- a cooling system in which fluid circulation through the channels of the engine and radiator is used to remove heat from the engine.

The cooling system of an internal combustion engine is a set of devices that provide the supply of cooling medium to heated engine parts and the removal of excess heat from them into the atmosphere, which should provide the most favorable degree of cooling and the ability to maintain the thermal state of the engine within the required limits under various modes and operating conditions.

During the combustion of the working mixture, the temperature in the cylinder reaches 2000 °C or more. The cooling system is designed to maintain the optimal thermal state of the engine within 80-90°C. Strong heating can cause disruption of normal working clearances and, as a result, increased wear, jamming and breakage of parts, as well as a decrease in engine power due to deterioration in filling the cylinders with the combustible mixture, self-ignition and detonation. To ensure normal engine operation, it is necessary to cool parts in contact with hot gases, removing heat from them into the atmosphere directly, or using an intermediate body (water, low-freezing liquid). When cooling is excessively strong, the working mixture, falling on the cold walls of the cylinder, condenses and flows into the engine crankcase, where it dilutes the engine oil. As a result, engine power decreases and wear increases. As the temperature drops, the oil thickens. This is the reason that oil is supplied worse to the cylinders, fuel consumption increases, and power decreases. Therefore, the cooling system must limit the temperature limits to ensure the best operating conditions for the engine.

Types of cooling systems

There are three types of cooling systems for internal combustion engines: air, liquid and hybrid.

Thermal engines for A. require cooling of the cylinders. Only for weak, bicycle gasoline engines, air cooling with the help of scars cast to the surface of the cylinder is sufficient; for stronger ones, it is necessary to circulate water using a pump between the double walls of the cylinders, cooled in a special tubular device placed in front of the A. and blown by a stream of oncoming air.

Why does the engine overheat?

Thermostat failure.

A failed thermostat is the most common cooling system failure. The thermostat, despite its simple design, is in an aggressive environment, becomes covered in oxides and fails... The engine will overheat if the thermostat is stuck in the closed position, since antifreeze will not enter the main radiator. Such a malfunction can be treated by replacing the thermostat with a new one, which it makes sense to “weld” before installation.

Clogged radiator.

We have a separate article about a radiator clogged with dust and cleaning it. A clogged radiator with plastic tanks inside, if heavily soiled, is almost impossible to clean. Radiators with brass tanks used to be soldered and pierced with a cleaning rod, but in modern radiators this is not possible. If the contamination is not severe, it makes sense to flush the cooling system. If the radiator is heavily contaminated, it is usually replaced.

Faulty pump.

If you did not change the antifreeze in a timely manner and the corrosion inhibitors it contained stopped working, then you may well see this picture:

The pump may also jam or slip (in this case, you will hear the belt whistling).

The pump is usually replaced.

Late ignition.

On old engines, if the ignition was adjusted incorrectly, overheating occurred, but today such engines are already rare.

Air cooling

Air cooling can be natural or forced.

Natural air cooling is the simplest type of cooling. Heat from an engine with such a cooling system is transferred to the environment through developed fins on the outer surface of the cylinders. The disadvantage of the system is that, due to the low heat capacity of the air, it does not allow a large amount of heat to be evenly removed from the engine and, accordingly, to create compact, powerful power plants. Uneven airflow requires additional measures to eliminate local overheating - more developed fins in the aerodynamic shadow, turning more heated exhaust channels forward along the flow, and cold intake channels backward, etc. Natural air cooling is common on engines of light, highly mobile equipment: motorcycles, mopeds, aircraft and car models. With the systematic increase in the speed of motorcycle engines on the most advanced models, air cooling is giving way to liquid cooling. Due to the low mass, natural air cooling was widely used on piston aircraft engines, where the butts of the propeller blades, which were close to cylindrical and had a low peripheral speed, practically did not work as a fan, but the speed of the flow incident on the aircraft was itself very high.

Stationary or tightly cowled engines are equipped with a forced air cooling system. In them, with the help of a fan, an air flow is created that blows over the cooling fins. The fan and finned surfaces are usually covered by a guide casing. The advantages of such an engine are similar to engines with natural cooling: simplicity of design, light weight, lack of coolant. However, such engines are characterized by increased noise during operation and large dimensions. In addition, when designing such engines, problems arise with cooling individual elements of the engine structure due to uneven airflow. Air cooling was widely used in passenger cars produced in Europe from the 1950s to the 1970s. These are mainly small cars such as Volkswagen Beetle, Fiat 500, Citroën 2CV; The representative Tatra 613 stands apart. In the USSR, the most famous air-cooled car was the Zaporozhets. Trucks with air-cooled diesel engines were produced (for example, trucks under the Tatra brand were equipped exclusively with such engines from the start of production until the beginning of 2010). Many tractors (sometimes heavy ones, for example T-330; more often small ones, from ordinary row crops to mini-tractors of small private farms) have air-cooled engines, which are characterized by steady engine operating modes and specific requirements for ease of maintenance. Currently (2015s), forced air cooling is used on most scooters, motorized tools (chainsaws, lawn mowers, etc.), engines of small generator sets, walk-behind tractors and other self-propelled and stationary small agricultural and municipal machines. For the latter, unified series of simple one- or two-cylinder air-cooled engines are very common, the same for different manufacturers (Briggs & Stratton, Honda, Subaru, Chinese), in the form of a compact complete block mounted on a horizontal plane.

Dimensions

Above, among the shortcomings, we highlighted the item about dimensions. If we compare the sizes of motors with different types of cooling and other identical characteristics, then the advantage will still go to the “air vent”.

Even though the fan and deflector are quite bulky devices, the parameters of the “air vent” are smaller than in the liquid-cooled version.

Additionally, housing a traditional water system requires more space under the hood to accommodate additional equipment. A rather large radiator with a fan is installed on the body. Hoses and pipes take up a lot of space.

Liquid cooling

Cooling systems are classified according to the way the coolant is used in the system.

Closed - in such systems, the coolant fluid circulates through a sealed circuit, heating up from a heat source (heater) and cooling in a cooling circuit (cooler). Depending on the design of the system, the coolant may boil or completely evaporate, condensing again in the cooler. Unclosed - in open (flow) systems, the coolant is supplied from the outside, heated at the heat source and directed to the external environment. In this case, it plays the role of a cooler, providing the required volume of coolant at the required temperature at the inlet and receiving the heated one at the outlet. Open - systems in which the heater is placed in a certain volume of coolant, which is enclosed in a cooler, if provided for by the design. For example, an open system with oil as a coolant is used to cool powerful electrical transformers.

“Purely liquid” cooling systems include only open cooling systems for river and sea vessels, where seawater is used for cooling. Some stationary engines of the early 20th century may have lacked a radiator; instead, there was a large-volume expansion tank - partly the heat was dissipated due to the evaporation of water, partly through the walls of the tank, and partly due to the large volume of water, which did not have time to warm up sufficiently while the engine was running .

"Air balloons" are loud

But this is true. But even the huge Tatra dump truck does not roar, the engine is simply noisier. The design features do not include any effective sound-absorbing systems. Liquid engines have such systems. In addition, the noise is amplified by the passage of air flows through the fins of the cylinders and heads.

Closed system (Hybrid type)

Nowadays the hybrid system is also called liquid. In fact, it is still hybrid, since air is also involved there.

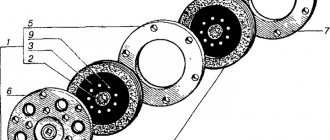

The hybrid type combines the above systems: heat is removed from the cylinders by liquid, after which it, at a distance from the heat-loaded part of the engine, is cooled in radiators by air.

The internal and external parts of the cylinders experience different heating and are usually made of separate parts:

internal - working bushing or cylinder liner

outer - jacket (for air-cooled engines the jacket has ribs for effective heat removal)

The space between them is called the casing; in a water-cooled engine, coolant circulates here.

The cooling system consists of a cylinder block cooling jacket, a cylinder head, one or more radiators, a forced radiator cooling fan, a liquid pump, a thermostat, an expansion tank, connecting pipes and a temperature sensor. This type is used on all modern cars. The coolant is pumped through the engine cooling jacket, taking heat from it, and then cools itself in the radiator. In this system there are two circles of fluid circulation - large and small. The large circle consists of the engine cooling jacket, water pump, radiators (including the interior heater), and thermostat. The small circle includes the engine cooling jacket, water pump, thermostat (sometimes the interior heater radiator is included in the small circle). Adjustment of the amount of liquid between liquid circulation circles is carried out by a thermostat. The small cooling circle is designed to quickly bring the engine into efficient thermal mode. In this case, the coolant is not actually cooled, since it does not pass through the radiator. As soon as it heats up to the optimal temperature, the thermostat opens and the coolant also begins to circulate through the radiator, where it is directly cooled by the incoming air flow (and in case of long-term parking, by a fan). At the same time, the more the coolant heats up, the more the thermostat opens, and the more the liquid cools in the radiator. This is the principle of maintaining an optimal engine temperature of 85-90 °C.

A very dangerous phenomenon is engine overheating (motor boiling). In this case, the coolant literally boils in the cooling jacket, which very often leads to serious consequences and expensive repairs. To prevent engine overheating, it is logical to use liquids with a high boiling point, but the easiest way turned out to be to keep the entire system under some excess pressure (about 1.1 atm), at which the boiling point of the coolant increases (about 110 °C and 120 °C for water and antifreeze, respectively). In addition, when the coolant temperature exceeds 105 °C, the fan turns on the forced cooling of the radiator.

About repair and maintenance

To operate these engines, the owner must have a little understanding of how the system operates and know where the engine temperature sensor is located. Otherwise, this is a reliable cooling system, which has no analogues in terms of simplicity of design. There is no need to change antifreeze every two years, no need to use sealant to eliminate leaks, or periodically change the pump. And there are quite a lot of “not necessary” ones.

Main parts of a liquid cooling system

In liquid cooling systems for piston engines of land and air transport, as well as stationary installations, coolant circulates in a closed circuit, and heat is dissipated into the environment using an air-flow radiator.

Main parts of the liquid cooling system:

The cooling jacket is a cavity that goes around the parts of the engine that require cooling. The liquid circulating through the cooling jacket takes heat from them and transfers it to the radiator.

Coolant pump, or pump, circulates fluid through the cooling circuit. Some engines, such as mini-tractors, may use a thermosiphon cooling system - that is, a system with natural circulation of coolant in which this pump is absent. It can be driven either through a belt drive from the motor shaft, or from a separate electric motor.

Thermostat - designed to maintain engine operating temperature. The thermostat redirects the coolant in a small circle - bypassing the radiator if the temperature has not reached the operating temperature.

The radiator has a developed surface, blown from the outside by an incoming air flow. The radiator is made of materials that conduct heat well, most often from aluminum (a radiator for cooling oil is most often made from copper).

The fan creates an additional air flow to blow over the radiator, including during stops and when driving at low speed. It can be driven by a belt drive from the engine shaft, but in modern cars, with the exception of large trucks, it is powered by an electric motor.

The expansion tank contains a supply of coolant. The expansion tank communicates with the atmosphere through a valve that maintains excess coolant pressure during operation, which allows the engine to operate at a higher temperature, preventing the coolant from boiling, which can lead to engine damage. Cars from the early to mid-20th century often did not have expansion tanks. In them, the coolant supply was located in the upper radiator tank. This was quite acceptable, since the cooling system mainly used water, and its expansion when heated was small. With the spread of ethylene glycol-based antifreeze, the use of an expansion tank has become mandatory. The translucent tank, located in an accessible location at the top of the system, also makes it easier to control the liquid level. Piston aviation also uses engines in which the cylinders are cooled directly by incoming air, and the cylinder heads are cooled using a liquid cooling system. This solution makes it possible to reduce the weight of the engine and at the same time more effectively cool the cylinder heads, which are the most heat-loaded parts of the engine.

Purpose

During operation of the internal combustion engine, temperatures in the combustion chamber can reach 2000 degrees. Without a reliable cooling system, oil and fuel consumption will increase. Overheating will lead to rapid wear and engine failure.

If the engine does not warm up enough, this will also have a negative effect on it. If hypothermia is observed, this threatens a decrease in power, intense wear, and increased fuel consumption.

Moreover, in most modern cars, in addition to the main tasks, this system also performs secondary functions. The first step is to ensure the heater is working. The system is also designed to cool not only the engine itself, but also the oil and fluid in the automatic transmission. Sometimes it also affects the throttle assembly along with the intake manifold.

In a modern system (whether liquid or air-cooled engine), up to 35 percent of the heat produced by the combustion of the fuel-air mixture is dissipated.

Evaporative cooling system

There is also a subtype of cooling system called an evaporative cooling system. Its main difference from conventional water or ethylene glycol is that the temperature of the coolant (water) is raised above the boiling point, as a result of which a large amount of heat is removed from heat-loaded parts during evaporation. The steam condenses into liquid in the radiator and the cycle repeats. Similar systems were used in the aircraft industry in the 30s of the 20th century. In addition, in China, as of 2014, diesel engines with power from 8 to 24 hp continue to be produced. with evaporative cooling, designed for walk-behind tractors and mini tractors.

Typical faults

Despite all the reliability of air systems, breakdowns do occur here too. One of the popular faults is electronics. The system has a temperature sensor. For those who don't know where the engine temperature sensor is located, it is located in the oil pan. As a result of excessive readings from this sensor, the system may fail.

If a malfunction lamp lights up on the instrument panel, then most often the reason is a broken belt. The most rarely diagnosed problems are related to the thermostat.

Useful tips

Please note that a decrease in the level of antifreeze or antifreeze does not always indicate problems with the cooling system. Coolant can go directly into the cylinders if there is damage to the cylinder head gasket, there are cracks in the head or block, etc.

In this situation, the engine often emits white smoke as the coolant escapes through the exhaust in the form of steam. In this case, the head or block must be removed; as part of the diagnosis, crimping of the block head is performed. Then a decision is made to repair the cylinder head or replace the element. Also, antifreeze or antifreeze may leak if problems arise with the engine block plugs. Leaks at the plugs will indicate that the engine plugs need to be replaced.

It should also be added that with the onset of the cold season, it is very important not only to have coolant filled strictly to the level, but also to the density of the antifreeze. Remember, if you had to add distilled water during operation, the density of the solution decreases

In simple words, when the temperature drops, the liquid can freeze. Freezing often results in damage to both the cooling system elements and the internal combustion engine itself.

The coolant density is measured with a hydrometer; if necessary, the antifreeze concentration should be increased by adding concentrate. At the same time, mixing antifreeze and antifreeze of different brands is strongly not recommended.

It is also important to remember that coolant concentrate is a strong poison! Do not allow the substance to come into contact with your skin or eyes, and do not take it orally!

Let us note once again that antifreezes or antifreezes based on ethylene glycol contain a package of active additives that prevent the formation of corrosion and have antioxidant and antifoaming properties. However, over time, the additives wear off and stop working.

As a result, the pump impeller is destroyed, the radiator “corrodes” from the inside, and the channels in the BC and cylinder head rust. Also, coolant decomposition products, combined with general contamination, can clog the system channels, disrupt the operation of the thermostat, etc. For this reason, the performance of the cooling system deteriorates, and the service life of its components is significantly reduced. In some cases, corrosion destroys the channels of the engine cooling jacket; antifreeze or antifreeze gets into the cylinders or into the lubrication system.

To prevent possible consequences and avoid a number of problems, the coolant must be changed once every 2 years. This is especially true when it comes to antifreeze. It is advisable to make the replacement by flushing the cooling system. Also today there are new generation antifreezes of the G12+ type, which are designed for 3-4 years of service.

If there are any doubts about the efficiency of the system, or the thermostat, etc. is suspected, an infrared thermometer allows you to measure the temperature of the hoses and pipes during the initial diagnosis. For a quick check, just turn on the heater in the cabin, then measure the temperature of the heater inlet and outlet hoses. The temperature should be almost the same. If obvious abnormalities are noticeable, this may indicate a need for repair.

Finally, we note that when placing hoses in the engine compartment, be sure to check for kinks. First of all, for example, after replacing pipes, you should make sure that the hose is not kinked

It is also important that the hose does not touch hot surfaces, moving parts or sharp edges.

Kinks impair coolant circulation, which can cause overheating under load. As for mechanical damage, moving parts can chafe the hose, sharp edges cause cuts, and contact with heated surfaces causes accelerated cracking of the pipes. The result is a coolant leak, which can cause the engine to overheat.

Installation of temperature sensors in the engine head, general recommendations

Installing temperature sensors in engine heads is not difficult. To install sensors without removing the cylinder heads from the engine, it is necessary to determine in advance where the recesses will be prepared. For example, by examining an analogue head in a store. When drilling a recess for the sensor, use a drill with a diameter 2-3 hundred parts larger than the diameter of the sensor and do not drill through the head! The minimum is considered to be a recess in which the sensor is placed at a height of at least 7 mm (applies to a kit sensor). In this case, a cambric should be placed on the protruding part of the sensors, depriving the sensors of airflow. The ideal option is that the sensors are completely immersed in the body of the head and do not protrude outward. The advantage of this installation is that you install it once and forget it! There is no need to dismantle the sensors in the future, for example when replacing spark plugs, which means there is no risk of damage. The closer the sensors are located to the center of the heads, the more accurate the readings and the faster their change. We do not recommend installing sensors in the engine head, on the exhaust manifold side - the temperature will be too high.

The thickness of the head where the spark plug is mounted is usually equal to the length of the spark plug thread. Quite often, a recess for the sensor is drilled near the spark plug, so that the spark plug is located between the sensor and the fan. This method is correct - the sensor is as close as possible to the center of the head. If you use this method, make sure that when installing the spark plug, the key does not touch the sensor.

Before installing the sensor in the recess, the recess must be filled with KPT 8 thermal paste or similar. Thermal paste fills air gaps and promotes 99.9% of heat transfer from the head to the sensor. After installing the sensor, the edges of the recesses are slightly deformed by the core (it is not permissible to deform the sensors). This prevents the sensor from falling out.

Installing a temperature sensor in the head of a Buran snowmobile

In our opinion, this is not the best place for installation. With this installation of the sensor (from the exhaust side), the readings will be higher. It is clear that exhaust gases have significant temperatures. In addition, the sensor wires were left unprotected and very soon, due to vibration, they would lose their insulation from being closed. About how the kit works Moto thermometer on the Buran snowmobile

Installing sensors in the engine head of a Taiga snowmobile

The sensor installation location is selected in the stiffening rib of the engine head, running crosswise, from stud to stud. The thickness of the metal in this place is about 26 mm

Oil for four-stroke engines

The viscosity of the lubricant determines the level of engine protection against wear.

If we are talking about lubricant for four-stroke engines, then the key parameter will be the viscosity, in general, as for automobile engines. Viscosity determines the level of engine wear protection. The loads in a motorcycle engine are significantly higher than in a car engine and the oil is quickly displaced from the rubbing pairs, which is what determined that the use of liquid oils is unacceptable. Japanese motorcycle manufacturers strongly recommend using an oil such as SAE 10w40. It is classified as an all-season brand. Experience suggests that such a lubricant can be used in equipment that is used from the thaw to the first snow.

But such motor oil has a significant drawback - with a sharp drop in temperature outside, it can quickly thicken; high temperatures will lead to its dilution to an unacceptable limit.

How to get to us?

When moving from the street. Profsoyuznaya towards Leninsky Prospekt. You need to cross the intersection with the street. Academician Volgin straight ahead and drive to the pedestrian traffic light, after the traffic light after 50 meters there will be a right turn under the barrier (at the entrance you will need to tell the security that you are going to the Avangard Automotive Technical Center), then move straight 150 meters and you have arrived, Welcome!

When driving from Leninsky Prospekt. on the street Miklouho-Maklaya towards the street. Trade union. Before the pedestrian traffic light (this is the first traffic light from Leninsky towards Profsoyuznaya), before reaching it 50 meters there will be a left turn under the barrier (at the entrance you will need to tell the security that you are going to the Avangard Autotechnical Center), then move straight 150 meters and you have arrived, Welcome welcome! Tel.