Fans and simply owners of Ural motorcycles own not just a means of transportation, but a thing that shaped an entire generation of bikers. Alas, age makes itself felt and it manifests itself in unpleasant little things. This can be considered the absence of a starter. The problem is not critical, but it causes some inconvenience. Craftsmen who began to adapt a starter from a car to their bike helped solve the issue. Today we will tell you how to install a starter on a Ural motorcycle with your own hands.

Why do you need a starter?

Some models of modern motorcycles are equipped with starters due to the lack of a crank. Here, the presence of a starter is assumed initially. However, in other cases it serves only for the convenience of the rider. There is no need to practice every time before a trip, especially if the valves or ignition are not adjusted.

The Ural, due to its archaic nature, did not even imply the installation of a starter. At the time of the release of the first motorcycles, the starter was a luxury that a Soviet citizen could not afford, and then the design was preserved because of its reliability.

Installing an electric starter on a Ural motorcycle will save you from an overinflated right leg and sudden injuries to the kneecap, so the procedure can be considered as simplifying the life of the rider.

Selection of parts

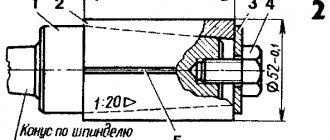

The best option is electric starters from the Kherson plant, which are used in tractor starting engines, as well as in small-class boat engines. However, you need to be very careful in choosing components - components marked ST353, 367 or 369 are suitable for the Ural. You should not purchase the ST366 starter, which was installed on the Zaporozhets - it has a reverse direction and a different shape of the Bendix casing, incompatible with a motorcycle engine . For such an electric starter, you should purchase a crown from the Buran snowmobile - it requires only minimal modification. Be careful - you need a unit with a top-mounted retractor relay, since, being located at the bottom, it will interfere with changing the oil in the engine.

Selecting the ring gear and starter

First of all, we pay attention to the flywheel of the motor, it is the key for further work. Its rotation, when viewed from the gearbox, occurs counterclockwise, which means you need to select a starter that rotates in the opposite direction (clockwise). Here are the models that suit us:

- ST 353;

- ST 367;

- ST 369;

- From VAZ 2110 (21011);

It is also possible to install a starter in the Urals from a number of models suitable for imported cars. The problem with such starters is their high cost, which also applies to modern VAZ car models. Here, choose for yourself what is your priority - the cost of the part or the service life.

Pay attention to the presence of the casing and its orientation. The method of fastening the part and further ease of maintenance will depend on this parameter. Rotating the starter relative to its own axis is not advisable and can lead to its breakdown.

Now you need to pick up the crown. The crown is a gear lining on the flywheel that transmits the rotation of the starter to the engine through a gear transmission. The problem is that purchasing the part is quite problematic. A spare part from the Buran snowmobile, as well as more modern domestic motorcycles “Voyage”, “Cobra”, “Wolf” can be suitable for the size of the flywheel. The size of the teeth of the first ring is 2.5, and the modulus of the last three is 2.2. This parameter must be related to the starter module.

If the modules do not match, there are several options to solve the problem:

- We change the starter ring/gear to one that matches the module.

- We adjust the teeth of the existing starter ring or gear to the module.

- We make the starter ring or drive gear from scratch.

Photo gallery

Photo 1. Parts for the device

Photo 2. Intermediate disk of the crown

Photo 3. Installation of the device structure

Price issue

Speaking of price, we can say that modifying this vehicle is quite expensive. Installing the device will cost from 300 to 500 rubles. A new type of crown can be purchased for 2,000 to 3,000 rubles, and an intermediate disk for the crown can be purchased for 1,000 rubles.

Loading …

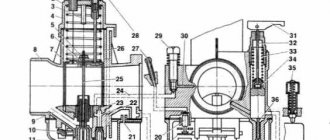

Starter fastener

First of all, we determine the place of attachment of the element. The most popular is the upper left side above the flywheel. In this case, we will only be faced with the need to cut out a window for engaging the starter gears. It is difficult to install the starter in the center or on the right side, due to the need to redo a number of engine elements.

For installation, a hole is cut out under the Bendix casing. Next, measurements are taken, and the starter mount is cut out of a 4mm thick sheet of steel. This thickness is necessary to withstand the loads that the fasteners experience during operation of the starter mechanism. In a similar way, you can make not one solid, but a pair of fasteners. This way you can simplify the process of making fasteners, but adjusting the gaps will become much more difficult.

Advice. For greater solidity of the structure, it is best to secure the starter tail rigidly to the motor or grab it with a clamp.

The finished plate is secured with bolts or pinched with argon, then a trial assembly is carried out. Now you need to make sure that the gaps are set:

- the gap between the flywheel gear and the roller clutch is 2-4 mm;

- between the bendix and the crown is 3-7 mm.

Next, the flywheel is rotated, observing the coincidence of the pitch of the bendix and the ring. In this case, rotation of the flywheel is ensured using a kickstarter. Once you are sure that everything is working as expected, you can perform a test turn by unscrewing the spark plugs. If the starter rotates the flywheel without any extraneous sounds, then the plate can be permanently welded with argon.

Important! Welding of the gearbox housing is possible only after dismantling all rubber parts, installing the primary and secondary shafts and securing the cover with 4 bolts.

Effortless: installing an electric starter on a motorcycle

Equipping a motorcycle with a starter in most cases is determined by the owner’s desire for convenience and practicality, less often - by urgent need. In some cases, for example, when the technical feature of the unit does not allow it to be equipped with a crank, installing this module is the only way out. A starter is an electromechanical device designed to start an internal combustion engine. The device is a powerful mixed-excitation electric motor powered by direct current provided by the on-board battery.

Battery and alternator problems

After installing the starter on a Ural motorcycle with your own hands is completed, a couple of unresolved problems remain. First of all, a car starter requires a more powerful battery. The way out of the situation is to install an inexpensive battery on a new mount (from the side of the motorcycle. Everything will look quite rough, but it’s inexpensive.

Another way is to select an imported battery of a similar size with an increased capacity of 18 A/h. You will have to overpay quite a bit, but the appearance of the motorcycle will not suffer.

Finally, it turns out that the original generator is rather weak and is unable to charge a new battery. We’ll answer right away that rewinding will help increase productivity, but it will not be enough for our purposes. What should we do then? There are several options:

- generator from IMZ. There is a cheap model 14.3771, which fits perfectly, even without modifications to our motorcycle. Its biggest drawback is its terrible build quality. The generator often fails. The solution is modern models of the DENSO brand, which are equipped with these motorcycles.

- imported car generator. The problem here is its installation. If you choose to extend the shaft and install it through a faceplate, please note that all work must be performed with high precision. Also, such generators can be installed using a belt drive. The method has a lot of advantages, especially its unpretentiousness. All you need to do is monitor the condition of the belt and check the cavity of the generator cover for dirt every 10–15 thousand.

The disadvantages of such a modification are decreased engine power and increased shaft load. On the other hand, power can be increased in other ways, but engine load cannot be avoided.

Selection options

An electric starter in the Urals is installed after all the technical characteristics of the vehicle have been determined. Often, car enthusiasts take advantage of the opportunity, if available, and introduce models from a donor car - the VAZ 2109 and its modifications.

You can use a product from other foreign-made machines, but it will cost a little more. When choosing a part, you should also take a closer look at the crown of the device. If the diameter and pitch of the teeth do not meet the requirements, then you need to disassemble the structure of the device and remove the axial shaft with gears. Its teeth are worn down. The diameter expands from the inside so that it can be pressed onto the front side of the ground part. Then they are welded to each other.

Handy tools and tuning of the Dnieper for sports

Tuning the Dnieper for sports primarily involves installing a plastic cladding. In the absence of special cladding panels and panels, the cladding can be made from a foam plastic model. Cheap and abundant material allows you to worry-free experiment with the design of the unit until the best option is found.

After cutting out the model, the foam is coated with a layer of liquid that prevents the fiberglass from sticking to it. The latter is cut to size, soaked in epoxy resin and applied in 4-5 layers to the foam. During the first two layers, it is recommended to add metal shavings to the resin, and, if possible, place a thin metal mesh between the fiber and the foam to strengthen the frame.

To completely dry the structure, you need to wait about a day, after which the foam can be removed. The resulting cladding is puttied, sanded, primed and painted. Painting in most cases is done in bright shades of blue, green, yellow, and red. Airbrushing is not uncommon, and it is performed entirely depending on the owner’s imagination.

Just as in the case of a chopper, tuning for sport involves changing the frame design, only in this case without lengthening or significantly tilting the front fork. A high “rocket” rear fender is installed, and the recessed seat is made to slope towards the high gas tank. The handlebars are shortened to an extremely comfortable length, and the exhaust pipe rises at an angle equal to the rear fender.

Bright, stylish, but still Dnepr

Looking at this motorcycle, different emotions immediately appear in me. On the one hand, the author of the project had a hand and spent a lot of time creating this “horse”, but on the other hand, I don’t see much point in them. It is unlikely that this homemade seat will be more comfortable than the standard one.

Exhaust

- the highlight of the whole design. As for me, the “cans” are too massive for the pipes that go directly to the cylinders. I think if they were made thicker in cross-section, this modification would look somewhat more impressive.

The colors here are extremely bright and dull

, but this is

a matter of taste

. And, according to the classics of the genre, we are witnessing the abandonment of the steering wheel and the fact that the author of the project gave preference to clip-ons, completely cutting down the ability to move around on this motorcycle.

Typical faults

Obviously, malfunctions occur on the most loaded elements of the starting device - the drive and the electrical component. For example, problems often occur in the starter armature:

- it rotates at low speed because it becomes dirty, or the contacts in the brush assembly (also the solenoid relay) burn out - in this case, the current strength should be less than normal;

- if the current strength is higher than normal, then the armature can rotate slowly due to breakdown of the winding and various mechanical damage - rotor misalignment, drying out of lubricant, wear;

- the armature does not spin at all, and the current strength is less than the standard value - there is a break in the circuit, it is also possible that the wiring of the solenoid relay is broken;

- if the rotor does not rotate, but the amperage is normal, there is a breakdown to ground.

Other common types of problems encountered with the 4320 starter include:

- the brush assembly is triggered, so the electric motor rotates, but the motor does not start;

- contacts oxidize or the flexible mass is damaged, which leads to the starter clicking without rotation;

- the bendix teeth grind off, which is why the starter is unable to grasp the flywheel, although it works;

- The solenoid relay deteriorates, so the starter continues to rotate even after starting the internal combustion engine - short circuits, burnt contacts and other troubles are also possible.

Before removing the electric motor, it is recommended to carefully check the operation of the battery, the condition of its terminals, as well as the amount and condition of the oil in the engine. You should know that powerful diesel engine starters have one feature - often problems arise one after another, like an avalanche. For example, excessive load on the device leads to overheating of the winding and then short-circuiting the insulation. At the same time, the bushings begin to wear out rapidly, the rotor shaft breaks, the drive and even the flywheel crown are damaged. If the operation of the power circuit is disrupted, this leads to the starter losing its power, and an excessively high current literally burns out the brush assembly and armature commutator due to breakdown.

Brutal design

In this model, the author decided to give a brutal look to the old bike, using mainly Soviet-made parts. He decided to emphasize the metallic essence of the motorcycle. To do this, he used several alloys: iron, aluminum, chromium.

The engine, rear wheel and steering wheel remained from the Dnepr 11. The fork, tank and front wheel were taken from IZH. Tractor Belarus was happy to provide a headlight and fitting for the bike.

In addition, the master himself built a fiberglass saddle. The taillight and oil pressure gauge came from the Zil-164 motorcycle.

Every detail has been repaired, painted or adjusted. As a result, the bike came out so powerful that it could compete with Harley himself.

Stages of turning a Dnepr motorcycle into a custom one

Perhaps this is said loudly about turning the Dnepr motorcycle into a custom one. Because more often such alterations fall under the definition of tuning. What is the difference between custom and tuning?

Tuning is the alteration of individual spare parts or components of a motorcycle. A custom motorcycle is a bike that has been completely modified to suit the owner's wishes. Moreover, it becomes unique and inimitable.

Stages of turning a Dnepr motorcycle into a custom one:

- engine replacement or upgrade

- front fork upgrade

- chassis modification

- exhaust replacement

- adding decorative elements

The engine is additionally cleaned and polished. This is done on purpose so that it does not differ from new parts. Various rings or a direct flow system are installed on the exhaust. You can also add a decorative nozzle.

All these manipulations are easy to do yourself, since they do not require special technical knowledge. Other spare parts can be purchased in specialized stores. For example, valve covers and engine ignition covers can be purchased in our online store.

Finishing

When the starter position is set, it must be removed in order to finally weld the flange to the gearbox housing. You can do this yourself, but you will need equipment for argon welding. Make sure all the parts are in place and start working. Remember that after welding the metal must cool on its own, since its forced cooling will lead to a significant decrease in the strength of the joint.

After the metal has cooled, assemble the starter on the flange and make sure that its gear does not move away from the ring even under fairly strong loads on the assembly body. Now you can connect the electric starter to the battery - during operation it should create a monotonous sound, and also rotate the gear without blocking or braking. In addition, it is worth checking how easily it engages and disengages with the crown. Unfortunately, installing an electric starter may interfere with the operation of the engine start pedal. Since it is not advisable to completely remove it, it is better to simply change the shape of the part, while maintaining a backup method of starting the motor.

DIY tuning

The starter installation procedure described above requires fairly good skill and special equipment. Therefore, if you do not have an argon welding machine or a lathe, you should find out in advance where you can use the services of professionals of the appropriate profile. All manufactured fastening parts and gears must have minimum tolerances, since the reliability of the installed electric starter depends on this. The starter itself must be in good technical condition - to make sure of this, it is worth checking the bushings and shaft. If all these conditions are met, the electric starter will serve you for many years, providing maximum convenience for starting your motorcycle engine.

A little history

The progenitor of the “Soviet Harley” appeared in the late 20s of the twentieth century. At first it was a model designed by Mozharov on the basis of IZH and PMZ, but with a heavy frame and a 1200 cc engine that consumed a lot of fuel, it had a power of only 24 HP and lost control at speeds above 60 km/h.

Therefore, it was decided to adopt European experience and use the advantages of the BMW R-71. Naturally, the German was not repeated completely, but only borrowed some ideas, adapting them to the realities of the USSR. In particular, they installed a double-disc clutch, increased the gear ratio and tank volume, increasing cross-country ability.

Electric starter

Well, I finally started writing this post. I’ve long wanted to install an electric starter on my Bolivar, but either I’m not up to it, I don’t want to disassemble the engine, and during the rebuild I want to quickly assemble it and drive it. However, after an unsuccessful trip to Rostov, on the birthday of the Olen bike house, when I turned the crankshaft in Yaroslavl with all the consequences, I decided to finally give myself an electric start during this capital campaign. Despite the fact that the Internet is full of articles on this topic, they are all quite vague, plus I have not seen a single video where a “live” 650cc Ural was started with an electric starter. No, the video is complete, but they show some intermediate stages, like: “here I attached the starter, here I connect the wires to the Akum and it seems like something is turning, but the engine is still half disassembled.” Somehow I got distracted, closer to the topic.

In order to install an electric starter, you need to buy a ring gear for the flywheel. Someone is remaking a crown from Buran (in my opinion), but I took a ready-made one, which is installed instead of the last clutch disc.

Ring gear

Together with the ring gear, a bracket for mounting the starter on the box was purchased. There are two such brackets, on top of the box and on the side. But, since I have a Ural gearbox, and the starter from the side looks, in my opinion, much more aesthetically pleasing, my choice fell on the side mount.

Additional work

Since the standard electrical system of the Ural motorcycle, as well as the circuit of most imported vehicles, is not designed to operate equipment with a starter, modifications will have to be made to it. At the slightest drop in ambient temperature, starting problems may arise - the starter will quickly discharge the battery, which will force you to recharge it and subsequently use the pedal. Experienced motorcyclists recommend installing a battery from a Japanese car from the 90s on a two-wheeled vehicle. This battery has compact dimensions and a fairly large capacity - up to 65 Ah.

However, installing a large battery will entail another problem - the generator will not be able to charge such a battery completely, and the starter will again be unable to be used. To resolve this issue, you can use the following technical solutions:

- Rewind a standard generator to increase its power by 100-200 watts. However, you need to understand that the reliability of such a node will decrease;

- Installation of a starter is often accompanied by replacing the standard generator with a unit from a light tractor or from a modern model from the Irbit plant;

- To replace the generator with a similar unit from an imported small car from the 90s - parts from Honda and Daihatsu are ideal.

Modifying the electrical network after installing the starter requires a certain amount of professionalism, since if the wires are connected incorrectly or if the insulation is insufficiently wound, you can simply burn the motorcycle.

Since the generator always loses some of its power over time, the starter may stop working again. To avoid such a problem, it is worth cleaning the brushes of the unit every 10 thousand kilometers, adjusting the clearance of its drive mechanism, and also eliminating minor faults. Also, every 5 thousand kilometers, inspect the wiring - if melted areas or breakdowns begin to appear on it, it is worth installing cables with a larger cross-section.

Inappropriate installation option

What carburetors are suitable and what is better to install? We will have to disappoint those who plan to use available models from Oka or Zhiguli during the conversion. All car modifications are out of play in this case. There are several reasons:

- The vacuum in the intake tract of a motorcycle differs from the parameters typical for car engines. Because of this, correct adjustment of the carburetor on a motorcycle becomes almost impossible.

- The selection is carried out not simply by working volume, but by the number of aspirations per unit of time. Aspiration can be roughly calculated by multiplying the engine displacement by the maximum speed.

- Car models pose a danger if the motorcycle falls because fuel can splash out and ignite.

Automobile carburetors are not suitable for conversion!

So the idea of using parts from Oka or other automotive equipment will have to be abandoned.