For high-quality operation of any equipment, it is necessary to carefully monitor the condition of the parts, namely, perform adjustments and inspections in accordance with the regulations, check the reliability of each fastening, the operation of the engine and fuel system. Inspecting the snowmobile's variator is of particular importance in proper operation. The duration of the transport service depends on its operation. Stable operation is possible only with correct adjustment.

How to remove the belt part: first pull out the protection, separate the disks in the driven pulley. To replace the variator belt, you need to do the same.

The procedure for adjusting the Safari driven variator on the Buran snowmobile:

- Measure the distance between the inner ends of the plates at a distance of 3.5 mm from their border. You need to understand what set of washers to use in thickness. To do this, take measurements along the end of the plates. If the depth is 29 mm, but you need 33 mm, then choose a set of 3 mm washers.

- Unbend the locking plate and unscrew the bolt securing the fixed cone. Remove the 2 washers and screw the bolt back into place.

- Install the puller and remove the fixed cone

- Insert the adjustment washers into the center between the fixed cone and the half rings.

- Place a stationary cone.

- Tighten with a bolt and washer and make sure that the key is installed; it needs to be recessed by 2 mm. Wrap the locking one, locking it. Measure the distance between the cones so that it is within 31.5 mm.

Spread the cones and insert the snowmobile variator belt for replacement and adjustment, then tap with a block or hammer. The gap between the two elements should be 1 mm.

What is a variator on a snowmobile and what does it serve?

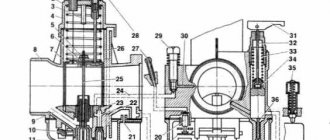

The snowmobile's variator is an automatic continuously variable V-belt type transmission. It contains driving and driven pulleys. The device regulates the gear ratio according to 2 parameters: engine speed and resistance. Regarding the combination of these parameters, a gear ratio is automatically set while the vehicle is moving. The drive pulley also operates the clutch - when the engine speed decreases below 2200 rpm, the engine shaft and the reverse device are disconnected.

The main purpose of the variator is to smoothly change the rotation speed of the gearbox shaft, which is the driven shaft. The second role is to protect the gearbox and crankshaft of the engine during uneven loads on the chassis.

Design features and configuration of the Safari variator

Reviews from real customers about the Safari variator. Characteristics, installation and adjustment instructions.

The “Safari” variator is used to ensure that speed adjustment occurs as smoothly as possible, both on motorized towing vehicles and on snowmobiles “Taiga” and “Buran”. “Safari” has a continuously variable automatic transmission and belongs to the category of parts with V-belt drives, so it can be installed on small-scale mechanization equipment and lifting vehicles. There are no significant differences between the designs for different models of domestic snowmobiles. Minor differences in the shape of the variator and the weight of the weights. Using the Safari variator, two parameters are adjusted: engine speed, resistance to movement of the snowmobile. The mechanism includes driving and driven pulleys. Please note: the driven pulley is not supplied with the main structure. If the engine reaches 2200 rpm, the pulley will act as a clutch. At the same time, it will separate the engine and the reverse shaft. How does the variator work? Before installing and adjusting the Safari variator, we strongly recommend that you read the operating instructions from the developer, which describe in detail the operating principle and proper use of the variator. One of the components of the mechanism is a centrifugal regulator, which includes a movable (rotates on axes) and a stationary cone with weights. To move the weights, a stop with rollers is used. The part also contains a spring and a cover. Using a thread, a fixed cone with a stop is attached to the shaft. The crankshaft is connected to a stationary cone. The idle speed is set using a spring. The variable speed belt, when installed correctly, should be 1-3 millimeters from the conical surface. Using this method, the idle speed is adjusted. The gap can be changed using rings. They are located between the shaft stop and the protrusion. What is the work of a variator? The manufacturer outlined all the characteristics of the Safari variator in the technical documentation. In it, the developer indicated the dimensions of the part: diameter 210 millimeters, length 167 millimeters, weight 3.8 kilograms. The variator works according to the established algorithm: the regulator rotates, as a result of which centrifugal forces arise that act on the weights. With the help of the influence of centrifugal force, the weights rotate, which helps to separate the movable cone from the stop. All these actions lead to compression of the variator belt in the pulley groove. The return spring counteracts the centrifugal force. Therefore, the weights overcome its impact without any problems. In this case, the number of revolutions must be at least 2200. The guides grab the belt when the threshold of 2200 rpm is passed, the force of the belt under the influence of these factors increases to the operating value, thereby creating torque. The resistance has been overcome. How to install the pulley correctly. Technical work on installing the Safari variator should be carried out referring to the operating instructions. For proper installation, we attach the pulley to the engine crankshaft, move the movable cone until a corresponding hole is formed into which the knob will fit, and tighten the structure. According to the data specified in the snowmobile operating instructions, install the belt and casing. If there is a need to remove the pulley, then to do this you need to: remove it from the crankshaft shank, remove the casing and belt from the variator, move the movable cone, use a spacer to lock the cone, fix the crankshaft on the motor (insert a metal rod under the tooth of the electric starting gear) . Using a wrench, remove the shaft. Adjust the belt. In order to correctly adjust the Safari variator, you should refer to the developer’s recommendations. This kind of action is necessary if you want to install a variator belt from RUBENA, DAYCO, GATES and other manufacturers. The fact is that belts of these brands may differ slightly from standard sizes. Standard belts have dimensions of 14x33x1120; there is no need to adjust belts of these sizes. Adjustment work is carried out after the pulley has been installed on the snowmobile. The distance between the driven pulley and the edges of the cones is measured; the distance should correspond to 33 (±0.5 mm) millimeters, if the belt has a value of 14x33x1118. When inserting the belt into the pulley groove, protrusion of the sides by more than 2 millimeters is not allowed. In this case the adjustment is correct. If the belt has a protrusion from the pulley guides that exceeds the standards established by the manufacturer, then it is necessary to make the adjustment as follows: using a removable key, unscrew the fastening bolt, remove the driven-fixed cone, remove the key from the shaft and install 1-2 metal rings. Reassemble the mechanism in reverse order. To install the Safari variator on the Buran snowmobile and adjust it, you must strictly follow the recommendations of the developers. The settings are made strictly in the area between the ends of the fixed cones of the pulleys. The distance between them recommended by the developer should be 55 mm (±0.5 mm). If it does not meet the manufacturer's standard, it must be properly adjusted in the slots in the base under the snowmobile engine. For these actions you will need to: move the engine in this area, turn on neutral, rotate the driven pulley 3-4 times (the belt should take place on the outer diameter during these actions), check the belt tension (press your hand on the center of the belt). The belt deflection under these conditions should be 32 mm (±5 mm) with a force of 11 kilograms per centimeter. When setting up the Safari variator on the Buran snowmobile, there are a few more subtleties that we will describe below. The belt is adjusted using 3 screws, which are included in the spare parts kit. The screws must be screwed into specially designated holes in the driven fixed disk. Make sure that the belt is properly tensioned at idle so that it does not jam. The CVT belt rests on the pulley shaft; there must be an appropriate gap between the cones and the belt. It can be adjusted by installing specially designed rings between the stop and the shaft. Tips for installing on a motorized towing vehicle. If you are planning to install the Safari variator on a motorized towing vehicle yourself, we recommend that you pay attention to the advice of snowmobile equipment experts. This will help you understand the entire process of adjusting and operating the mechanism. Belts with a Kevlar traction layer are not prone to slipping. Take advantage of this when making adjustments by reducing the preload. The drive belt in this situation will fit better onto a smaller pulley. At low engine speeds, the speed of the car will be high, which will help significantly save fuel consumption. The start of the motorized towing vehicle is more difficult - this means that the drive belt has worn out and it falls below the discs. It should be replaced with a new one. Maintenance of the Safari variator. Every component of a snowmobile requires periodic maintenance, including the CVT. The manufacturer recommends performing such procedures every three thousand kilometers. To do this you need to: lubricate the shaft (the shaft is installed under the split bushing). It is recommended to use Litol-24 universal lubricant. Periodic lubrication slows down the failure of the snowmobile's mechanical parts. After a run of 6 thousand kilometers, it is imperative to check the condition of the liners on the axles of the weights. How much wear has occurred can be determined by measuring the backlash; its permissible value is 1 millimeter. In the same way, we determine the size of the gap between the fixed cone liners and the guides. The gap should correspond to the figures of 1.5 millimeters. Warming up the engine must be done properly in a neutral position - this will prevent rubber from wrapping around the shaft. If you do find a rubber coating on the shaft, it should be removed using a cotton cloth soaked in gasoline. How to disassemble a variator. Have you decided to disassemble the Safari variator? To do this, you will need to perform several sequential actions: remove the regulator from the snowmobile. Fix the fixed cone, if possible, in a lathe or use another method available to you. Insert a block of wood or aluminum rod between the parts of the movable body. Unscrew the cone together with the stop and the cover. Remove the six bolts that secure the cover to the movable cone. After unscrewing 4 of the 6 bolts, hold the cover and unscrew the remaining 2 fixing bolts - this sequence will prevent the spring from “flying out”. When you reach the stop, remove only the liners. Rollers and axles should be wiped with gasoline and kerosene. After replacing the liners, reassemble the stop in the reverse order. Be careful and careful to prevent lubricant from getting on the surface of the disc cones. Reviews from snowmobile professionals. Both specialists and ordinary owners write reviews about the Safari variator on various Internet sites. Professionals talk about the excellent quality of the part, they advise when buying a variator to pay attention to the crosspiece and spring of the part; they should be reinforced, there should be no foreign particles on the casting and there should be no defects. It is strongly recommended not to start the engine with the protective casing and belt removed - this will prevent the pulley from turning away from the shaft. If you follow the tips and recommendations, the service life of the part will increase significantly and save your budget. Reviews from owners of the Safari variator. Customer reviews of the Safari variator indicate that the part is designed and manufactured to high quality. If you follow the maintenance recommendations, the variator operates without any technical problems. Its price is affordable to all owners of snowmobile equipment. "Safari" is recognized as the best CVT compared to its analogues. In this article, we talked about all the design features of Safari CVTs, and clearly outlined how to install them on a snowmobile or motorized dog, configure them, and carry out technical operation. We hope that your variator will serve for a long time without any defects.

Which disc is the leading one on the Taiga snowmobile variator?

The drive pulley is mounted on the snowmobile's crankshaft, and it moves with it at the same angular velocity. The driven one is connected to the gearbox input shaft and rotates at different speeds - minimum or maximum.

To fully understand which disk is the leading one on the variator of the Taiga snowmobile safari, study the operating characteristics of the driving disk determined by the following elements: spring stiffness, shape, weight of the levers. Changing the gear ratio is realized through compressing and unclenching the pulleys. The snowmobile's drive belt is driven to rotate around the changing dimensions of them all. Centrifugal force compresses the flanges of the variator drive pulley.

CVT malfunctions

Wear and defects of belts that occur during operation? this is the best indicator not only of malfunctions of variators for snowmobiles, but also of the gearbox, engine and chassis of the device.

If even the best belt wears more intensively on one side, this means that the surface of the corresponding pulley is either damaged or worn. The malfunction is eliminated by replacing the defective part. Thus, they also manifest themselves:

- unadjusted clutch;

- loose mounting of the drive pulley on the engine.

In this case, the defective part is replaced, the coupling needs to be adjusted, and the fastening must be tightened.

During operation, the belt can slip and at the same time wear out more quickly, but evenly, for three reasons:

? Does it have low tension between the pulleys? you need to tighten it, increasing the center distance between the pulleys. The tension is checked with a force of 10–12 kg on the upper part of the V-belt drive? the deflection should be about 30 mm.

? Does the V-belt transmission system get oil? You need to wipe the pulleys with gasoline and replace the seal on the bearing.

? Is the spring on the pulley weakened or broken? The defective part is replaced.

Stained wear on a belt can occur due to:

- driven pulley failure? the defective part is replaced;

- wedging of the caterpillar (a pebble may get stuck, a bearing may crumble, etc.)? the track is checked and the interference or malfunction is eliminated;

- increased engine speed at idle? you need to adjust the idle speed of the internal combustion engine.

Vibration of a snowmobile during its operation can also occur due to malfunctions in the variator:

- Has there been play in the drive pulley? the failed part is replaced;

- Is the belt installed with a wedge angle that does not correspond to the variator? the consumable part needs to be replaced urgently;

- Increased idle speed does not allow the gearbox to change gears? adjust the engine idle speed.

Misalignment of the variator pulleys and runout of the drive pulley can, when the variator is operating under load, tear material from the sides of the belt or even twist and fray it. What is the best way to troubleshoot this problem? This means replacing the drive pulley and carefully adjusting the variator.

Repair tips from experts

In addition to the variator with a belt, according to the regulations, it is necessary to check the condition of the track and its tension; its relaxation is characterized by dull noises when driving a snowmobile. To tension the belt, lift the rear of the vehicle and determine the gap between the rail and the track support. Normally it is 50 mm. Loosen the mounting bolts and locknuts on the guide rollers. The greater the sag, the tighter the fastening bolts are tightened. When the desired tension is achieved, secure the roller with locknuts. This process is for two rollers.

The situation with the wear of the guides along which the tracks move is similar to an engine overheating: the parts wear out if you move for a long time along the highway or ice. To solve the problem, you need to find snow cover to cool the staples and reduce friction.

The wear of the variator belt on a snowmobile can be calculated by certain signs: difficulty developing maximum speed, whistling, starting from a standstill at high speeds. If there is at least one sign, change the belt after a preliminary inspection.

Selection of belts for popular snowmobiles in Russia

The best belt for any popular snowmobile model is one that has the length, width and wedge angle that are calculated by the CVT designers and are specified in the operating instructions for the specific product. The vehicle owner should know these characteristics of such a consumable spare part as a belt when choosing it.

Naturally, the durability and reliable operation of the belt in a snowmobile's variator also depends on the rubber material from which it is made. In addition to original products, rubber tires from the Czech Rubena ArtiCa and from WORLD MOTORS are suitable for the Buran snowmobile, for example. For Yamaha snowmobiles, in addition to original products, rubber goods from well-known manufacturers Gates and Carlise are suitable. Yes, in fact, all belts for popular snowmobiles are produced with standard technical characteristics, which depend on the power of the vehicle and the center distance between the variator pulleys.

But rubber products made from the most wear-resistant and durable materials using polymer threads will not serve their intended life if the variator itself has defects and malfunctions.

Installation of forced piston

Don't know how to increase the engine power of a 50cc scooter? The fastest, easiest and most effective way would be to install a tuned CPG. Most motorcycle manufacturers produce original sports parts for their scooters.

A simple replacement of the piston system will be enough to instantly increase the power to 75-80 cubic meters. Naturally, such manipulation may require the intervention of experienced specialists. You can order inexpensive original tuning parts, get advice and replace parts at the licensed motorcycle store dvako.com.ua.

Partner news - June 30, 2021 356

We would be very grateful if you share this news on social networks

Installation and dismantling of the drive pulley

Installation of the pulley on the crankshaft shank of the motorized towing vehicle engine is carried out using a threaded connection. To do this, the movable cone must be moved so that the hole for the knob on the shaft becomes accessible and the variator can be installed using the knob. The tightening torque is 8-10 kgm.

There is a design option where the variator is secured using a key. To do this, the variator pulley with a keyway is put on the shaft shank with a counter groove along with the key. The pulley is tightened using a bolt.

To install the V-belt and transmission protective cover, please refer to the operating instructions for the motorized towing vehicle.

Removing a pulley from an engine crankshaft with metric threads is carried out in the following sequence:

- removing the variator protective casing;

- removing the V-belt;

- the movable cone moves to the side so that the mounting hole on the shaft becomes accessible;

- the cone is locked using a spacer against reverse movement;

- the crankshaft is prevented from turning;

- Using a crank, the shaft turns away.

For a variator with a keyway, the dismantling procedure is as follows:

- removing the variator protective casing;

- removing the V-belt;

- the variator pulley is prevented from turning;

- the fixing bolt is unscrewed;

- removing the pulley from the shaft.

Shifting gears on a manual transmission of an ATV

ATVs with manual transmissions have a foot lever on the left to change gears, like motorcycles, and a manual clutch lever on the handlebars on the left.

The foot lever device can be of two types:

- One lever. Gear shifting is carried out with the toe of the foot, pressing the lever from top to bottom (gears from 1 and higher) or from bottom to top - from a higher gear to a lower one.

- Two levers. Shifting gears is done with the heel and toe of the left foot. The rear lever shifts gears up, the front lever shifts down.

The switching itself is performed in the same way as on motorcycles:

- We start the ATV (with neutral or park gear always engaged).

- Fully depress the clutch.

- We press the gear shift lever with our foot, selecting first speed.

- Lightly press the gas trigger and at the same time smoothly release the clutch lever. When learning to drive any type of vehicle with a manual transmission (passenger car, motorcycle, truck), this point is the most difficult, and it can only be developed with practice, grasping the balance in working with the clutch and gas. If you have experience driving any vehicle with a manual transmission, you will quickly get used to it on an ATV with such a gearbox.

- Having completely released the clutch, we move only with the help of the gas, increasing or decreasing it (and, if necessary, braking with the foot or hand brake).

- Having picked up speed, we squeeze the clutch again and engage the next gear with our foot.

- Press the gas trigger and smoothly release the clutch.

- Repeat steps 6-7 to further increase gears.

- If the gear needs to be lowered, we proceed in the same order: depress the clutch and press the gearshift lever with your foot to reduce the gear.

When exactly to switch speeds up and down is determined by the tachometer, driving speed, road complexity, the weight of the load taken and the characteristics of the ATV itself (power, weight).

Adjusting the Mikuni carburetor on a Buran

The fuel mixture will become richer. In the case when the engine stalls and stops at the moment of sharp closing of the throttle, it is necessary to unscrew screw 4 by the same number of revolutions. The fuel mixture will become lean. If the carburetor is properly adjusted, screw 4 is unscrewed no more than two turns from the fully screwed position.

The Mikuni carburetor for Buran is an excellent technical solution for a snowmobile. Its installation and operation greatly simplifies the owner’s winter chores. Adjusting the mechanism is simple. It’s better to set it up correctly once, so you don’t have to look at it all winter. Owners give only laudatory reviews about this carburetor.

It is clear from the article that the type of carburetor described is reliable, durable, and unpretentious. The mechanism is simple, without technical frills, so all reviews about it are only positive. Wide unification, stable operation in any frost. The author recommends installing Mikuni carburetors on snowmobiles, motorcycles, and all light vehicles without a doubt. This technique will not let you down.

Driving a car with a CVT at low temperatures

Warming up the variator is mandatory at low temperatures. Cold oil in the transmission is poorly distributed within the system; some elements and parts remain without lubrication.

Warming up like an automatic transmission by switching the “PRND” modes and back is not recommended, since this does not improve warming up (the variator is designed completely differently than other gearboxes). Alternatively, you can turn on the neutral “N” for a few seconds, this will slightly warm up the fluid coupling (clutch).

You need to move away after making sure that the car has warmed up to the required limit. After starting to drive, maintain a calm driving style for at least a kilometer, this will completely warm up all the elements of the box. The costs of excess fuel will save the cost of installing a new gearbox.

The lower the ambient temperature, the longer it takes to warm up the box. At temperatures of -35 °C it is better not to operate a car with CVT. If you still decide to travel in severe frost, then it is recommended to warm up for at least 30 minutes and adhere to a very gentle driving regime the whole way.

In Europe (Finland) they found an alternative to idling the engine for warming up. Cars are equipped with an electrical system for maintaining operating temperature. The machine is powered from the mains via a regular plug. Cars with such equipment are easily recognized by the characteristic cutouts on the bumper.

Jerks

A similar effect can be observed when you slip a wheel and suddenly it hits a hard surface. That is, rotating at high speed on ice, for example, it stops abruptly when it reaches the asphalt. There is a shock in the transmission. Or when towing another vehicle. You take off, the cable tightens, and you suddenly stop. The blow comes again.

In both cases, the belt may slip along the pulley. One such slip will be enough to scratch the pulley. After this, increased wear and rapid “death” of the gearbox occurs.

Unlike climbing a curb, the electronics do not protect the CVT in such situations. It simply does not have time to “strangle” the engine in order to reduce the torque on the pulley and protect the variator.

If there is an urgent need to pull someone out with a cable or drive yourself out of a snow mess, there are small tricks that will help save your continuously variable transmission.

When towing with a cable:

- Smoothly select the length of the cable so that it becomes taut.

- When it reaches its maximum length, release the gas pedal. The inertia of your car will be enough to pull someone out of the mud or carefully take off from a standstill without damaging the CVT.

If your wheels slip on ice:

No need to press the gas pedal to the floor. To make the wheels spin on ice and the car to get out of the slippery surface, just press the gas halfway. When the wheel reaches the asphalt, the box will not feel a strong impact.

Types of gearboxes for ATVs and a list of gears in them

Gearboxes for ATVs can be of two types:

- Mechanical. The gearboxes of motorcycles are similar. They are installed mainly on racing models, but in recent years they have begun to be found on utilitarian ATVs. They have a foot clutch or a clutch with a lever on the steering wheel (in most cases this is exactly what it is), and a foot-operated gear shift lever. A manual transmission usually has 4 forward gears, neutral and reverse.

- CVT. They have high and low (L and H) forward gears, neutral, reverse and a parking brake. Some ATVs (the cheapest and least powerful ones) may only have one forward gear. There is no need to press the clutch to shift.

Rarely and mainly in older models, but other variations can be found. For example, an “automatic” with the ability to manually change gears.

ATVs with manual transmission are a little more difficult to drive (at least at first, until the habit develops), but you can more accurately select the appropriate mode. And vice versa: CVT “boxes” are much easier to use, they are easy to master for a beginner who gets behind the wheel of an ATV for the first time. But when actively driving along a route with variable difficulty, driving a CVT will be a little less convenient.

For example: you are driving on a flat, compacted dirt road on H, and you see a large section of muddy road ahead with deep mud (or a steep incline, or bumps, or rocks). You will have to come to a complete stop and switch to L, drive through the mud, and when you get back onto a dry road, you will have to completely stop again and switch back to H.

Pedal to the floor

This is the weakest aspect of the continuously variable transmission. The more often you drive “sneaker to floor”, the faster the variator will fall apart. With a quiet ride, in the “pensioner” style, it can last many hundreds of thousands of kilometers.

The main thing for yourself is to learn one rule: “If you feel that the car is hard right now, do not press the pedal all the way” - this will greatly extend the life of the variator.

Automakers are aware of the problem and are trying to combat it. Some models have additional gears for low gears.

In some cases, where there is no such “planetary”, when driving onto a curb from a standstill, the computer “strangles” the engine, preventing it from developing maximum torque. In this case, you will not be able to drive onto the curb if you drive up close to it and stop. No matter how you turn the engine, the electronics will not allow the car to move in order to protect the variator from damage.

How to change gears on an ATV

Any wheeled vehicle - from a bicycle to a multi-ton truck - has a transmission in its design: a system that transmits rotation from the engine to the wheels. The operation of the transmission - and therefore the driving speed - can be controlled by changing gears.

In each type of transport, gear shifting is organized differently. In the article below we will tell you exactly how to change gears on ATVs, and what gearboxes are found on such equipment.

Adjusting snowmobile snowstorm

Snowmobiles "Buran" are equipped with several types of carburetors. One of the most popular fuel devices is the Mikuni carburetor for Buran. This is an economical, trouble-free mechanism. Thanks to its simple design and ease of maintenance, it has won a lot of fans all over the world. All owner reviews about this type of carburetor are invariably positive.

Operation of technical equipment in winter requires a special approach to the quality of main components and mechanisms. The fuel mixture is prepared at constant sub-zero temperatures. Therefore, in the Buran snowmobile, the manufacturer practices installing a Mikuni carburetor on the Buran snowmobile.

The design of the Mikuni carburetor on Buran

The good thing about this carburetor is that it is attached directly to the engine pipe with two M6 bolts. There is no need to adjust the gaps; the fastening is rigid, classic, through two rectangular gaskets made of petrol-resistant rubber. The cross-section of the gasket material is 1 mm; the gaskets are glued to rectangular pipes in special grooves for fastening to the engine.

Two cables are stretched from the control handles of the Buran snowmobile. One cable controls the fuel supply, it is called gas, the second cable controls the enricher - the air damper. Both cables are equipped with bosses that are easily inserted into working fastening and control units.

⇓ First position - the flag is lowered down. The fuel channel is closed in this position.

Summarize

What does the owner of a car with a CVT need to know so as not to quickly “kill” it and extend its life by many thousands of kilometers. Let us recall simple operating rules:

- We don't skid on ice or mud. If you need to slip, we dose the torque with the gas pedal.

- We try to avoid towing trailers and other vehicles. If an urgent need arises, then we use the cable correctly and do not allow the machine to stop abruptly when tensioning the cable.

- The CVT gearbox does not like full throttle driving. Steady driving will extend the life of your CVT.

- We monitor the cleanliness of the cooling system of the continuously variable transmission. She doesn't like overheating and falls off quickly.

- We change the oil in the box strictly according to the regulations and compliance with the technology of the unit manufacturer.

I ask you to supplement this article with advice on how to increase the service life or how to properly use CVTs on cars. Perhaps I missed something, I will be grateful for your additions in the comments.

Safari CVT Maintenance

- Every 3000 km, lubricate the shaft under the split bushing. For lubrication, use CIATIM-201 or Litol-24.

- Every 6000 km, check the condition of the bushings on the weight axles and the condition of the liners 8.

- The wear of the weight bushings can be assessed by the amount of radial play of the weights (see Fig. 2). The permissible play is no more than 1 mm. The wear of the liners can be assessed by the size of the gap between the liners and the guide ribs of the moving cone. The permissible gap is no more than 1.5 mm.

Warning ! To prevent rubber from enveloping the shaft, warm up the engine only in neutral. If rubber deposits appear on the regulator shaft, remove this deposit with a rag soaked in gasoline.

Driven pulley

Remove the CVT housing and CVT belt from the snowmobile.

Unscrew bolt 15, remove lock washer 14, bushing 13, then remove the driven pulley from the variator shaft.

To disassemble the variator driven pulley, use a spring compression tool (variator driven pulley half-clutch puller).

Align the pin with the keyway

Remove the spring retaining ring 12 to remove the coupling half 11, spring 10 and movable disk 6 of the pulley.

WARNING

The driven pulley coupling half is spring loaded, use the tool shown above

Check for cracks, scratches and free movement when reassembling the stationary disc.

Using a bore gauge, measure the diameter of bushings 7 and 9.

The measuring point must be at least 5 mm from the edge of the sleeve.

If the wear on bushing 7 is more than specified, it is necessary to replace the movable disk with bushings; if on bushing 9, replace the bushing.

Wear limit of the driven pulley bushing, mm

Check the liners for wear. Replace when the side edge is 3.5mm or less.

Here measure the thickness of the base

Surface adjacent to the disk

When replacing liners, always install a new set (3 pieces) to maintain equal pressure on the coupling half 11.

Reassemble the pulley parts in reverse order of disassembly.

15 Pulley fixing screw

Tightening from 21.57 to 27.45 N m (2.157...2.745 kgf m).

ADJUSTMENT

See section 05-05 for pulley adjustment.

Adjust the height of the variator belt in the driven pulley to obtain the specified belt tension section 05-02.

WARNING

Always check the adjustments of the variator belt and pulley if the variator parts have been removed, replaced or disassembled

Typically, no precise recommendations are given for adjusting the preload of a new spring during break-in. The factory preset spring preload is slightly increased to compensate for the spring preload setting. After break-in (300 km of operation), set the spring load in accordance with the technical data of section 10-02.

Spring preload

To check the spring preload adjustment, use a steelyard and spring scale bracket.

Remove the variator belt. Install the bracket onto the movable disk. Secure the fixed disk 2 from turning, pull the movable disk with a steelyard (spring scales) perpendicular to the pulley axis.

Take the first torque measurement when the movable disk begins to turn. Turn the movable disk 10 mm along the outer diameter. Keep the steelyard in this position. Slowly release the force from the steelyard and take a second measurement of the unwinding force when the movable disk begins to return. Spring preload is the arithmetic average between these two measurements.

The role of the flag in the carburetor

If you put the flag up, the engine begins to receive a significantly larger amount of fuel. At this moment, the snowmobile operates at increased crankshaft speeds. The use of a flag greatly facilitates the operation of the entire mechanism in the cold season: autumn, winter, early spring, frost and cold.

After starting a cold engine, you should thoroughly warm up the mechanism that has cooled in the cold overnight. The raised flag allows you to do this much faster than the standard mode. The snowmobile will run for a while on suction, quickly warm up and you can hit the road.

E-CVT box

This is a type of continuously variable transmission for hybrid vehicles. A logical question will arise: “Do the rules for driving a CVT apply to e-CVT boxes?” - No, they don’t.

This is a completely different gearbox, although only one letter in the name has been changed. This unit is designed for hybrid cars and has nothing in common with a simple CVT. This gearbox is considered by many to be “unkillable”; its reliability is an order of magnitude higher than that of a classic automatic transmission, not to mention CVT transmissions. But we will talk about this in detail in a separate article.

Design and principle of operation

The fundamental elements are two pulleys and, accordingly, a belt. The cut belt has a trapezoidal shape. The name of the belt (V-belt) comes from the principle of its operation. The transition of the belt to the maximum radius is similar to a wedge. As the pulleys wear out, the radius becomes smaller and the scooter loses speed.

The main condition for stable operation of the variator is its tightness on the pulleys and the absence of slippage. Experienced users of this type of technology claim that 100% absence of slippage cannot be avoided. But it is necessary to minimize it as much as possible. In case of severe slippage, the operation of the entire transmission is at risk. Breakdowns and replacement of parts cannot be avoided. In addition, efficiency is significantly reduced. A striking example of slippage is the drop in engine speed at the very start (the engine seems to be running, but the movement of the equipment is not significant).

Also, straight belt slippage depends on the pulley spring. If it has lost its rigidity, it must be replaced. In addition, unstable, deteriorated performance may be due to wear of the belt itself.

High-quality famous belts from 6000 km.

How else can you determine the correct operation of the variator? – when starting to move, the engine speed is the same until the start of acceleration. At maximum throttle, the engine speed should approximately correspond to the engine power. “People’s” craftsmen sometimes do some “alterations” so that the dynamic qualities of the scooter increase. Also, to speed up the scooter, there is an option to completely replace the variator. For example, you can buy a sports variator for a 50 or 150 cc scooter.