Design and operation of the transfer case Ural 4320 and 5557

Today we will talk about the transfer case of the Ural 5557 and 4320, and also discuss their design.

The transfer case is a unit that is responsible for distributing torque from the engine to certain drive mechanisms, and they most often increase the number of gears in the transmission.

The Ural transfer case distributes torque between the axles and increases the torque of the drive wheels, which guarantees stability while the Ural vehicle is moving. The Ural transfer case significantly affects the cost of the fuel mixture and the traction and speed parameters of the vehicle. Because of this, the cost of transporting various cargo directly depends on the correct choice of parameters owned by the transfer case itself.

Ural 5557

In this article you can easily find answers to the most common questions:

- Transfer case of the Ural 5557, 4320 and its device;

- Functioning of the part as a transfer case of the Ural 5557, 4320;

- Common malfunctions of the transfer case of the Ural 4320, 5557;

- Adjusting the transfer case of the Ural 5557 and 4320.

Device

The basis of the car is a load-bearing riveted frame made of high-strength steel and characterized by increased rigidity. The design provides short rear and front overhangs, thereby increasing cross-country ability. The platform for transporting people and cargo is made of metal. It has lift-up side seats and an opening tailgate. The body assumes the possibility of installing an awning, arches and mounting sides on both sides. Some modifications received a wooden platform. The sides of the Ural 4320 are lattice or solid. The design provides for a front location of the unit. To access the engine, the hood opens upward. On the sides there are wide, flat fenders that protect the cabin from foreign objects and dirt while driving.

The truck has a 6 by 6 wheel arrangement. The model is equipped with single wheels with automatic adjustment of the air filling of the chambers on 3 drive axles. Recommended tires: 14.00-20 OI-25.

Basic information about the transfer case of the Ural 5557 and 4320

The Ural 4230 and 5557 vehicles use a two-stage transfer case equipped with an asymmetrical cylindrical center locking differential with a power drive. The transfer case is mounted on the car frame using four rubber pads. The design of the transfer case of the Ural 5557 and 4320 is absolutely the same as that of the KamAZ 4310.

In the middle of the crankcase the following are located on bearings:

- Intermediate roller with gears of the lowest high gear;

- Rear drive shaft with middle axle. An asymmetrical cylindrical center differential is installed on these rollers;

- Front axle drive shaft;

- The primary roller has high and low gears, and a clutch is installed between them to change gears.

In order to maintain atmospheric pressure in the crankcase cavity, a fitting with a tube is installed on the bearing cover, connecting the crankcase to the atmosphere through a sealing system. The outlet tip of the tube is brought to a level above the maximum fordability to prevent water from being sucked into the crankcase while overcoming water obstacles.

The crankcase is made of cast iron, there is a hatch on top, the crankcase itself is one-piece, closed with a lid with an oil guide tray. Oil is poured into the crankcase through the top hatch with the cover removed or through the hole under the control plug, which is located on the rear wall of the crankcase. The oil is drained through the bottom hole, which is closed with a plug with a magnet. The crankcase is ventilated using a fitting, and its tube is included in the general sealing system of the units.

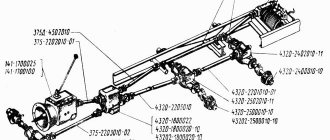

Transfer case Ural 4320

How does the transfer case Ural 4320 and 5557 function?

In the Ural 4320 and 5557, the torque supplied to the drive wheels can change. That is, the transfer case is considered at the same time an additional gearbox, which increases the number of gears and the limits of change in the gear ratio in the transmission. Thanks to the inclusion of a low gear in the gearbox and transfer case Ural 4320, 5557, it is possible to overcome high resistance to movement and stable movement of the machine at low speed.

The Ural 4320 and 5557 boxes with a rigid connection between the drive rollers of the drive axles have a ratio of torques that are supplied to the main gears of the drive axles, depending on certain parameters of the machine design and driving conditions. With the drive locked and driving straight on roads with good grip but little resistance and differences in wheel radii, certain drive wheels may slip and slide. This leads to faster wear of tires, transmission units and additional loads.

In order to eliminate these undesirable phenomena, a differential drive is used in this part. In this case, the torque is distributed between the drive rollers of the drive axles using a differential, which allows these rollers to rotate at angular speeds different from each other. Thanks to the properties of the installed differential, torque is distributed between the drive axles. That is, thanks to the transfer case differential, costs are reduced while driving on the road. Although the use of a drive differential while driving on slippery roads that have little grip can lead to a decrease or loss of vehicle maneuverability. To increase cross-country ability, vehicles are equipped with a device that blocks the differential.

Common malfunctions of the transfer case Ural 4320, 5557

Ural 4320 and 5557 boxes may have the following problems:

- Difficulty shifting gears of the transfer case differential unit. Most often, this problem occurs when burrs form on the couplings and pliers, the clamps jam, and the sliders bend. To eliminate this problem, it is necessary to clean the tongs and parts of the clamp, as well as put the sliders in order, straightening or replacing them.

- Loud noise. This problem can arise due to damaged gears and displacement of the rollers among the axial directions. In this case, it is necessary to check the adjustment of the bearings in the first and intermediate rollers, and also adjust the oil level.

- Oil leaks through the seals. This problem can occur due to wear of the seals during the formation of cracks. To solve this problem, it is necessary to replace damaged parts and clean the tube, which is responsible for sealing.

- The transmission and differential unit disengage on their own. Most often, this problem occurs due to damage to the switch forks and coupling connections, as well as due to movement of the rollers. To correct this problem, you need to replace worn parts and adjust the roller bearings.

We hope that our article gave you all the answers to your questions and now you have gained basic, basic knowledge on this topic. Good luck on the road and follow the traffic rules!

Source

Modifications of Ural 4320:

- Ural 4320 – chassis with a basic metal cabin with a load capacity of 7000-9000 kg;

- Ural 4320-19 – long-wheelbase chassis with a lifting capacity of 12,000 kg;

- Ural 43203 – chassis with reinforced front suspension;

- Ural 43204 – chassis with increased load capacity;

- Ural 44202 – truck tractor;

- Ural 43206 - chassis with a 4 by 4 wheel arrangement.

For cars, the Ural 4320 remains the base model. This truck is highly practical and designed specifically for the needs of the army. Its main area of application is the armed forces. However, the machine is also used in the public utilities, forestry, construction, mining and commercial sectors. Here it is in demand as an all-terrain vehicle used for transporting people and equipment.

Troubleshooting, as well as regulation of transfer case, drive Ural-4320, 5557

- high noise The box is capable of producing noise effects in the event of increasing damage to the gears and when the shafts are displaced among the axial directions. This may be due to worn bearings or the fact that there is not enough oil in the gearbox housing. If increased noise is observed, you should check whether the bearings in the first and intermediate shafts are adjusted correctly, and also adjust the oil level.

switching the gear of the transfer case differential unit is difficult. Basically, a similar problem is encountered when burrs form on the couplings and tongs, jamming of the clamps is observed, and the sliders bend. To eliminate the malfunction, you should clean the tongs, parts of the clamp and put the sliders in order by straightening them or replacing them.

The differential block and transmission turn off without permission. Basically, such problems arise due to damage to the connections of the couplings and switch forks, and this may also be due to the fact that the shafts have moved. To cope with the problem that has arisen, it is necessary to change parts that have worn out, and it is also worth adjusting the shaft bearings.

oil flows through the oil seals. This problem arises due to wear of the oil seals and cracks in them. To solve this problem, it is worth replacing the damaged parts and blowing (cleaning) the tube responsible for sealing.

Stages of adjusting the intermediate shaft of the Ural transfer case

- The first step is to remove the rear cover from the intermediate shaft.

- Next, you should loosen and tighten the nut that secures the shaft bearing, and tighten the gear sleeve tightly enough.

- After this, you need to lock the nut and install the cover.

- You should check how the axial movement of the shafts proceeds; similarly, the indicator leg is also installed; in total, the indicator leg should move from 0.03 to 0.08 millimeters.

- If the bearing size is larger than the specified values, excess gasket material should be removed from under the bearing cover at the front.

- To eliminate erroneous measurements, you should check the process of moving the shafts, and carry out the procedure two or three times.

Stages of adjusting the transfer case differential lock clutch

- The position of the clutch should be checked and, if necessary, adjusted.

- To adjust the position of the clutch, it is worth locking the differential by turning the rod.

- When checking the position of the coupling, you should install the rod, fixing it in the forward position by the flange, turning the shaft related to the front axle drive.

- The correct position of the coupling is when it touches the splined end. If this is not the case, you should move it forward while rotating the rod clockwise.

- To adjust the position of the seventh clutch, it is worth adjusting the selection of the thickness of the gaskets. The coupling is secured normally when the difference between the splines on both sides of the carriage is no more than one millimeter.

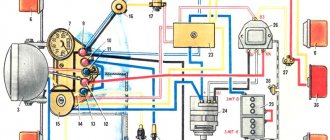

The process of adjusting the transfer case drive, its control

To adjust the gearbox control drive, it is worth changing the length of the rods five and six forks. It is correct if the rod is in the middle position and corresponds to the neutral position of the clutch, while the location of the second lever should correspond to the middle of the slot in the floor in the cabin. If the top gear is turned off and the differential is unlocked, lever one and lever two (Fig. 1) should be in the same plane. After making adjustments, you should check how easily the gears shift, tighten the pins and tighten the fork locknuts.

Rice. 1 Control of the transfer case of the Ural vehicle

1-differential lock lever; 2-gear shift lever; 3-pressure spring; 4-roller levers; 5.6-thrust; 7.8-leashes; 9-bracket; 10-rod gear shift fork; 11-adjusting gaskets; 12-rod differential lock fork transfer case; I-differential unlocked; II-differential locked; A - forward position of the lever (high gear engaged); B - middle position of the lever (neutral); C-rear position of the lever (low gear engaged)

Source

Spare parts for Ural, Kraz, MAZ, Kamaz trucks. Engine parts YaMZ-236, YaMZ-238

__________________________________________________________________________

__________________________________________________________________________

Transfer case of the car Ural-4320, Ural-5557

___________________________________________________________________________

On the Ural-4320, 5557, torque from the gearbox is transmitted to the transfer case, which serves to distribute torque between the front drive axle and the two drive axles of the rear bogie of the vehicle. In the transfer case (transfer case) of the Ural-4320, 5557, the torque supplied to the drive wheels can be changed, i.e. the transfer case is at the same time an additional gearbox, increasing the number of gears and the limits for changing the gear ratio in the transmission. The inclusion of a low (first) gear in the gearbox and in the transfer case of the Ural-4320, 5557 makes it possible for the vehicle to overcome high driving resistance (climbing up to 58% or difficult ground conditions) and ensure stable movement of the vehicle at low speeds (2-5 km/h). For transfer cases Ural-4320, 5557 with a rigid connection between the drive shafts of the drive axles (locked drive), the ratio between the torques supplied to the main gears of the drive axles depends on some design parameters of the vehicle and driving conditions. When the drive is locked and driving in a straight line on roads with good traction but low resistance, due to differences in wheel radii, some drive wheels may slip or slip. This leads to additional losses during movement, additional wear of tires, loads and wear of transmission units. To eliminate these undesirable phenomena, the Ural-4320, 5557 transfer case uses a differential drive. In this case, the torque between the drive shafts of the drive axles is distributed by a differential, allowing these shafts to rotate at different angular speeds. The distribution of torque between the drive axles is determined by the properties of the installed differential. Thus, the use of a differential in the transfer case Ural-4320, 5557 allows to reduce losses when driving on roads. However, the use of a differential drive on slippery roads and wet soils with low traction can lead to a decrease and loss of vehicle patency. To increase cross-country ability, cars are equipped with a differential locking device. The transfer case (transfer case) Ural-4320, 5557 (Fig. 16) is mechanical, two-stage, with an asymmetrical center differential, mounted on the vehicle frame on four rubber pads.

Fig. 16. Transfer case for cars Ural-4320, 5557 1,22,36-flanges; 2,10,16,25,32,39 - bearing caps; 3.18 tapered roller bearings; 4.38-high gears; 5-bushing; 6-top hatch cover; 7-gear clutch; 8.20-low gears; 9-transfer case; 11-primary shaft; 12,13 speedometer drive gears (drive and driven); 14-shaft flexible speedometer drive; 15-breather; 17-intermediate shaft; 19-spacer sleeve; 21 rear axle drive shaft; 23-oil drain ring; 24.40 bearing nuts; 26-rear differential bearing housing; 27-rear differential cage; 28-differential cage with lower shaft gear; 29-ring gear; 30-sun gear; 31-differential locking clutch; 33-bolt; 34-flange reflector; 35-shaft front axle drive; 37-satellite Differential transfer case Ural-4320, 5557 planetary type with four satellites, 30 sun and 29 crown gears. The moment from the sun gear 30 is transmitted to the front axle drive shaft 35, and from the ring gear 29 to the rear axle drive shaft 21. When the differential transfer case Ural-4320, 5557 is working (unlocked), uniform traction of all axles is ensured and additional loads in the transmission are eliminated. Depending on the road conditions, the differential of the transfer case Ural-4320, 5557 can be turned off (locked), and then the drive shafts of the front and rear axles rotate as one unit. The drive shafts of the front and rear axles have oil scavenge rings 23. On the outer surfaces of the oil scavenger rings, helical grooves are cut that direct oil when the shafts rotate from the cuffs into the crankcase. The spiral of the helical groove is made in different directions: for the front axle drive shaft - left direction, for the rear axle drive shaft - right. In accordance with their purpose, the letters “P” (front) and “Z” (rear) are stamped on the oil sump rings. When assembling the transfer case Ural-4320, 5557, make sure that the oil rings are installed correctly, otherwise oil leakage through the cuffs is inevitable. Transfer cases for cars Ural-43202-0351-31, Ural-4320-0911-30, truck tractors Ural-4420-10, Ural-4420-31, Ural-44202-0311-31, Ural-44202-0612-30 differ from transfer case for Ural-4320-10, Ural-4320-31 cars with speedometer drive gears. The Ural-4320 transfer case, on which a reinforced auxiliary power take-off box is installed, has an extended input shaft and a modified crankcase in the auxiliary take-off mounting area. The parameters of the speedometer drive gears depend on the gear ratio of the main drive of the drive axle and the size of the tires installed on the vehicle. Adjusting the transfer case (transfer case) Ural-4320, 5557 and the control drive Tapered bearings are adjusted by changing the number of gaskets under the covers when the transfer case is removed from the vehicle. Before adjusting the bearings, install the Ural-4320, 5557 transfer case so that the top hatch is in a horizontal position, and remove the cover from it. The axial movement of the primary and intermediate shafts should be 0.03-0.08 mm; control the axial movement of the shafts with a dial indicator. To adjust the bearings of the primary shaft of the Ural-4320, 5557 transfer case: - check the tightness of the flange mounting nut and, if necessary (tightening torque less than 200 N.m (20 kg/cm)), tighten it; — install the indicator stand on the plane of the crankcase hatch so that its leg rests against the end of the spline in the middle part of the input shaft; - using the mounting blade as a lever, move the input shaft through the gear until the indicator needle comes to a complete stop, smoothly reduce the amount of axial force applied at a lever length of 0.5 m to 2-5 N (0.2-0.5 kgf) and record the reading indicator; — applying axial force in the opposite direction, similarly record the second indicator reading. The total movement of the indicator leg should be 0.03-0.08 mm; for larger values, remove the shims from under the front bearing cap. To adjust the intermediate shaft bearings of the Ural-4320, 5557 transfer case: - remove the rear cover of the intermediate shaft bearings; — loosen and tighten the intermediate shaft bearing fastening nut, tightly clamping the gear spacer; — lock the nut and install the cover; — check the axial movement of the intermediate shaft in the same way as the input shaft, while placing the indicator leg against the end of one of the gears; the total movement of the indicator leg should be 0.03-0.08 mm; — adjust the bearings by removing the shims from under the rear cover of the intermediate shaft. To eliminate errors when measuring, check the axial movement of the shafts before and after adjustment two or three times, first turning the shafts. Check and, if necessary, adjust the position of the differential lock clutch of the transfer case Ural-4320, 5557 and the gearshift clutch. Adjust the position of the differential lock clutch 31 (see Fig. 16) by rotating the rod. When checking the position of the clutch, set the rod to the front fixed position and turn the front axle drive shaft by the flange. If the clutch does not touch the splined end of the front differential cage of the Ural-4320, 5557 transfer case, it is installed correctly. If the clutch touches the race, move it forward by rotating the rod clockwise. Adjust the position of gearshift clutch 7 by selecting the thickness of the shim pack 11 (Fig. 17).

Rice. 17. Control of the transfer case of the Ural-4320, 5557 1-differential lock lever; 2-gear shift lever; 3-pressure spring; 4-roller levers; 5.6-thrust; 7.8-leashes; 9-bracket; 10-rod gear shift fork; 11-adjusting gaskets; 12-rod differential lock fork transfer case; I-differential unlocked; II-differential locked; A - forward position of the lever (high gear engaged); B - middle position of the lever (neutral); C-rear position of the lever (low gear engaged) The clutch position is considered normal if, with a fixed neutral position of the gear shift fork rod, the difference in the free length of the spline of the middle part of the input shaft on both sides of the carriage does not exceed 1 mm. Adjust the transfer case control drive Ural-4320, 5557 by changing the length of rods 5 and 6 with adjusting forks so that with the middle position of the rod corresponding to the neutral position of the gearshift clutch, lever 2 is in the middle of the slot in the cabin floor. With top gear engaged and the differential unlocked, levers 1 and 2 should be in the same plane. After adjustment, check the ease of gear shifting, tighten the pins and tighten the fork locknuts. Possible malfunctions of the transfer case Ural-4320, 5557 and control drives Increased noise in the transfer case Ural-4320, 5557 can be explained by increased wear of the gears and increased displacement of the shafts in the axial direction, which is usually associated with wear of the bearings or a lack of oil in the transfer case housing. If there is increased noise, you need to check the adjustment of the bearings of the primary and intermediate shafts, check the level and, if necessary, add oil to the crankcase. Difficulty shifting gears and differential locks of the Ural-4320 transfer case is usually associated with the formation of burrs on the splines of gears and shift clutches, jamming of the clamps or bent sliders. To eliminate the malfunction, it is necessary to clean the splines, clean the retainer parts and straighten or replace the sliders. Self-disengagement of gears and differential locks of the transfer case Ural-4320, 5557 is a consequence of wear in the connection of clutches and shift forks, wear of the splines of the clutches and shafts, as well as increased axial movement of the shafts. To eliminate the malfunction, it is necessary to replace worn parts and adjust the shaft bearings. If oil leaks through the seals, they must be replaced; if there is wear and cracks on the working surfaces, it is advisable to clean (blow out) the tube of the crankcase sealing system. Maintenance of the transfer case Ural-4320, 5557 Maintenance of the transfer case includes: - checking and tightening the crankcase fastenings and its covers - adjusting and lubrication of control drives - maintaining the required oil level in the crankcase - periodic oil changes Oil is poured through the hatch in the upper part of the crankcase to the level control hole located on the rear wall of the transfer case housing Ural-4320, 5557, having previously removed the cover. Oil can also be added through the control hole. The oil is drained through a hole in the lower part of the crankcase. There is a magnetic plug installed in the drain hole, which is recommended to be thoroughly washed in kerosene when changing the oil. The transfer case housing is filled with 3.5 liters of MT-1bp oil (automotive transmission oil).

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

- Cardan shafts and power take-off Ural-4320

- Transmission gearbox Ural-4320

- Bridges Ural-4320

- Transfer case Ural-4320

- Steering Ural-4320

- Truck cranes and cranes based on trucks

_________________________________________________________________________

_________________________________________________________________________

- Cylinder block and cylinder head YaMZ-236 HE2, YaMZ-236 BE2

- Checking and adjusting YaMZ-236

- Power system and lubrication system YaMZ-236

- Driven and driven clutch discs YaMZ-236, 238

- Cooling and lubrication systems YaMZ-238

- Fuel injection pump YaMZ-238

_________________________________________________________________________

- Kamaz diesel engine

- Repair and adjustment of Kamaz power steering

- Kamaz-152 gearbox with divider

- Gearbox parts for Kamaz-5320 gearbox

- Kamaz transfer case and driveshafts

- Kamaz gearbox repair

- Clutch KamAZ-5320

- Construction of Kamaz-4310 drive axles

- Power steering MAZ-5551, 5549, 5335, 5336, 5337

- Front axle and steering rods MAZ-5551, 5549, 5335, 5336, 5337

- Clutch adjustment MAZ-5551, 5549, 5335, 5336, 5337

- Adjustment and repair of gearboxes MAZ-5551, 5549, 5335, 5336, 5337

- Repair and maintenance of the rear axle MAZ-5551, 5549, 5335, 5336, 5337

- Front axle parts and steering rods MAZ-5516, 5440

- Steering Maz-5516, 5440

- Details of driving axles Maz-5516, 5440

- Clutch device ZIL-130

- Repair of ZIL-130 gearbox

- Repair of rear axle ZIL-130

- Basic parts of the ZIL-130 engine

- Transfer case and power take-off ZIL-131

- Drive axles ZIL-131

- Steering ZIL-131

- Maintenance of ZIL-645 engine parts

Control mechanism and devices URAL-4320-10, URAL-4320-31

The Ural 4320 is a popular truck that is excellent for use on rough terrain and in forestry. This is facilitated by high ground clearance and a powerful engine. This machine is equipped with YaMZ diesel engines. Power can exceed 300 horsepower. The gear shift scheme is competently designed by the manufacturer of this equipment. Approximately 30 liters of fuel are consumed per 100 km. If this indicator has increased, it is necessary to carry out premature diagnostics of the automotive system.

The winch for the Ural-4320 is necessary for self-pulling vehicles or pulling out other vehicles. Maintenance of the winch consists of directly checking and tightening all fasteners.

Model history and purpose

Production of models of the Ural 4320 line began in November 1977. The release of the series in a noticeably modernized form continues at the present time. The predecessor of the car was the Ural 375D, which debuted back in 1961. With this model, the Ural 4320 was unified in many elements. Initially, the car was equipped with a gasoline unit with high fuel consumption (about 40-48 liters per 100 km), which was considered its main drawback. Diesel versions of the truck (with a KamAZ engine) appeared only in 1978. Moreover, their number in the first years of production was limited. However, the plant gradually switched to the mass installation of Kama diesel engines in the Ural 4320. This was the main difference between the first generation of the model and the Ural 375D.

The basis of the design of the Ural 4320 was a supporting frame, providing high strength. Single-ply tires, all-wheel drive and short overhangs ensured good cross-country ability of the vehicle.

In 1986, the truck was updated. At the same time, the appearance of the model has been preserved almost unchanged. The motor range has not undergone any significant changes. The main unit remained the KamAZ-740 engine. It was used until 1993. However, after a fire at the manufacturing plant, supplies of the power plant ceased. Instead, the Ural 4320 began to be equipped with engines from the Yaroslavl Motor Plant (YaMZ-238 and YaMZ-236). Initially, modifications with the YaMZ-238 were distinguished by a long engine compartment; versions with the YaMZ-236 retained the same shape. However, since the mid-2000s, all variations of the Ural 4320 have received an extended engine compartment.

In the mid-1990s, the truck underwent a restyling. The car began to be equipped with a wide bumper with headlights, and plastic plugs were installed on the wings in the previous place where the headlights were attached. For the needs of the Ministry of Defense, cars with a narrow bumper were still produced. In 1996, production of a lightweight version of the Ural 43206 with two axles began.

The next update occurred in 2009. The car has noticeably changed, receiving a modernized cabin with a fiberglass tail at the front. The shapes of the Ural 4320 have become more streamlined. The classic radiator grille with vertical lines on some versions was replaced by a grille with horizontal lines. On some modifications, they began to install the Iveco “P” cabover type from the UralAZ-IVECO joint venture. It was distinguished by an original rounded integral hood. The previous units were replaced with modern diesel engines YaMZ-536 and YaMZ-6565, which comply with the Euro-4 standard.

In 2014, the Ural 4320 series was transformed into the Ural-M series, maintaining most of the characteristics. In the fall of 2015, another modernization took place. Its result was the appearance of the Ural Next series, which was distinguished by a modern GAZelle Next-type cab with a new plastic tail of the engine compartment and improved components.

Transmission system components

Ural vehicles are valued for their high power characteristics, excellent load capacity, and driving dynamics. The performance indicators of this vehicle are largely influenced by the installed gearbox. This device affects power gain.

The Ural-4320 is equipped with a five-speed gearbox. It has a long service life and can withstand the loads placed on it well. The Ural gearbox housing is attached to the clutch housing. The manual transmission on the Ural car has fixed shaft axles. The upper crankcase cover is equipped with a gear shift mechanism.

Gearbox diagram

The transmission system includes lockable cross-wheel and center differentials. On the truck there is a dependent power take-off box or KZOM.

It should be noted that there is a transfer case on the Ural 4320. It is 2-stage and affects the fuel consumption for each kilometer traveled. This box is securely fixed to the frame with several special rubber pads.

Power take-off box

The Ural transfer box is an additional gearbox. It ensures stable movement of the machine at low speed. The installed Ural power take-off is single-stage. It is necessary to drive auxiliary units.

Gearbox Power Line Gear Shift Mechanism

Specifications

Engine

The latest versions of the Ural 4320 are equipped with several variants of V-shaped diesel engines produced by the Yaroslavl Motor Plant. The most widely used models are:

- YaM3-236NE2 : displacement – 11.15 l, rated power – 230 hp, maximum torque – 882 Nm, number of cylinders – 6;

- YaM3-236BE : working volume – 11.15 l, rated power – 250 hp, maximum torque – 1078 Nm; number of cylinders – 6;

- YaM3-238 : displacement – 14.86 l, rated power – 240 hp, maximum torque – 882 Nm; number of cylinders – 8;

These units were liquid cooled. The power supply system is a mechanical in-line injection pump.

The YaMZ-7601 unit (rated power – 300 hp) is installed upon request.

Transmission

The wheel formula is 6x6. 4320 has high cross-country ability, which can be achieved using single-pitch wheels with automated adjustment of air filling of the chambers on all wheels. The suspension installed in front is dependent and rests on semi-elliptical springs with double-acting shock absorbers. There are also dependent ones at the rear and they are located on springs with reaction rods. The Ural-4320 has all axles (there are only 3) driven. The wheels that are in front and which are also controlled by the steering wheel have CV joints. The YaMZ-182 clutch has a friction drive, where the pneumatic amplifier is located, and has one disk with a diaphragm pull-type spring.

With a 2-speed manual transfer case, front-wheel drive is always on. The manual transmission of the Yaroslavl Motor Plant contains 5 gears with a locked center differential, and is perfectly synchronized. So, it allows you to get 10 gears for forward movement and a couple of speeds for reverse. The transfer case contains a center locking differential, which distributes torque between the drive front axle and a pair of drive axles at the rear in a ratio of 1 to 2.

These gearboxes are controlled mechanically. Cardan transmission – 4 cardan shafts. The main gear of the drive axles is double, containing a pair of bevel gears and a pair of cylindrical gears. The robust bumper at the front and rear has been fitted with strong towing devices in the form of hooks and a tow bar on the frame, enhancing the truck's technical capabilities.

Brake system

It includes two systems: a 2-circuit working vehicle and a spare single-circuit vehicle. In addition, there is an auxiliary function of brakes with pneumatic drive from the exhaust system. The braking system is mechanical and has a brake drum on the transfer case. The parking brake design is of a drum type, installed on the output shaft of the transfer case.

Scheme

Gearbox diagram

Electrical diagram

Diagram of hydropneumatic clutch drive

Brake system diagram

Operating principle and troubleshooting of the Ural gearbox

The Ural gearbox is a device in the vehicle system that is responsible for transmitting power.

How does the checkpoint work?

The KPP-141 device, installed on some Ural models, includes the following elements:

- Coupling mechanism. It helps temporarily separate the engine and transmission. This allows you to change gears without reducing the speed of the power unit.

- Driven gears and shafts. The drive, intermediate and secondary shafts are installed here.

- Synchronizer. It ensures silent operation of the mechanism and equalization of gear speeds.

The gears rotate freely when the neutral mode is engaged, at which time all clutches and synchronizers are in the open position.

When the driver begins to squeeze the clutch mechanism and shifts the handle to some other gear, a special fork device begins to move the clutch into the engagement position with the corresponding pair at the end of the gear.

The gear mechanism is rigidly fixed to the shaft and stops spinning on it. The clutch in this position facilitates the transmission of rotational motion and traction force.

While the vehicle is moving, the gearbox is activated by the gear shift knob. It moves sliders equipped with forks, which begin to move the synchronizers at the required speed. A color diagram of gear shifting is in the Ural user manual.

Gear ratios of the Ural box:

- first stage - 5.26;

- second stage - 2.90;

- third stage - 1.52;

- fourth stage - 1.00;

- fifth stage - 0.664;

- reverse gear - 5.48.

Malfunctions and repairs

Basic malfunctions and repairs of the box:

- Extraneous noise in the mechanism. In this case, it is recommended to conduct an external inspection of the system and replace damaged and worn parts.

- The shafts move along the axis. It is necessary to replace the parts that secure the bearing, or replace failed bearings.

- Unstable operation of the gearbox. This problem may be due to wear on the reverse spline shaft bushings. Damaged mechanisms should be replaced.

- The clutch does not engage fully. In this case, it is recommended to conduct an external inspection of the coupling mechanism for damage and defects, check the level of lubricating fluid in the system and replace damaged elements.

- The fork rods are difficult to move. This malfunction can be caused by damage to the locking pins and synchronizers. It is necessary to replace the mechanisms with new ones.

- If the gearbox switches off spontaneously, it is necessary to adjust the gap between the valves, replace worn synchronizer rings, install new springs, and tighten fasteners.

- If the switching is unclear, you need to remove the cover of the locking device and inspect the main components for wear, replace the clutch and gears.

The history of the appearance of the Ural-4320 car

Ural-4320 trucks began to be mass-produced in 1977. The main difference between the new truck and the Ural-375D was the presence of a powerful diesel engine, the fuel consumption of which was significantly less than that of the gasoline modification. The military and business executives liked the new model so much that by 1986 the plant had produced more than a million Ural-4320 chassis, on which various bodies were installed.

The first models, which were produced before 1993, were equipped with KAMAZ diesel engines, but after the fire in 1993, the Kama plant stopped supplying its engines to other manufacturers. We had to switch to diesel engines from the Yaroslavl Motor Plant. Since it was not immediately possible to reach an agreement with the Yaroslavl plant on the supply of engines, in 1993 and 1994 he was forced to return to the production of cars with the ZIL-375 gasoline engine. According to its design, it was the same Ural-375D only with a cabin from the Ural-4320.

When it was possible to agree on the supply of Yaroslavl diesel engines, two types of engines were installed on all Ural-4320 chassis:

- YaMZ-238;

- YaMZ-236.

All trucks with YaMZ-236 engines remained externally unchanged, and modifications with YaMZ-238 received a new cabin with an increased size of the engine compartment. In addition to the size of the hood, these modifications can be quickly distinguished by their appearance, since for trucks with YaMZ-236 the air filter simply did not fit under the hood and had to be placed on the right wing. Starting from the mid-2000s, all Ural-4320 chassis received the same cabs with an extended engine compartment.

In 2014, the entire family of trucks on the Ural-4320 chassis was modernized into the Ural-M series. At the same time, the new modification retained the cabin of the 4320 model. In 2015, the entire Ural-M series was modernized by installing the new generation “NEXT” cabin. The truck began to look more modern, although it lost its charm and brutality. Despite this, the Ural-4320 cabin will continue to be installed on the Ural-M chassis, which will be produced for export.

Transfer case Ural 4320, design and operation

Today we will talk about the transfer case of the Ural 5557 and 4320, and also discuss their design.

The transfer case is a unit that is responsible for distributing torque from the engine to certain drive mechanisms, and they most often increase the number of gears in the transmission.

The Ural transfer case distributes torque between the axles and increases the torque of the drive wheels, which guarantees stability while the Ural vehicle is moving.

The Ural transfer case significantly affects the cost of the fuel mixture and the traction and speed parameters of the vehicle.

Because of this, the cost of transporting various cargo directly depends on the correct choice of parameters owned by the transfer case itself.

In this article you can easily find answers to the most common questions:

- Transfer case of the Ural 5557, 4320 and its device;

- Functioning of the part as a transfer case of the Ural 5557, 4320;

- Common malfunctions of the transfer case of the Ural 4320, 5557;

- Adjusting the transfer case of the Ural 5557 and 4320.

Basic information about the transfer case of the Ural 5557 and 4320

The Ural 4230 and 5557 vehicles use a two-stage transfer case equipped with an asymmetrical cylindrical center locking differential with a power drive. The transfer case is mounted on the car frame using four rubber pads. The design of the transfer case of the Ural 5557 and 4320 is absolutely the same as that of the KamAZ 4310.

In the middle of the crankcase the following are located on bearings:

- Intermediate roller with gears of the lowest high gear;

- Rear drive shaft with middle axle. An asymmetrical cylindrical center differential is installed on these rollers;

- Front axle drive shaft;

- The primary roller has high and low gears, and a clutch is installed between them to change gears.

In order to maintain atmospheric pressure in the crankcase cavity, a fitting with a tube is installed on the bearing cover, connecting the crankcase to the atmosphere through a sealing system. The outlet tip of the tube is brought to a level above the maximum fordability to prevent water from being sucked into the crankcase while overcoming water obstacles.

The crankcase is made of cast iron, there is a hatch on top, the crankcase itself is one-piece, closed with a lid with an oil guide tray.

Oil is poured into the crankcase through the top hatch with the cover removed or through the hole under the control plug, which is located on the rear wall of the crankcase. The oil is drained through the bottom hole, which is closed with a plug with a magnet.

The crankcase is ventilated using a fitting, and its tube is included in the general sealing system of the units.

Transfer case Ural 4320

How does the transfer case Ural 4320 and 5557 function?

In the Ural 4320 and 5557, the torque supplied to the drive wheels can change.

That is, the transfer case is considered at the same time an additional gearbox, which increases the number of gears and the limits of change in the gear ratio in the transmission.

Thanks to the inclusion of a low gear in the gearbox and transfer case Ural 4320, 5557, it is possible to overcome high resistance to movement and stable movement of the machine at low speed.

The Ural 4320 and 5557 boxes with a rigid connection between the drive rollers of the drive axles have a ratio of torques that are supplied to the main gears of the drive axles, depending on certain parameters of the machine design and driving conditions.

Dismantling the transfer case

It is more convenient to remove the transfer case if the car is installed on an inspection ditch in a room equipped with a lifting device.

To dismantle the transfer case from Ural-4320, -4420 and -44202 vehicles, lower the folding bracket of the spare wheel holder and remove the wheel.

Remove the driveshaft of the middle axle drive, disconnect the flanges of the driveshafts of the intermediate, front axle drive and front winch drive from the flanges of the transfer case and the additional power collection box.

Disconnect the wires from the speedometer sensor.

Undo the cotter pins and remove the pins, disconnect the rear ends of the control rods for the transfer box, auxiliary power take-off box and parking brake.

Unscrew the sealing tube from fitting 11. Move the disconnected ends of the cardan shafts and control rods of the transfer case, additional power take-off and parking brake to the side and secure them to the vehicle frame.

Fasten the load-lifting device to the bracket on cover 4 of the top hatch of the transfer case and lightly tighten the slings of the lifting device.

Undo the cotter pins and unscrew the nuts of the studs securing the transfer case to the brackets, remove the cushions and washers, carefully lower the box onto the trolley and remove it from under the car frame.