The first production Voskhod motorcycle was equipped with a K-36B type carburetor, which had two metering systems - main and idle, as well as an enrichment device.

To rinse and clean it is necessary to disassemble in the following order: 1 - close the gasoline tap and disconnect the gasoline hose; 2 — unfasten the latches and remove the housing cover along with the cables, spool and fuel corrector; 3 - remove the rubber coupling; 4 — unscrew the two fastening nuts and remove the carburetor; 5 — remove the sealing gaskets; 6 - perform a complete disassembly.

Wash the removed parts with clean gasoline, inspect and reassemble in the reverse order. The factory settings ensure maximum and optimal engine efficiency.

Adjusting the K-36B carburetor

Adjustment at idle speed is carried out as follows: 1 - before starting the adjustment, you need to start and warm up the engine. 2 — set the fuel corrector coin to the farthest position from you; 3 — by turning out or screwing in screw 14, set the minimum possible engine speed; 4 - tighten screw 13 until it stops, gradually unscrew it, achieve clear, stable operation of the engine; 5 - set screw 14, lower or raise the throttle to the minimum stable idle speed.

The quality of the mixture is adjusted in operating modes by moving the metering needle 6 in the throttle valve to one of the five annular grooves, while raising the metering needle ensures enrichment of the working mixture, lowering ensures depletion.

Adjusting the K62 carburetor

The carburetor is one of the main components of a motorcycle, which affects the operation of your bike’s engine. Its correct adjustment affects how it starts, runs, and engine power. The second element is the ignition system. In this article we will talk about adjustments that can be found on motorcycles Minsk, IZH Jupiter and Planet, Voskhod.

The K62 carburetor has two adjusting screws, with which you can change the idle speed, and a needle, by changing the position of which, you can change the property of the mixture (enrich or lean it). When we raise the needle, we enrich the mixture; when we lower it, we make it leaner. Adjusting the quality of the mixture is carried out by walking 2-3 km (at a speed of about 60-70 km/h) and looking at the spark plug. If the candle is covered with the working mixture (the candle is oily, dark brown or black), we lower the needle; if it is too dry (the color is white, light straw), we raise it. As a result, a light brown soot should appear. But this is just part of the adjustment; each time you need to set the carburetor idle speed. So we continue to adjust further:

To adjust the idle speed on the K62 carburetor there is a “quality screw”. This screw supplies air even when the throttle is closed. We repeat, the propeller produces air, although some people think that this propeller is designed for fuel. Therefore, by tightening the quality screw, we close the air flow, that is, we enrich the mixture. If we unscrew the screw, the mixture becomes leaner. As was said, this screw provides air in all positions of the damper, and therefore at idle speed of the crankshaft. Therefore, the quality screw belongs to the idle air regulator. At this moment, it significantly affects the operation, but if the gas is at medium or high speeds, then the influence is not large, but it is present. So, it all comes down to the fact that the idle speed is adjusted, and this automatically affects all engine frequencies. Now, after a short introduction, let’s talk about the idle speed adjustment itself. To keep things simple, let’s talk about adjusting K62 K carburetors and similar ones for Minsk and Voskhod motorcycles. But by analogy, the adjustment of all types of carburetors is the same, so it will also work on IZH and other motorcycles.

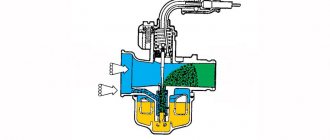

K-36B carburetor diagram

1. Fitting. 2. Fuel corrector. 3.Fuel corrector spring. 4. Locking needle. 5. Throttle valve spring. 6. Dosing needle. 7. Mixing chamber housing. 8. Air intake channel. 9. Sprayer. 10. Main jet. 11. Fuel corrector jet. 12. Float. 13. Idle speed adjustment screw. 14. Throttle set screw. 15. Throttle valve. 16. Cover of the mixing chamber housing. 17. Cable guide. 18. Leaf spring. 19. Float release button. 20. Float chamber cover. 21. Float chamber housing.

What kind of carburetor is installed on Ant

The first Ant scooters were equipped with a cast-iron engine, as well as a K62G carburetor. This unit had a diffuser with a diameter of 26 mm and a mixing chamber of 28 mm.

After some time, the engine was modernized. As a result, a petal valve appeared at the inlet, the cylinders changed shape, as did the cooling fins. Additionally, the carburetor itself was replaced. Now the K65G model was installed on the scooter. Although it is worth noting that structurally they are in many ways similar to the previous unit.

There have been no changes in terms of the diameter of the mixing chamber or diffuser. They had similar dimensional characteristics.

But the throughput of the main fuel jet (GFJ) was changed. Now it has become 130 ml per minute versus 125 ml per minute with the old carburetor. The diameters of the nozzles were also changed from 2.6 to 2.63 mm, as well as the diameter of the needle and the transition hole.

The corrector has changed, but only slightly. In the K62G, in order to further enrich the fuel, a needle was used, which was immersed in the well of the float chamber. With a new carburetor, fuel is taken directly from the chamber using a fuel manifold jet.

Adjusting the K-62V and K65P carburetor

Adjust the idle speed in the following sequence: 1 – screw screw 18 until it stops, which regulates the air supply for idle speed. Then unscrew one turn. 2 – Open the throttle slightly using the throttle. 3 – Start the engine and warm it up. 4 – Using bolt 16, lowering the throttle valve, achieve minimal stable engine operation. 5 – Unscrew screw 18 to set the maximum speed. 6 – Using bolt 16, lower the damper again to minimum speed. 7 – Check the adjustment. Sharply open the throttle with the throttle. If the engine stalls or there is a failure in operation. When switching from idle to main working. The adjustment is incorrect. Screw 18 needs to be used to enrich the fuel mixture - tighten it by a quarter. Or repeat the entire adjustment. 8 – Adjusted correctly, if there is no dip and the motor does not stall. And it continues to gain momentum.

Adjusting the K62 carburetor:

Hello! Please tell me, I have a Minsk 125, it’s a Pakko (original, new), it’s not in use, it works fine, that is, the idle is normal, it picks up speed briskly, but as soon as you start to move out of place, it doesn’t pull well, or it may even stall, you just need gas open more than halfway. The quality screw is screwed in completely, but if you unscrew it by 1-1.5 rpm, you won’t be able to move it at all - the engine will stall. The spark is normal, the ignition is set correctly, the needle is in the middle position. Please tell me what’s wrong, this is the first time I’ve encountered such a problem?

Adjustment with dosing needle

The dosing needle for adjustment has five positions and is fixed with a special lock. Raise the needle one notch and increase the fuel supply. We lower it and reduce the fuel supply.

Under normal conditions, the needle is installed in the central groove.

When operating a motorcycle at high temperatures of plus 35 degrees and above, as well as in rarefied air at an altitude of 2000 and above above sea level. The needle should be released one division.

And vice versa at low temperatures of minus 15 degrees and below. The needle should be raised one notch

Adjusting the fuel level

For this purpose, there is a brass adjusting element on the float, as shown by the white arrow in the photo.

The entire adjustment process comes down to setting the float in a certain position. Remove the bottom carburetor cover and turn it upside down with the float.

We look from the side so that the mark on the float from the mold (black arrow shows) is parallel to the carburetor plane (red arrow shows).

In this position of the float, the fuel level will be within 12 ... 14 mm. This level is necessary for normal engine operation.

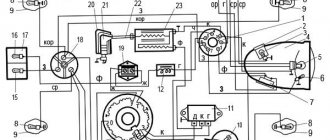

Scheme of the carburetor K-62V motorcycle Voskhod

1. Idle fuel jet. 2. Main fuel jet. 3. Float chamber. 4. Sprayer. 5. Float axis. 6. Float lever bushing. 7. Air channel. 8. Nozzles. 9. Dosing needle. 10. Body. 11. Throttle. 12. Needle lock. 13 Throttle spring. 14. Throttle lift limiter (removed after engine break-in). 15. Throttle control cable. 16. Throttle lift adjusting screw. 17. Cover. 18. Idle speed adjustment screw. 19. Fitting for fuel intake. 20. Transition hole. 21. Idle air channel. 22. Drainage hole. 23. Idle air channel. 24. Locking needle with washer. 25. Float. 26. Float sink.

Which carburetor is suitable for the Ant instead of the original one?

Now there are no particular difficulties in finding analogues. All thanks to the arrival of a large number of spare parts and consumables from China on the Russian market.

If we talk about which analog carburetors are now most often installed on the Ant, then the scooter is mainly equipped with PZ 26 and PZ 27 devices. They are intended for Chinese engines with a volume of 110 to 150 cm3.

Before you replace the original factory system with them, be sure to take into account a few points related to installing the PZ 26 and PZ 27 on the Ant:

- The jets will have to be replaced. This applies to the idle and main jets.

- You also need to make a flange to secure the carburetor to the engine cylinder. The fact is that at the bottom of the carburetor there is a recess along with a drain hose. This notch will most likely be in contact with the clutch release lever.

- To install an analog Chinese carburetor, it is warmed up and bent to the side, taking into account the squeeze.

- If this installation option is not suitable, you will have to make a longer pipe. In this case, the lever will be able to rotate freely without touching the carburetor. But you will additionally need to select a suitable air filter pipe.

- A bonus of the PZ 27 carburetor is an accelerator pump. Although in the case of the Ant scooter it doesn’t make much sense. Therefore, the issue of installing an additional cable can be eliminated.

On the Internet you can find positive reviews about 2 more alternative carburetors. These are PZ 30 and Jikov, which is installed on Java 638 motorcycles. But in reality, these are far from the best solutions for the Ant scooter.

This is due to the fact that the carburetors considered have a large diffuser diameter. And these are suitable only for engines that are forced and have high operating speeds.

If you install a PZ 30 or Jikov instead of a factory carburetor from an Ant scooter, you can hardly count on stable idle speed. Even the most careful adjustment and selection of jets will not help here.

So it turns out that the best option for replacing a failed carburetor is an original spare part. That is, the new K65G. If this option cannot be implemented for one reason or another, then choose between PZ 26 and PZ 27. But this is not the optimal option, since certain modifications and alterations are required.

Basic rules for repairing a K65 carburetor

The K65 carburetor replaced the K62 carburetor.

Due to constant breakdowns and shortcomings, technologists decided to modernize it. Despite the fact that the K65 carburetor appeared quite recently, its adjustment is not difficult. There are some nuances that you need to know, but they can affect everyone. Even those who want to know how to adjust the carburetor on a scooter.

Before you begin your own repairs, you must fulfill some conditions.

- It is necessary to warm up the engine thoroughly;

- The carburetor must be in good condition. Otherwise, it must be blown out and cleaned;

- You should pay attention to the air filter. If necessary, it is washed.

Direct carburetor repair work begins with adjusting the free play of the throttle cable and the idle speed.

— The free play of the throttle cable is adjusted as follows: the lock nut on the bolt is loosened, the adjusting bolt is tightened and unscrewed until the free play of the cable is 1-2 mm.

This is interesting: Adjusting the carburetor of a 4T 50CC scooter China

— Adjusting the idle speed is done as follows: unscrew the bolt and thereby increase the speed. In order for the speed to be reduced, the bolt must be tightened. The idle speed will then be adjusted when the engine runs stably at minimum idle speed.

The K65 carburetor adjustment itself

This also includes adjustment of the main dosing system. For this purpose, several grooves are carved into the needle. By moving the latch along them, you can precisely adjust the fuel consumption. If the mixture needs to be enriched, the needle rises. If it is necessary to lean, the latch moves so that the needle drops.

Since the boundary at which the fuel is located in the float chamber greatly affects the quality of the mixture at all stages of engine operation, it also needs to be adjusted. To help the amateur car mechanic, there is a tongue on the float.

The fuel level will change if the tongue is bent or straightened. The best option for accurately adjusting the fuel level would be to measure using an ordinary ruler. It must be placed on the connector plane. The tongue should be bent so that the float strip is at the mark of 13 mm or plus/minus up to 1.5 mm.

To normalize the quality of the idle mixture, a special screw is provided that controls the volume of air entering the channel of the idle design. If you listen to the advice of specialists who have independently adjusted the idle system more than once, you need to perform the following steps:

- The screw is screwed in all the way and the idle speed is adjusted;

- You should check the motorcycle in action, that is, ride it;

- If acceleration, starting, and idling occur in normal mode, then it is worth unscrewing the bolt a little and checking how much worse or better these characteristics have become;

- If the parameters have become better, the bolt is unscrewed a little more, if worse, it is tightened;

- Similar procedures should be carried out several times.

This concludes the work on adjusting the carburetor of the K65 model.

What kind of carburetor is used on the Izh Planet-5 motorcycle

The latest Planet model was produced in several variations. Early transitional models were equipped with K-62I carburetors. Then they began to install the K-65I and the more progressive K-68I with a cylindrical throttle valve.

All three carburetors: top left - K62I, top right - K68I, bottom - K65I

All three carburetors have a similar operating principle. From the tank, through the fuel valve, fuel enters the float chamber. The floats are made of petrol-resistant lightweight material. As soon as gasoline fills the chamber, the floats will float up and the shut-off needle will block the fuel supply channel.

From the chamber, fuel enters the atomizer through the main fuel jet. In it, the fuel is mixed with air entering through a special hole in the atomizer body. The finished mixture enters the mixing chamber (diffuser) and then into the engine cylinder. This dosing system is called the main one. And it only works at medium and high engine speeds, when the throttle is raised more than 2/3 of its stroke.

To operate the engine at low speeds, the carburetor is equipped with an idle system. It consists of a fuel tube, mixture quantity and quality screws, a special air channel, transition and idle holes in the diffuser.

The fuel rises through the tube due to the vacuum in the mixing chamber and is mixed with air entering through the air channel. As a result, the resulting mixture, when the throttle is opened slightly, exits through the idle hole (it is specially located behind the throttle valve, at the end of the diffuser).

If you continue to raise the throttle, the vacuum will increase in the area of the transition hole and the mixture will also begin to flow through it. In general, when you lift the throttle (turn the throttle lever), the mixture becomes leaner and the engine speed increases. The air flow speed increases and, by lowering the pressure in the mixing chamber, the fuel supply increases.

The carburetor of the Izh Planeta-5 motorcycle also contains an engine starting and warming up system (to facilitate engine starting in the cold season). The enrichment corrector is installed on the carburetor body or brought to the motorcycle handlebar using a cable. When it is lifted, 3 channels will open in the carburetor body. Through the fuel channel from the float chamber, the fuel will enter a special cavity, where it will mix with air coming from the air channel (this channel is usually located at the end of the diffuser on the air filter side).

As a result, the finished mixture will flow through a special channel to the outlet of the mixing chamber (behind the throttle valve). The channels are designed in such a way that the finished quality of the mixture is sufficient to warm up the engine.

Float stopper or additional starting device. When you press it, the floats lower and additional fuel enters the chamber. When starting, the mixture is richer and the engine starts easier. It is recommended to use the drowner only at temperatures of +5 C and below.

how to adjust fuel consumption in a K62V carburetor. Sunrise 3m

The quality adjusting screw is fully tightened, and then unscrewed half a turn or a little more. After starting the engine, warm it up to normal temperature.

By rotating one quantity screw, the minimum stable engine speed is achieved, by rotating the other (quality screw) the mixture is leaned until interruptions occur. After this, turning the quality wing, enrich the mixture until the engine begins to operate stably. Now, turning the screw from which the adjustment began, reduce the speed and find a new position for the quality screw and repeat this until a minimum but stable engine speed is achieved.

The correct idle speed adjustment is checked by sharply opening and closing the throttle. If the engine stalls when the throttle is opened suddenly, you should enrich the mixture by turning the quality screw a quarter or half a turn. If the engine stalls when the throttle is closed abruptly, the mixture is leaned out by turning out the same quality screw by the same amount.

Rice. Carburetor K-62:

1 — idle fuel jet, 2 — main fuel jet; 3 — float chamber, 4 — sprayer; 5 — float axis, 6 — float lever bushing; 7 — air channel, 8 — nozzle, 9 — dosing needle, 10 — body; 11 — throttle, 12 — needle lock; 13 — throttle spring; 14 — throttle lift limiter (removed after engine break-in); 15 — throttle control cable, 16 — rod with idle speed adjustment screw (lowering the throttle); 17 - cover; 18 — idle speed adjusting screw, 19 — fuel inlet fitting, 20 — adapter hole, 21 — idle speed emulsion channel; 22 — drainage hole, 23 — idle air channel, 24 — locking needle with washer, 25 — float, 26 — corrector emulsion channel; 27 — dosing needle; 28 — float stopper, 29 — plunger, 30 — plunger spring, 31 — corrector control cable. To achieve optimal fuel consumption, you also need to set the gasoline level in the float chamber. The distance from the housing parting plane to the farthest upper part of the float should be 26 (+0.5/-0.5) mm. It is adjusted by bending the float tongue.

Carburetor of Izh Planeta 3.4 motorcycles

Izh Planet-3 motorcycles were equipped with K-62P and K-36I carburetors. The latter had a unique design for its time. The throttle shape was U-shaped, which made it possible to significantly reduce the dimensions of the carburetor (in comparison with the K-28 and K-37 produced at that time). The corrector was moved out of the diffuser area and regulated not the air, but the fuel. This solution made it possible to reduce fuel consumption by 4-6% due to more stable mixture adjustment.

The mixing chamber cover was fastened with special locking springs, which made it possible to quickly and conveniently replace the throttle cable or rearrange the needle. The main fuel jet was screwed into the bottom of the carburetor next to the drain plug. To clean it, it was not necessary to dismantle the carburetor. The diameter of the diffuser of the K-36I carburetor at the outlet is 28 mm, and in the middle it is 26 mm. That is, the mixing chamber is a kind of aerodynamic profile, which has a beneficial effect on mixture formation.

Another feature of the K-36 carburetor is its operating principle, which is similar to a car carburetor. The screw for the amount of mixture in it regulates not the air, but the fuel emulsion entering behind the throttle. Due to this, the sensitivity of the carburetor settings at idle has increased. Adjustment is carried out with screw 1 for the quantity of the mixture (at an angle) and screw 2 for the quality.

The K-36 carburetor has one drawback. It is sensitive to road dust. The upper latches do not seal the lid of the mixing chamber tightly and dust particles get there, the valve begins to jam and wear out. That is why motorcycles on which such carburetors were installed (Kovrovets, Izh Planeta-3, etc.) were equipped with carburetor protective covers.

Later, new K-62 carburetors with the indices I, P, B began to be installed on the Izh Planet-3, 3-01 and 4 motorcycles. The power of two-stroke engines grew and there was a need to increase the diameter of the diffuser (now it was 32 mm), throughput jets, etc.

The new carburetor design made it possible to uninterruptedly supply the engine during sudden braking and acceleration, tilting and rolling of the motorcycle.

Setting up such a carburetor is carried out similarly to the K-68 setting described above. The quantity screw is not located on the side of the carburetor, but in the upper part.

Engine

The “heart” of a motorcycle, even with the most careful use, gradually wears out - this is facilitated by the abundance of heterogeneous mechanical loads in the cylinder-piston group and other moving parts, temperature effects on the metal, the chemical composition of the working mixture and exhaust gases.

DIY motorcycle repair Voskhod most often includes the following engine work:

- removing the power unit from the motorcycle frame;

- partial or complete disassembly of the internal combustion engine;

- replacing piston rings;

- restoration of the cylinder mirror;

- repair or replacement of the piston, connecting rod, crankshaft;

- replacement of support bearings, liners, seals;

- lubrication, fastening, adjustment work.

Engine repair, like the repair of other units, must be preceded by a comprehensive diagnosis of its technical condition, which includes an analysis of operational parameters (approximate indicators of developed power and speed, fuel consumption, sound of operation, color and character of the exhaust). If necessary, diagnostics are performed on the bench, and specialized instrumentation is used.

It is important to navigate the structure of a two-stroke internal combustion engine of a motorcycle and understand how each specific type of repair is performed. So, when replacing piston rings, you can do without removing the engine. It is enough to unscrew the stud nuts, remove the cylinder cover and, opening access to the piston, bring the piston to top dead center. Then the worn rings are removed and new ones are installed. The engine is assembled, not forgetting to replace the gasket. This completes the repair.

Much more complicated is the process of replacing the crankshaft bearings and its seals, the need for which, especially if the motorcycle is used incorrectly, arises quite often. You will need to disconnect and remove the internal combustion engine, clean its external surfaces, disassemble the crankcase, allowing access to the crankshaft, and dismantle the latter. It is important to be careful when knocking out old bearings - if they become distorted, they can damage the seat. And, no matter how trivial it may sound, do not forget to remove the retaining rings. Then the new bearings are carefully pressed in, the crankshaft is installed on the left side of the pan and the engine is turned over. A pin is put on the nuts and the assembled module is screwed into the studs. The power unit is assembled in the reverse order. In case of wear of the inner surface (mirror) of the cylinders, they are bored to repair size and ground. This is a complex and highly precise job that must be carried out by experienced professionals and using special equipment. However, preliminary work - removing and disassembling the internal combustion engine - can be done independently. After the repair, you will have to replace the piston with rings with parts from the corresponding repair group.

This is interesting: When and how to change spark plugs?

One carburetor for a Ural motorcycle

Among the frequently encountered options for tuning a Ural motorcycle, it is worth noting the installation of one carburetor in the Ural, usually a car one. This is done primarily to reduce fuel consumption. After all, it is well known that boxer engines with original carburetors have a considerable appetite (6-9 liters per 100 km).

In addition, due to the design features of single-chamber float-type carburetors, Ural motorcycles have a noticeable dip during sharp acceleration from a standstill. For some this is unacceptable. Improving the dynamic characteristics of a motorcycle is another reason why such carburetors are installed.

To install one carburetor in the Urals, you need to make so-called “pants” - inlet pipes for each cylinder with a common flange for attaching the carburetor. Since car carburetors are located (longitudinally) in the center of the engine (where the air filter was), the pipes must have strictly the same length and a smooth surface inside, without burrs or steps.

If the carburetor is installed transversely, then the right (left) pipe must be made shorter so that the first channel of the diffuser is exactly in the middle. This way we will ensure equal supply of fuel to the cylinders. The air filter is installed above the carburetor or, if there is not enough space, to the side of it.

Another important point. The intake manifold does not have to be one piece. It must have at least one elastic connection. The motor has a certain thermal expansion. Since the motor is quite wide, this expansion is enough for the connections to the heads to break the tightness of the connection and begin to suck in air. The solution is tritely simple, an incision is made in any convenient place and connected with a rubber pipe.

So, the first car carburetor for the Ural motorcycle is the DAAZ 1111 (1113) from Oka. It is designed for a similar volume - 650 cubic cm. But before installation, it will be necessary to replace the standard jets in the first chamber with 90, and in the second with 92.5. The air channels remain the same.

The K-133 carburetor from Zaporozhets is installed in a similar way. Owners note a noticeable reduction in fuel consumption (3-5 liters per 100 km) compared to two carburetors. The downsides of this carburetor are its dated single-barrel design and workmanship. Today on the market there are more advanced 5-system carburetors with suction, accelerator pump, etc.

One of these is the DAAZ-2108–1107010 carburetor. It is initially configured for a 1.5 liter V8 engine. Before installation on a motorcycle, you will need to select the appropriate jets.

The filter for the carburetors described above is made independently. They make a platform for the filter element, and cover it with a decorative cover on top. They also make an adapter for a standard filter box, if there is enough space for it.

Ignition and carburetor

It is these two components that, as a rule, determine the stability of the engine. Often, interruptions in the crankshaft rotation speed, loss of traction, and difficulties starting the engine are associated precisely with their malfunctions. Repairing the ignition and carburetor usually comes down to adjusting them. Setting the ignition includes setting the gap between the coil core and the sensor magnet within 0.295...0.305 mm. The piston ignition timing should be 3.5-5 mm to top dead center.

Adjusting the carburetor is somewhat more difficult. If you are repairing a Voskhod-3M motorcycle, then you will have to deal with the K65V carburetor, and the main tools will be the quality and quantity screws included in its design. Using the first, you can lean or enrich the mixture - change the proportion of fuel and air entering the cylinder. The second determines its volume per working cycle. With the standard setting, the quality screw is screwed in completely and then unscrewed half a turn. Then the rotation of the quantity screw achieves the minimum stable speed and the quality of the mixture is re-adjusted. Finding the optimal adjustment balance is a search for maximum traction and stability with minimum fuel consumption.

Carburetor of Izh Planet Sport motorcycle

Motorcycle Izh Planet Sport 350. A legend of the Soviet motorcycle industry. Early models of the motorcycle were equipped with Japanese components, in particular a Mikuni carburetor with a diffuser diameter of 32 mm. Thanks to him, the motorcycle's power was 32 hp. at 6700 rpm.

The reliability of the carburetor is explained by the simplicity of the design. The throttle has a cylindrical shape. To drain excess fuel, there is a special plug at the bottom of the float chamber. The carburetor is adjusted using an air screw and an idle screw (similar to the K-68). To make starting the engine easier in cold weather, there is an enrichment lever.

Later versions of the motorcycle began to be equipped with the domestic K-62M carburetor. The engine power with it dropped to 28 hp.

As you can see, different carburetors were installed on Izh motorcycles of the Planet line, but mostly domestic ones. As engine power increased, the characteristics of carburetors also changed. For high-quality and long-term engine operation, it is necessary to inspect and clean the carburetor in a timely manner (every 3000-4000 km). If desired, imported carburetors can be installed on Izh Planet motorcycles. The main thing is to choose the right jets with the required throughput and match the diameter of the diffuser.

Transmission

During transmission repairs, the following work may be required:

- Adjusting the clutch, replacing its disc and bearing;

- Clutch drive repair;

- Replacement of gearbox bearings;

- Repair of switching module parts;

- Restoration or replacement of gearbox gears.

Most of them require high qualifications and are difficult to do at home. The exception is the repair and replacement of drive mechanisms. So, sometimes there is a need to restore the splines for the gearbox foot, replace the clutch cable or its jacket, or adjust the clutch. These works are carried out without disassembling the crankcase.

Repair and operation of the Voskhod motorcycle are closely interconnected due to the age of the model. However, with the proper approach to organizing and carrying out repairs, the motorcycle will remain your faithful friend and assistant for a long time.