head gasket is made of soft metal (copper, aluminum) and after tightening the cylinder head nuts it is deformed, thereby ensuring a tight connection. Reinstallation of the cylinder head gasket is not permitted.

2. Install the timing chain guide.

3. Install the cylinder head.

4. Set the piston to TDC according to the marks on the flywheel. This is usually the "T" mark on the flywheel. Align the mark with the tide on the engine crankcase.

ATTENTION!

The following operation is one of the most important when assembling the engine. It is important to align all the marks very accurately. An error in installing the chain even by 1-2 teeth will result in the engine not working correctly, and it will probably even lead to serious damage to the timing and cylinder-piston gas parts when trying to start the engine!

5. After making sure that the timing chain has not jumped off the drive sprocket on the crankshaft, install the camshaft into the cylinder head, at the same time putting a chain on its sprocket so that the marks on the camshaft sprocket are parallel to the plane of the edge of the cylinder head, and the cams are directed downward (inside the head).

6. Install the rocker arm support, orienting it according to the installation marks. Lubricate the cams and camshaft bearings.

On the rocker arm support are the letters “EX” - which means “EXHAUST” - release. The "EX" mark should be located above the exhaust valve.

ATTENTION!

• Check the correct axial alignment of the camshaft (make sure that the camshaft bearings are correctly positioned on the beds). Probably, on some scooter models, the holder will have the mark “IN” - “INTAKE” - inlet. Accordingly, the “IN” mark must be located above the inlet valve.

ATTENTION!

If the copper washers are severely deformed (flattened), they must be replaced, since if the washers do not fit tightly due to oil leakage, the pressure in the lubrication system will drop and the motor will quickly fail. Sealing this connection with any sealant is unacceptable.

7. Install sealing copper washers on the studs.

8. Screw on all four cylinder head nuts without tightening them.

9. We recess the working rod of the timing chain tensioner inside the housing.

10. Reinstall the timing chain tensioner and tighten its mounting bolts.

11. Insert the working bolt and the timing chain tensioner spring, tighten it. In this case, you can hear characteristic clicks - the ratcheting mechanism of the tensioner working rod will be activated, which, under the influence of a spring, will come out of the housing and tension the timing chain.

12. Sequentially, crosswise tighten the cylinder head nuts in 3-4 steps. The final tightening torque is 10-15 Nm (More accurate values can be found in the repair instructions for the specific scooter model).

13. Screw in and tighten the additional cylinder head bolts.

14. Using a socket wrench for the central bolt of the flywheel, or with your hands holding the flywheel, slowly turn the engine crankshaft clockwise 3-4 turns to make sure that the timing timing is set correctly and the piston does not collide with the valves.

15. We install the crankshaft at TDC of the compression stroke and once again check the correct installation of the camshaft according to the marks.

17. Rotate the crankshaft several turns and once again check that the valve clearances are set correctly.

18. Install the cylinder head cover and tighten its bolts.

19. Place the crankcase ventilation hose onto the fitting in the cylinder head cover.

20. Install the cylinder cooling casing.

ATTENTION!

Do not forget to remove the paper from the intake manifold if you covered it from dirt during disassembly.

21. Install the inlet pipe assembly with the carburetor.

ATTENTION!

In most cases, when installing an exhaust system, the exhaust pipe gasket will need to be replaced. It is better to replace it with a new one during assembly.

Tools

We free access to the cylinder head: depending on the scooter model, we remove the hood or seat tank. We find the valve cover there, unscrew the four 8mm bolts and remove it from the engine.

The valve cover looks like this. In my case, to get to it I had to remove the hood, saddle and seat tank.

There is a generator casing on the right side of the engine - remove it. If you are too lazy to remove it, just take out the plug. The plug is located in the upper part of the case and can be removed using a regular screwdriver. Through the plug we will control the position of the marks on the rotor.

We insert a 14 mm socket wrench into the center of the generator casing and turn the engine (clockwise) until the “T” mark (from the English “Top” means top, in our case the piston position is at TDC) on the generator rotor is exactly opposite the ledge.

After the mark on the generator coincides with the ledge on the engine crankcase, we check what position the camshaft is in. The camshaft should be in a position where both valves are closed. And it gets into this position every second revolution of the crankshaft since it rotates twice as slow.

The correct position of the camshaft is determined by its sprocket. The sprocket should become the large hole facing up, and the small holes and the marks that are knocked out near them should become parallel to the plane of the valve cover connector.

This is ideal, but in practice the asterisk rarely becomes the way we need it. And the chain is often to blame for this - it stretches and the camshaft begins to slightly not catch up with the crankshaft. If your sprocket has become a little crooked, then by and large it’s nonsense. But if you have it for some reason, then this problem needs to be solved very quickly - otherwise sooner or later the valve will bend.

Once again, check that the “T” mark on the generator rotor is opposite the protrusion, and that the camshaft sprocket is in the correct position. Unscrew the locknuts on the adjusting bolts.

We unscrew the adjusting bolts a little, insert a measuring probe between the valve and the adjusting bolt and, without removing it, tighten the adjusting bolt with our fingers, clamp the adjusting bolt with pliers and secure it with a lock nut.

After tightening the locknut, check how easily the dipstick moves. Ideally, the feeler gauge should move between the valve and the bolt with barely perceptible force.

How to tell if replacement is needed

It is clear that the circuit must be changed when there is obvious dysfunction. When the chain wears out a lot, it makes a loud noise. Well, or jumped over the tooth of a star. Or it fell off, which indicates its stretching and wear.

Standard chain lifespans should be close to the lifespan of the scooter engine itself. It's logical. Each owner operates the vehicle differently, but the average chain lifespan is somewhere between 15,000-18,000 km. In a situation where the engine was halved to eliminate other faults, and the chain was immediately replaced after using it for, for example, 9000 km, everything is clear.

To change or not to change?

Suppose you “overhaul” your engine: you change the seals, crankshaft, gaskets and other devices, but you doubt whether to replace the timing chain with a new one or not. If you doubt it in vain, change it for a new one at the first opportunity. And now I will explain why.

See for yourself: a chain has an average service life of approximately 18,000-20,000 km of a scooter (personal experience), approximately the same as the average service life of the engine itself. And for example, after driving 6,000 km, the crankshaft jammed or the engine leaked, or something else happened that requires complete disassembly of the engine. Naturally, you disassemble the engine, replace the crankshaft with a new one, and leave the chain, which by that time has exhausted a third of its service life.

And what happens? The chain, after 12,000 km, will exhaust its service life and become unusable, but the crankshaft and other parts will be in good order and you, like it or not, will have to again, because of the chain alone, half the engine. Is it necessary? The chain is a consumable item. Never skimp on it!

Personally, I never check timing chains. I simply throw them in the trash, no matter how awesome they seem to me. For me, a chain is a consumable, just like a spark plug, oil or oil seal. But if you are important, or money is tight, you can use the old fashioned way.

We stretch the chain along its length, hold it with our fingers and try to position it in a horizontal position

- If the chain describes an arc that looks very much like a 90-degree angle, then feel free to throw it in the trash.

- If the chain bends slightly and describes a small arc, then such a chain is quite suitable for further use

For clarity, I took a new and heavily worn chain, put them together and checked for horizontal deflection. As you can see: the new chain (above) described a barely noticeable arc, while the worn and useless chain sagged like snot, almost at an angle of 90 degrees.

The worn chain turned out to be almost a centimeter longer compared to the new one.

How to replace the timing chain in an engine

Having decided on such an action as replacing the timing chain of a scooter, you need to decide on how to implement your plan.

There are two replacement options:

- With a thorough disassembly of the scooter engine

- No engine disassembly.

How to change, everyone decides for themselves. Both methods, advantages and disadvantages are described in detail below.

With disassembly

You should choose the right tools - generator and variator pullers (you can make them yourself), a kickstarter sprocket puller, 8, 10, 12 and 17 mm sockets, a hammer, two screwdrivers (flat, Phillips).

The engine is removed from its place, the oil is poured out, all parts are wiped and cleaned. Next, remove the muffler and cooling casing. We remove the generator only with a puller. To do this, unscrew the bolts from the impeller and remove it from the rotor. It is necessary to fix the rotor with a puller and unscrew the nut. Then we tear the rotor off the crankshaft journal. Remove the variator cover. Also, secure the impeller with a puller, unscrew the nut, and remove the variator from the axle.

Below the variator is the kickstarter gear. Likewise, a puller is required for it. Then we clean the cylinder connector, valve covers and cylinder head. After unscrewing the bolts on the valve covers, remove it. Next, remove the scooter's timing chain tensioner. After unscrewing the bolts on the cylinder head, we pull out the camshaft bed.

Next, remove the chain from the camshaft and pull it out of bed. To avoid losing the guide bushings that center the parts relative to each other, you need to remove them and put them away. We remove the cylinder head, the cylinder itself, and the piston (to do this, remove the retaining ring and pin from the upper connecting rod head).

After unscrewing the bolts on the crankcase cover, tapping it a little, remove it from the engine. We take out the starter intermediate gear, use a screwdriver and a hammer to unscrew the overrunning clutch nut (clockwise) and remove the gear and housing from the trunnion. We reached the chain!

Remove the protective shield from the oil pump. Place a metal stick under the chain, twist the nut on the oil pump sprocket, remove it and remove the chain.

No disassembly

We take the following tools: a Phillips screwdriver, pliers, a new chain and a special puller. More details about it will be below. We flare the new chain - to do this, use a puller to press the pin out of the joint of the links, but not completely.

A little about the puller

It is called a timing chain puller. It can be made by a turner by turning a threaded extruding pin and rolling a strong pin into it with a diameter similar to that of a chain pin. You can purchase a ready-made bicycle one. Just narrow the pin a little to the desired size.

Remove the cooling casing from the scooter engine, then the cylinder head cover. Next you need to remove the chain tensioner. We remove the camshaft bed, take out the shaft, remove the star.

We take the puller, center it with the pin, and gradually press out the pin. You can press it out completely, it will not be useful. We compare the links of the new and old chains, thread the wire into the seat of the pin and fix the ends of both chains. We turn the cooling impeller counterclockwise, gradually replacing the old chain with a new one.

Then we separate the ends of the chains, throw out the old one, and combine the new links from the ends. We check the alignment, install the pin, and use pliers to carefully press the pin in so as not to damage the new chain. We first check the mobility of the links. We finalize the pin with a puller. Again we control mobility. This point is very important: if you install the pin unevenly and miss it, it will begin to rest against one of the links and squeeze out the next one.

As a result, the subsequent pin or link bends, causing it to jam and become immobile.

Next, we assemble the engine in reverse order, placing marks on the rotor. When installing the camshaft bed, after tightening the nuts, you need to check the valve clearances with a feeler gauge. Upper valve – inlet: 0.05mm, lower – exhaust: – 0.1. The feeler gauge should fit freely between the valve and the adjusting bolt.

Then install the chain tensioner. We unscrew the bolt on the top of the tensioner, install a screwdriver in the groove, and, turning it, push the rod back. We fix everything else back according to the diagram.

Installing piston rings

Remove the set of piston rings from the box. A piston ring set for a Chinese four-stroke scooter usually consists of five items. Three of which are a single assembled oil scraper ring, the other two: upper and lower compression.

A typical set of piston rings looks something like this

Carefully unpack the kit with perfectly clean hands.

In the kit you will find two of the thinnest rings and one thick corrugated ring (expander) - this will be an assembled oil scraper ring that needs to be installed on the piston first.

We place an expander in the lowest groove of the piston

We place thin oil scraper rings in the same groove - one under the expander, the second on top of the expander

We find the lower and upper compression rings in the kit and install them, respectively, in the middle and upper grooves of the piston - with marks on the side surface to the cylinder head (cylinder head). The lower compression ring differs from the upper one in color (not always) and the shape of the working edge (always). In most kits, the lower compression ring is painted black, and its working edge has a slight bevel.

Which method is preferable?

It is logical that the first option with complete disassembly of the scooter engine is more complicated and takes more time and effort. But, as you can see, it is more reliable. Firstly, the factory integrity of the circuit is not compromised; secondly, when disassembling the scooter engine, you can see any defects, such as cracks, wear, change the seals, clean the parts.

The second option is more simplified and can be used when you only need to replace the chain. And you are confident in the quality of your work.

Final word

The scooter is a fairly popular vehicle and is in increasing demand.

Because it leaves traffic jams behind, has low operating costs and is economical in terms of fuel and lubricants. Many people prefer to do scooter repairs on their own, especially since four-stroke engines are simple and reliable to use. Timely technical inspections, careful operation and the above article will allow you to enjoy riding this miracle of the Asian motorcycle industry for a long time.

Additional actions

If you know how to tighten a motorcycle chain, it wouldn't hurt to check the condition of the sprockets and other transmission parts. If signs of significant wear are detected, they should be replaced immediately, since breakdowns of this type seriously affect the reliability and durability of the motorcycle transmission. If you find that the chain is very stretched, it is better to get rid of it immediately - especially if you like to ride at high speed or perform stunts by tipping the motorcycle onto its rear wheel.

In addition, when regularly tightening the chain, it should also be cleaned and lubricated. It is better to use special products in cans that are supplied under high pressure - they effectively wash away all foreign deposits and also penetrate into all internal parts of the chain drive, contributing to its effective lubrication. The procedures are also performed with the rear of the motorcycle raised, which allows you to quickly spin the wheel if necessary. There are also special devices for cleaning the chain. The device is fixed to the transmission mechanism of the vehicle, after which all that remains is to engage first gear and ensure a continuous supply of cleaning agent to the receiving tube.

The motorcycle is serviced approximately every 500–2000 kilometers, which ensures the reliability and durability of all mechanisms. Every time you clean and lubricate, you should check the degree of chain tension to prevent serious sagging. Experts say that on average, tensioning has to be done every 2–5 thousand kilometers, depending on the operating conditions of the motorcycle. It is worth completely changing the chain every 10–15 thousand kilometers, or more often with an aggressive driving style or with frequent off-road trips. Failure to comply with these deadlines leads to accelerated wear of the transmission and the approach of expensive motorcycle repairs.

How to set the ignition on a 4t scooter? Operating principle, causes of malfunction and setup

How to set the ignition on a 4t scooter? Problems with ignition of a 4-stroke engine can appear for various reasons, but they all lead to the same result - the engine stops starting. But the lack of a timely spark may not be the only reason that the engine does not start. To make sure that it is the ignition that is causing the engine failure, it is necessary to check all other possible faults that may interfere with engine operation and eliminate them. Breakdowns may occur in the ignition system, the causes of which can arise from both the mechanical and electrical side. Using simple techniques, you can determine whether the problem is a mechanical fault or an electrical component. At home, you can fix any breakdown in the ignition system of a 4-stroke scooter engine.

Professional approach

Many motorcyclists treat chain tensioning as a routine procedure, during which significant tolerances can be made and the position of the rear wheel can be adjusted “by eye”. This approach when setting the required chain tension is unacceptable - all operations must be performed as carefully and accurately as possible, using special tools. If you want to extend the life of the chain and avoid severe wear on the transmission when using the motorcycle in extreme conditions, you should purchase a special laser gauge to set the optimal wheel position. In the most difficult cases, if you cannot understand the structure of the adjusting mechanism or cannot loosen it, you should contact the specialists of a motorcycle service station. They will carry out all the necessary work, providing you with a guarantee of the quality of the result and the reliability of the motorcycle.

Reasons for failure of a 4-stroke scooter engine

If the scooter engine does not start, there can be a variety of reasons: 1. There is no fuel supply to the combustion chamber. 2. Air supply is not adjusted. 3. There is no compression. Burnt and deformed valves do not provide compression. The reason for the lack of compression may be incorrect assembly of the cylinder-piston group, as well as a malfunction of the cylinder itself. 4. The gas distribution mechanism responsible for the operation of the valves is faulty. 5. The spark plug is faulty. 6. An ignition spark is not produced during the mechanical operation of the generator.

The principle of operation of the ignition on a 4-stroke scooter engine

Ignition on a 4t scooter depends on the synchronous movement of the gas distribution shaft located in the cylinder head and the magneto. There is a protrusion on the outside of the rotor housing that contacts the ignition sensor during rotation. At the moment of contact, a spark appears on the spark plug. The rotor is connected to the crankshaft. At the moment the spark occurs, the crankshaft and piston are in the extreme dead center position. How to set the ignition on a 4t scooter? It is necessary that during the passage of the dead center the position of the gas distribution shaft corresponds to the moment of ignition of the fuel in the combustion chamber.

Adjusting the ignition of a 4t scooter

In order for the rotation of the generator rotor and gas distribution shaft to correspond to the desired piston operating cycle, it is necessary to set their position according to the marks. On the magneto body there is a marker for the position of the dead center of the cylinder in the form of the letter “T”. The rotor can be adjusted manually, or using a kick starter. The position of the camshaft is determined by the marks on the timing sprocket. Three points marked on the star from the outside form an equilateral triangle, the vertex of which should be directed to the extreme position from the piston. Adjusting the ignition consists of setting the correct position of the timing star.

Ignition advance

How to set the ignition on a 4t scooter with advance? There is an opinion that if you do this, the speed and power of the motor will increase. In theory, this is true. If the spark at the moment of compression occurs slightly before the moment the cylinder passes the dead center, this should give the desired effect. But the technical implementation of such an ignition setting on a scooter is associated with the transfer of its protrusion on the generator rotor housing. There is a method that is simpler and safer, which gives a certain effect. You can make a step on the ignition ledge. To do this, you need to remove a layer of 0.5 mm from half the surface of the protrusion. The step should start from the side that first contacts the ignition sensor. The resulting dual spark will provide more predictable engine starting and will also increase the likelihood of ignition when exposed to adverse weather conditions and improper fuel and air settings.

How to set the ignition on a scooter - an eternal question and a simple answer

Operating a scooter and enjoying its ownership brings a lot of positive emotions to the owner. In general, a scooter is a truly unique motor scooter, which is an almost universal transport. The scooter is great for driving around the city and for traveling outside of it. And everything would be fine, but sooner or later the moment comes when it has to be repaired and maintained, something that motorcyclists like to do much less of. Also, you often have to adjust and set the ignition, which few people know how to do correctly. It’s exactly how to set the ignition on a scooter that will be discussed in today’s article.

Broken ignition as a cause of engine failure

First of all, I would like to talk about what can cause a four-stroke scooter engine to fail, and whether misconfigured ignition should be blamed for this. Answering this question, we can answer with one hundred percent confidence that an incorrectly configured or simply faulty ignition may well become the cause of engine failure. However, it is too early to blame everything on a faulty ignition system until you check the main parts that affect the performance of the engine. Let's talk about them in more detail.

The first and perhaps most obvious is a lack of fuel or a clogged carburetor. Before you start trying to adjust the ignition, thoroughly clean the carburetor and make sure that fuel is flowing to the engine. Also, check that the carburetor is providing sufficient air supply.

The second, most common reason why an engine refuses to start is faulty spark plugs. Make sure that the spark plugs used in the scooter are not punctured and have a good enough spark. Simply replacing the spark plugs usually helps.

If you are completely convinced that there are no more reasons for the engine not to start, then you can dig deeper and look for the problem in an incorrectly configured ignition. Let's figure out how to set the ignition on a scooter.

Preparation

So that you don’t have green snot later about the fact that the tuning piston does not fit into the crankcase and you were allegedly deceived here - remove the old piston from the engine and measure the hole for the liner with a caliper. If the hole is smaller than the tuning piston sleeve, the “meat” of the crankcase allows it, hands grow from where it is needed - a round file will help you (only before boring - disassemble the engine, assemble the empty crankcase with bolts, bore the hole, make sure that the piston enters the crankcase without problems - wash the parts from shavings and reassemble the engine. Or, as a last resort, coat the crankcase and file with grease to at least somehow protect yourself from sawdust getting into the inside of the engine.)

The hole for the 162QMK engine sleeve (such engines are installed on Chinese scabs, more popularly known as “Leika”) in stock is 65 mm. Without boring, a piston of 57mm (150CC), 61mm (1700CC) and 62mm (180CC) easily fits into this crankcase. You won’t find a 62mm piston on sale during the day, so it was decided to install a regular 61mm piston on this engine.

By the way, for those who do not know, a piston with a diameter of 61 mm can be easily installed not only on the Leica engine, but also on any other Chinese 150 equipped with a 157QMJ series engine. There, if you put your hands to it, you can stick a piston at 62mm, but only if the “meat” of the crankcase allows it. Everything is individual, you need to look at the place. In any case, the distance along the studs is the same for both the 61mm piston and the 62mm piston.

On the 139QMB series engine from a regular Chinese 80-six, you can easily install a piston 39mm (45CC), 47mm (72CC), 50mm (84CC)

From left to right: 39mm (45CC), 47mm (72CC), 50mm (84CC)

How to set the ignition on a scooter

Many people ask about how to set the ignition on a 4T scooter. In fact, this process is not as complicated as it seems at first glance, because all you need is a screwdriver and marks. In order to adjust the ignition on a scooter, you need to set the timing star position correctly. In our task we will be helped by special marks that have already been placed by the manufacturer at the factory.

Pay attention to the magneto housing. There should be a special mark on it in the form of the letter “T”. It is this mark that indicates the dead center of the cylinder (the extreme position of the piston in the cylinder when it reciprocates). Based on this mark, you need to align the rotor so that the mark on the rotor coincides with the “T” mark on the magneto housing. To do this, crank the kick starter with little effort or move the rotor manually.

Then, you will need one more, last mark located on the timing star. This mark consists of three holes or points that are marked on the outside of the timing sprocket. These points subsequently form a triangle, where one of the points or holes is the largest. After you adjust the ignition, the largest hole should be at the top, and the other two points should be opposite each other in a horizontal position. You can see more details on how to set a tag on a 4t scooter in the video below.

Ignition advance

Some motorcyclists who understand proper ignition settings prefer advanced ignition settings. If we talk about this process more simply, then with this ignition, the motorcycle engine has a little more power and starts much easier. The thing is that with ignition set to advance, the spark plug produces a spark a little earlier than the piston in the cylinder reaches top dead center. Thus, we get a small increase in power and easier starting in bad weather conditions, for example, during cold weather.

Answering the question of how to advance the ignition on a 4T scooter, we can say that this is no more difficult to do than a normal setting. If you are already familiar with how to set marks on a 4t scooter and how to set up the ignition itself, then you will not have any difficulties. All you need to do is not completely connect the marks on the rotor and magneto housing. About half a centimeter is enough to get the ignition to advance.

This completes the ignition adjustment on the scooter. As you can see, there is nothing difficult here, the main thing is to connect all the marks correctly.

Examination

First, you should determine whether your chain needs tension - for this you need to take a control measurement. The motorcycle must be placed on the side stand, removing panniers and other foreign objects from it. As a tool, you should take a tape measure, a ruler or a fairly large caliper. Make sure there is no load on the suspension and start taking measurements.

Very often the question arises, how should the chain be tensioned to avoid accelerated wear of motorcycle components? It is best to check the operating instructions developed by the motorcycle manufacturer, since the standard indicator may be individual for a particular vehicle. If this is not possible, you should use average values equal to:

When checking, it may be discovered that the actual indicator is outside the acceptable range. In this case, it is necessary to urgently tension the chain to avoid motorcycle breakdown in the near future. In addition, it is worth performing another check, assessing the technical condition of the circuit. Gradually spinning the rear wheel, determine the degree of sagging at each point - if this indicator differs significantly, the part urgently needs to be replaced. If your chain is very stretched, but you need to get to a store or service center, then to adjust you need to choose a position with minimal slack.