Cars admin26.02.2020

Any, even the most advanced motorcycle equipment needs careful handling and professional care. The engine is the heart of the Alfa moped. If handled incorrectly, the consequences can be unpredictable. In order to avoid the risk of irreversible damage to the moped, it is important to know how to independently disassemble and reassemble the engine of this model. Repairs are easy. This will require experience, as well as knowledge of some nuances.

Engine Features

The engine of the Chinese Alpha moped has characteristic features, thanks to which fans of motorcycle technology prefer this particular model.

Engine for Alpha moped

Engine capacity - 72 cc. With the right approach, it can be upgraded to 110 cc. Also, if desired, you can increase the speed by 10 kilometers.

The weak point of the engine is the gearbox, which requires close attention and a delicate approach . When repairing the “heart” of a moped, you need to know how to correctly disassemble and reassemble this part of the motorcycle “organism”.

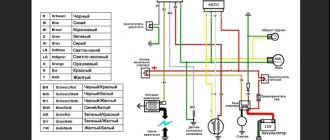

Alpha is equipped with a powerful engine, the circuit of which is complex. If you can’t figure it out on your own, it is recommended to contact an experienced specialist. The price of repairs is quite affordable.

Alpha moped repair

The affordable price has made the Chinese 50 cc moped “Alpha” the literal favorite in the demand for “stools”; in the same bunch is its slightly more durable twin brother “Delta”. Economical, with an engine capacity of 72 cc and air cooling, the Alpha moped is unpretentious and easy to maintain. The clear design of the Alpha moped engine allows you to repair or tune the equipment yourself.

Alpha moped engine repair

Before disassembling the engine of the Alpha moped, we fix the scooter with the central stand and free it from the plastic. We disconnect all engine power systems and do not forget to drain the oil.

We remove the engine along with the transmission, and on a flat surface we continue the home repair of the Alpha moped.

It will help to properly dismantle the Alpha moped engine by disassembling it according to the following scheme:

If this is your first time doing a DIY repair on an alpha moped and you need to disassemble it, don’t forget to sketch a diagram of how everything was in place! If the valves need to be replaced, or if there are gaps in the fit, then they need to be removed:

To complete the repair of the Alfa moped engine, after replacing the parts, we begin assembling the engine in the reverse order, putting everything in its place, observing the marks. Don't forget to add fresh oil.

Alfa moped box repair

The gearbox of the Alpha moped sometimes fails and requires constant attention. Repairing a gearbox at home is not particularly difficult for a beginner.

We carefully read the instructions for the alpha moped, do-it-yourself gearbox repair.

Let's take it slowly, in order:

When the repair of the Alpha moped box is completed, assemble the gearbox using the reverse algorithm.

Tuning

For many, Alfa moped repair begins almost immediately after purchase. Thanks to the presence of spare parts and the simplicity of the Alpha moped engine, tuning is common. This could be replacing the not very comfortable original seat, or increasing the engine capacity to 110 cc. Replacing the sprocket from 14 to 15 or even 16 will increase the speed to 10 km/h.

Increase in cylinder volume - replacement from 50 cc. at 70 cc., will add power, which is sometimes lacking. To do this, in addition to the cylinder head, you will have to change the pistons and carburetor. You can carry out such maintenance of the Alpha moped yourself. If you bought an Alpha moped, repairing the gearbox and engine yourself will be a good opportunity for you to study your equipment.

And finally, some useful tips that will make repairing an Alpha moped a more enjoyable experience for you.

Have you disassembled the timing belt and CPG? Place parts in separate boxes. Sketch the position of the gears and forks on paper before removal. If you decide to increase the speed of the Alpha moped using an asterisk, do not forget that the front and rear change at the same time.

Monitor the speed, prevent clutch wear, and change fluids in a timely manner.

Don’t be afraid of repairs, learn the hardware, watch video lessons, and you won’t need the services of a mechanic.

Hang panniers, change headlights and mirrors. The Alpha moped is from the series that will respond to any of your concerns with reliability in thousands of your future kilometers.

Causes of malfunction

The Chinese Alpha moped, whose price is affordable, does not cause owners many problems. Interruptions in a moped engine have several causes, and once you understand them, you can quickly fix the breakdown.

Disassembling the moped engine

So, if the engine starts with great difficulty, the muffler “shoots”, and smoke comes out of the chimney, it means that the moped is “capricious” due to problems with the carburetor. In order to solve this problem with the Alpha moped, you need to:

- clean the carburetor;

- thoroughly clean the moped's air filter;

- tighten the screws;

- adjust the moped carburetor.

If the Alpha slowly picks up speed, and its engine is not able to develop the declared power, then the reason is the incorrect operation of the moped valves. It can also “get sick” due to gaps and incorrect timing. In order to make the Alpha moped function normally, it is necessary to replace the used valves with new ones.

If the Alpha moped is not able to reach the required speed, despite the roar of the engine and solid revolutions, it is impossible to stop the spinning wheel, and gear shifting occurs intermittently, then the cause of the malfunction is clutch wear.

Moped clutch parts

To eliminate the breakdown, you must perform the following manipulations:

- remove the engine;

- remove the plastic cover;

- unscrew the tightening screw;

- Unscrew the adjustment mechanism and tighten the screw tightly;

- start a moped;

- turn on first gear and drive a few meters.

Another cause of moped engine malfunction may be wear on the drive sprockets. If they are very worn, they must be replaced with new ones.

You may encounter the problem of engine overheating. The situation can be corrected after adding oil. If oil leaks, you must urgently contact a professional service .

Alpha moped engine overheating

Engine disassembly

Disassembling the Alpha engine is quite simple. To do this you need:

- “arm yourself” with a key;

- Unscrew the bolts on the intake manifold (by 10);

- unscrew the cylinder covers and the bolts located there (4 pieces);

- remove the cylinder head.

After performing the necessary manipulations, you need to properly assemble the engine, installing all the parts in place.

Gearbox disassembly

It is necessary to disassemble the gearbox in order to replace used parts. This is done after the following parts have been dismantled:

Gearbox disassembly

Repair of this part of the engine is carried out as follows:

- Using a screwdriver or blade, remove the retaining ring and the drive gear;

- Carefully unscrew the gear fixing bolt and remove the gear shift mechanism;

- remove the gear shift fork and shaft;

- remove the crankshaft and drum (including the core);

- After replacing the worn part with a new one, reassemble (in reverse order).

Photo report: Assembly of the gearbox (box) of the “Ant” scooter

After completely disassembling the engine of the Ant scooter, many, especially beginners, have difficulty reassembling the gearbox, and this is not surprising. There is very little reference information, there are too many “ant” experts, the matter is further complicated by the fact that there are no marks on the gearbox parts that greatly simplify the work on the correct orientation of the gearbox parts relative to each other.

In fact, everything is not as complicated as it might seem at first glance...

The gearbox, after disassembling the engine and troubleshooting the parts, turned out to be in very good condition; only one gear of the first gear had to be replaced (extreme wear of the bushing and, as a consequence, increased backlash of the gear on the shaft) and all the bearings (due to severe wear). All other gearbox parts were checked for wear and so on without any problems. Complete disassembly of the “ant” engine is described in detail in the article: Photo report: Disassembling the engine of the “Ant” scooter

Before assembling the gearbox, we carefully wash all the parts from dirt, pay special attention to the engine crankcase and the condition of the threaded connections, buy a new set of oil seals and gaskets (preferably made of paronite). The general principles of engine crankcase repair are described in detail in the article: Photo report: Repairing a scooter engine crankcase

And so, the right half of the crankcase is completely washed, laid on wooden blocks and is completely ready for the introduction of our gearbox into it.

We insert the retaining ring into the mounting hole of the secondary shaft bearing.

Using a mandrel, install the bearings into their mounting holes. Don't forget to place a special washer under the input shaft bearing.

We check the performance of the copier, for this: we press on it with a screwdriver or a finger and release it - several times, there should be no jamming or excessive play in its operation, the working surface should be strictly in the form of a cone (not “slicked”).

We carefully inspect the teeth of the “pawl” of the gear shift mechanism; there should be no cracks, chips, or wear. The teeth should be sharp (not “slick”).

In the same way, we inspect the teeth of the crescent of the gear shift mechanism.

We assemble the gearshift shaft and install the return spring.

We install the gearshift shaft into the engine crankcase.

We install the secondary shaft in its place.

We put the fourth gear gear in its place.

Apply any grease to the thrust washer of the tracing shaft (marked with an arrow) and place it on the mounting hole of the tracing shaft.

We unfold the crescent of the gear shift mechanism so that its last tooth (marked by an arrow) engages with the gear of the copier shaft.

We take the copy shaft and carefully inspect the forks of the gear shift mechanism, they should not show signs of excessive wear and signs of overheating (blue), wear on the working surface of the forks should not be more than 0.5 mm. You should also check the ease of movement of the forks on the shaft and the play, which should not be excessive.

These small abrasions on the forks are considered quite normal for this engine.

We take the copy shaft in our hand (with the daisy pointing towards us) and turn the forks of the gear shift mechanism all the way to the right (clockwise), the forks should take the position as in the photo.

We put the gearbox gears on the forks; the first and third gear gears (large) are placed on the long fork; the second and fourth gear gears (small) are placed on the short fork.

We install the copy shaft assembly with gears in place, while carefully ensuring that it is the last tooth of the crescent of the gear shift mechanism that engages with the gear of the copy shaft (as in the photo). If the crescent meshes with the gear with another tooth, then the gearbox will not work correctly in this case.

Reinstall the input shaft.

We put the first gear gear on the secondary shaft and swing it; if large play is detected, we replace the gear with a new one.

We install the copy shaft clamp along with the spring on the gear shift mechanism shaft.

After assembling the gearbox, we must check its functionality and prepare the engine for final assembly. The final assembly of the engine is described in detail in the article: Repairing the Ant scooter engine

scooter-mania.ru

Engine Features

The engine of the Chinese Alpha moped has characteristic features that make motorcycle lovers prefer this model.

Engine on Alpha moped

Engine power 72 cc. See: With the right approach, it can be upgraded to 110 cP. Additionally, if you want, you can increase your speed by 10 kilometers.

The weak point of the engine is the gearbox, which requires close attention and a gentle approach . When repairing the “heart” of a moped, you need to know how to properly disassemble and reassemble this part of the motorcycle “body”.

Alpha is equipped with a powerful engine, the circuit of which is complex. If you cannot figure it out on your own, it is recommended that you consult an experienced professional. The price of repairs is quite affordable.

Causes of malfunction

Chinese moped Alpha

, the price of which is affordable, does not give the owners many problems. Interruptions in a moped engine have several causes; once you understand why, you can quickly eliminate the breakdown.

Removing the moped motor

So, if the engine starts with great difficulty, the muffler “shoots” and smoke comes from the pipe, which means that the moped is “capricious” due to problems with the carburetor. To solve this problem with the Alpha moped, you need to:

- clean the carburetor;

- thoroughly clean the moped's air filter;

- tighten the screws;

- adjust the moped carburetor.

If the Alpha is slow to pick up speed and its engine is unable to produce the stated power, the reason is that the moped valves are not working properly. In addition, he can get sick due to gaps and poor timing. For proper operation of the Alfa moped, it is necessary to replace the exhaust valves with new ones.

How to properly assemble the gearbox of a Viper Activ alpha delta moped

moped gearbox

Viper Activ Alpha Delta hur man monterar vaxelladan

moped

In this video I will tell you.

If the Alpha moped is not able to reach the required speed, despite the roar of the engine and a solid speed, it is impossible to stop the rotating wheel, and gear changes occur intermittently, then the cause of the malfunction is a worn clutch.

Moped clutch parts

To fix the problem, you need to do the following:

- remove the engine;

- remove the plastic cover;

- unscrew the clamping screw;

- unscrew the adjusting mechanism and tighten the screw tightly;

- have a moped ;

- turn on first gear and drive a few meters.

Another cause of moped malfunction may be wear on the drive sprockets. If they are very worn, they must be replaced with new ones.

You may have a problem with the engine overheating. You can correct the situation after refilling the oil. If there is an oil leak, you should urgently contact professional service .

Alpha moped engine overheating

Engine disassembly

It is very easy to disassemble the Alpha engine. To do this you need:

- "Hand" with a key;

- Unscrew the bolts on the intake manifold (10);

- unscrew the cylinder covers and bolts (4 pcs.);

- remove the cylinder head.

After completing the necessary manipulations, it is necessary to correctly assemble the engine and install all the parts in place.

It may help to figure out the nuances of the scheme. The training video also contains many useful tips for repairing the most important “body” of the Alpha moped.

Conclusion

To properly carry out independent engine repairs, you need to familiarize yourself with the instructional videos. Make no mistake, the placement of the forks and gears will help the engine layout of this model. If you do not have access to the diagram, you need to mark them on a piece of paper.

Moped Alpha

rarely needs repairs. If the owner is not confident in his abilities, then the repairs should be carried out by a professional. Otherwise, the price of the issue will be very high.

Source

Removing the gearbox

Disassemble the transmission to replace the waste. This is done after dismantling the following parts:

Removing the gearbox

Repair of this part of the engine is as follows:

- Using a screwdriver or knife, remove the retaining ring and drive gear;

- carefully unscrew the clamp bolt and remove the gear shift mechanism;

- Remove the shift fork and shaft;

- Remove the crankshaft and drum (including the core);

- After replacing the worn part with a new one, reassemble (in reverse order).

How to disassemble a box on a moped

mechanical, four-speed and made in a single block with the engine. Gear shift mechanism

consists of a lever, shaft, ratchet and shift drum.

In the neutral position, the clutch cams for 1st, 2nd, 3rd and 4th gears are located with a gap relative to the gear cams. This neutral position in the shift mechanism is ensured by a detent lever. When you turn the gear shift lever, its shaft rotates, which through the ratchet mechanism transmits rotational movement to the shift drum disk, rigidly mounted on the drum. Rotating in the crankcase, the shift drum acts through curved grooves on the shift forks, which, moving along the axis, displace the couplings along the splines of the secondary shaft until they engage with the gear cams. When the force is removed from the lever, the gear shift shaft returns to its original position under the action of a spring, while the ratchet mechanism of the shaft, after interacting with the shift drum disk, remains in the same position. The gearbox is lubricated from a common oil bath. Oil is poured into the crankcase in an amount of 0.8 liters through the filler hole (the oil change procedure is described in the “Moped Maintenance” section). Oil leakage from the crankcase is prevented by oil seals (on the secondary shaft and kick starter shaft), rubber rings on control shafts and gaskets between parts of the boat. The oil level in the crankcase may drop due to its leakage through the seals, loose connections between the crankcase parts and the crankcase cover. Operating a moped with a low oil level can cause failure of engine and gearbox parts. Operating a moped with a low oil level is not allowed!

What is the gear ratio of the gearbox and final drive?

The gear ratio is nothing more than the ratio of the number of teeth on the driven gear to the number of teeth on the drive gear. In practice it looks like this. If one (driven) gear has 60 teeth, and the other (drive) has 30, then the gear ratio of this pair is 2 (60:30). Gear ratio is one of the main characteristics of gears, which ensure the transmission of torque from the engine to the drive of some other device (unit). At the same time, this mechanism allows you to increase or decrease the amount of transmitted torque. For example, by changing the number of teeth on both gears, you can increase or decrease the torque transmitted from the engine to the “consumer”. The gear ratio in the gearbox affects such characteristics as acceleration dynamics and maximum speed of the moped. In relation to gearbox stages with different gear ratios, it looks like this: the larger this number, the “shorter” and “more powerful” the gear, that is, when accelerating, the engine spins up faster to maximum speed, and the motorcycle accelerates more intensely. True, this reduces the maximum speed in this gear. Consequently, there is a need for more frequent switching. The acceleration dynamics are also influenced to the same extent by the gear ratio of the main pair. The higher it is, the more dynamic the motorcycle is, the better it pulls in all gears, but the maximum speed is lower. By reducing the gear ratio, they increase the maximum speed (if the engine has a so-called power reserve), but lose in the acceleration dynamics of the motorcycle. For example, installing a main pair of 4.1 or 4.3 instead of 3.72 makes the moped more dynamic, but less fast. Transmission gear ratios are selected depending on the power and torque characteristics of the engine, wheel size, braking system capabilities, and if the moped is tuned, the owner’s wishes are also taken into account.