MOTORCYCLE FORK EXTENSION

Making a chopper yourself is considered an expensive endeavor.

But not always. It turns out that you can build stylish motorcycles at low cost. I assembled my chopper on the basis of the Izh-Jupiter-2 motorcycle. This is a great foundation that didn't cost me much. In principle, my technology can be used if you have at your disposal any “Izhevsk” motorcycle, a “Java” or, with slightly greater modifications, any other. The main features of a chopper are a teardrop-shaped fuel tank and a large bent steering wheel.

I had such a tank. But in the absence of it, it could be purchased, exchanged, or, at worst, found in a landfill. Tanks from Izh-49, Izh-56, Planeta or Jupiter of the first and second models are suitable, and with minor modifications - from the old Ural or Java-250.

As a rule, the steering wheel has to be ordered externally, but you can make it yourself. I made the handlebar from a steel pipe with an outer diameter of 22 mm using a pipe bender. And to chrome plate it, he turned to specialists from a neighboring plant. For those who don’t have such a factory nearby, I recommend covering the steering wheel with a simple “silver” coating.

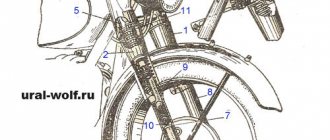

The next thing that defines the appearance of a stylish motorcycle is the front telescopic fork. On choppers it is usually extended using special inserts machined from a steel bar, the finishing outer diameter of which is equal to the outer diameter of the fork leg.

At the lower end of the extension insert, a thread is made with a pitch and length, as on the oil filler plug of the fork leg, and at the upper end there is a blind hole with the same thread parameters. Then a through axial hole with a diameter of 8-10 mm is drilled to fill the oil.

I did not lengthen the fork (however, for those who want to do this, I still provide a drawing of the insert), I just replaced the oil seals and oil in it, pouring 200 cm3 of a mixture of MGP-10 fluid and automobile engine oil into each leg in a 1:1 ratio. Now about the wings.

I replaced the front one with a chrome one from an Izh-Jupiter-5 motorcycle. I left the rear one in place, although I shortened it a little. I attached the chrome backrest of the saddle, and the registration number plate to the backrest.

The front headlight is original, but with a new rim, the rear headlight is new, round, from a decommissioned ZIL car. I also had to replace the mufflers: on my chopper they now come from the Izh-Jupiter-4 motorcycle. As you know, the main thing in any car is the engine.

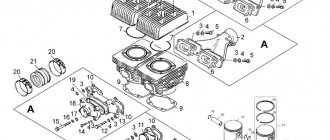

Before starting operation, I carefully overhauled the engine of my motorcycle. I replaced the worn piston rings and installed new cylinder heads (from Jupiter-4). The combination of Jupiter-2 cylinders with these heads made it possible to increase the compression ratio and, accordingly, engine power (up to 20-22 hp), and obtain a smoothly varying torque output over the entire speed range.

I also carefully polished the exhaust ports and chamfered the intake and exhaust ports. In addition, I conscientiously cleaned the exhaust pipes. To do this, I fluffed one end of a piece of steel cable, and threaded the other through the outlet pipe and clamped it in the chuck of a hand drill.

When the cartridge rotated, the cable also rotated, and its fluffed end did an excellent job of scraping off carbon deposits. I also replaced the old K-36D carburetor with a new K-65D. As a result, the average fuel consumption dropped to 4.5-5 liters per 100 km, and the maximum speed increased to 120-130 km/h. High-quality car paint is also very important.

I painted my chopper with Finnish automotive enamel. Thus, the result is a fairly stylish motorcycle with a minimum of capital investment. It completely suits me, and it doesn’t leave other motorcyclists indifferent.

(Author: K. KHLEBNIKOV, engineer, Krasnoyarsk)

Fork leg extension (L and M - plug thread parameters)

Steering dampers.

As already mentioned, with small fork rake values, the motorcycle steers easily and quickly, but suffers from a lack of stability at low speeds. This isn't much of an issue on sportbikes, which require precise handling while still being quite fast. The problems start when you hit a big enough bump. The motorcycle fork compresses, the wheelbase decreases, the motorcycle loses stability, and the front wheel dances from side to side. And so on until the fork unclenches and the wheelbase returns to its original length.

Once this happens, the gyroscopic effect that occurs on the front wheel causes the motorcycle to "bob its head." The gyroscopic effect causes the motorcycle's front wheel to wobble from side to side. In some cases, the handlebars dangle so much that the grips touch the motorcycle’s gas tank. Usually this all ends in a highside, when the motorcycle throws the rider forward, over itself.

At one time, this behavior of the motorcycle was the reason for the recall of a batch of Suzuki TL 1000S after a couple of weeks after they hit the windows of motorcycle dealerships. And this is the same reason that led engineers to develop steering dampers for motorcycles. A steering damper is a great thing to use on the track and if you don't fully trust your motorcycle. There are two main types of steering dampers: linear and rotary. Linear dampers consist of a hydraulic cylinder and a rod with a piston, one side is attached to the motorcycle handlebar, the other is attached to the frame. Such dampers are similar in appearance to shock absorbers and are not activated during normal driving, but as soon as the shock begins, the damper takes on most of the load.

Rotor steering dampers are also available. They are mounted on the motorcycle steering column above the bearing and work by increasing the steering column's resistance to sudden left-right movements. The resistance is achieved by damper hydraulics. Just try hitting one of the handlebars with your fist when the steering damper is installed - and you will understand how it works.

How to lengthen a fork in the Urals?

The steering fork is not only one of the most important design elements, but also an integral part of the overall style of the motorcycle. Not everyone likes its factory parameters, so lengthening and changing the angle of inclination of this part is far from uncommon.

One of the main reasons for performing this procedure is the owner’s desire to turn his road-spec unit into a chopper (a type of motorcycle with a low seat, an extended frame and front forks). Before lengthening the fork in the Urals, you should decide on the required length, which, according to the recommendations of experts, should not exceed the factory one by more than 15 cm.

To increase the length of the fork, a special insert machined from a steel rod is usually used. The part is a cylindrical blank. Its conical part is equipped with a thread for a plug and is intended for installation in the upper traverse. The other side of the insert has a threaded connector for the fork stem and threads similar to those on the plug.

The parameters of the extension must be similar to the parameters of the standard Ural fork ( diameter 36 mm and identical thread pitch on the nut screwed into the fork). The workpiece must be solid-body, have a hole and thread for the fork spring rod. BzYU In the case of self-manufacturing of the insert, the following actions are carried out:

- Thread cutting in the lower part of the plug-in module with a length and pitch identical to the oil filler plug in the fork.

- Drilling a blind hole with similar thread parameters.

- Drilling a through axial oil filler hole (8-10 mm).

- Filling 0.3 m3 of liquid (for example, a mixture of MGP-10 with motor oil in a 1:1 ratio)

One shock absorber or two? Foaming of oil in shock absorbers.

In the good old days, all motorcycles had two rear shock absorbers. In the course of evolution, the design of two shock absorbers was replaced by a monoshock absorber. Question: why?

And the answer is quite simple. In a system of two shock absorbers, they are located quite close to the rear wheel. This means that the piston inside the shock absorber moves almost the same distance that the pendulum travels. Large bumps force the piston to travel a distance of 10 centimeters up and then down, which gives the effect of foaming the oil inside the shock absorbers. When the consistency of the oil begins to resemble a Frappuccino, the shock absorbers begin to handle bumps much worse.

A monoshock system involves mounting directly at the base of the swingarm. The pendulum moves up and down the same distance, but the shock absorber piston travels a much shorter distance than with a pair of shock absorbers. And modern progression systems further soften the load on the shock absorber. Thus, the monoshock absorber copes with large bumps more easily and handles small ones faster. Looking ahead, I would like to note that, reading the paragraph about BMW suspensions, you will understand why the shock absorber mount on the first Paralever was subsequently shifted to the very base of the pendulum - precisely because the original design with a mount at the rear wheel did not provide any advantages over the same suspension design with two shock absorbers.

How to lengthen the fork on Izha?

In Izha, as in the Urals, if possible, it is better to use a ready-made insert, the description of which is indicated above. In order to extend the fork on something else if there is none, you will need two frames (upper and lower parts) and two pipes that are inserted for reinforcement. The top frame duplex tubes are cut to be as close to the steering column as possible, but no further than the bend. With the pipes of the second frame, the opposite is true - cutting is done as close as possible to the lower bend.

The pipes are inserted into each other and scalded, after which the joints are ground off using a grinding flap wheel on a grinder.

A lot of good things

About 20 years ago, the guys from Bimota and Yamaha, like Pinky and Brain of the cartoon, planned to take over the world with motocross motorcycles. In the case of Yamaha we are talking about the GTS 1000, in Bimota we are talking about the even more technically complex Tesi model.

The sport tourer GTS 1000 failed to translate its theoretical merits into everyday use, which is probably why it was not a bestseller among others, which is why it disappeared from the market after five years. Although the Tesi can still be purchased, it is a motorcycle for fans of the brand and alternative solutions. The design solutions of both motorcycles had many disadvantages: they were technically complex and, therefore, expensive to manufacture, provided a turning radius that was too small for a road motorcycle, and did not provide the best transmission of torque.

Countless racing prototypes with alternative suspensions have led to the fact that today, even in racing, the compact and not very expensive USD fork rules the roost.

It is important to know!

- If you decide to lengthen the front fork on Izha or Ural by 15 cm or more, you reduce the stability of the motorcycle’s structure. This must be taken into account when choosing speed and making sharp maneuvers.

- Changing the fork length leads to a change in engine tilt. In this case, the oil may go closer to the gearbox, and the oil pump will perform its function worse.

- When lengthening the steering fork, in order to avoid its deformation, the feathers must be clamped with a third crossbar.

This process does not require any special skills. By following these instructions, you will achieve the desired result without spending a lot of money, effort and time.

[sc:ads5]

Fork extension

Fork extension

Post by BikerZheka » Jul 13, 2006, 08:24

Post by danik_ik » Jul 13, 2006, 11:46 am

BikerZheka , the fork on the IZh is so flexible that it’s a thankless task, although to each his own. Personally, I don’t like that in normal use it plays back and forth on the dirt with a span of at least a centimeter. I'm going to install a fork on my sportbike

. And there is also such an important thing as controllability. Are you taking it into account?

I’ll tell you right away about the most incorrect way. Last year I disassembled the fork, where the reverse limiter was unscrewed from the plug, and between it and the plug there was a ten-centimeter spring. Such a fork is absolutely non-rigid (regardless of the diameter and material of the pipes), and is capable of jamming and breaking at any time. Never do this.

Next are the correct ways to lengthen the fork without replacing the supporting pipes, in order of improving quality.

1) Screw in. The top plug is replaced with a similar one, but ten centimeters high. The disadvantage is the high requirements for threads on both the cork and the feathers, otherwise there is low rigidity and strength at the connection point.

2) extension with tightening along the cut. The extension is made at the top - with an outer diameter like that of the fork's supporting pipes, and at the bottom - with a similar inner diameter. The lower part of it is put on the fork tube; on this part there is a longitudinal cut, tightened with several screws.

The disadvantage is the need for milling or metalworking work, plus a change in geometry if the internal diameter does not exactly match the diameter of the fork pipes.

3) extension with wedge tightening. It is made similarly to the previous one, but does not have a cut; instead there are 3-4 transverse holes, slightly intersecting the hole for the fork pipe. Two cylinders with small cutouts for the pipe to be secured are inserted into these holes in opposite directions, which are then tightened with a bolt, and the recommended pipe is wedged in the hole. I saw the description about six months (or more) ago in “moto”, in an article about fine-tuning the Yamaha V-max, it seems. The only disadvantages are milling and/or metalworking work. Maximum rigidity and strength.

And one last thing. We must not forget that lengthening the fork does not increase the suspension travel. Thus, lengthening the fork when converting a motorcycle into an SUV increases the ground clearance, of course, but the high probability of suspension breakdown spoils half the fun. And if a chopper is made with a large offset of the front wheel, then the bending force goes off scale, so IMHO you have to forget about Izhevsk forks (except, with a reasonable and moderate approach, PS and Orion).

He said what he knew.

Post by BikerZheka » Jul 13, 2006, 12:51 pm

Post by danik_ik » Jul 13, 2006, 3:44 pm

BikerZheka , easy. You take a plug and a pipe and go to a turner. You show the plug and say: “I want exactly the same one, with the same threads, but the cylindrical part should be not two millimeters long, but ten centimeters, two pieces.” The length of the threads is as shown in the sample. The outer diameter is exactly the same as the pipe. The external thread should not fit into the pipe tightly, but tightly (when screwed in, the screw should not swing in the thread, even if it only fits three to four millimeters). The depths of the holes with internal threads must be strictly the same, since the backstops are screwed into them “at point-blank range”. The same applies to the length of the external thread.

Flex deck

If you take a closer look at the torsional resistance of modern suspensions, you will realize that a certain range of flexibility is encouraged. Thanks to this, the system absorbs impacts caused by uneven surfaces. In turn, very rigid structures transfer these shocks to the chassis, which can cause steering wheel chatter or vibration, that is, high-frequency vibrations of the front wheel. In addition, the so-called wheel speed curve, i.e., the distance that it travels when the springs are compressed on an uneven road, is close to ideal in a telescopic fork. All other systems, including BMW Duolever, work in the opposite direction to the direction of impact, which is detrimental to comfort.

The aluminum bottom shelf can be up to 100mm high. Attached with three screws, it connects both fork legs while strengthening it. Often too much

Beautiful fixation of the thin-walled but huge front wheel axle of the MV Agusta F4

Large fork piston of the Big Piston type, which goes directly into the shins. Below that are small-diameter traditional fork pistons with rebound damping adjustment (right) and rebound damping, which are housed in a single shock cylinder (called a cartridge).

An example is the targeted flexibility of the shock absorber forks on some racing cars. Strange as it may seem at first glance, the milled upper fork flanges hold the upper shank and allow smaller or larger deformations using deep recesses. That is why massive lower shelves secured with several clamping screws on each leg have almost completely disappeared from sports and production cars.

The very large diameters of the front axles, once installed, for example, in the F-series MV Agusta motorcycles, ensure maximum torsional stability of the legs. The designers also made no changes here and left their diameter at 30-35 mm.

Over the years, many of the shortcomings of the telescopic fork design have been addressed. For example, by coating the surface of the shin with special coatings (for example, titanium nitride), friction is reduced, or by carburizing the friction of Teflon-coated plain bearings operating with sealants is reduced.