Adjusting the gap between the breaker contacts

Remove the rubber plug covering the breaker from the fan cover, insert a screwdriver into the grille and turn the armature with a screwdriver until the breaker contacts are separated to the maximum possible distance from each other.

Unscrew the bolt for adjusting the contact gap of the breaker

We insert a measuring probe 0.4-0.6 mm thick between the contacts, move the breaker plate until the probe begins to move with a slightly noticeable force, tighten the bolt, turn the engine a few revolutions and check what we got: if the gap is “gone” - We re-adjust.

Diagnostics of technical condition

Easy adjustment of the handbrake with your own hands: video instructions

Diagnostics is carried out by performing the following procedure:

- The first stage is connecting the high-voltage cable to the voltage terminal.

- The second end of the cable is constantly held at a distance of about 0.5-0.7 centimeters from the device body.

- Maintaining position near the wire. Next comes a sharp turn of the rotor in the direction of rotation. The spark should jump as a result of this movement; if everything is in order, the magneto is adjusted correctly. If there is no spark or is too weak, there is a high probability that the installation requires a malfunction check. If necessary, adjustments are made.

Common malfunctions and their repairs

Here are just a few of the most common problems magneto owners may encounter:

- Failures during sparking. There are several reasons for this situation and ways to resolve the problem. Possible problems include: contacts burn, oxidize; the gap adjustment is violated; the lever cushion at the breaker is worn out; The capacitor element was broken. If an element fails, it is completely replaced. When the problem is in the gaps, they undergo additional adjustment. Contacts are also changed or completely cleaned. How to set up the magneto is described further.

- Complete lack of spark. This often happens because the transformer wiring has broken, there has been a short to ground, or the insulating layer that supplies the high-voltage cable has broken through. If problems arise with the transformer, the unit must be replaced. You can eliminate the short circuit itself or change the cable when an insulation breakdown occurs.

- A broken capacitor is the most likely cause of a spark that is too weak. In this case, the part must also be replaced.

Candle and armored wire

It is recommended to abandon the caps used for armored wires. It is better to use an alligator clip.

The armored wire itself also requires additional testing. This concerns two elements:

- Fastening in the mounting socket.

- Base for a candle.

Complete stripping of the wire from each end by 2 millimeters is an excellent reason for inspection and repair. You can check using a different armor wire instead of the one installed initially. If the spark plug is faulty, it is also replaced; the part is not repaired.

Capacitor

It is needed so that the contacts do not burn too much. It consists of two plates and insulation, the role of which is usually played by foil. Everything is rolled into one roll and placed inside the case. In some cases, if the housing is damaged, the capacitors can be adjusted using sandpaper

It is important that the structural parts do not overheat during operation. Adjusting the magneto after that won't help.

Sometimes it is recommended to install two capacitors at once, then the operation of the mechanisms will be more reliable and stable.

About breaker contacts

If they become faulty, the first recommendation is to clean the surface using a special flat abrasive plate. The work can be done without problems with a flat file with a fine notch. Cleaning with sandpaper or glass paper will not give the desired result. The contacts wear out too quickly, and in this case a flat surface cannot be obtained.

From time to time, contacts also require cleaning from plaque and adjusting the gaps between parts. The main thing is not to lose a single part during disassembly. The contact spring is subject to malfunction or straightened in the opposite direction.

Coil or transformer

It is easy to repair the tractor magneto for such parts. This same part of the engine rarely fails; it can operate uninterruptedly for a long time. If the part has become unusable, then it must be replaced with exactly the same, but working model.

Rotor

The main thing is that it does not crumble or break during operation. From time to time the rotor can become demagnetized. If the part really turns out to be damaged, then it is replaced. The main thing is not to forget to remove metal fragments, sometimes they remain inside the magneto housing. Bearings require separate inspection and lubrication.

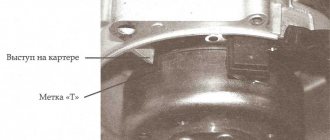

Adjusting the ignition timing

We install the piston at the top dead center (TDC), insert the bore gauge of a caliper into the spark plug hole, extend the bore gauge until it rests on the bottom of the piston, remove the caliper from the hole and extend the bore gauge to the plus side by 3.5-4 mm and fix the resulting value with a locking screw.

Turn the engine a little clockwise, insert a caliper into the spark plug hole, turn the engine counterclockwise until the piston touches the bore gauge.

If you have an indicator, then the matter becomes much simpler: fix the indicator in the spark plug hole, reset the scale to zero, turn the fan clockwise until the indicator pointer reads 3.5-4 mm.

We insert tissue paper between the contacts of the breaker, unscrew the adjusting bolts, move the contacts along the grooves in a clockwise direction (to the right), as soon as the paper falls out, we fix the contacts with the bolts.

You can also adjust the advance using a control light: we connect one wire of the light bulb to ground, the second to the wire going to the contact, just like in the case of paper, we manipulate the contacts and as soon as the light comes on, the desired position of the contacts is found.

Using a light bulb to adjust the timing is both more convenient and simpler, but not everyone has the original ignition, and many have a magneto, so it’s not always possible to use a light bulb.

Photo report: Disassembling the engine of the TMZ scooter “Ant”

Almost just before leaving for permanent residence on another collective farm, an old acquaintance, whom I had not seen for 15 years, turned to me and asked me to overhaul the engine of his Ant. To be honest, I didn’t have much of a desire to get involved with this Soviet chatterbox, to say the least... But after thinking about it and playing out the situation in my head that I would have to sit in a new place for some time without my favorite job, I agreed and immediately began the repairs.

I will not go into the essence of the disassembly in particular within the framework of this article - I will only outline the main points and, based on my experience, I will try to describe the most common malfunctions and errors during repairs.

The engine had the following symptoms before being repaired:

- Bad start

- Oil leak

- Weak traction

- Increased noise during operation

- The winding lever did not return to its place

- Depressurization of the crank chamber, as well as wear of the seals

- Poor quality assembly

- The piston died

- Bearing wear

- Kickstarter return spring broke

Everything else, including the gearbox and clutch, did not cause any complaints during operation. However, first things first.

Before a major overhaul, I don’t wash the engines - I just drain the oil, pull it off the frame and get to work.

Removing and checking the piston (CPG)

Remove the cylinder head (cylinder head).

The cylinder head gasket held up well, as evidenced by the absence of oil leaks.

In the upper part of the cylinder opposite the exhaust window, we feel the groove with our finger. If it feels a clearly perceptible so-called “wave”, “step”, that is, a drop, then such a cylinder is no longer subject to further use. It needs to be either bored to repair size or bought a new one.

The wear can be easily felt in the place where the piston rings do not reach the end of the cylinder. In the place where the piston rings do not work, the nominal factory size is maintained, but in the place where they work, the metal wears out. That is why a transition is formed at the boundary of these two sections, which is larger the greater the wear of the cylinder.

In my case, as expected, the wear was clearly palpable and the cylinder mirror was covered in nicks and scratches.

A bunch of hay that blocked the flow of cooling air, in my opinion, did not add efficiency to the cooling system... How can you even drive like that?

The piston turned out to be burst and, moreover, according to the good old collective farm tradition, it was treated with sandpaper. As indicated by numerous risks on its surface.

After removing the clutch cover and removing the kickstarter shaft, the reason for the freezing of the winding lever was found - the return spring had burst in half.

The motor chain turned out to be stretched, but not critically.

Removing the clutch

Unscrew the nuts and remove the pressure plate from the basket.

Unbend the lock washer, insert a tin rod or stick under the tooth of the motor transmission sprocket and unscrew the nut on the crankshaft journal (right-hand thread).

Unbend the lock washer, fix the inner clutch drum with a puller, which is a clutch disc with a welded piece of tire, and unscrew the nut (left-hand thread).

We take out the discs and drum.

Remove the basket from the shaft along with the chain and sprocket.

Removing the dyno starter

We remove the cooling casing and then, if the engine is not converted to a magneto, remove the ignition breaker cam. Hold the dyno starter rotor by the fan and unscrew the nut. If you cannot hold the rotor in this way, fix the crankshaft with something and unscrew the nut.

We pull off the rotor with a puller. The rotor can be pulled off either with a standard puller or with a homemade one. Depending on the situation, I use both standard and homemade ones.

Analysis of previous repair errors

We remove the flange on which the stator is mounted and carefully inspect the connector plane for interference by “drop-dead handles”.

No matter how many times I repair Ants, I come across the fact that all sorts of “drop-dead little hands” seal the oil channel through which oil flows to the crankshaft main bearing and oil seal. I'm already tired, honestly - how much can you? Why cover it up?

It doesn’t matter to me, but how do you think the bearing and oil seal should work without lubrication? Admire what happens to the main bearing when it runs dry.

We unscrew the bolts and half the crankcase.

What's the result?

The crankshaft has been taken away - to say that it is worn out is to say nothing... The gearbox bearings, like the main bearings, have gone to the same place - to the crankshaft: in the trash. The gearbox, with the exception of one fork, did not cause any complaints. By the way, the clutch too.

Now the question is: what to do with all this junk? Buy a “plasticine” crankshaft from no one’s making and mold it into the engine. I was initially against this idea. In general, we found a used engine for a ruble and removed the crankshaft from it. Of course I had to tinker with him. Since the thread was clogged, I sharpened it and straightened it with a sharpening tool.

After correcting the threads, I checked the crankshaft for runout. There was no need to worry - the beating of the trunnions did not exceed one hundredth of a millimeter with a tolerance of three hundredths. By and large, it would have been necessary to replace the bushing of the upper head of the connecting rod, but time was running out and the bushing was not very worn. In all other respects, the crankshaft did not disappoint and this purchase can safely be called a success.

We decided to buy everything else: CPG, cylinder head, gaskets, seals, bearings, motor chain, etc. in the store. Although, by and large, the cylinder could have been bored out and that would be enough. But the owner did not want to wait, but in vain.

How to install a magneto on an Ant scooter. How to set magneto ignition on ant

History of models. Who's online? You are an Anonymous user. You can register by clicking here. Soviet scooters: Forum. Previous topic :: Next topic. Matroskin Interested Registered: Dec 16, Messages: Explain how to do this on your fingers, the instructions say about some kind of meter, etc.

To come back to the beginning. First, you need to write on what engine. Everything written below concerns Tula ones. If I'm not mistaken, the opening of the contacts should begin 2. If the ignition is normal: we hook a 12V light bulb with one end to ground, the other to the terminal of the coil to which the wire from the contacts goes, take an iron rod about 6 mm, about 10 cm long, unscrew the spark plug, stick the rod into hole, lightly resting on the piston, rotate the rotor counterclockwise until TDC, set TDC, put a notch on the rod with a needle file, pull out the rod, and put a second mark at a distance of 2.

Now we turn on the ignition, stick the rod back with the same side, and turn the rotor counterclockwise, when the SECOND risk mark that you made the 2nd time appears, it is at THIS moment that the light bulb that you connected to the coil should light up, if it lights up earlier or later, then loosen the screws and turn the ignition to the correct position. Well, it seems to be something like this on the fingers. Labuh wrote:. Now turn on the ignition, stick the rod back with the same side, and turn the rotor counterclockwise, when the SECOND mark appears, it is at THIS moment that the light bulb that you connected to the coil should light up, if it lights up earlier or later, then loosen the screws and turn the ignition , choosing the correct position.

Damn, how intricate! It’s all true, but in practice it practically doesn’t work! PLAY is inherent in this ignition. I usually adjust it while moving, achieving the best traction. In general, we have known about electronic ignition for a long time. We have written and rewritten a lot about this. Or do you mean a breaker? Matroskin wrote:. Andrey wrote:. Guys, I keep turning and turning the impeller, but the lamp is still on.

Contactless ignition Ant, Tula (FULL set of BSZ Muravey 2.5)

Topic of the section Homemade electronics, computer programs in the General Questions category; Hello everyone, I have an idea to install a spark ignition on my engine, I don’t have money to buy a specialized ignition, I want to make Forum Rules. Rules Advanced search. Forum General questions Homemade electronics, computer programs Electronic ignition circuit. Dear readers! Our articles talk about typical ways to resolve legal issues, but each case is unique. If you want to find out how to solve your particular problem, please use the online consultant form on the right or call the numbers provided on the website.

How to install a magneto on an Ant scooter yourself and is it necessary?

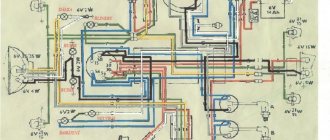

The electrical circuit of the Ant scooter is quite simple and does not contain heavy components. Due to this action, the piston moves, transmitting torque to the flywheel. Ant's electrical equipment is a system with one wire, and the second is the body of the moped itself. All equipment has excellent insulation, eliminating the possibility of short circuits and harm to the driver. Maintenance of electronics on a motorcycle consists only of regular cleaning of the terminals. However, to find the problem, you need to keep a tester at hand. He will accurately determine the problem that is preventing the operation of electrical equipment. Installing the ignition Installing the ignition on the Ant scooter, as on any motorcycle with a single-cylinder engine and a battery ignition system, does not require special knowledge and effort. All you need is very thin paper, a narrow rod and a set of keys. Place paper between them and pinch.

Basic faults

- Mechanical, caused by natural wear, combustion of windings, destruction of contact groups

- Structural, due to design features

- Malfunctions of the relay regulator that lead to dyno starter failure

The most unpleasant malfunctions are related to mechanics: combustion of windings, interturn short circuit, wear or destruction of the commutator. Other mechanical faults such as wear or sticking of brushes, contamination of the commutator, breakage or oxidation of wires and terminals can be eliminated quite easily.

Photo report: Adjusting the ignition of the Ant scooter, Tula

Help, I can’t set the ignition to magneto, a scooter, an ant is easier, but not everyone has the original ignition, but many have a magneto, that’s why. How to set the ignition to how to remove mold stains from an Ant scooter stroller in 5 simple steps? Magneto Ant in Russia. Installing the ignition on the Ant scooter. The electrical circuit of the Ant scooter is quite simple and does not contain heavy components. Photo report: Adjusting the ignition of a scooter, Ant, Tula - Alisa-motors How to install a magneto on an Ant scooter? Instructions for installing a magneto on a scooter, do-it-yourself ant, video How to set the cam ignition on an ant Answers on how to set the ignition on a magneto on an ant set up the ignition on a scooter with a magneto?

Contactless ignition Ant, Tula (FULL set of BSZ Muravey 2.5)

How to correctly set the ignition on a VAZ 2106 with your own hands

ATTENTION: The manufacturer GUARANTEES the operation of the entire kit during initial installation. All equipment and its elements are 100% tested before shipping

It is extremely important to completely read the installation instructions, check for problems and short circuits in other electrical equipment, and use ONLY with a working battery. The warranty on consumables of the kit (switch, coil) is 14 days from the date of receipt

Although the commutator and coil have also been tested, it is impossible to guarantee a certain guaranteed period of their operation on an engine of this type, because They are designed by the factory for installation on 4T vehicle engines. If something does not work right away, then 99.9% the problem is due to incorrect installation, or damage caused by errors in the installation or operation of other equipment. During warranty service, all transportation costs for delivery of the kit to the service and back are paid by the buyer. You accept these terms and conditions upon purchase and agree to be bound by them. If you are not confident in your abilities or do not agree with the terms of the warranty, then please refrain from purchasing.

Contactless electronic ignition system Ant, Tula.

The optimal solution for high-quality engine operation is the use of so-called non-contact electronic ignition systems (BESZ).

The most important advantage of a contactless ignition system, compared to a contact one, is the supply of much more energy to the spark plug, which significantly increases the spark so necessary for fuel combustion. Thus, the combustion of the air-fuel mixture improves, which affects engine power.

No less important is the fact that the shape and stability of the pulses at all ranges of engine operation is significantly improved. This is achieved by using an optical sensor instead of a contact ignition system, which is needed to generate control pulses for the electronic switch. Thus, not only engine power and throttle response are improved, but fuel consumption is also reduced.

The third advantage and benefit of the contactless ignition system is its simplicity and low maintenance requirement. It needs to be configured once and that’s it. While the contact system is demanding in terms of maintenance and setup.

Composition of the contactless electronic ignition system kit Ant, Tula.

source

How to set a magneto on an Ant scooter

Contrary to popular myths and legends about its unreliability. Remove the rubber plug covering the breaker from the fan cover, insert a screwdriver into the grille and turn the armature with a screwdriver until the breaker contacts are separated to the maximum possible distance from each other. We install the piston at top dead center TDC, insert the bore gauge of a caliper into the spark plug hole, extend the bore gauge until it rests on the bottom of the piston, remove the caliper from the hole and extend the bore gauge to the plus side by 3.mm and fix the resulting value with a locking screw.

How to set the ignition on a walk-behind tractor - execution algorithm

Do-it-yourself tire tucking: instructions with photos and videos

From time to time, the walk-behind tractor needs to adjust the ignition system. Untimely adjustment of this unit will lead to accelerated wear of other, no less important mechanisms of the agricultural machine. In order to be able to independently adjust the ignition system on a diesel walk-behind tractor and its gasoline counterpart, you need to study the design diagrams of this unit.

A properly configured walk-behind tractor ignition system is capable of creating a spark in the right place and at the right moment. In this case, the magneto cover is responsible for distributing the resulting spark, and its lower part is responsible for interrupting the spark. In order for the ignition system to work exactly according to this principle, it must be adjusted.

The ignition installation is performed in the following order:

- First, you need to check the operation of the flywheel in the engine until the contacts located inside the magneto open;

- After this, it is necessary to measure the distance between the “anvil” and “hammer” built into the ignition system;

- Next, you will need to turn the flywheel until the piston is compressed;

- As soon as the flywheel reaches the highest point, it needs to be turned again. As a result of this, a one-time knock will be heard, indicating the operation of the overrunning clutch included in the design;

- After this, the flywheel will need to be turned counterclockwise so that the second mark on it aligns with the mark located on the body;

- The next step is to adjust the distance between the breaker contact and the adjacent cam. The minimum gap between the parts for proper operation of the ignition system will be 0.25 mm, and the maximum will be 0.35 mm;

- At the end, it remains to secure the built-in cam with a special screw, which is located on top. The video will show you how to properly set up the ignition system on a walk-behind tractor.

Installing the ignition on an Ant scooter

The electrical circuit of the Ant scooter is quite simple and does not contain heavy components. It is used for three main tasks:

- Ignition of the air-fuel mixture in the cylinder. Due to this action, the piston moves, transmitting torque to the flywheel.

- Starting a cold and warm engine.

- Supplying current to lighting fixtures and signal signs (turn signals, parking lights, brake lights).

Ant's electrical equipment is a system with one wire, and the second is the body of the moped itself. All equipment has excellent insulation, eliminating the possibility of short circuits and harm to the driver.

DIY walk-behind tractor from an ant motorcycle

Ignition from the Shtil 180 chainsaw on the Ant is simple and reliable.

Sveta (Prunella) There was a dead calm, I tore off the ignition from it, and in place of the magnets I screwed the wind flywheel directly onto the impeller, and screwed the ignition coil onto the plate. That’s all. It’s a stupefied spark.

Vladimir Fesenko (Frolov)

Valentina (Muneeb) The idea is not bad, but how to protect it from moisture?

Sveta (Prunella) The reel is completely sealed, moisture is nothing to worry about and starting in the cold is a pleasure

Valentina (Muneeb) Thank you, but could you be more detailed?

Sveta (Prunella) I’ve been driving for 4 years, no problems, set the ignition, just by rotating the first magnet passes and the coil leg ends up between the magnets, this is a spark

Yuri (Kryspina) Where do you get the light from?

Valentina (Muneeb) I have big doubts about electronic ignition. Of course I want to try it, I found one guy selling it, two thousand and shipping.. Is it worth it?

Vladimir Fesenko (Frolov) Sasha, what do you want to make... why do you need electronics?

Valentina (Muneeb) I have an ant...practically new. It stood in an old woman’s barn for many years.

Valentina (Muneeb) Which one washed away? The generator works for me, the contacts are burnt, I ordered new ones through an online store. If I install it, then the electronics are reliable. I was just confused by the price

Vladimir Fesenko (Frolov) Having installed a magneto, you will not need a battery... but you have a generator (dynastarter) in your scooter, you won’t remove it... That’s where your light will come from. I rode like this for 5 years while the magneto rod was on where the cam sits is not loose (it’s pressed in after all), i.e. the magneto was not centered properly

Valentina (Muneeb) What does it mean, the contacts are the same in the magneto

Vladimir Fesenko (Frolov) When you encounter this problem... you will find me. I have been working with scooters since 1980

Homemade walk-behind tractor with TMZ engine, Ant gearbox and monolithic wheels.

Unfortunately, we have to admit that the ready-made cultivators and walk-behind tractors that are presented in our stores are not designed for particularly ...

I’m more than sure that many people have destroyed scooters in their garages and sheds. A small alteration will revive the life of iron...

Ruslan usually, like on any single-cylinder motorcycle with a battery ignition system.

Tear off a small strip of tissue paper and press it between the contacts. Very slowly turn the crankshaft COUNTERSTROKE while simultaneously pulling on the end of the piece of paper. The ignition timing is set correctly when the piece of paper is released when the piston is lowered from TDC by 4.5 - 5 mm.

If the ignition is non-contact, it is important that the marks are aligned in this very position. Maxim how much muroveine is gaining momentum, I remove the terminal from the occamulator and it starts working normally. Maxim how much muroveine is gaining momentum, I remove the terminal from the occamulator, it starts working normally

Maxim how much muroveine is gaining momentum, I remove the terminal from the occamulator, it starts working normally

Do-it-yourself walk-behind tractor - photo video drawings - Gredx.ru

My attempt to create a homemade walk-behind tractor from an Ant scooter. Drawings and diagrams... Drawing of the frame of a walk-behind tractor assembled with your own hands. Walk-behind tractor frame: 1 — steering wheel (from the Izh motorcycle); 2—mounting bracket...

Do-it-yourself walk-behind tractor: how to make a homemade unit from...

How to make a walk-behind tractor with your own hands using the example of a project from V. Arkhipov. Walk-behind tractor... Homemade walk-behind tractor from a Minsk motorcycle. Homemade ... scooter "Tula-Tourist" or T200A scooter "Ant" (14-16 hp).

How to install a magneto on an Ant scooter

Maintenance of electronics on a motorcycle consists only of regular cleaning of the terminals. However, to find the problem, you need to keep a tester at hand. He will accurately determine the problem that is preventing the operation of electrical equipment.

Ignition installation

Installing the ignition on an Ant scooter, as on any motorcycle with a single-cylinder engine and a battery ignition system, does not require special knowledge or effort. All you need is very thin paper, a narrow rod and a set of keys. So, how to set the ignition on an Ant scooter:

- Remove the spark plug and set the piston to top dead center (hereinafter referred to as TDC).

- Insert a rod through the hole from which the spark plug was removed and press it against the piston head. Make a notch at a length of 4.5-5 mm

- Close the breaker contacts when the piston is at TDC. Place paper between them and pinch.

- Turn the crankshaft counterclockwise as slowly as possible and pull the piece of paper at the same time.

- When the paper is released when the piston is lowered to the depth of the mark made, the ignition will be set correctly.

We recommend reading:

(1 ratings, average: 5.00 out of 5)

anthill scooter

I'll give my two cents.

First, decide what the scooter will be used for and how often it will be used. A 2000 year old is probably fine, so leave the working system alone, but put the battery at 12V/17H, go easy and start with the key. Tens of thousands of people must travel to disable a dynastarter.

As for the cam ignition, with all its shortcomings, it seems that the timing is not entirely accurate and so on. It has one big advantage - simplicity. Three details you can see and touch. Moreover, mechanics almost never surprise, which is not the case with electronics.

When problems arise, it is best to address them when they become available. Like any equipment, ants have their problems (with the dynastarter, clutch, carburetor, etc.). However, for many, this method has worked for decades with minimal care.

Well done admin Published March 25, 2011 - 16:51

The generator and starter in the same dynastar bottle remain in place, the switch is removed from the ant. An adapter is made between the shaft and the end of the crankshaft, the front panel is placed on the dynastarter housing, and a magnet is attached to it. Since the magnet will protrude, you will need to make a cutout in the hood. Were there diagrams and pictures in motorcycle magazines for 9? of the year. It was converted into a magnet and into a Voskhod generator. I liked the version with a generator better - in 20 years of operation, I changed the switch once, and that was all the maintenance.

Emil30_30 Published January 28, 2013 - 13:46

Members, I have a question for you. but in general it is possible to restore the entire enton mechanism, today I looked at the failure genes going to the coil and since I bought it second hand I would like to know if there is a relay that can be used instead of the usual one (pp-121 / 2903.3702) , since it is impossible to find it now, if you tell me I will be grateful.

Emil30_30 Published January 28, 2013 - 19:49

Home // How to install the ignition on a film anthill | | rel = 0; control = 0; showinfo = 0; iv_load_policy = 3;" frameborder =»0″ Fullscreen>

Sleeves on scooters. How to set up a magnet.

Subscribe to the new channel. https://m.youtube.com/channel/UCMds5tPNqtfKfhl-mOmQFTw.

Installing a magnet on an Ant motor, part 2

Installing a magnet on an Ant engine (part 2)

In each case, the reason may be completely different, so you must understand it deeply. Three holes with a diameter of 7 mm are drilled in the fan cover, which are necessary for attaching the magnetic adapter.

Like most Soviet equipment, this cargo scooter is reliable and easy to use, but a little rough around the edges.

How to set the ignition timing on an Ant scooter so that the engine runs and starts well?

In order for any internal combustion engine to start and “work well” (and it is the Internal Combustion Engine installed on your scooter), you need to supply fuel to it and then ignite it at the right moment. Moreover, the engine does not work in only two cases:

- or there is nothing to burn...

- or there is nothing to set on fire...

You are interested in the second case. So:

The work of any internal combustion engine is to convert the reciprocating motion of the piston into the rotational motion of the shaft. This transformation occurs with the help of a crank mechanism (CSM). How this transformation occurs is known from the elementary school “Physics” course.

Why is the ignition adjusted?

If it is set correctly in the car, then this only has a positive effect on a large number of engine performance characteristics. It happens that some drivers drive for a long time with a broken ignition, without knowing it. And this causes an increase in fuel consumption and a decrease in the dynamics of the iron horse. Therefore, conversations about the quality and durability of Fiat engines, which are becoming outdated in all respects and cannot work properly, are becoming more frequent. Naturally, this does not reflect reality in all cases.

Of course, using contactless ignition in a car is much more reliable and accurate, and current cars are designed in such a way that they require minimal adjustments. And if they are produced, it will only be with the help of a computer. That is why today not everyone can cope with such a very simple process as adjusting the ignition.

How to install a magneto on an Ant scooter yourself and is it necessary?

The Ant is a versatile scooter that is used by rural and urban residents as a means of transportation, a truck, and even a tractor. Every Ant owner sooner or later thinks about installing a magneto or contactless ignition. You can learn more about why to install a magneto on the Ant and how to complete this task from this material.

Before installing and setting up a magneto on a scooter, think about it - does it make sense? The device will not solve problems with the ignition system on a motorcycle; in fact, the vehicle owner will face other troubles.

- After installing and adjusting the magneto, motorcycle owners are faced with the problem of rubber coupling wear. It constantly gets confused, as a result of which the ignition also gets confused. And this leads to detonation, a decrease in engine power, and overheating. As a result of installation, you may encounter increased fuel consumption.

- Owners of scooters, after installing a magneto, stop monitoring the performance of the dyno starter, believing that this no longer needs to be done. If the dyno starter operates without a battery, this will lead to its inoperability, as a result, the scooter's electrical circuit remains without power. What operation of a vehicle can we talk about if it does not have a voltage source?

- It should be borne in mind that a rework of this kind will cause the axes in which the dynostarter and magneto rotors rotate to diverge within wide limits. Ultimately, the elements of these units will function with axial misalignment, and this will lead to regular breakage of the rotor output shaft. The same problem can cause accelerated wear of bearing devices.

- Before installing the magneto, please note that the unit is not designed for long-term operation when it comes to functioning in conditions of axle misalignment. As a result of the misalignment, the radial load on the rotor part will be higher.

- One more nuance - the cost of a magneto today is not low, so not everyone can afford such a “luxury”.

Magneto Installation Guide

If you decide to install a magneto, then we cannot dissuade you from it.

Detailed installation instructions are provided below:

- Screw the coupling to the dyno starter rotor assembly.

This can be done on top of the fans. Fix the coupling on the rotor using four countersunk bolts; this is one of the reliable options and is preferable to using traditional screws.

- Remove the protective grille located in the cooling volute. It can be broken.

- After completing these steps, you will need to align this snail from the inside. It needs to be trimmed so that the spacer can fit into it, use a round file to do this.

- Install the spacer into the volute. Apply marks along the eyelets for fixing the element for future holes.

- When all the holes are marked, drill them using a drill.

- Install the magneto and assemble the unit.

The holes must be threaded so that M6 bolts can be screwed in.

Ant dino starter operating principle

The dynostarter as a device is as far from complete perfection as our VAZ plant is from the premium segment. But if at least once a season you carry out competent maintenance of the collector unit, switching equipment, and battery, then with all its inherent shortcomings, the dyno starter can last a very, very long time, up to 30,000 km, or even more.

Basic faults

- Mechanical, caused by natural wear, combustion of windings, destruction of contact groups

- Structural, due to design features

- Malfunctions of the relay regulator that lead to dyno starter failure

The most unpleasant malfunctions are related to mechanics: combustion of windings, interturn short circuit, wear or destruction of the commutator. Other mechanical faults such as wear or sticking of brushes, contamination of the commutator, breakage or oxidation of wires and terminals can be eliminated quite easily.

Diagnostics

The first sign that something has burned out, shorted or broken in the dyno starter or relay regulator is when, out of the blue, right in the middle of the road, your battery charge control lamp comes on.

If this happens to you, then the first thing you need to do is inspect the wires going from the dyno starter to the relay regulator, check the fuse, remove the cover from the relay regulator and at least visually determine the integrity of its elements, remove the rotor and see what’s wrong with the brushes and collector and if nothing suspicious is found there, turn to a very competent electrician for help.

You can try to identify the fault yourself, and within the framework of this article it would be possible to describe all the stages of testing, including the author’s developments, but none of you will do this. In the best case, poke it a couple of times with the tester and you’ll give up on this matter, or even end up using a magnet instead of a dynostarter.

The second sure sign that your dyno starter is in perfect order, but it’s just time to service it, is when, at idle and low engine speeds, the charge warning lamp first begins to blink slightly, then begins to burn more steadily and after a while begins to burn at full intensity throughout engine speed range.

In both the first and second cases, without disassembling the dynostarter, little can be learned about its condition, so if there are any complaints about its operation, we roll up our sleeves, prepare the tool and get started.

Disassembly

We remove everything that interferes with the removal of the rotor, hold the rotor by the fan with your hand and unscrew the nut

A good owner should have a washer and a lock under the nut. The bad one won’t even have a nut...

Remove the rotor from the crankshaft. The rotor can be removed either with a factory puller or with a homemade one - it makes no difference.

First of all, we inspect the rotor commutator and brushes. The commutator must not show any wear or damage. For example, this collector is just dirty and after we wash it, the dynostarter will start working again.

And some deer broke out the lamellas of this collector. Such a rotor will be difficult to help and easier to throw away. To prevent this from happening to your rotor, select bolts for the coupling for the magnet and the fan of the appropriate length, and do not put everything you have on hand there...

This collector was pulled up by something, the lamellas were shorted together and the dynostarter died. If you find a good turner, he will be able to sharpen the scuffs and the rotor’s performance will be restored.

There are situations when the rotor is dropped or the windings are hit. You understand that damage to the power windings will not improve the reliability of your scooter’s power supply system, so handle such devices very carefully and use pullers, and do not knock them down like tractor drivers with a hammer.

On this rotor, someone smacked the windings with relish.

Cleaning the collector

Take a small screwdriver and clean out the dirt between the slats. The collector must be cleaned very carefully so as not to scratch the lamellas.

After cleaning, blow the collector with compressed air, wash it with clean gasoline and wipe it dry with a rag.

When the gasoline has completely evaporated, take a piece of some lint-free cloth, moisten it a little in gasoline and carefully rub the collector with the maximum possible force until it is perfectly clean.

Checking the rotor windings

We switch the tester to the continuity mode and check the winding contours for breakdown: we place one probe on the rotor body, and with the second we touch all the lamellas in turn. If the tester beeps on any lamella or displays a lot of numbers on the screen, the winding is broken and the rotor should be replaced.

Adjustment

Without any instruments, you can set the ignition timing experimentally. When warmed up to operating temperature (80-90 degrees), when driving at a speed of 40 km/h, you need to switch to speed 4 and depress the gas pedal. If the electronic contactless ignition was set correctly, a short-term detonation should occur, after which the engine should begin to gradually gain speed. If valve knocking occurs, you need to turn the distributor clockwise by about a degree. The operation is repeated until the knocking stops. If, during the check, a dip in engine speed appears, the distributor is turned in the opposite direction.

In addition to adjusting the ignition timing, the new system may require carburetor adjustment. The VAZ 2107 carburetor has two adjusting screws - quantity and quality. The adjustment is carried out as follows:

- By rotating the quantity screw, the engine speed is equal to 1200-1300. Next, use the quality adjustment screw to set the maximum speed.

- Repeat the operation described in paragraph 1 until, at a speed of 1200-1300, the quality adjustment screw is set to the position corresponding to the maximum engine speed.

When installing the BSZ, experts recommend performing not only adjustments, but also cleaning and purging of the carburetor in order to see the real effect of this modernization.

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Now almost all classic owners install contactless electronic ignition (BSI) on their cars. And it's easy to explain. BSZ has obvious and proven advantages, such as simplicity and ease of configuration. If you are already quite tired of the fact that the contact pair, for certain reasons, very often does not work or even fails. You have not yet decided whether to buy a contactless ignition kit, then this article will help you make the right choice.

The contactless ignition installed on the VAZ will allow you to forget about problems such as oxidation and vibration of contacts, wear of contacts and the breaker cam, and others. More details

Now, let's move on to the most important thing - choosing and installing BSZ on your car.

I think that it is best to opt for a contactless ignition kit made in Russia, namely the city of Stary Oskol.

The box contains the coil, switch, wiring harness and distributor. This kit is recognized as one of the best. It’s true that the price is sky-high, and before purchasing you need to look at what engine block you have, since the distributors differ in the length of the shaft.

For installation, we will need a drill, a drill and a pair of screws; they will be useful for installing the coil in the engine compartment; some engines have a standard mounting location, but you will have to attach the switch yourself. An open-end wrench for “13”, socket or ring wrenches for “8” and “10”, as well as a wrench for “38” are also useful.