Maintenance and repair

5.18 Reinstalling the crankshaft and measuring the radial clearance of the main bearings

Reinstalling the crankshaft and measuring the radial clearance of the main bearings

Selecting new bearing shells

Inspection of main bearings and connecting rod lower end bearings

Measuring the radial clearance of the main bearings

EXECUTION ORDER

1. Clean the backs of the bearing shells and their beds in the cylinder block and in the main bearing caps. 2. Insert the bearing shells into place, making sure that the protrusion on each shell matches the notch in the cylinder block or main bearing cap. Try not to touch the working surface of the earbuds with your fingers. 3. Radial clearance can be measured by two methods. 4. The first method (which is more difficult to implement as it requires the use of an internal micrometer set or an internal/external flaring caliper) involves installing the main bearing caps into the cylinder block/crankcase with the bearings installed in them. After tightening the mounting bolts to the required force, the inner diameter of each pair of bearing shells is measured (the crankshaft does not need to be installed). After measuring the diameter of each corresponding crankshaft journal, to obtain the radial clearance, it is necessary to subtract the second from the first result. 5. The second (more accurate) method involves using a product called a plastic gauge (Plastigauge). The gauge is a thin plastic thread of absolutely circular cross-section, which is crushed between the bearing shell and the crankshaft journal. After removing the lid and liner, the width of the crushed thread can be measured using a special scale printed on the kit packaging. The gap is determined by the width of the crushed thread of the meter. The measuring set can be purchased from a Saab dealer or vehicle repair shop. When using a plastic meter, proceed as described below. 6

Once the upper main bearing shells are in place, carefully reinstall the crankshaft. Do not use any lubricants at this stage; The crankshaft bearing journals and the surfaces of the bearing shells must be absolutely clean and dry.

7

Cut several pieces of plastic thread to the required size (the length of each piece should be slightly less than the width of the main bearing), and lay each piece on the corresponding crankshaft journal coaxially with the journal. A piece of plastic thread should be laid approximately 6 mm to one side of the center line of the neck.

8. After installing the lower main bearing shells, reinstall the main bearing caps and tighten the bolts in a progressive order to the required torque. Be careful not to move the gauge thread or rotate the crankshaft during the measurement procedure.

9. Loosen the bolts and remove the main bearing caps, being extremely careful not to disturb the crushed gauge threads or rotate the crankshaft.

10. Compare the width of the crushed plastic thread on each neck with the scale printed on the kit packaging. The measured value indicates the amount of clearance in the bearing. Compare the measured gap with the values given in the Specifications at the beginning of this Chapter.

11. If the clearance is significantly different from what is expected, the bearing shells may be the wrong size (or excessively worn if old shells are installed). Before you decide that you need to install liners of a different size, make sure once again that when measuring, no dirt or oil gets on the crankshaft journal or liners. If the crushed plastic thread of the meter is wider at one end than at the other, then this indicates the presence of a taper in the crankshaft journal. 12. If the gap value is outside those established by the Specifications

limits, select the thickness of the liners to ensure the required clearance. When calculating the required clearance, remember that it is always better to err on the side established by the Specifications

lower limit, since as the liner wears out, the thickness of the gap will increase. 13. If necessary, install bearings of the required size and repeat the procedure for measuring the bearing clearance. 14. Finally, carefully scrape the crushed plastic gauge thread from the crankshaft journals and bearing shells. To do this, use your fingernail or a wooden or plastic scraper that will not damage the bearing surface.

Final installation of the crankshaft

Assembling the crankcase halves

We degrease the connector of the halves, knock out the guide bushings a little so that they extend 5-6 mm above the plane. Depending on your desire, we assemble the checkpoint. Personally, I assemble the gearbox only after assembling the engine, it’s more convenient for me.

We apply any automotive sealant to the connector, install the second half of the crankcase, tap it with a mallet, install the gearbox cover and tighten the crankcase with bolts.

We do not pull the bolts anyhow, but strictly according to Feng Shui: we pull about a third of the force, first the middle crosswise, then the periphery, and gradually increasing the force over several circles, we tighten the bolts as much as is sufficient.

Installation of the cylinder-piston group

It is not advisable to remove the gearbox cover until the sealant has dried; there is no need to rush in this matter. It’s better not to rush things and install the cylinder while the sealant dries.

Add some motor oil:

- into the upper head of the connecting rod

- lower connecting rod head

- into both oil channels of the crank chamber

To improve lubrication, it is advisable to drill holes in the piston bosses. But you don’t have to drill - it depends on your desire.

Install the piston pin retaining ring into the boss. Before installation, it is advisable to bend the locking ring a little and be sure to check how it fits after installation:

- If the retaining ring dangles, straighten it or replace it with a new one.

- If the retaining ring is not completely flat, replace it with a new one.

Assembly of the Izh Planet 5 box

Let's look at what the Izh Planet gearbox is. We will learn not only how to assemble it, but also how to identify faults and eliminate them.

It is not uncommon to experience problems when riding an Izh Planet 5 motorcycle due to the low reliability of the gearbox. This is due to low-quality components, primitive production of the 20th century and low requirements for the precision of manufacturing the crankcase, bearings, gears and shafts. There are, of course, some advantages to the simplicity of the design of such an Izh Planet gearbox; it is low-cost production, which is rather better for the manufacturer. But the main advantage is the ability to repair it yourself. Here we will look at what the Izh Planet gearbox is, we will learn not only how to assemble it, but also how to identify faults and fix them.

To begin with, I would like to announce the list of numbers of bearings and seals used in the IZh gearbox:

- One input shaft bearing - number 204

- One secondary shaft bearing - number 192906КМ

- Two intermediate shaft bearings - number 203

- One secondary shaft oil seal - size 34.5x52

Weaknesses and shortcomings of the IZH-P5 engine of the IZH Planet 5 motorcycle

Why did they stop producing the IZH Planet motorcycle in Russia? Oddly enough, the Kovrov Machine-Building Plant named after Dektyarev (ZID), as well as the former Soviet, now Belarusian Minsk Motorcycle Plant, still supply their motorcycles to the market. As for the Izhevsk Machine-Building Plant, which produces IZH motorcycles (Planet, Planet-Sport, Jupiter), the last production batch of motorcycles was produced in 2008, then, due to difficulties arising from the economic crisis, the production of IZH motorcycles was curtailed. It’s a pity, because the state could have provided assistance to the plant. At that time, Izhmash had a lot of experimental design work on promising motorcycles, both with two-stroke and four-stroke engines. I have a lot of positive memories associated with the IZh “Planet-3” and “Planet-5” motorcycles.

Any motorcycle model starting from Planet-2 gave a head start to Jupiters in terms of cross-country ability, old or new, it doesn’t matter. Didn’t he even sail on it, even to the taiga or the forest, fishing or hunting?

A very reliable “workhorse” with traction like a tractor, and my father and I never transported anything on it. We bought it in 1989 and to this day my father drives it, but it looks like new and makes my heart happy with its proper operation. Planet motorcycles, even its oldest models, continue to serve their owners regularly and reliably, despite the stoppage of production, there are no problems with spare parts for repairs on the market, and there is no limit to the maintainability stock. In this article, we will look at the IZH-P5 power unit of the IZH Planet 5 motorcycle, or more precisely, its technical characteristics, weaknesses and disadvantages. The IZH-P5 power unit differs from the IZH-P4 20 hp. the previous model of the motorcycle “IZH Planety-4” increased by 2 hp. power, a higher compression ratio and an engine head, the 4th model has two exhaust pipes, the 5th has one. Gearboxes differ in the number of teeth on the gears and, accordingly, in the gear ratios. Gearboxes are interchangeable.

Photo report: Repair of the engine of the IZH-Planet motorcycle 2, 3, 4 and fifth model

Nowadays it’s rare to find a “Planet” anywhere, especially in stock form.

Grandfather's sheds where they once stood in abundance have long been cleaned out by the suffering, and the garbage dumps where they once lay are overgrown with grass... The only place where you can still find something more or less decent is local newspaper advertisements. You can also search on Avito, but before you buy it there, see the product in person, otherwise they will send you a bag of bricks instead of an engine...

I was lucky: I found an advertisement in a local newspaper for the sale of an engine from a sidecar, went to the place, inspected it, made an agreement, bought it and brought it home. Don’t let the fact that the engine is from a motorized stroller scare you - the engine is completely identical to the original Planetovsky one.

In general, when I tossed the engine around, I was happy and immediately upset... I was happy because the engine was stock and had no signs of interference. There was also original oil and a USSR spark plug. I was upset because the piston and lower connecting rod bearing were killed.

I had a good factory cylinder in stock: bored to repair size + a factory piston, chrome rings and pin were purchased for it a long time ago.

I bought the connecting rod from an online store. We managed to find a factory one - not plasticine. I modified it a little: I made a small cut in the lower head to improve bearing lubrication, decompressed the crankshaft, threw out the old connecting rod, installed a new one and then centered the crankshaft using an indicator.

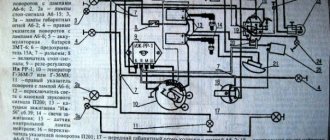

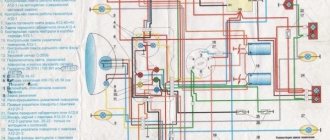

Wiring diagram IZH Planet 5

Detailed color wiring diagram for motorcycle IZH Planet 5

Explanations for the diagram

The numbers on the electrical diagram correspond to the following elements:

- Light switch, dimensions/low.

- Light switch, direction indicators and horn buttons.

- Front turn signals.

- Instrument panel lighting.

- Indicator lamp for generator operation.

- Oil pump operation indicator.

- A light indicating the operation of the neutral gear in the gearbox.

- Direction indicators.

- High beam headlight indicator.

- Front parking light bulb.

- Headlight lamp.

- Sound signal.

- Hall Sensor.

- Generator.

- Egnition lock.

- Turn signal interrupter relay.

- Neutral gear warning lamp sensor.

- Block BPV 14-10.

- Switch.

- Battery.

- Fuse.

- Relay block.

- Ignition coil.

- Foot brake light sensor.

- Rear direction indicators.

- Rear light with lamps.

Description of the symbols for the terminals on the rectifier-regulator block BPV 14-10:

- –x1 — “minus” of the generator excitation winding;

- –x2 — “minus” of the battery (“ground”);

- x2 - “positive” wire to the control lamp of the instrument panel;

- x3 - “positive” wire to the panel indicator;

- x4, x5, x7 - phases of the stator winding;

- x8 - “plus” of the battery.

Other faults

It happens that disassembling/assembling the Izh-Planet 5 box may be necessary if the fourth speed disappears. This is often due to broken bearings on the output shaft. Such a nuisance occurs due to the presence of axial play, displacement of the bearing assembly, or its failure. You can try to fix the problem in the same way as repairing the second gear. If this does not help, you will need to completely disassemble the unit.

When the speed switch jams from a high range to a low mode, the spring system of the switching mechanism has failed. It needs to be replaced. Strained operation of the unit after assembling the Izh-Planet 5 gearbox indicates incorrect installation of the adjusting washers. To avoid this, it is necessary to mark and record the previous placement of these elements during the process.

Most common problems

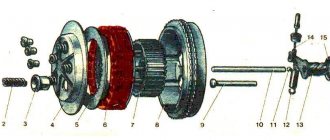

Gearbox assembly

Most often, the motorcycle in question loses or shifts poorly in second gear. This may be due to careless turning on of speeds. For example, when picking up high speeds in first gear without neutral, when engaging the second speed gear, an impact occurs, which contributes to intensive wear of the unit. Therefore, it is not recommended to “spin” the first speed too much. If, nevertheless, problems with the second position continue, there are several options for resolving them.

In some cases, the simplest method will help, without completely disassembling and then reassembling the Izh-Planet 5 box. It is necessary to place the motorcycle on the right side, and then remove the kick starter and gear shift foot along with the shaft. Next, the crankcase cover and clutch basket along with the discs are dismantled.

When the gears of the box wear out, the meshing of the teeth deteriorates. In turn, this leads to slipping, jerking and failure of the second gear. Another reason could be wear on the input shaft bearings. Since it moves slightly to the left due to vibration, it is necessary to move it into place with light blows using a mallet. The installation of washers of suitable diameter will allow you to fix the element in the desired position. Then the bearing stopper and other dismantled parts are reassembled in the reverse order.

How to adjust a motorcycle clutch?

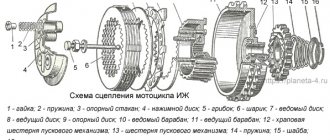

As always, we delve into theory.

Junker's clutch type is multi-disc in an oil bath. On the left, on the gearbox shaft, sits a basket with alternating disks, thin steel and thick getinaks. They are pressed against each other using 5 (or 6) powerful springs. Getinaks disks are connected to the basket (and, through the motor chain and 2 sprockets with the crankshaft), and steel ones are connected to the gearbox shaft (and, through the gearbox, actually to the wheel). The springs are so powerful that the entire power of the engine, without slipping (and the disks are all in oil) is transmitted to the rear wheel. Next, when you press the clutch lever, the cable pulls the lever (it sits on the right engine cover - look), which pushes the steel rod (it passes through the axis of the drive sprocket, you can take it out and turn it in your hands), and this rod rests on that part a basket with disks, which is connected to the getinax disks, and they, overcoming the resistance of the pressing springs, move away from the metal disks. That's it, the clutch is loose. The engine with its getinaks disks rotates on its own, the steel ones with the gearbox stand still. Attention! There is more than one push rod. There are 2 of them, and between them there is a ball from the bearing (eliminates rotational force). Easily lost! Be careful when disassembling, otherwise you will end up with a failed clutch.

Now about the adjustments.

The clutch is adjusted NOT ON THE HANDLE, but by changing the force of pressing the discs against each other. The free play of the cable is simply selected on the handle. The force of pressing the disks against each other is regulated by preloading the springs, on which, for adjustment, “fungi” with a groove for a large flat-head screwdriver are put on. Access to these “fungi” appears by unscrewing the cap on the left engine cover (the hole through which you pour oil into the engine). And not to all of them at once, but only to a part – i.e. to adjust everything you will have to rotate the crankshaft with a kickstarter

IMPORTANT! All springs must have the same preload! Those. all mushrooms twist at the same number of revolutions

Or rather, half a turn - a turn is too large an adjustment step.

What to do if the clutch slips?

1. Make sure that the clutch handle has free play and that you have not unscrewed the adjuster on the handle so that the clutch is constantly depressed. 2. Open the left cover (no need to drain anything, at the same time check the oil level in the engine on the dipstick - it should be between the marks) and evenly, carefully tighten all the fungi half a turn. We start the engine, check the clutch operation, if it still slips, turn it off and repeat the procedure. At the same time, we look at the condition of the teeth on the textolite disks - if they break off on some disk, then it begins to rotate with the steel disks and the clutch operates. Good official Hyundai dealers will help you make the right decision. For an office move, movers are indispensable, I recommend Best-Loader.Ru. Wheel storage in Moscow. What to do if the clutch does not disengage?

1. See paragraph 1. higher. 2. See point 2 above, only the fungi are unscrewed half a turn. Well, the reasons for a driven clutch are natural wear of the discs, weakening of the springs, breaking of the protruding teeth on the getinaks discs, pulling out of the cable and LOSS OF THE BALL when repairing a motorcycle.

Now about what a semi-automatic clutch is.

When you change the speed, the shaft on which the gear shift paw sits turns, and with its fork protruding into the right cover, it presses on the clutch lever (the same lever to which the clutch cable fits and which presses on the steel rod), and thereby duplicates the pressure on the clutch handle by hand. And don’t blaspheme the semi-automatic in vain! A very necessary and useful thing! Firstly, your clutch cable has simply never broken on the road - it’s impossible to get going without a semi-automatic vehicle. Secondly, on the road, starting from 2nd speed, I never used the manual clutch at all - there was no need. When changing the speed, I simultaneously disengage the clutch, change the speed and smoothly engage the drive! (You make one move, oh IT makes 3!

) The only thing is that it’s inconvenient to get going with a semi-automatic vehicle if you’re not used to it, but it’s quite possible.

Adjusting the clutch on a motorcycle

The clutch is regulated by changing the force of pressing the discs against each other, which, in turn, is regulated by preloading the springs. To do this, special “fungi” are put on the springs, which can be accessed after removing the cover on the left engine cover (oil hole). It is worth saying that in this way you can not get close to all the “fungi”, but only to some of them. All “mushrooms” can be adjusted by rotating the crankshaft using the starter

It is worth noting that absolutely all springs must be equally tensioned, i.e. each “mushroom” is twisted the same number of half turns

Thus, if the clutch is slipping, there are only two steps to follow:

- Make sure there is free movement of the handle. If it is not there, the clutch will be constantly depressed.

- Open the left cover, without draining any liquids, and tighten all the “fungi” evenly. After this, you should check the operation of the clutch. If slippage continues, it is worth repeating the procedure.

During adjustment, you should be careful and pay attention to various details, for example, the oil level in the engine, the condition of the teeth on the discs, etc. If after adjusting it there is no improvement, then you can begin the process of replacing the clutch

If after adjusting it there is no improvement, then you can begin the process of replacing the clutch.

It is worth noting that the malfunction of this element of the motorcycle should not be neglected, because if at the beginning of the day the clutch begins to slip, then after just a few hours of intensive motorcycle riding, it can completely die, thereby causing harm to the vehicle as a whole. After all, small particles of burnt clutch discs get into the oil, along with which they are sent to the precision joints of the liners, connecting rods and pistons, thereby damaging the engine

Therefore, if the time has come to replace the clutch, it should be done immediately.

With constant use of the motorcycle and long mileage, the basket itself wears out along with the clutch - wear appears on the edges of its longitudinal slots. Its appearance in these places makes it very difficult for the clutch discs to move. A shallow hole can be corrected using a regular file, however, this is a completely extreme case; still, if it appears, it is better to install a new basket.

So, there are different types of motorcycle clutch, however, the most common type is the multi-plate clutch in an oil bath. This is what is most often installed on motorcycles. Therefore, we will consider replacing the clutch using the example of a multi-disc clutch.

Preparing for assembly

Preparation for assembly can be divided into two main stages: measuring and, if necessary, eliminating the axial play of the tracer shaft and checking the suitability of the secondary shaft bearing for further operation.

The first stage is measuring and eliminating the axial play of the copy shaft

We put adjusting washers on the tracking shaft from the locking side. In my case, there were four adjusting washers, but you may have more or less, or maybe not... We move the locking bar to the side and install the copy shaft in its place. We put a standard thrust washer on the second end of the tracing shaft.

We place a new gasket (required) on the plane of the gearbox cover connector, on which you will later finally assemble the gearbox, and tighten the gearbox cover fastening screws with the required force.

We turn the engine over and measure the axial play of the copy shaft, the norm is 0.2-0.4 mm, but it will be better if you can ensure the axial play at a level of no more than 0.2 mm. Adjustment of axial play is accomplished by simply adding or removing shims.

I measure the play with an indicator. If you don’t have one, try measuring the backlash with a caliper; if you don’t have a caliper, so be it - measure by eye...

Second stage: checking the suitability of the secondary shaft for further use

Under normal operating conditions, the secondary shaft bearing runs for quite a long time. But no matter how much we want and try, it wears out. It would be nothing if it weren’t for safety: if your secondary shaft bearing falls apart while driving, and it will certainly fly apart if you don’t change it in time, the gearbox sticks together with the rear wheel, and it’s tight and you’re grinding the asphalt with your butt...

Carefully, take out the secondary shaft over some tray and carefully inspect the shaft bearing raceway, the races and the rollers themselves. The working surfaces of the bearing and rollers should be free of holes, edges, signs of wear or overheating

The path must have a perfectly flat working surface.

Example of a secondary shaft race and race in perfect condition.

To facilitate reassembly, apply some kind of lubricant, such as lithol, to the treadmill and carefully place the rollers on the track and, turning it a little, insert the shaft into the cage. As soon as the sprocket splines rest against the edge of the oil seal, use a thin screwdriver in a circle to straighten the edge of the oil seal and push the shaft until it stops. And immediately, so that the shaft does not fall out, put the sprocket on it and secure it with a nut.

"Sores"

There are three problems in the planetary checkpoint:

- Oil leak from the intermediate shaft plug

- Poor gear engagement in first gear

- Constantly loosening the bolts securing the gearshift shaft stop

I solve the problem with oil leakage very easily and simply: I take out the retaining ring; I remove the intermediate shaft bearing, degrease the plug, retaining ring, mounting hole, then apply sealant to the outer edge of the plug, put it in place and immediately press it with the bearing and voila - the leak is eliminated!

Due to a factory defect, the gear-carriage for engaging the first-third gear does not fully engage the first-gear gear with its cams, but only in a small part, barely catching the gear with its cams, which is why the edges quickly wear out and the first gear begins to knock out.

This moment is clearly visible in the photo. For this particular gear, the hook was no more than a couple of millimeters. It is difficult to cure this “sore”: from the side of the first gear gear, you need to grind the end of the intermediate shaft by 3-4 mm and, using adjusting washers, move the first gear gear to the carriage. I don't see any other way.

During operation, the bolts securing the stop are constantly unscrewed, either due to vibration or something else - they are unscrewed and that’s it, no matter how you tighten them... Even special lock washers do not help. I struggled with this disgrace for a long time using all the traditional methods known to me and came to the conclusion that the best solution to this problem is red thread locker. Feel free to put bolts on it and get rid of this problem once and for all.

When is it necessary to repair and adjust the gear clutch on an Izh motorcycle?

Regardless of the amount of experience the motorcyclist has, the feelings regarding gearbox malfunctions are almost the same:

- At first it seems that the clutch is slipping slightly. After two or three days, confidence appears - yes, it is slipping, because as soon as you add speed, the acceleration rate lags behind the engine speed level. The breakdown is especially obvious when moving uphill.

- The clutch “leads” or the clutch is incompletely disengaged when the control lever is depressed. In such a situation, the disks of the assembly remain pressed against each other and do not stop transmitting torque to the gearbox. You can finally verify such a breakdown after lifting the rear wheel - it continues to rotate in this situation.

If you want to know how to adjust the clutch on an Izh-Jupiter 5 motorcycle, then information about the reasons causing the listed factors would be useful:

- Use thicker oil in winter.

- Weakening of pressure springs.

- Worn clutch discs.

- Wear of clutch control mechanism elements.

In most cases, if signs of slipping or incomplete disengagement of the clutch are detected, a simple adjustment of the mechanism is required. To do this, it is enough to have a “13” key and a slotted screwdriver.

Tuning the IZH Jupiter engine

Before you start, you need to decide how much power you would like to give to your engine. If you are quite satisfied with the average power, then you will need a ZiD-200 resonator. But if you want to make the IZH Jupiter 5 motorcycle fast and powerful, start tuning the engine by installing a resistor from the SMB-5 “motoblock”.

Replacing the air filter plays a big role in engine modification. The better the air is cleaned, the more horses the engine will be able to produce. After all, the degree of engine overheating depends on the amount of incoming air. It is best to use imported air filters. They provide improved cleaning and longer service life.

Next you should work hard on the injection system. An excellent option is to install a “Planet” carburetor with a diffuser diameter of 0.32 cm. Two carburetors will provide much greater acceleration and good dynamics. We take the flanges securing the cylinder from the standard tube, grind out the aluminum studs, and cut off the flange from the carburetor from the inlet tube from the Planet.

We grind the ends of the cylinder heads on a machine, and press the cylinders themselves. The maximum permissible volume of PIC is 18 cubic meters. see Install factory copper layers under the cylinder heads. And we adjust the ignition advance angle to increase compression.

We use the second flange from the old carburetor. Then we weld the parts using “cold” welding. And finally, we modify the assembly to be compatible with the inlet channels. all the cracks with epoxy liquid . Voskhod carburetors will provide uniform traction. In this simple way, you can add not only a couple of additional horses to your pet, but also provide more lively dynamics that give a good riding experience. The motorcycle is very reliable for everyday use, and if you take good care of it, breakdowns will occur very rarely.

Assembly

In a carefully washed and prepared for assembly crankcase we place the input shaft, the first gear gear and the follower shaft with pre-selected shims.

We put a fork on the gear-carriage for engaging the second-fourth gear (it is smaller than the gear-carriage for engaging the third-first gear, you can’t go wrong) as shown in the picture. We put the gear on the input shaft and insert the fork pin into the upper groove of the follower shaft.

We put a fork on the gear-carriage for engaging the first-third gear, as shown in the picture, place it on the first gear gear and insert the fork pin into the lower groove of the copy shaft.

We install the fork guides in their places (with grooves towards the clutch basket). By the way, if necessary, the “Planetovskaya” gearbox can be assembled and disassembled without disassembling the clutch basket and without removing the guides. But to do this, during installation you will have to pull the tracing shaft towards you a little, insert the pins of the forks into the grooves and after that, remove the locking bar and push the tracing shaft all the way.

Install the intermediate shaft.

On older engines, the end gear is installed separately. On later ones, it is made integral with the intermediate shaft.

We fill the return spring of the gear shift shaft as shown in the picture.

We check the functionality of the gearshift shaft pawls: compress and unclench them several times

We pay special attention to their working edges: they should be sharp and not licked. And don’t forget to check the spring that compresses the pawls: it must be of the correct shape and ensure the elasticity of the pawls’ movement

We squeeze the pawls and install the gear shift shaft in its place.

We rotate the tracking shaft with the mark on the body towards the gear shift shaft and so as not to miss the mark during installation, we cover the gap between the teeth opposite the mark of the tracking shaft with lithol or paint it. It will be more noticeable this way.

We look for a mark on the sector and when putting the sector on the gear shift shaft, we combine the mark on the sector with the mark on the tracking shaft body: the tooth opposite the sector marks should strictly fit between the teeth opposite the mark of the tracking shaft.

To ensure that our marks do not get lost during installation, we tie together the sector and the copy shaft with ordinary sewing thread.

We put standard thrust washers on the input and follower shafts and insert the guide bushings of the gearbox cover into place.

We degrease the surfaces, apply sealant, lay the gasket, install the cover and tighten the mounting bolts with the maximum possible force. We adjust special washers under the bolts marked with yellow arrows.

After tightening the gearbox cover, we check the axial play of the primary and secondary shafts. Normal: 0.2-0.4mm.

If the play is greater than normal, remove the plate, seat the bearing and adjust the required number of shims under it.

Installation of bearings and seals

We install a retaining ring in the left half of the crankcase.

Depending on the model of the main oil seal, we install a spacer sleeve in the mounting hole of the main bearing, or, if the oil seal was initially wide (there are some), we heat the crankcase and, on the inside of the crankcase, place the oil seal until it stops against the retaining ring.

My engine had a regular narrow oil seal, so I put in a bushing.

Using a mandrel, install the main oil seal into the preheated crankcase.

Quickly, before the crankcase cools down, place the oil guide washer on the oil seal. The oil guide washer has a saucer-shaped profile. We place it on the oil seal so that the concave side faces us, and the curved side faces the clutch basket.

While the crankcase has not cooled down, we press the outer race of the main bearing into it using a mandrel.

If you are going to replace the main bearings with new ones, don’t be lazy: find a sheet of iron 7-8 mm thick, cut a wedge in it for the connecting rod, pass the sheet of iron between the cheeks of the crankshaft and use a mandrel to drive the main bearing onto the axle.

This way you will protect yourself from damage to the crankshaft. The main bearing has a very high interference and fits into the axle with a very large force. It is not uncommon for people to simply knock out the axle (the axle on the planetary crankshaft is pressed into the cheek) inside the crankshaft, but they were never able to put the bearing on.

Native made in USSR 2505 KM

Motorcycle Izh Planet 5 engine specifications

Two-wheeled motorcycle IZH Planet 5 engine, which developed only 22 hp. pp., throughout almost the entire period of its production, and from 1987 to 2008 it was considered one of the most common middle-class motorcycles among domestic buyers.

- Engine for the fifth model.

- Reasons for repair.

- Engine modernization.

This motorcycle was developed and manufactured at the Izhevsk Machine-Building Plant (Izhmash), which is located in the capital of the Republic of Udmurtia. The main advantages that ensured the popularity of Izhevsk motorcycles, and not only in Russia, should be considered:

Ease of use. Simplicity of design and maintenance. High overall reliability. Economical, repairable motors. Affordable prices.

In addition, Izhmash constantly sought to make changes and improvements in the design of its products, including the Izh Planet 5 motorcycle model and the Izh Planet 5 engine. At the plant itself, production was regularly modernized in order to improve quality. Thus, the assembly of power units, including the assembly of the IZH Planet 5 engine, was carried out at a specialized technological site.

Engine for the fifth model

The Izh Planet 5 engine contains the following main characteristics and indicators:

- execution type – two-stroke with one cylinder;

- cylinder working volume – 345 cubic meters. cm;

- piston diameter – 72 mm;

- power – 22.0 l. With. at 4800 crankshaft rpm;

- battery voltage – 12 volts;

- cooling option – air;

- ignition type – contactless;

- the ratio of the mixture of oil and gasoline (A 76) is 1/30.

Reasons for repair

Complete disassembly of the Izh Planet 5 engine during repair work is carried out if damage or breakdown of the following elements occurs:

- crankshaft;

- bearings;

- piston;

- connecting rod

Failure of these parts can occur due to engine jamming, general severe wear, which is accompanied by increased noise during operation, as well as various knocking noises in the crankcase. In addition, repair of the Izh Planet engine with its complete disassembly is carried out when the crankshaft seals are worn out. At the initial stage of production of power units, the reed valve on the Izh Planet 5 had certain technological shortcomings associated with low strength. Therefore, it quickly collapsed, its elements fell inside the cylinder, which required further disassembly and, in most cases, replacement of the Izh Planet 5 piston.

If, when operating the engine, all routine and technical maintenance procedures established by the manufacturer were observed, and appropriate technological materials and fluids were used, then it was operated for a long time, while maintaining its technical parameters.

Engine modernization

The design features of the IZH Planet 5 motorcycle are that the owner, having certain technical skills, could do tuning work with his own hands to give his motorcycle a more modern look and increase its power. Tuning the IZH Planet 5 engine was aimed at increasing its power. Such work usually began with repressing the crankshaft of the IZH Planet 5 engine, which made it possible to increase its power by 10-15%. The next step to increase power was boring the cylinder to a repair size of 76 mm and modifying the piston group. In some cases, a piston group from an IZH Sport motorcycle was installed.

For more charged versions, turbocharging was used on the engines of IZH Planet 5 motorcycles. But, no matter how well the work on modifying the IZH Planet 5 engine is carried out on your own, this still leads to a decrease in service life and an increase in the number of repairs.

Assembly and disassembly

Before you think about power, you need to understand motorcycle maintenance. Often, chasing speed and appearance, owners forget about the basic rules for operating their pet. Due to negligence, and not only, various types of breakdowns occur. You can troubleshoot problems yourself. Considering that disassembling and assembling the IZH Planet 5 engine is very simple, they can be done at home. However, it is recommended that you consult the factory-produced motorcycle operation and maintenance book.

There are cases when the maintenance book was lost long ago, or was not received at all upon purchase. In this case, here is a simple procedure for disassembling the engine:

It should be noted that the cleaner your workplace is, the better the repair will be done, since dirt that gets inside the engine can make it difficult to operate and even cause another breakdown. Don't be too lazy to wash the engine well before work .

Write down or mark the progress of your actions. This will help with assembly. Group the parts in the order they are disassembled and assemble them by location. The more organized the disassembly process is, the faster you will assemble the IZH Planet 5 engine, the technical characteristics of which will once again delight you.

Purpose of the IZH Planet coupling

Clutch. the name of this node indicates the work it does. In our case, the crankshaft meshes with the gearbox of the IZH planet engine. The clutch should move smoothly, without jerking, which is necessary to start the motorcycle and smoothly change speed. In case of heavy loads, it protects engine parts from damage.

The clutch is located in the left half of the crankcase, under the left engine cover. To get to it, you need to drain the oil and remove the cover before removing the arms and unscrewing the mounting bolts. The clutch is always in working condition, the discs are tightly compressed by springs. The engine transmission consists of two sprockets. The small wire is located on the crankshaft. The big star led the drum. The connection is made by the motor circuit. The engine's gear ratio is 2.17 for all single-cylinder IZ models. Switching off occurs using a special device. The shutdown mechanism is installed in the right engine cover. The adjustment is made using this mechanism.

Main stage

As noted in the assembly diagram of the Izh-Planet 5 box, further disassembly operations are carried out above the insides of the roof of the unit, since the secondary shaft and sector could remain in it. If it is necessary to remove them, you need to straighten the petals of the lock washer, unscrew the nut, remove the star and washer. Holding the gear very carefully to prevent the shaft from jumping out, the cover is moved to a clean and flat surface with the gear facing up.

It is worth noting that the bearing of this part of the assembly does not have a retaining ring. Therefore, when removing the shaft with bearing, the rollers may fall out, so be careful. If the specified element has exhausted a decent service life, there is a risk that when dismantling the secondary shaft, the outer ring may jump out of the seat and remain on the rollers. Next you need to start pressing out the oil seal. To do this, the installation rings are removed from the hole in the cover, after which the outer ring of the bearing is removed.