Conversion of the Dnepr motorcycle to one K65D carburetor

Hello Dear Like-minded People! So, I thought about installing one carburetor, instead of the old K301. Because it was very difficult to set up synchronization, the consumption was high, and in general they were outdated. I thought for a long time about which one to choose, there were many options - Solex, DAZ, K133, from a tractor launcher, etc. I read a post on this resource that you can install one K65D carburetor from Jupiter. Here was my topic about one K65D, logically it would have been better to install the K65I from the Planet, but it turned out the way it turned out. K65D (Pekar, Russia). Diameter of the mixing chamber, mm – 32; Diffuser diameter, mm – 30; Throughput, mlmin - GTZh - 260 - idle metering tubes - 50 - fuel corrector nozzle - 255 Ambient temperature range at which the engine starts and stable operation is ensured in all operating modes - from -20C to +50C.

A stainless steel pipe with a diameter of 28mm was found, and 4 pipe angles with a diameter of 25-28mm were purchased, the diameter of the angles varied. The flanges were made of metal 5mm thick, there were two more metal options - 3-3.5mm, 10mm. 3mm - in my opinion, too thin, most likely they would begin to bend when tightened, and 10mm - this is too much, and it is more difficult to work with such material.

Here is the finished flange.

The most difficult thing was to make a structure with a flange that was attached to the carburetor, or rather to make a hole in the pipe, it took a long time. Since the drills did not have such a diameter, it turned out that it was decided to use a trick, namely, take a piston pin with a diameter of 30 mm, cut longitudinal lines on it with a grinder, it turned out something like a milling cutter. We didn’t drill the hole, but squeezed it out, the finger was red-hot.

It was difficult to secure the manifold to the flanges in place. Fortunately, four pipeline bends were purchased; without them, it’s unlikely that anything would have worked; we would probably have had to bend the pipe. And so we put one knee, on the other it turned out, something like the English letter “S”. Thus, we made a less abrupt transition.

Of course, there was a lot of welding stuck on, the welder offered me to remove everything with a grinder, I refused. All the same, the collector needs to be covered with something and insulated. There is an idea to cover it with outdoor insulation for the wires. The whole rework took quite a long time; they started at 13:00 and were finished at 21:30. Because it was dark, the collector was poorly welded, leaving many small holes. I noticed this already at home, so I went to the welder again. The second time they boiled it well, checked it, put it in water and blew into the collector, everything was clear.

The first launch went surprisingly well. There is nothing, without changing the position of the needle in the carburetor in the middle. I installed it, replaced the air filter with a sock, pumped it up, grabbed the first kick, but stalled, and started on the second. I adjusted the idle and that's it. The precise operation of both boilers was a pleasant surprise. After unscrewing the throttle, a shot followed, it was the first and the last. This didn't happen anymore. The traction at the bottom is crazy, at first you can even climb the wall. The top was most likely cut off, acceleration was normal up to 70 km/h, then I don’t know. The collector cools down strongly, even in the heat of 30C, it is covered with dew. The consumption, it seems to me, is still high, the candles indicate this, they are too black. I lowered the needle to the very last mark, it didn’t seem to be as black as before. Maybe this is because I drive mostly at idle... This is the experience of converting it to one carburetor, I’m happy, I definitely won’t go back to two. I apologize for the photos because I took them on my phone!

Thank you for your attention!

Settings

The last stage is starting the Ural engine and setting it up. Some imported carburetor models do not have an enricher, which must be taken into account when purchasing. Otherwise, the idea is simple: when the engine starts, we do a test drive, with maximum spin in low gears and try to reach speeds of more than 100 km/h. If the engine does not pull, perhaps a more efficient jet will solve the problem; you also need to work some magic with the idle speed setting.

Note! This entire system has one significant drawback - problems with operation at low temperatures. In cold weather, condensation forms in a long manifold, which inevitably leads to deterioration in engine performance.

You can try to isolate the inlet with rubber pads or other insulating materials. Plus, you shouldn’t do test runs and adjustments in the cold season.

Conclusion

Now you know how to install one carburetor on a Dnepr or Ural motorcycle. Before you start work, weigh the pros and cons, correctly assess your abilities, because if you don’t have a lot of money to entrust this work to workshops, you will have to use the skills of a welder, designer, mechanic and others. On the other hand, by correctly completing all the described points, you will lighten the burden of owning Soviet equipment and will be able to ride a motorcycle without any problems, even in everyday use.

How to install one carburetor on a Ural motorcycle | Life in RGV style

One of the disadvantages of heavy and large motorcycles is the constant need to adjust the carburetor in order for them to work in sync.

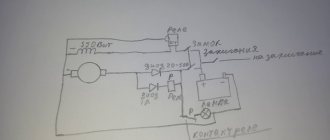

In such a situation, instead of 2 conventional carburetors, you can install one, but very powerful one. To do this, you need to create an exact replica of the lower carburetor part using a metal plate. Then you need to make a thread, put on the nuts and weld them to the plate itself.

At the end parts of the plate, it is necessary to cut holes in the form of an ellipse, insert metal strips into them and weld them. The thickness of such a strip should be no more than 1 mm. After welding all the parts, the place where the carburetor is screwed must be aligned and it is necessary to determine whether the dimensions are suitable for future installation.

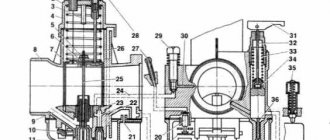

Carburetor - removal and disassembly

It is possible to partially disassemble the carburetor (removing and washing the throttle, repairing the drive, etc.) without removing it from the engine.

1. Place the motorcycle on the center stand.

2. Remove the protective covers.

3. Shutting off the fuel supply, disconnect the fuel hose from the carburetor.

4. Use a screwdriver to loosen the clamp and disconnect the rubber air filter pipe from the carburetor.

5. 10 mm

Unscrew the mixture corrector nut.

6. Remove the corrector plunger assembly.

7. Disassemble the corrector plunger.

8. Pulling the cable sheath upward, unscrew the throttle valve cover.

9. Remove the throttle valve assembly. Cover the hole with a clean cloth.

10. To replace the cable, you need to compress the damper return spring, and, pushing the cable down, remove its end from the cut in the damper needle nut.

1. 12 mm

unscrew the two bolts securing the carburetor adapter pipe to the cylinder. We remove the carburetor with the pipe, being careful not to tear the paronite gasket.

2. Hold the bolts with a 12mm

, unscrew the nuts securing the adapter pipe with a 13 mm

. We remove the pipe.

1. Using a screwdriver, unscrew the two screws securing the carburetor cover.

2. Remove the float chamber. There is a paper gasket underneath, be careful not to tear it.

3. Using a thin drift, carefully knock out the float axis.

4. Use thin pliers to remove the axle.

5. Remove the float along with the locking needle.

8 mm socket wrench

We turn out the seat of the shut-off valve.

7. Using a screwdriver, unscrew the jets of the main dosing system and the idle system.

8. 6 mm

turn out the additional jet.

9. 12 mm

We turn out the fuel-emulsion nozzle of the main dosing system.

10. Turn out the “quantity” and “quality” screws.

13. We wash all carburetor parts, except gaskets and rubber parts, in acetone or solvent for nitro paints. We clean all channels and jets with copper wire or toothpicks soaked in solvent, and blow them with compressed air from the compressor.

It is unacceptable to clean carburetor jets with steel wire, needles or any other tool.

We assemble the carburetor in the reverse order, while lubricating the rubber o-rings, threads and gaskets with engine oil or BSK brake fluid containing castor oil.

We tighten the “quantity” and “quality” screws until they stop. Then we unscrew the “quality” screw one turn (preset), and unscrew the “quantity” screw five to seven turns.

We check the operation of the shut-off valve. When the carburetor is oriented with the throttle channel down, the air supplied by the mouth into the inlet fitting should not pass through the valve.

Adjusting the position of the needle of the main dosing system is carried out by rearranging the lock washer in the grooves of the needle:

- washer to the left - enrichment of the mixture; - washer to the right - lean mixture.

One Carburetor K68 on K750

Making an adapter for 1 carburetor

In this article I will not argue why alone, I personally rode a monocarb before, and it was such a trip that forced me to remake my own motorcycle, I don’t know how this will affect your opinion, but I’m happy with the result.

And so the K-68 carburetor was installed on the K750 motorcycle, due to availability, and for the same reason that it had proven itself well for this.

Manufacturing process

First, I started making flanges, I have a small lathe, I turned them from a 3mm thick plate, as experience has shown, they turned out to be unsuitable (too thin, they are deformed), after which new ones were turned from a 10mm thick plate.

I selected the pipe according to the internal diameter of the intake manifold,

Fortunately, there was an old crankcase and a couple of cylinders, the box was also found, how could it be more convenient to work on a model,

In order not to do everything on my knee, I took a hard rubber hose and inserted it into the inlet holes

I put a piece of plywood under it

I transferred the internal contour of the future collector to it

I cut a blank from an oak tree on a circular saw,

I went through it with a cutter and a knife, which repeats the outer diameter of the pipe

I machined two plugs for the pipe,

I also made an external template of a straight block to match the pipe

I filled the pipe with sand and sealed it with plugs. As it turned out, heating with a blowtorch is not so effective; a conventional stove heats the metal to red hot in 5-7 minutes, at normal heat.

Before bending, the wooden templates were well watered,

I bent it in 2 passes, for each cylinder, using a lever pipe of a larger diameter.

I screwed the flanges to the cylinders and grabbed them with points, removed them, boiled them in cleats, checked the tightness using old 3 mm flanges and a bicycle inner tube, eliminated the defects, screwed them onto the motorcycle, saw how the carburetor would turn out, since I wanted to achieve a horizontal manifold, I had to use an elbow from such same pipes.

Welded it and checked for leaks.

Cleaned it and washed it with gasoline.

I put it on the motorcycle, the motorcycle started up immediately and without problems, the idle adjustment immediately pleased me, the engine speed can be lowered to monstrously low, with the old K302 this was problematic, I set the speed to more or less reasonable.

After which the test drive, the dynamics of the motorcycle changed for the better, when riding it was the impression that the motorcycle had a different engine, the engine spins up faster, which was pleasing, there were no shortnesses, hiccups, or skips, it felt like the cylinders were actually working more harmoniously.

The myth that a motorcycle is difficult to start in the cold, I came across this, the problem is not big as it can be solved simply, with the ignition off and the gas turned off, pump the kick several times, then open the gas, pump up the carburetor, and pump with the kick, turn on the ignition and start the engine, As soon as the engine makes a few strokes, turn the trigger a little for 10 seconds, maintain stable speeds, I repeat stable (without fanaticism) slightly above idle, then let the engine warm up at idle.

Is it possible to install one carburetor on a Ural motorcycle? This question is asked by many owners of popular motorcycles in our country. The reason for this interest is obvious. Ural motorcycles, regardless of the year of manufacture, are standardly equipped with one carburetor for each cylinder. This provides better filling with the combustible mixture, but creates many problems during adjustment.

The best carburetors.

What are the best carburetors for the Ural 750cc with sidecar drive? I drive mostly in the forest, and in the mud, and sometimes I ride on the highway too.

Rename the topic, you are misleading people, do you want to buy the best carburetors, sell them as a gift. I won’t say anything on the topic; I haven’t driven a 750 Ural and don’t plan to.

I don't buy or sell while I'm interested.

if price-quality then k68t. not China.

Where can I find them?

All you can fart?

Never mind. If you don’t drive in winter, then monocarb from the car

If you don’t drive in winter, then get a monocarb from the car.

to 63u. if you find it. there the needle is bronze and longer than 65. Unlike the Kuikhins, you can climb deep into shit. nothing gets caught, and they are easy to clean.

Yes..expensive.

What kind of carburetors (from what motorcycle?)? __________________________________________________ “Please note that Republican credit cards are not in use here!”

Former alcohol, converted to gasoline. 34 diffuser. Without accelerators.. They were made for a cross-country stroller, but they were not useful.

And why are they better than the cheap K68 or the same vacuum seals from disassembly?

Judging by the stamp, Italian? For sale? How expensive? __________________________________________________ “Please note that Republican credit cards are not in use here!”

PMed me

The question implies an answer in the style: “Every sandpiper praises its own swamp..”) As in most similar topics.

I myself am puzzled by this topic now. There are dellorto 30, and keihin 32 and 68And and not I, and IKOVY, etc. I came to the conclusion that none of the above fits. But I still have volume 833.

For heavy use you need carbs: -not vacuum ones! -protected! -Easy to wash! -Easily disassembled! -reliable! -cheap! -have repair kits!

..I have some ideas..if I can, I’ll voice them.

Mikuni from a dog. Other options do not meet at least two of the proposed requirements, including k68. Protected - you had vacuum bsr36-89, which should work perfectly with normal jets. Chinese copies from sfmoto are relatively cheap.

Big ones. A maximum of 32-34mm diffuser is needed. And again, the priority is the gate.

Other options are expensive. Unless we put China. There are analogues of pwk series keihins. They also have needles and jets for every taste and color. The question is how long it takes. Originals are expensive. It's a double-edged sword.

For heavy use you need carbs: -not vacuum ones! -protected! -Easy to wash! -Easily disassembled! -reliable! -cheap! -have repair kits!

..I have some ideas..if I can, I’ll voice them.

1. vacuum ones are no worse than gate valves on off-road terrain 2. if by protected we mean from dirt and water, then they are protected no less than gate valves, and even more if used from ATVs. Also, if possible, use “lying” carbs so that you can place them much higher than the cylinder + they will not interfere with your legs. However, if you drown a motorcycle up to the gas tank, then the engine needs more protection, but why drown it if you can usually go around it? 3.inside? To avoid getting clogged when driving off-road, just move the ventilation hoses higher and that’s it. 4. 4 screws on the bottom, 4 on top and the carb is in full view. 5. The Japanese don't break. 6. one thousand to one and a half rubles apiece for disassembly. 7. See previous paragraph.

I have K68u carbs from Pekarovsk, with installed GTZh from Izha Jupiter 235. I drove about 5 thousand on them in a wheelchair. Then for some reason I installed the K68T with the original 220 jets. I bought it while drunk. It got duller at the bottom. I can sell k68U with Iupaka fluids. I installed VasyaPZ) which already creates a certain aura of hihyha. Anyway, my 750 pikhlo exploded. I’ll definitely have a 650cc for about 2 years, I’m tired of spending money on this Ural

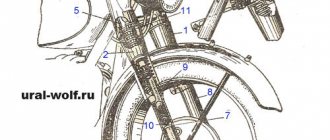

What needs to be done to install a monocarburetor

If you install one carburetor on a Ural motorcycle, this will largely solve this problem. This is a possible, although not ideal, solution. In bringing the plan to life, certain difficulties will have to be overcome. Necessary:

- Clear space above the engine crankcase. This is where it is most convenient to secure the intake tract and connecting flange.

- Make an intake manifold.

- Select a suitable carburetor according to the parameters.

All this will require a significant investment of time and money.

On a note

We must not forget that before installing a new carburetor in the Urals, the power unit should be diagnosed, subjecting its components to the most thorough revision. Only after making sure that all parts are in good working order should you begin further work. After all, if there is something wrong with the engine, then it doesn’t matter how many carburetors there are on the motorcycle - 1 or 2.

Before installing a new carburetor, engine diagnostics are required.

The work ahead will not be easy. If you feel that you are not ready to handle it yourself, it is better to entrust the matter to specialists who already have experience in such alterations. But be careful not to give your pet into the hands of amateurs. Remember that it is very difficult to choose a suitable carburetor for a motorcycle, and especially for the Urals!

Inappropriate installation option

What carburetors are suitable and what is better to install? We will have to disappoint those who plan to use available models from Oka or Zhiguli during the conversion. All car modifications are out of play in this case. There are several reasons:

- The vacuum in the intake tract of a motorcycle differs from the parameters typical for car engines. Because of this, correct adjustment of the carburetor on a motorcycle becomes almost impossible.

- The selection is carried out not simply by working volume, but by the number of aspirations per unit of time. Aspiration can be roughly calculated by multiplying the engine displacement by the maximum speed.

- Car models pose a danger if the motorcycle falls because fuel can splash out and ignite.

Automobile carburetors are not suitable for conversion!

So the idea of using parts from Oka or other automotive equipment will have to be abandoned.

Installing a new carburetor

Before setting up a new carburetor to 65, you must carry out the following steps:

- When installing a new K65, the top cover is removed from it, the housing is placed on the engine, and the cable is connected to the throttle.

- The throttle lever raises and lowers the throttle several times. This checks its work.

- Then the throttle rises until a gap forms between its lower edge and the diffuser. This value is 3 mm.

- If the K65 carburetor has a corrector, then it is removed, the cable is attached to the piston, and then the assembly is put back.

- It is necessary to check the free movement of the cable sheaths.

- Then the screw is screwed in and released by 0.5-1.5 turns. The fuel hose is connected to the fitting and the presence of leaks is checked.

- Using the starter, you need to turn the crankshaft 3 turns. The engine turns on and warms up for some time. After this, the corrector or launch unit is removed.

The agony of choice

There is more than enough advice on the Internet about which carburetor to install for a Ural motorcycle. But not all of them should be trusted unreservedly. Indeed, in the process of realizing your plans, you will encounter considerable difficulties. Here are some examples:

- An affordable option can be considered the domestic K28G carburetor, which was equipped with the Tula-200 scooter produced during Soviet times. But there are no new ones on sale, and finding a used one in decent condition is very difficult. Unidentified defects will negate all expected benefits.

- Mikuni or Keihin models, borrowed from Japanese motorcycle models with a similar number of aspirations, cost a lot of money and will still require additional modifications. You will have to grind out new jets and change the factory settings.

Simply installing one carburetor instead of two without modification will not work!

Whatever option you prefer, simply installing one carburetor instead of two will not work. It will require major remodeling.

Engine and gearbox

The motorcycle used a four-stroke gasoline engine with a power of up to 36 horsepower. Torque was supplied to the four-speed gearbox through an automobile-type clutch - dry, equipped with two discs. A cardan shaft was installed between the box and the rear wheel gearbox. The technical characteristics of the Ural M-67-36 motorcycle were significantly increased in the version with a sidecar wheel drive. The drive was carried out by a shaft passing from the rear wheel gearbox to the wheel hub of the side trailer. However, such cars are quite rare. The bulk of the motorcycles were produced in the classic single-wheel drive version.

Need an intake manifold

A separate problem is the manufacture of the intake manifold. Since casting the part at home is not possible, you will have to use thick-walled stainless steel pipes. It is important to meet the following conditions:

- The internal diameter of the pipe must correspond to the diameter of the inlet holes on the cylinders.

- The diameter, flow area and bending of both branches of the collector must be the same.

- The connecting platforms should be made of thick, at least 5 mm, and even sheet. It would be good if all operations could be performed on a milling machine. In the absence of one, you will have to arm yourself with a good plumbing tool, be patient and do everything yourself.

- Internal welds, if any, are carefully ground. Irregularities and protrusions on the inner surface of the intake tract are unacceptable.

Change or leave, what do you prefer?

If you don’t do everything as expected, then selecting and installing a carburetor for a Ural motorcycle will only be a waste of time, effort and money. But even when all the conditions are met, it should be remembered that such a modification, although it will make it possible to easily adjust the supply of the fuel mixture, will create other problems:

- In the intake manifold, which is necessary to switch to a single carburetor, condensation will accumulate in cold weather. This will make starting the engine more difficult.

- A converted Ural with one carburetor will lose some power and will consume more fuel. After all, the filling of the cylinders will worsen.

- You will need to decide where to install a new air filter that matches the parameters, of which there will also only be one now.

After studying the issue, many leave the option with two carburetors

Based on the above, many prefer to leave two carburetors on the Ural motorcycle, as before, replacing them with more advanced ones. Models with constant, rather than variable, discharge in diffusers are better suited for this. They allow you to get rid of failure during acceleration - a disease of many two-cylinder four-stroke engines.

Preparing for adjustment

Adjusting the K-37A carburetor of the Ural motorcycle has three stages of adjustment: 1. idle; 2. at medium speeds; 3. uniform operation of both carburetors.

Before starting the setup, it is advisable to remove the carburetors and disassemble them to check for serviceability. To do this, check the fuel level, if necessary, change it and bring it to normal. Clean all jets and fuel and air passages. Check the control drive of each device. When installing, pay attention to the tightness of all connections.

Before starting, pay attention to the condition of the piston and measure the compression ratio in the cylinder. The cylinder-cylinder head connection is assembled without air leaks. If you need to replace the gasket.

Pay attention to the ignition. Inspect the spark plugs and spark quality. In case of malfunction, install new spark plugs.

Carburetor adjustment should be carried out on a warm engine, and the carburetors should first be adjusted individually.

The float chamber of the K-301 carburetor of the IMZ Ural motorcycle works as follows. When there is no fuel in the float chamber, the float moves down under its own weight and the needle allows fuel to enter the float chamber. As the float chamber is filled with fuel, the float floats up and at a certain level (22±1.5 mm from the plane of the lid) the needle blocks access to the fuel. If the engine is not running, the fuel level remains unchanged.

After starting the engine, fuel begins to be consumed and its level decreases. The float lowers again and allows fuel to flow. Thus, the fuel level in the float chamber fluctuates depending on the operating mode of the engine. However, this fluctuation is very small (within 1.5 mm) and the fuel level is practically considered to be constant.

The mixing chamber has a variable cross-section. The narrowest point is called the diffuser. Its diameter is one of the main determining dimensions and characteristics of the carburetor. For the K-301 carburetor of the IMZ Ural motorcycle, it is 28 mm. The diffuser contains a flat throttle valve (or throttle), consisting of a body and a cheek. The cheek is shorter in height than the body. Therefore, the narrowest gap is formed between the body and the diffuser, while between the cheek and the diffuser the flow area is somewhat larger.