Hello, dear readers. Today we are going to present the final part of the article devoted to motorcycle-type carburetors. The principles of mixture formation, the main metering system, design features of the diffuser and throttle valve, the idle system and carburetor auxiliary devices have already been discussed.

In this final publication, we will look at the features of carburetors for four-stroke small-displacement engines.

At the end of the post you will find links to the PDF version of the article. The PDF version includes all 6 parts published here separately. Save it in your library and forward it to those interested.

In addition, at the end there is a list of references and the author’s final words on the series of publications “Motorcycle-type carburetors”.

General problems of mixture formation

A common problem with carburetors is that the engine's response to changes in throttle position is actually limited by the amount of vacuum, since it affects the flow of fuel from the main metering system.

In the previously discussed carburetor designs, when the throttle is opened sharply, the cross-sectional area of the diffuser also increases sharply. However, this does not lead to a simultaneous sharp increase in air consumption by the engine, since its speed does not grow so quickly. It turns out that the air flow does not change, but the flow area increases - this leads to a decrease in flow speed and a decrease in vacuum. In other words, the vacuum, due to which fuel flows out of the atomizer, decreases just at the moment when the fuel supply needs to be increased. As a result, due to insufficient vacuum, it is often necessary to close the throttle to achieve the required engine dynamics.

For carburetors, in which the diffuser cross-section is directly dependent on the position of the throttle, engine speed does not affect mixture formation in any way. With constant vacuum carburetors, the diffuser cross-section and the corresponding fuel supply are a function of not only the throttle opening, but also the engine speed. With this carburetor design, optimal engine dynamics are achieved, since the amount of fuel always corresponds to the current amount of air consumed.

Method of folk Kulibins

Vacuum carburetors often fail for this reason. To the question: what to do, people have long found an answer. In general, there are three solutions:

- The easiest, but also the most expensive, is to just buy a new carburetor and throw the old one in a box with garage trash, and go for a ride and enjoy the speed;

- Order and wait a long time for a part;

- Take special glue and simply seal holes or cracks in the membrane.

The third method is, of course, temporary, but with high-quality work and good materials, your membrane will last longer than the new ones from the repair kit. For gluing, we prepare a convenient place, glue, scissors and material for the patch.

We take the material for the patch. The Internet is replete with names of exotic materials. There are condoms, balloons, and surgical gloves. However, it is better to use an elastic, thinner membrane from another device. This patch will be more reliable. We cut it with scissors to the size of our part, coat it with glue.

What glue is best to use? People advise using any cyanoacrylic-based glue for gluing rubber products. We apply it to the damaged part and our patch, connect them, press and hold for a while. We leave our gluing until the glue is completely dry, assemble and install the carburetor on the scooter engine and ride with pleasure.

In conclusion, we note that all troubles with any mechanism can be solved on your own, saving time and money from the family budget.

Basic elements in the design, adjustment parameters

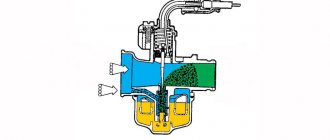

Constant vacuum carburetor designs have two elements to control airflow speed:

- Driver controlled flat plate throttle ( a

in the picture below) - Cylindrical valve with metering needle, actuated by vacuum ( b

in the figure below)

Airflow Controls

Let's take a closer look at the cylindrical damper.

Longitudinal section of a carburetor with constant vacuum

The cylindrical damper 1 is connected to the vacuum chamber through a rubber membrane 2. The upper cavity of the vacuum chamber 3, through one or more holes 4, communicates with the smallest cross-section of the diffuser - under the cylindrical damper. The lower part of chamber 5 communicates with the atmosphere through channel 6, led into the carburetor inlet.

In constant vacuum carburetors, spring 7 and the holes in the lower part of the cylindrical damper are adjusting elements, since they jointly influence the movement characteristics of the damper.

QUICK CLEANING

(K126G carburetor) The car has stopped idling - this is one of the reasons for cleaning the carburetor. remove the air filter housing. remove all rods, feed, pipes. remove the carburetor itself (four nuts hold it in place). ***It is better to change the gasket under the carburetor. Take a small brush (for example, a toothbrush) and gasoline. And we begin cleaning the carburetor completely. Everything needs to be cleaned, all the flaps, recesses. Remove the lower part of the carburetor where the chambers are located. You need to clean the inside of the chamber from carbon deposits (unscrew the four bottom bolts). *After cleaning, everything should work perfectly, all cameras open without difficulty. Also remove the upper part and clean it (when you remove the upper part, you need to be careful; there is a needle in the middle, the most important thing is not to lose it or forget to put it back). Next, remove the jets, clean them, and install them back. Now we assemble everything in reverse order, tighten it, and install it. (that's all this carburetor was cleaned).

Operating principle

Under the influence of vacuum, the damper rises until the elastic force of the spring balances the lifting force.

As the vacuum increases, the damper lift height increases. When the throttle is closed or partially open (flat valve), the vacuum under the cylindrical valve is small, so the valve is only raised. With larger throttle openings, the air flow rate in the diffuser increases, which causes a proportional increase in damper lift. When the throttle is opened suddenly, the cylindrical valve does not open as quickly. Its rise depends on the speed of the engine, and not on the mechanical action of the throttle. Now it becomes clear how a constant vacuum carburetor prepares the mixture regardless of the throttle position. From the considered principle of operation it follows that the lifting height of the cylindrical damper depends on two variables:

- flat throttle opening angle;

- engine speed.

These two parameters set the operating conditions of the engine, according to which the amount of air and fuel entering the engine is regulated. Interestingly, the operation of the main metering system depends on the same parameters as the operation of the electronic injection system.

Starting device

When the engine is cold and the ambient temperature is relatively low, part of the combustible mixture does not reach the combustion chamber, condensing and settling on the walls of the intake manifold. As a result, the mixture becomes leaner, making it more difficult to ignite. Starting the engine becomes problematic, and operation is unstable and difficult to control until the engine is completely warmed up.

To facilitate the task of cold starting, special starting devices are used - enrichers. They are designed to provide the required enrichment of the combustible mixture during cold start and warm-up. In other words, the enricher prepares an additional amount of combustible mixture, which is sufficient (when working with other carburetor systems) for starting and stable operation during the first time after starting.

Similar devices are found in the designs of all carburetors, with the exception of some specific models used on sports motorcycles, where the starting procedure is somewhat different.

In the simplest case, the starting device is a kind of lever that allows the driver to forcibly lower the floats in the float chamber, thereby increasing the fuel level, which leads to a richer mixture. The principle of operation determined the name of the enrichment agent - float drowner. With this design, enrichment of the mixture occurs in all carburetor systems, and a return to normal operation is possible only after starting the engine (when some of the fuel is consumed and the level returns to normal).

The main advantage of the float sink is the simplicity of its design. The disadvantages include the dependence of the degree of enrichment of the mixture on the exposure time. Since the impact is carried out manually by the driver, the composition of the mixture will depend on his skill and experience. In addition, to work with the drowner you need direct access to the carburetor, which is not always possible. For these reasons, float suppressors are becoming less and less common in modern carburetor designs. More advanced enrichers have been developed with a fuel supply independent of other carburetor systems, including jets, valves and other control elements.

Let's consider the following enrichment design.

Design of the Dellorto carburetor enricher of the VHSB series: 1 - valve control lever;

2 - cylindrical valve; 3 — channel for supplying the mixture to the diffuser; 4 - emulsion tube; 5 - air channel; 6 - fuel jet The control element is a miniature cylindrical valve 2. The valve is controlled manually by the driver (directly or via a cable). The maximum enrichment is determined by the corresponding jet 7, regardless of the degree of valve opening and the variant of its drive. The design of the enrichment fuel well and the location of the fuel nozzle are such that the operation of the enrichment can be divided into two stages.

Comparative characteristics of carburetors

Although this type of carburetor is called “constant vacuum”, in reality the numerical value of the reduced pressure is not a constant in the strict sense of the word. This is clearly visible on the graph of the dependence of the vacuum value on the air flow rate with the throttle valve fully open.

Dependence of vacuum value on air flow

The graph shows that in a carburetor with a constant vacuum, the vacuum in the diffuser first increases sharply to a certain value, after which it continues to slowly increase (curve a). For carburetors, in which the metering needle, together with the throttle valve, is rigidly connected to the gas handle, this dependence is much more linear (curve b). Due to the significant difference in the nature of the graphs, the term “constant rarefaction” is quite acceptable.

What means to clean

You cannot clean with gasoline, diesel fuel and kerosene, as you do in everyday life. The debris and deposits that clog the fuel system come from gasoline. To clean the carburetor and not spoil its operation, you need to use specialized cleaning products and dampers - “carbs”, and not multifunctional cleaners containing oils and silicones. They will only pollute the system more.

It is best to use aerosols. Thanks to the pressure in the cylinder, during cleaning they remove dirt and carbon deposits. You can also clean it without disassembling the parts. You should also be aware of carburetor self-cleaning means. This product is poured into the fuel tank, and then it enters the carburetor, thereby removing dirt and deposits. This cleaning will not completely remove dirt, but it works well in emergency situations. To clean the aerosols with the product, you will need about 10 minutes, but the result will be visible immediately.

| Liqui Moly Vergaser-Aussen-Reiniger | Quite a popular and high-quality liquid. Using this composition, you can remove not only carbon deposits and tar deposits from the surface, but also clean channels and throttle valves. The product can also be used to clean injectors | Aerosol in a 400 ml can | 3918 | 280 rub. |

| ABRO CARB&CHOKE Cleaner | Designed for quick and high-quality cleaning of carbon deposits, carbon deposits and dirt from carburetor systems and parts - idle system, carburetor channels, throttle valves, air and fuel jets, intake valves and piston heads | Aerosol in a 283 ml can | SS200 | 172 rub. |

| RAVENOL Carb Reiniger Spray | Guaranteed and quickly cleans of carbon deposits, carbon deposits, resins and varnish films: throttle valves, air and fuel jets, idle air system and valve, carburetor channels, intake valves and piston heads | Aerosol in a 400 ml can | 4014835703544 | 450 rub. |

| 3M PN08796 | This is a highly effective aerosol cleaner for removing tar, oil and carbon deposits from automatic choke valves and carburetors. | Aerosol in a 354 ml can | PN08796 | 339 rub. |

| HI GEAR HG3201 | The aerosol composition effectively and without disassembling restores the characteristics of the carburetor, allowing you to avoid costly and time-consuming repairs to the power system | Aerosol in a 312 ml can | HG3201 | 320 rub. |

| XADO JET100 ULTRA | Universal carburetor and injector cleaner | Aerosol in a 250 ml can | ХВ30014 | 460 rub. |

| MANNOL 9970 Carburetor Cleaner | Capable of providing high-quality cleaning of the carburetor without disassembling it. Removes high temperature deposits from both the internal and external surfaces of the carburetor. Completely optimizes the operation of the fuel system. This product is suitable for two- and four-stroke gasoline engines, with or without catalyst. | Aerosol in a 400 ml can | 2430 | 120 rub. |

Aerosol cleaning

In order to clean the carburetor with an aerosol product, you will need to remove the air filter and spray the product into the device. The deposits begin to dissolve instantly. If the parts are dirty, then this procedure should be repeated several times. Warm up the engine for 5-7 minutes at idle speed. With the engine running, apply the cleaning agent to the carburetor and other parts of the fuel system. Turn off the engine and spray the product again after 5-10 seconds. Next, adjust the idle speed. The product does not need to be wiped off or washed with water. Reattach the air filter.

Liquid cleaning

To perform self-cleaning with a liquid agent, you need to pour the cleaning agent into the fuel system. We fill the device with fuel. The product is mixed with fuel and enters the carburetor when the engine is running. When the fuel begins to burn, the product begins to act and does not completely clean the parts.