How to lubricate the starter during assembly - the best means and methods of using them

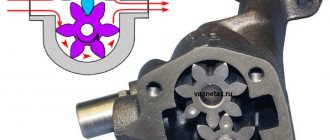

The starter is a component that is not very demanding on the availability and quality of lubricant. It does not have rolling bearings (this does not apply to all starters), and the sliding friction surfaces are provided with copper-graphite bushings, which work perfectly without additional lubrication. The only exceptions are gear-type starters, the planetary mechanism of which requires lubrication. But they also use plastic gears with a low friction coefficient.

Which parts of the starter need to be lubricated?

The gearbox definitely requires lubrication. Without it, it will not refuse to work, but increased wear and tear will quickly lead to the need for repairs. All other components and parts can also be lubricated, but only with a thin layer and only if regular maintenance of the starter is expected.

The fact is that with all the positive properties of the oil film, and this:

The presence of oil and other fats on parts contributes to the accumulation of contaminants, including abrasive types. Instead of increasing the resource, there will be a catastrophic decrease in it, jamming and failures.

But with careful handling, the absence of extreme dust during operation and planning periodic disassembly of the starter to update the lubrication and clean the parts, it is better to cover the surfaces during assembly with an anti-friction layer of oils and lubricants.

The scooter does not start from the starter - reasons and methods for solving the problem

A common problem is that a scooter or moped starts with a kickstarter, but refuses to start with an electric starter.

Let's consider all possible causes and methods for eliminating them. There may be several reasons why a scooter or moped does not start from the starter, both individually and in combination. Let's look at each of them:

Electric starter does not work

The scooter will not start from the starter if the electric starter itself is faulty. Everything is simple here. If the battery is serviceable and charged, the entire electrical circuit works, but when you press the starter button, only a click of the relay is heard, most likely the electric starter is faulty, or the contacts have come loose (oxidized).

It is very easy to check if the starter is working properly. Apply voltage to it directly from the battery, bypassing the starter relay. If the starter turns, then it is normal.

Starter relay does not work

The scooter will not start from the starter if the starter relay is not working. A faulty starter relay cannot start the starter, here everything is also simple and clear. If you do not hear the relay click when you press the starter button, it may be faulty. The relay needs to be replaced.

What to lubricate

When choosing a lubricating product, difficulties are inevitable, since standard lubrication of the starter during operation is not provided by any manufacturer, and there are no authoritative recommendations in this regard.

You will have to choose the recipe yourself, using the known properties of popular types of oils and greases.

Lubricating starter parts with a product like ShRB-4 intended for completely different purposes looks like an unexpected, but quite original solution. Indeed, many properties are a good fit.

This plastic type is designed for use in conditions of increased exposure to wet dirt on sliding pairs.

Usually these are steering ends and ball joints in conditions of loss of tightness of the covers. Since there can be no question of tightness in the starter version, the characteristics of such a well-adhering and reluctant to break oil film of long-fiber lubricant should be convincingly suitable.

It should be applied to the rotor supports and the splined part of the starter overrunning clutch.

Litol 24

Multi-functional lubricant for wide applications, developed mainly for sealed rolling bearings. However, it has a certain water resistance and frost resistance and is quite acceptable for use in the absence of other lubricants.

It will work fine, but may not last as long as some other products. It has several analogues with similar names and increased frost resistance.

Grease for CV joints

It differs fundamentally from all others in its special extreme pressure properties, which are not relevant for starters. But application is quite possible, since in all other respects it is the same Litol. It will work well, for example, in a planetary starter gearbox.

Engine oil

All greases and oils are made on the same base, only greases are additionally thickened with special compounds. Since it is important for a starter to obtain a thin oil film, and not to retain large reserves of lubricant, which are more likely to cause harm than benefit, liquid oil is acceptable for use.

They can lubricate surfaces for which it is important not so much reduced friction as protection against corrosion and dry wear. For example, the armature of the retractor relay, which does not need to be lubricated, but a thin film of liquid oil will not hurt.

If its rollers and springs are covered with something, then ATF looks most preferable.

Graphite grease

The product is well suited for heavily loaded low-speed components, especially springs; it has nothing to do with the starter. Especially if it is an old “graphite” on a solid base. It's better not to lubricate anything at all.

Castrol

The products of this company contain a wide range of lubricating products.

For starters, Castrol LMX multifunctional lubricant is used, its properties are similar to the mentioned Litol, in many ways superior to it, although in some places it is inferior, in particular in the lower temperature limit. You can safely use it with positive results.

Ciatim-201

Delicately working, one might say, instrument lubricant. It has good low-temperature performance and will serve well in starter friction units. Especially during winter operation in harsh climates, where this is especially important.

Bendix scooter device

Nowadays, no one will be surprised by the presence of a starter, even on very cheap and simple scooters and motorcycles.

And once upon a time, during the times of the USSR, it was difficult to imagine that a motorcycle or moped could be started with a button (O tempora! O mores!). But ok, what happened is past. Let's better move on to studying the device with which almost any internal combustion engine is electrically started. First, a little theory: as you know, starting a modern internal combustion engine is carried out using a starter. The starter is a simple DC motor; when starting the engine using the “START” button, the driver supplies current from the battery directly to the starter.

The starter, when current passes through it, begins to rotate and then, through the bendix directly connected to it, transmits its rotation to the engine. After the engine is started and the “START” button is turned off, the Starter stops, and Bendix at this moment disconnects the engine and starter.

On different models of scooters, the bendix may be located differently or may be absent altogether (a freewheel may be installed instead). In our case, the bendix is on top.

And this is what the starter bendix looks like when removed.

A theory is a theory... To understand the structure of the mechanism in more detail, it simply needs to be disassembled and studied in more detail.

Remove the retaining ring

Removing the thrust washer

Now you can completely disassemble the mechanism

As you can see, the Bendix consists of two gears rigidly connected to each other, the connection between the gears is carried out using a helical gear located on the shaft along which the second gear (in the hand) moves relative to the first in the axial direction, there is also a stabilization mechanism in the Bendix design, which the required moment rigidly fixes the gears together.

How does it all work?

When you press the start button on the scooter, the starter begins to rotate the main gear, and the second gear, due to its mass, does not have time to spin and begins to move along the helical gear along the shaft, thereby engaging with the ring gear of the variator plate.

When the engine starts, the opposite happens, the crankshaft speed increases and becomes greater than during startup, and the second gear, under the influence of a force applied to it in the opposite direction, seems to be wound onto the helical gear and disengages from the ring gear and then comes back under the action of a spring. in its place.

Bendix condition: the second gear is fully engaged (when the engine is running).

Bendix condition: During engine starting, the second gear engages with the ring gear.

But everything would be fine if not for one thing...

It happens that when starting, the engine seizes, then stalls, seizes again (twitches), at this time, when the engine seizes, the second gear comes out of mesh, and the engine stalls at that moment, and you continue to press the start button, and you hear a characteristic sound from the engine approximately This is when you accidentally press the start button while the engine is running, and in order to start the engine in this case you have to release the start button and then press it again, which is not entirely convenient.

To avoid turning off the bendix when the engine starts unstable, an additional unit was introduced into the bendix design, which precisely serves to stabilize the operation of the bendix under unfavorable starting conditions.

This mechanism is mounted on the second gear and is a centrifugal clutch, which consists of three weights, which, under the influence of centrifugal force, are pressed against the outer drum of the main gear (rigidly connecting the gears to each other), thereby preventing the second gear from disengaging during unstable conditions. launch conditions.

To disassemble the stabilization mechanism we need to remove the retaining ring.

Then you need to remove the washer

Now in front of you is the stabilization mechanism itself

The mechanism is removed, as you can see three weights tightened by a spring

Guides along which weights move

What malfunctions could there be in the stabilization mechanism?

The main malfunction in this mechanism is the breakage of the spring, or it happens that the mechanism is simply clogged with dirt; it happens that when a spring breaks, another non-original, stiffer one is installed, which leads to failure of the mechanism. It is also worth noting that this mechanism does not require lubrication.

How should the Bendix starter be maintained?

If, when starting the engine, strange sounds occur in the area of the starter and the engine crankshaft does not rotate, this may indicate a malfunction of the starter bendix, disassemble it, wash it in clean gasoline, lubricate the helical gear with refractory grease (without fanaticism), in most cases this helps restore performance Bendix.

Source

How to lubricate the starter

It is impossible to lubricate the starter from the outside, especially without removing it from the car. Therefore, this operation is performed only if it was decided to repair the unit, and not replace it as an assembly, as is done in most cases.

The process itself is very simple; during assembly, a thin layer of lubricant is applied to all rubbing parts; there is no need to stuff or inject anything.

These are the rotor and gearbox sliding bushings, planetary gears, the retractor relay armature and the splines along which the overrunning clutch moves.

The drive gear does not need to be lubricated. Additionally, to protect against corrosion and oxidation, a layer of technical petroleum jelly or universal grease is applied to the electrical contact connections.

Source

Can you push?

If, after pressing the starter button, you hear a short-term unusual grinding noise and the engine does not start, then, most likely, the problem is not in the starter - the battery has simply “died”. The symptoms of a starter malfunction are different: when you press the start button, a single metallic click is heard from the contacts of the starter relay, but this is not followed by engine noise. What to do?

Engage first gear and, with the clutch depressed, pushing the motorcycle back and forth, press the starter button. If the motor starts working, we can conclude: there is poor contact between the carbon current-collecting brushes and the commutator. Dust got between the rubbing parts (commutator brushes), causing sparking and forming a kind of dielectric. When the motorcycle was pushed back and forth, while sliding, the brushes found contact - and the starter started working.

This method of starting a motorcycle will help if the “disease” is at an early stage. However, a moment will inevitably come when the motor cannot be excited.

Which parts of the starter need to be lubricated?

Before moving directly to the choice of lubricant, it is necessary to decide which internal parts of the starter are to be lubricated. Let's list them:

As for the starter shaft, its rear part needs to be lubricated to facilitate the movement of the longitudinal clutch. Otherwise, there is a risk of a wedge between the clutch and the gear, which can lead to breakage of their teeth.

Also, some experts recommend lubricating the retractor relay and starter bushings. There are many different opinions on this matter. However, we are of the opinion that it is only necessary to lubricate the shaft, gearbox, and less often the overrunning clutch. You can read about the reasons below.

Not all starters have a gearbox; it depends on the design and model of the car. Its purpose is to reduce the mechanical forces on the starter, which reduces the current consumption. If the gearbox is not sufficiently lubricated, this will result in excessive load on the associated mechanisms and wear on the battery. Now let's move directly to the question of choosing a lubricant for a car starter.

Main breakdowns and methods for solving them

On scooters, the electric starter often fails. Of course, Kickstarter can help out, but it’s not very convenient to use. The engine may not start due to a faulty battery: the contacts have come loose, the charge has run out, the device is worn out. If there is no spinning sound when the starter turns on, then the problem is in the battery. If you can’t charge it, it means it’s out of order, worn out and you’ll have to install a new one.

If pressing “Start” does not produce a click in the electric starter relay, the problem is more serious. The unit may be faulty and needs to be replaced. The problem can arise when various components wear out. Most often they need to be replaced.

You can fix some scooter problems yourself

Electric starter does not work

If the scooter does not start from the foot, then its operation is impaired. If the electrical circuit is working properly, but the relay clicks when you press “Start,” then the problem is a bad contact or a broken starter.

To evaluate its performance, you need to apply voltage to it without activating the relay. If the electric starter does not turn, then it needs to be replaced.

Starter relay failure

The relay maintains the voltage at the required level for further distribution to headlights, dashboard indicators and other elements. Its durability depends on the battery. If the voltage in the generator increases or decreases, the relay is faulty. Because of this, the starter does not start. In this case, the relay needs to be replaced.

What lubricant to use for the starter

Before moving on to specific brands, it is necessary to determine what kinematic viscosity a particular lubricant has so that it is suitable for lubricating the starter and its components. According to current standards, the kinematic viscosity of the base oil used to produce starter lubricant must be below 100 cSt (cSt, 1 cT = 1 mm²/s). Such compositions are intended for operation in conditions of very low temperatures, high speed of interaction of rubbing metal or other pairs and low mechanical load.

There is no universal answer to the question of what kind of lubricant to lubricate the starter with. However, there are several common options that motorists use today. First of all, it depends on the air temperature at which you plan to operate the machine. In particular, to what minimum temperature does the temperature in your region drop in winter?

Among other cheaper means used, the following are popular:

When choosing a particular lubricant, you need to know its characteristics, first of all, the operating temperature range. After all, the composition must ensure normal operation of the mechanism both in severe frost and in heat. Next, we will analyze in more detail the characteristics of the listed compositions.

"Litol 24"

Graphite grease

Castrol LMX LI-KOMPLEXFETT 2

"Ciatim-201"

CV joint lubrication

Rules for operating a moped

The service life of a moped depends on maintenance. Care comes down to following the rules recommended by the manufacturer.

The main ones include:

- Testing a new scooter. The first concerns the running-in of a new scooter. The scooter must not be overloaded for the first 1000 km. When driving for a long time, you must stop every 30 minutes to prevent the engine from overheating.

- Correct use in winter. You need to drain the fuel before storing the scooter in the garage for the winter. Remaining fuel can destroy the tank and flood the carburetor. If you plan to use the scooter in winter, you need to change the fuel, check the battery charge, oil level, condition of the filters and tire pressure (it should be about 1.5 atmospheres).

- Correct use in summer. In hot weather, it is important to prevent the scooter from overheating. When driving for a long time at 30 degrees, the cylinders will be constantly overheated. This could cause the belt to break or the engine to break down. You should also not squeeze the throttle for too long, and when stopping, immediately turn off the engine.

- Use quality fuel. Gasoline must be at least 92. On a new moped, you need to change the oil for the first time after a run of 500 km. Subsequent replacement will be required every 1000 km. The first time to change the oil in the rear gearbox is after 200 km, then every 5000 km.

- Replacing the variator belt. This part is considered a consumable item, as it wears out quickly due to the high power load. If the moped stops squeezing out high speed, then the part and its components need to be replaced.

- Carburetor maintenance. The procedure includes a visual inspection for leaks and gasoline consumption levels, checking the condition of the connecting elements and the serviceability of the unit elements.

- Filtration quality control. The filter must be replaced promptly and impregnated with a special product after installation. This is necessary for high-quality air purification. Dirty air reduces the life of the motor.

How to lubricate the starter

Let's consider this process using the example of lubrication of a VAZ classic starter. To do this, you must first remove the unit from the car. To do this, use a 13 key. To perform lubrication, it is necessary to disassemble the starter, but not completely, as is done during repair or maintenance work. That is, it is necessary to provide access to the starter shaft (for other machines it is also necessary to get to the gearbox). The work takes place in the following sequence:

Checking and lubricating the starter on a VAZ 2114

Scooter kickstarter repair

Any scooter, be it Japanese or Chinese, has the ability to start from an electric starter or a kick starter. If the first one doesn’t work for you, which is a very common problem, kickstarter comes to the rescue. Let's look at the reasons for its breakdowns.

Probably 80 percent of scooter owners use kickstarter. Kick means foot, that is, you start the scooter using your foot, which you need to press on the foot located on the variator. And if you often start the scooter this way, the kickstarter may break. The reason may be either poor quality design (most often in Chinese models), or incorrect and rude attitude. Using my own example, I will say that having a Japanese scooter with a kick starter failure there were no problems, while a Chinese two-seater scooter received two kick starter failures in 1 year. If you simply compare the material of both scooters, then even by touch you can see that on Chinese scooters the variator cover or the kick starter itself has very cheap material.

The best starter lubricant

We will try to systematize the information and provide you with a table that provides information on which lubricant is best to use for the planetary starter gearbox, as well as its shaft. We are not trying to impose our vision, but only present the information that we managed to find .

Surely, based on the information provided, it will be easier for you to make your choice. After all, there are a lot of opinions on the use of certain lubricants on numerous forums. There are also differing opinions regarding the general advisability of lubricating individual starter components. Let's talk briefly about this below.

So does the starter need to be lubricated?

On numerous forums on the Internet, there are different opinions on whether certain parts of the starter need to be lubricated. It’s worth saying right away that the planetary gearbox . By doing this you will only contribute to its normal operation. For this purpose, it is better to use: from expensive lubricants LIQUI MOLY Thermoflex or RAVENOL Arctic Green Grease AGG2, from cheap ones - “Litol 24”, graphite lubricant, CV joint lubricants. Also, the choice should be based not only on price, but also on operating temperature.

As for the gearbox shaft , for this it is better to use the above-listed Molykote 3400A Leedfree, Molykote BR 2 Plus, graphite lubricant, Castrol LMX, “Ciatim 201”. The choice again depends on price and temperature conditions.

Starter solenoid relay lubrication

There is an opinion that it is necessary to lubricate the copper-graphite bushings on the armature axis. Actually this is not true ! Their normal sliding is facilitated by graphite, which is powder applied to their working surface. As you know, graphite is excellent for gliding. At the same time, dirt does not accumulate on it.

Regarding the question of how to lubricate the starter solenoid relay and its armature, there is a recommendation not to lubricate it at all . The fact is that the lubricant in this place collects various dirt on itself, forming a dense mud layer, which undoubtedly harms the normal operation of the Bendix. And if this same lubricant thickens in the cold, then this will be all the more harmful for the mentioned elements of the starter and threatens emergency operation until it completely fails.

What's the result?

Thus, the selection of lubricant for the starter largely depends on the operating conditions of the machine. In particular, it depends on the frost in which she drives. The main thing is that the lubricant is always of normal consistency. to do a preventive inspection of the starter every 40.50 thousand kilometers or every 2 years and lubricate its shaft and planetary gearbox. But lubricating the shaft where the bendix moves or the solenoid relay not only makes no sense, but is also harmful. Copper bushings are also included in the list of non-lubricated parts, but are only subject to wear control.

Source

Removing the rotor

Insert the bolts into the required holes. We take the bolts from the cooling impeller - they fit there perfectly. In order not to touch the windings, we screw restrictive nuts onto the bolts - they will not allow the bolts to go deep inside the generator.

We apply the puller to the rotor and screw the bolts into the holes. In order not to break the thread, slightly tighten the central bolt and see if all the bolts are tight. If any bolt is loose, tighten it.

This way we will evenly distribute the load between the bolts. If you neglect this moment, the entire load, unnoticed by you, can rest on only one bolt or two, and then they will break out of the rotor along with the thread. We don't need this, of course.

Now the main thing: what is there, you cannot tighten the central bolt by force. In this case, excessive force will not achieve anything. Everything must be done slowly and competently. Otherwise, you will tear the puller out of the rotor along with the roots, and then your budget will become completely financially insolvent.

You only need to remove the rotor this way: Lightly tighten the central bolt of the puller with a wrench, lightly hit the end of the central bolt with a small hammer - the rotor, usually, after the first blow, flies off the cone without talking, if it doesn’t fly off, pull the bolt again and hit again.

I learned this technique back in 1996, when I had the opportunity to remove the reel drive pulley of the Kolos combine harvester from the shaft. If it weren’t for one smart person who promptly told me how to work with a puller correctly, then I would have smashed both the pulley and the puller and the sledgehammer along with the combine...

The rotor sits on a key. If you do not plan to further disassemble the engine, leave it as is. And if you plan, you better get it, otherwise you’ll lose it.

A broken key can be easily removed with small pliers; if the key fits very tightly, leave it, it won’t get away from you.

So that you don’t have to guess later how your stator was positioned, we put marks with a core or take a photo, remember it, or do something else. This is necessary in order to protect yourself from problems with a lost outline.

How to clean the starter bendix

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Lubrication for the starter is necessary in order to reduce the internal mechanical losses that are present during its operation. If there is no lubrication on the shaft or gearbox, the starter will work under difficult conditions, which will lead to significant wear and even premature failure. Therefore, not only the fact of lubrication itself is important, but also what kind of lubricant is used in the car starter. Let's look at this question in more detail.

Repairing a kickstarter on a Chinese scooter using improvised means

It is shown how you can eliminate some kickstarter breakdowns using simple means. more info on the page - valeraprivalov.ru/problemyi-s-kikstarterom-na-skutere-super-sport-acar/

Comments

This is a ratchet from a Suzuki Lets

How did you drill the gear? I tried it manually but there was steel in there

At the end of the season, my kickstarter failed again. The teeth of the crescent were immediately a little scratched and in the end a couple of teeth broke off. then I solved the problem with starting the scooter this way - https://www.youtube.com/watch?v=USmTDyuNiWI

I already had it with a hole. I bought this scooter as a non-running scooter. Kickstarter didn't work. This gear was simply given away and there was no shaft on which it was put on. Perhaps it was pressed onto the shaft, but not much. And of course, drilling is a problem - you need to use a drill with a pobedit tip in a lathe. In order for the gear to spin smoothly on the shaft, everything must be accurate.

I have a problem with the leg, when I start the scooter everything is fine, but after I start it, it’s as if something is rubbing there and there’s a very loud and nasty grinding sound, and it wobbles just like in the video, if you press it to the variator, the noise disappears, but as soon as you let go it's starting, help me, I'm sorry, I'm already for it. I'm scratching my head about the fact that it could be a 4t 50cc engine

This is interesting: What needs to be changed when buying a used car?

Dude, exactly the same problem. Have you solved it? Also, I put my foot against the variator when I’m driving, the sound disappears.

It’s so difficult for me to say what the problem is with your scooter. you need to remove the cover and where it rubs should be visible. perhaps your version of ". It seems like a crescent moon is rubbing against the ratchet due to a bad washer or bushing. - is correct. Perhaps the crescent axle bushings need to be replaced or there may be some other reason. you have to look visually - after all, I only repair my scooter, but mine didn’t have such a problem.

It’s like a crescent moon is rubbing against the ratchet due to a bad washer or bushing, but I’m not sure whether this is due to this or not

Source

Which parts of the starter need to be lubricated?

Before moving directly to the choice of lubricant, it is necessary to decide which internal parts of the starter are to be lubricated. Let's list them:

As for the starter shaft, its rear part needs to be lubricated to facilitate the movement of the longitudinal clutch. Otherwise, there is a risk of a wedge between the clutch and the gear, which can lead to breakage of their teeth.

Also, some experts recommend lubricating the retractor relay and starter bushings. There are many different opinions on this matter. However, we are of the opinion that it is only necessary to lubricate the shaft, gearbox, and less often the overrunning clutch. You can read about the reasons below.

Not all starters have a gearbox; it depends on the design and model of the car. Its purpose is to reduce the mechanical forces on the starter, which reduces the current consumption. If the gearbox is not sufficiently lubricated, this will result in excessive load on the associated mechanisms and wear on the battery. Now let's move directly to the question of choosing a lubricant for a car starter.

Starter lubricant must have the following properties:

Factory puller

The rotor can be removed using either a factory puller or a homemade one. The option with a factory and homemade puller has its pros and cons. I'll start with the disadvantages of the factory puller.

The main disadvantage of a factory puller is its price. A factory puller is very, very expensive. About 500-600 rubles. But price is essentially not a very important criterion for me. Versatility, reliability, ease of use and durability are much more important to me. Unfortunately, the factory puller does not have all these advantages, except perhaps ease of use.

The versatility of the factory puller is zero and, unfortunately, it is only suitable for a certain series of engines. And if you need to repair a scooter that is not widely used in our country, then you will also have to buy a new puller for it. And this will be very, very difficult to do, since tools for rare models of scooters are as rare on sale as spare parts.

The reliability of the factory puller is extremely low. I won’t say that the problem is in the design itself, rather the opposite: the design is more than perfect. Where else could it be more perfect?.. Nut + bolt - that’s its entire design.

But the quality... There is something to discuss here. The quality of factory pullers leaves much to be desired. They are enough for literally several times, and I’m talking about expensive pullers for 500-600 rubles.

Cheap ones at 220-250 rubles in terms of quality are completely out of the question. Not only are they made of some kind of plasticine, but even this seems not enough for the manufacturer of this shit. He still manages to make them thinner or even thicker than necessary.

This is what the cheapest puller looks like, or rather, what’s left of it: a bolt from it is lost somewhere. It was used only once - the thread was immediately torn off, both on the puller itself and on the rotor, although before using this guan it was good there.

And even if you imagine the situation. that I will be able to buy a good branded puller, even if it costs 1,500 rubles, but it costs about that much. So where do I put the tusks (or rather, where can I get away from them???), who kill the threads under the puller and then, with an innocent look, roll their garbage dumps to me for repairs?

This is what a high-quality factory puller looks like. Their prices are real - from 500 rubles and above.

Cons are minuses, but the factory puller also has its advantages. One of which is ease of use. And it is really convenient and easy to use. What's inconvenient about that?.. Screw it into the rotor, tighten the bolt and the rotor itself jumps into your hand.

What lubricant to use for the starter

Before moving on to specific brands, it is necessary to determine what kinematic viscosity a particular lubricant has so that it is suitable for lubricating the starter and its components. According to current standards, the kinematic viscosity of the base oil used to produce starter lubricant must be below 100 cSt (cSt, 1 cT = 1 mm²/s). Such compositions are intended for operation in conditions of very low temperatures, high speed of interaction of rubbing metal or other pairs and low mechanical load.

There is no universal answer to the question of what kind of lubricant to lubricate the starter with. However, there are several common options that motorists use today. First of all, it depends on the air temperature at which you plan to operate the machine. In particular, to what minimum temperature does the temperature in your region drop in winter?

Among other cheaper means used, the following are popular:

When choosing a particular lubricant, you need to know its characteristics, first of all, the operating temperature range. After all, the composition must ensure normal operation of the mechanism both in severe frost and in heat. Next, we will analyze in more detail the characteristics of the listed compositions.

"Litol 24"

Graphite grease

Castrol LMX LI-KOMPLEXFETT 2

"Ciatim-201"

CV joint lubrication

Homemade puller

Unfortunately, homemade, just like factory-made, is not without its drawbacks. It is moderately reliable, versatile, and cheap, but it is not so convenient to use, and if you do not know how to use it, you can easily break the threads under the bolts of the cooling impeller.

Which puller you will use is up to you to decide. I have described all the pros and cons of both options for you.

For myself, I chose the option with a homemade puller. And the price has nothing to do with it. It's all about experience. Over the years of work, I tried a lot of things and eventually came to the conclusion that there is nothing better than a homemade tool puller.

I screwed a bolt from a regular car puller into the nut, attached the washer to the cooling impeller, marked points with a pencil through the holes for the bolts, marked and drilled the holes.

If you don’t want to make a puller, buy a factory one at the store or ask your friends. Just before purchasing, just in case, remove the cooling impeller and look at the condition of the thread.

How to lubricate the starter

Let's consider this process using the example of lubrication of a VAZ classic starter. To do this, you must first remove the unit from the car. To do this, use a 13 key. To perform lubrication, it is necessary to disassemble the starter, but not completely, as is done during repair or maintenance work. That is, it is necessary to provide access to the starter shaft (for other machines it is also necessary to get to the gearbox). The work takes place in the following sequence:

Checking and lubricating the starter on a VAZ 2114

Why does the kick starter break?

There may be several reasons for the breakdown, because they are the ones that most often happen to most scooter riders.

Kickstarter build . If you decide to change the kick starter or another part, be sure to do it correctly. You will need to assemble the spring, retaining rings and other elements according to the instructions. If you miss something, the kick starter leg simply will not return to the right place (see photo).

Worn teeth . Another common failure. If you press the kick starter foot sharply and often, the teeth connecting the foot and the variator will simply wear off, which threatens the same slippage of the foot. The result will be the inability to start the scooter, so keep an eye on the condition of the teeth.

Broken variator cover . Most often it happens with Chinese scooters, which I myself have witnessed more than once. If you press the leg with great force or sharply, the cheap and low-quality material of the variator cover will simply crack around the leg. Here, repairing a variator on a scooter is unlikely to help, as well as welding. The Chinese variator cover is difficult to weld, the weak material does not allow this, so the only option is to buy a variator cover.

We looked at several reasons why the kick starter breaks down; repairing this rather problematic element may take you a little time, but when you have a similar breakdown on the road, you will have to roll the scooter. There may also be three repair options. In the case of cracked teeth, the only possible solution is either replacement or welding. In the case of replacing a kick starter, you simply need to correctly assemble the entire structure, which will be discussed in another article. And if the variator cover is cracked, all you have to do is replace the cover itself. You can try to weld it, but I’ll tell you right away that there is little chance of fixing it this way.

The best starter lubricant

We will try to systematize the information and provide you with a table that provides information on which lubricant is best to use for the planetary starter gearbox, as well as its shaft. We are not trying to impose our vision, but only present the information that we managed to find .

Surely, based on the information provided, it will be easier for you to make your choice. After all, there are a lot of opinions on the use of certain lubricants on numerous forums. There are also differing opinions regarding the general advisability of lubricating individual starter components. Let's talk briefly about this below.

So does the starter need to be lubricated?

On numerous forums on the Internet, there are different opinions on whether certain parts of the starter need to be lubricated. It’s worth saying right away that the planetary gearbox . By doing this you will only contribute to its normal operation. For this purpose, it is better to use: from expensive lubricants LIQUI MOLY Thermoflex or RAVENOL Arctic Green Grease AGG2, from cheap ones - “Litol 24”, graphite lubricant, CV joint lubricants. Also, the choice should be based not only on price, but also on operating temperature.

As for the gearbox shaft , for this it is better to use the above-listed Molykote 3400A Leedfree, Molykote BR 2 Plus, graphite lubricant, Castrol LMX, “Ciatim 201”. The choice again depends on price and temperature conditions.

Starter solenoid relay lubrication

There is an opinion that it is necessary to lubricate the copper-graphite bushings on the armature axis. Actually this is not true ! Their normal sliding is facilitated by graphite, which is powder applied to their working surface. As you know, graphite is excellent for gliding. At the same time, dirt does not accumulate on it.

How to unscrew the nut?

To fix the rotor, I sometimes use a homemade puller similar to the factory one.

I made it from old unnecessary pieces of hardware, and it works no worse than the factory one. If you don't mind the money, you can buy yourself a factory one. It is inexpensive and easier to operate than a steamed turnip: insert the pins into special holes in the rotor, rest the lever on something and calmly unscrew the nut. By the way, such clamps are sold not only in spare parts stores, but also in power tool stores.

In power tool stores, traders position this device as a universal wrench for loosening nuts on angle grinders (angle grinders). It’s called: “universal wrench for angle grinders.” It costs only 160 rubles, and the original, supposedly “correct” one costs 350 rubles.

If you buy the same one for yourself, immediately cut its pins, otherwise they are very long in stock and can damage the generator windings during operation.

We examine the scooter from all sides to see if there is a generator on it, remove the casing and cooling impeller from it.

Unscrew the bolts and remove the impeller from the rotor.

Let me digress a little: do not lose the bolts that secure the impeller to the rotor, but it is best to immediately remove them. I had the opportunity to repair a scooter, the owner of which lost the original bolt and tightened another one in its place, but it turned out to be a little longer and broke the windings when starting the engine.

The bolt was only a few millimeters longer than the original one.

We fix the rotor and unscrew the nut. As I already said: in my work I sometimes use homemade tools, in this case a puller.

We unscrew the nut and remove it together with the washer from the rotor. If the puck is not there, then someone has already managed to dig around there before you...