Carburetor design

The carburetor for the Ural motorcycle is a horizontal device designed to prepare the air-fuel mixture. The float chamber is located in the center of the assembly. The mechanism is equipped with a flat throttle valve with vertical stroke, two dosage systems - the main one, the idle one. They shape the volume and quality of the mixture.

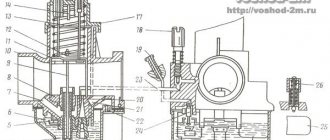

The starting device is located separately, consisting of three main blocks, Fig. 2:

- building 8;

- chamber with float 38;

- cover 4.

Rice. 2. Schematic representation of the carburetor for 63. 1 - Fitting with lock nut; 2 - Throttle spring; 3 - Throttle lift limiter; 4 - Housing cover; 5 - Lock nut; 6 - Dosing needle bar; 7 - Throttle; 8 - Housing; 9-Air channel of the sprayer; 10 - Float lever axis; 11 - Spray body; 12 - Sprayer; 13 - Float chamber cover; 14 - Main fuel jet; 15 — Idle fuel jet; 16 - Lock washer; 17 — Channel for supplying the fuel mixture from the starting device; 18 - Float; 19 — Stop for adjusting the fuel level; 20 - Fuel valve; 21 - Drainage hole; 22 - Emulsion hole: 23 - Transition hole; 24 — The air channel of the jet is idle, running; 25 Dosing needle; 26 - Air channel of the float chamber; 27 — Fuel receiving fitting; 28 — Idle speed adjustment screw; 29 — Mixture quality adjustment screw; 30 - Air channel; 31 - Starting lever; 32 - Rod; 33 - Spring; 34 - Starter plunger; 35 — Float drowner; 36 - Plunger needle; 37 — Fuel jet of the starting device; 38 - Float chamber.

The float chamber communicates with the atmosphere through the vertical outer channel of the housing 26. The top cover of the chamber has a drainage hole 21. The carburetor of the Ural motorcycle is equipped with a lever float mechanism consisting of two floats 18. Both products have the shape of rectangles, connected together by a common lever made of the innovative material caprolactam as one piece.

Axle 10, pressed into the lever, presses the structure with floats against the two columns of the housing. The brass fuel valve 20 visually resembles a needle. There is an elastic washer on top of the cone. It is practically eternal, almost not subject to wear. Thanks to it, the Ural carburetor always has a stable level of gasoline in the float chamber. The valve has a groove at the bottom that connects it to the float. Therefore, it never gets stuck in the guide channel.

Third stage

Let's move on to the final part - adjusting the carburetor of the Ural motorcycle. Now you need to adjust the main dosing system. It consists of throttle valves, needles and main fuel jets. The bottom line is that due to the variable cross-section of the carburetor needle, directly proportional dosing of fuel occurs depending on the amount of air passing through the carburetor diffuser. Make sure that the carburetor needles are straight and the holes for them in the throttle bodies are not worn out. Replace the spark plugs with new ones or clean the old ones. Ride a motorcycle at a constant speed of 70 km/h for 10 minutes. Stop, turn off the engine, unscrew the spark plugs and, according to the photo below, determine the correct adjustment:

- This is the color of the candle when properly adjusted. As you can see, the brick color of the spark plug insulator is due to correctly tuned carburetors.

- If the candle is black, this is a sign of a rich mixture. Therefore, we lower the needles in the carburetors by one notch (initially they should be installed in the middle position).

- If the candle has white carbon deposits, raise the needles by one notch.

If, after moving the needles one notch, you cannot achieve a brick shade of the candle, try setting it 2 notches lower or higher, depending on the color of the insulator. As a result, we will get the correct mixture at constant engine speeds when driving along the highway.

It is important to know: if the spark plugs have black soot with a shine, perhaps the cylinder-piston group of the motorcycle is worn out, and the spark plugs are simply splashed with oil. It is worth thinking about repairs as soon as possible.

In this article we looked in detail at what it is to adjust the carburetor of a Ural motorcycle. Correctly setting the carburetors on a Ural motorcycle is the key to good engine performance.

Preparation of the air-fuel mixture

From the starting device into the carburetor on the Ural motorcycle, the fuel mixture is directed through channel 17 to the mixing chamber.

The non-separable plunger 34 has built-in parts:

- conical needle 36;

- spring 33, which prevents needle 36 from jamming;

- the tip to which the rod is connected.

The nozzle of the main dosing system 12 is pressed into the housing 11, where 4 radial holes are made. The throttle, which has a U-shaped cross-section, is made of a sheet of brass. The throttle wall has a semicircular segment cut out. It faces the air purifier. This groove ensures that the carburetor in the Urals receives the specified vacuum above the nozzle while the engine is operating at low idle loads.

The materials from which the dosing needle is made are stainless steel or brass. There is a thread on top that serves to move relative to the sprayer. With significant differences in temperature conditions, overcoming high mountain areas, and increased load operating conditions, this provides the opportunity to change the composition of the mixture.

When starting a cold engine at an external temperature of 15°C and below, it is necessary to ensure a strictly controlled mixture composition. For this purpose, the carburetor in the Urals motorcycle is equipped with a float quencher 35. The mechanism body, the plunger tip of the starting device, the cover, the nozzle, and the float chambers are cast from a stainless zinc alloy.

To facilitate the start of a cold engine, plunger 34 is raised using lever 31 to its uppermost position. By turning the crankshaft with a kick starter, a vacuum is created behind the throttle. Thanks to this, fuel flows through nozzle 37 to the cavity under the plunger.

Penetrating into the carburetor in the Urals, gasoline is mixed with air entering through the channel from the inlet pipe. Next, the rich emulsion follows along channel 17 to the mixing chamber, and from there to the engine cylinder. If the plunger is fully raised, the mixture is enriched as much as possible, limited only by the throughput of nozzle 37.

As the plunger begins to descend, the mixture gradually becomes leaner. The fuel supply is controlled by the gap between the channel walls and the metering needle. If you lower the plunger completely, the needle will block the fuel channel, the carburetor for the Ural motorcycle will stop supplying the air-fuel mixture to the engine combustion chamber, and the vehicle will stall.

Second phase

Now let's move on to the main second stage of carburetor adjustment in the Urals. Place the Ural motorcycle on the center stand, or in any way convenient for you, hang the rear of the motorcycle so that the rear wheel is in free rotation.

Start the motorcycle again and remove the spark plug wire from the right cylinder. Engage 4th gear, add a little gas, and the speedometer should show 55 km/h. Lock the throttle in any convenient way in this position (there is a small screw in the throttle for this). Then put the right spark plug wire back and remove the left one. Using the screws on the carburetor covers, we adjust the length of the cables so that when working on each cylinder, the speed on the speedometer does not change. This will ensure synchronized operation of the throttle valves during transient operating conditions.

Adjusting the main carburetor systems in the Urals

Adjustment of carburetors on a Ural motorcycle is carried out after checking and adjusting the gaps between the spark plug electrodes, breaker contacts, valve stems, and the ends of the rocker arms. Each of the two carburetors is separately adjustable. It is necessary to begin adjusting the carburetor in the Urals after measuring the gap between the tip of the cable sheath and the fitting, which should be 2-3 mm.

Rice. 3a. The main elements of the carburetor: 1 - main air path: 2 - throttle valve; 3 - subsidizing haze; 4 — air nozzle; 5 - sprayer; 6 — air channel; 7 - well; 8 — main fuel jet; 9 — float chamber (central location).

Rice. 3b. Fuel corrector: 1 — air inlet channel: 2 — spool; 3 — spool needle; 4 — fuel jet: 5 — sprayer; 6 — output emulsion channel; 7 — spool return spring; 8 — corrector control cable.

If the gap does not correspond to the specified size, the union locknut is loosened. Turn to the right or left to set the required gap. After this, the fitting is re-locked with a lock nut and the carburetor of the Ural motorcycle is adjusted. By turning off the warm engine at a minimum engine speed without load, the basic settings are made. The idle system is adjusted for each of the two mechanisms separately. The Ural carburetor is adjusted with the second cylinder turned off.

Idle adjustment

By rotating screw 28, the crankshaft speed is set to the minimum stable engine speed. Screw 29 is slowly unscrewed gradually until the motor begins to malfunction. It also gradually, slowly twists until a calm, stable speed is achieved. Once again, use screw 28 to reduce the opening angle of the throttle valve until the minimum speed is reached.

At the same time, screw 29 adjusts the saturation of the mixture. Such operations are repeated until the minimum stable engine crankshaft speed is obtained. The carburetor of the Ural motorcycle is adjusted in the same way for the second cylinder. The test is carried out by sharply opening and closing the throttle. In this case, you must sharply turn the throttle towards yourself and release it to its original position.

Operating modes

Modes of medium loads are characterized by the position of the needle relative to the throttle. Adjustment is carried out by choosing its most optimal position. The settings must be repeated when seasonal conditions change (winter-summer), during the running-in of new vehicles, in order to increase engine power. In this case, the dosing needle 25 moves along the thread relative to the bar 6. The locknut 5 is loosened.

When screwed into the bar, the needle rises in relation to the nozzle hole. The mixture becomes richer. When unscrewing, the mixture becomes leaner. One revolution of the needle moves 0.5 mm. The quality of the adjustment is checked by sharply turning the throttle knob. The loud pops that the carburetor makes on a Ural motorcycle indicate that the mixture needs to be enriched. To do this, the needle rises.

When operating motorcycles, owners often wonder which carburetors are best to install on a Ural motorcycle. Now Chinese carburetors are widespread in the Urals. There are some good examples among them. Foreign-made Solex and Weber models performed well in operation. However, their prices are higher than domestic ones.

What carburetors should I put on the Ural IMZ motorcycle? In my opinion, a Russian-made K63 carburetor would be good for the Urals. This is a trouble-free mechanism, the professional adjustment of which allows it to last for several decades. Every 5 thousand km it is recommended to clean it, blow it out, and rinse it.

The jets must be washed with acetone. The parts are wiped with rags or soft vinyl. The throttle should be installed after servicing with the cutout facing the air filter. Regular maintenance will ensure long-term trouble-free operation of the K63 model.

Five random articles about motorcycles:

Java 638 carburetor

Four years have passed since the start of production of YAVA-638.

This model, as noted more than once in the magazine, is superior to the previous YAVU-634 in all technical parameters. The new engine is more powerful and at the same time is not inferior to the previous one in terms of efficiency and ease of starting. And the 2928CE carburetor plays a significant role in this. It is more perfect, but at the same time much more complex in design. And in operation it is noticeably different from the carburetors of previous YAV models. And it is not surprising that many people treat the new device with distrust. In response to requests from readers, we invited our regular author V. SECRETOV to talk about the structure of the YAVA-638 carburetor and the features of its adjustment. Many “yavists” ask the question: why was it necessary to change the carburetor? Why not install the well-proven JAVA-634 on the new JVA? Here's the thing. To increase the power of the JAVA engine, it was necessary to increase the diameter of the diffuser by 2 mm, and for the 2928CE carburetor it is 28 mm. However, bypass... Read more >>

Two years in Java

Read more >>

Java 634-7-00

New model YAVA-634 7.00 appeared in stores selling motorcycles this year.

This machine is a further modernization of the base model YAVA-634 (“Behind the wheel.” 1974, No. 8). which, after improvements in 1977, received the index JAVA-634.8.00 (“Behind the Wheel,” 1977, No. 3). A new block of control devices: on the left is the speedometer, on the right is the tachometer, in the center are warning lights. The 1981 YAVA motorcycle differs from previous modifications primarily in the new block of control instruments (tachometer, speedometer, four warning lights), elastically mounted on the front fork. The tachometer (new on road cars of this brand) is mechanically driven. In addition, the shape of the switches (made in the GDR) and control levers located on the steering wheel has been changed. Gas tank, switches and levers on the steering wheel. Other innovations include increased capacity from 16.2 to 17 liters and a modified... Read more >>

Conversion of Java electrical equipment 6V to 12V

Remaking the electrical equipment of Java Our magazine has repeatedly discussed the shortcomings of the power supply of the YAVA-634 motorcycle, produced before 1985.

At low crankshaft speeds (up to 1800 per minute), the 6-volt generator does not produce energy, and all consumers at this time are powered by the battery. If the lights and headlights are on, the battery is quickly discharged, which, with repeated cycles, leads to its failure. The only measure to avoid this trouble is to maintain medium speed even on bad roads or stops at intersections. It is clear that this causes great inconvenience, especially for residents of rural areas. The currently produced YABE model “638” uses a 12-volt electrical system (its description and diagram are given in No. 6, 1987), where a more advanced and powerful generator begins to work already at 1000 rpm. It is clear that many owners of the old model want to switch to new electrical equipment, but encounter an obstacle:... Read more >>