Why does the engine shoot into the carburetor: resulting in popping noises

A fairly common problem with carburetor cars is the characteristic popping noise in the carburetor.

The malfunction may occur when the engine starts and fires into the carburetor, as well as during operation of the internal combustion engine after the power unit has been started. At the very beginning, we note that experts consider the main reasons to be a severe depletion of the fuel-air mixture, ignition timing, or malfunctions of the gas distribution mechanism associated with incorrectly set phases. As for the CIS, most carburetor cars on the roads are Russian-made models. Next, we will look at problems when a VAZ engine shoots into the carburetor, why a 406 engine shoots into the carburetor, and also talk about how to detect and fix such malfunctions with your own hands.

Popping noises in the muffler of a scooter: causes and solutions

A scooter is a mechanical vehicle with an internal combustion engine. As a complex technical device, it is not immune to malfunctions. For example, frequent or single extraneous sounds resembling pops begin to be heard from the muffler. These uncomfortable noises can occur both during continuous operation of the engine and when it is started or stopped.

The unexpected occurrence of popping noises is not a serious failure; the owner can continue to use the vehicle. However, prolonged ignoring of the situation is fraught with negative consequences for the engine, deterioration in the performance of the machine, and failure of the exhaust system of the scooter. It is advisable to correct such malfunctions immediately. Shots in the muffler indicate that the fuel mixture in the exhaust system is burning out, and this leads to loss of power, increased fuel consumption, and unstable engine operation.

The main reasons for the appearance of pops

1. The nature of the phenomenon is considered to be the ignition of the working mixture that has accumulated in the muffler. That is, fuel that does not burn out in the engine in a timely manner ends up in the exhaust system. As it accumulates at a certain temperature, combustion occurs. There are several reasons for the formation of shots in the exhaust pipe.

2. Most often, the spark plug is to blame for this, as it does not produce a spark in time. During the operating cycle, the required volume of the fuel mixture does not ignite, and it goes into the exhaust system. Such a cycle negatively affects the operation of the engine and negatively affects the condition of the muffler. The spark plug needs to be removed and cleaned, its suitability for further use must be determined, and, if possible, adjusted. It is advisable to always have a spare working (new) spark plug.

3. In some cases, the cause of popping is an overly rich mixture. The situation may arise if the carburetor is incorrectly configured or if dirt gets into it. To correct the problem, just check the cleanliness of the carburetor and its settings. The composition of the fuel-air mixture of a scooter directly depends on the proper functioning of the starting enrichment. Its breakdown can also contribute to significant enrichment of the fuel.

4. Popping noises that appear after heating the power unit indicate a violation of the adjustment of the thermal clearances of the valves. To prevent the fuel mixture from entering the exhaust manifold, the valve plate must close the seat tightly enough.

Every scooter owner should be prepared for the possibility of technical problems. There is no need to panic here; any malfunction can always be successfully fixed.

What to do if the engine shoots into the carburetor and muffler

The appearance of popping noises in the muffler and carburetor is usually accompanied by a whole list of other symptoms:

- the engine “shoots” and does not start;

- work at XX is extremely unstable;

- the engine loses power and does not “pull”;

- the motor is prone to overheating;

- fuel consumption increases noticeably;

In this case, the unit’s response to pressing the gas pedal is not clear; delays and dips appear; the machine may jerk under load and in transient modes. In the language of ordinary car enthusiasts, the engine begins to “sneeze.” If the carburetor shoots when starting the engine, and the additional symptoms described above are also present, then certain elements and settings should be checked.

Diagnostics of the ignition system and OZ settings

The check should begin with the high-voltage wires of the ignition system. Violating the order of their connection will lead to the fact that the moment of spark formation on the spark plug will not occur at the end of the compression stroke, and the very order of supplying sparks to the cylinders during engine operation will also be disrupted. In this case, the engine may start, but during operation there will be shooting in the carburetor, which will be repeated at certain intervals. To solve the problem, you should connect the wires to the spark plugs, taking into account the fact that there are special marks on the distributor cover. These labels will help you make connections in the correct order.

If the engine shoots into the carburetor, the reason may be early ignition. This means that the spark appears too early. In other words, the mixture does not ignite at the end of the compression stroke, but at the moment the piston begins to approach TDC, completing the stroke.

In this case, the mixture of fuel and air in the cylinder burns untimely, as a result of which the combustion process is disrupted. The result of early combustion is a “lumbago” in the form of a pop in the carburetor. With late ignition, popping noises can go into the muffler, since combustion is still ongoing when the intake valve begins to reopen on the next stroke. Moreover, the combustion of the remaining mixture also extends to a new portion of the fuel charge, which is sucked into the engine from the carburetor into the intake manifold during intake. Under such conditions of disrupted combustion, the engine overheats. Often late or early ignition can be determined by the condition of the spark plugs. If the spark plugs are white, with carbon deposits, etc., then the OZ needs to be checked and set by adjusting the ignition timing. This adjustment is made by turning the distributor in accordance with the scale.

You should also check the Hall sensor and pay attention to the ignition distributor bearing. Problems with bearing fastening or other nuances may indicate the need to replace the distributor. Let us add that during diagnostics it is optimal to install an initially serviceable device on the car, which will allow faster and more accurate localization of faults in the ignition distributor. Similar actions should be performed with the ignition system switch. If it breaks down, sparking is disrupted and the spark itself is not supplied at exactly the specified moment.

Lean mixture: carburetor and fuel system

Running a carburetor engine on a “poor” fuel-air mixture often leads to the formation of pops and shooting in the carburetor. This phenomenon occurs because the lean mixture burns too slowly. The problem resembles an ignition failure, that is, the lean mixture burns after a new intake stroke has begun. It turns out that after exhaust, the intake valve opens on the intake stroke, and the lean fuel mixture still burns out in the combustion chamber. The incoming portion of the mixture also lights up. As a result, cotton is created in the intake, which reaches the mixing chamber of the carburetor itself. It should also be remembered that a lean working mixture is one of the main reasons for engine overheating.

It is also necessary to check at what level the fuel is in the float chamber. Another reason for a lean mixture may be air leaks. At the same time, you should check the carburetor accelerator pump, especially if shooting occurs when you press the accelerator sharply. Note that in most cases, to normalize the operation of the internal combustion engine, it is enough to clean the carburetor with a “carbicleaner” type cleaner and then correctly configure the device, as well as replace the fuel filters.

The carburetor sneezes into the air filter on a motorcycle. A motorcycle shoots into the muffler - problem solving

In order for a motorcycle engine to start without problems and gain speed well, at least two systems must work. One of them is the ignition system, the second is the power system. Simply put, there must be a spark in the combustion chamber at the right time and fuel mixed with air must enter the cylinder in the required quantity.

So about fuel. Before setting up the power system, you need to make sure that the ignition system is configured and working as it should. Are you sure everything is fine? Then let's begin.

You need to start with candles.

They can tell you a lot.

We unscrew the spark plugs after driving along the highway for about thirty kilometers, at least at medium or higher engine speeds, and carefully inspect them. Black carbon deposits, similar to soot, indicate that there is not enough air for the mixture to burn normally. The mixture is rich. Lots of gasoline and little air. If the spark plug insulator is completely free of soot or white, then the mixture is poor. Too much air and not enough gasoline. Normal color should be sand to brick red. If the spark plug insulator is of normal color, then you shouldn’t go into the carburetor. You should be guided by the rule that the best is the enemy of the good. Read also: Mobihel paint colors, car enamels color chart

If the carburetor is rich

First of all, we inspect the air filter. It may be dirty. The air passages may also be blocked, for example, a rag has been sucked in, the air pipe is pinched, or the air damper does not open completely. We sorted out the air supply, everything is clean, free, without obstacles. Go ahead.

You can remove the carburetor, completely disassemble it, wash it, blow out all the channels, dry it and reassemble it, but complete disassembly is not always required; more often you can get by with just adjustments. But if your carburetor does not respond to the rotation of the quality adjusting screw, then disassembling and washing is simply necessary.

First of all, check the fuel level in the float chamber

. How to do it?

We start by checking the shut-off valve or, simply put, the needle. A shut-off valve that does not hold is the cause of many troubles. Including an increased level of gasoline, which leads to over-enrichment of the mixture. On carburetors K-62, K-63, K-65, K-68, needle valves come in two types. With a ring or a rubber cone. To get to it, you need to remove the bottom cover of the carburetor, which is attached to the body with two screws (be careful when removing, do not damage the gasket), then remove the float, carefully pushing its axis out of the guides. The needle, as a rule, remains on the float tongue or falls out. Be careful not to lose it.

We inspect the needle, if it has a rubber cone, then we inspect the cone, it should be free of damage and foreign objects (hairs, grains of sand, etc.). If the needle has an o-ring, then look at how this ring sits on the head of the needle. If the ring is loose or missing altogether, it is necessary to replace (install) either only the o-ring or the needle. The ring should fit tightly. The needle must move along the seat without jamming, otherwise we replace the entire valve.

With the carburetor removed, you can check the level like this.

We turn the carburetor over with the float up and measure the distance from the plane of the body to the very top of the float. It should be within 26-27 mm. If it does not match, then adjust the size by bending the float tongue.

Is it possible to check and adjust the fuel level without removing carburetors in the Urals? Are they installed on the cylinder heads at angles to the horizontal and vertical planes?

With some skill this is possible. To do this, you will need a free float from the same carburetor. In a motorcycle mounted on the central stand (we are talking about a single motorcycle), open the gas tap. We wait a while for the carburetors to fill with gasoline. Close the gas valve and disconnect the gas hose from the carburetor. Remove the bottom cap of the carburetor with gasoline and lower the spare float into it. Next, we lean the lid against the lower plane of the body so that the planes of the lid become a continuation of the plane of the body (we simulate the installation of the lid, set the actual angle of inclination of the lower part), while the fuel level should be below the edge of the lowest corner of the lid and not overflow through it . If it does not correspond, then by bending and bending the tongue we achieve the desired level. In this case, the bottom cover and gas hose will have to be removed and replaced several times to test filling with gasoline. After adjusting the level, we proceed to the next one.

Adjusting idle speed and mixture quality (Carburetor K-62, 63, 65, 68).

We make adjustments on a warm engine. The procedure is approximately this:

1. Set the minimum stable engine speed by rotating the quantity screw (on K-62,63,65 this is the top 13mm wrench bolt, on K-68 this is a horizontal screw for a screwdriver). 2. Slowly rotating the quality screw in one direction or another (on all of the listed types of carburetors this is a vertical screw for a screwdriver), we catch the moment the speed increases to the maximum (approximately 1.5-2.5 turns from the fully tightened position, but deviations in that direction are possible or other party). 3. Repeat steps 1 and 2 until normal idle speed is established. 4. Check the adjustment by opening and closing the throttle. 5. If the engine stalls when you sharply open the throttle, turn the quality screw 1/4-1/2 turn (enrich the mixture). 6. If the engine stalls when the throttle is suddenly closed, turn out the quality screw 1/4-1/2 turn (lean the mixture).

Owners of motorcycles not only made in Russia, but also of foreign cars often face the problem of “shooting” from the muffler. This happens due to improper care of the air-fuel mixture ignition system. The motorcycle shoots the muffler in several cases:

- when using low-quality gasoline;

- malfunction of the electronics system responsible for fuel supply;

- gasoline does not enter the combustion chamber in pure form;

In such cases, you don’t need to wonder why the muffler on a motorcycle shoots. Poor quality gasoline has a very high combustion temperature due to the addition of water, so it does not ignite completely. The remaining drops fall on the walls of the heated muffler

. Their ignition creates pops.

Read also: How to check polarity with a multimeter

The motorcycle also shoots into the muffler when releasing the gas. The lower the pressure created in the internal combustion chamber, the more droplets enter the muffler. On some bikes, fuel accumulates in the muffler, followed by rare but very loud bangs.

Most often, but not always, owners of the Russian motorcycle industry face this problem. For example, a Ural motorcycle shoots into the carburetor. This occurs due to direct clogging of gasoline in the carburetor itself. To avoid this problem, it is necessary to constantly clean the filters and change the consumables responsible for cleaning the engine. Proper operation of your bike will not only ensure good engine performance, but will also maintain factory specifications.

Debriefing, or Adjusting the carburetor unit of the Alpha moped

After the moped has been run-in, a full cycle of technical inspection is carried out, which includes changing the oil in the transmission and engine, as well as adjusting the valve clearance. In addition, the manufacturer recommends replacing the air filter element. During operation, disturbances in dynamics are possible, requiring individual adjustment of the carburetor on an Alpha moped. Qualified adjustment of this unit will improve driving performance and help reduce fuel costs. This operation is similar to adjusting the carburetor on a scooter and will not cause much trouble for both beginners and experienced motorcyclists.

Signs that require an urgent check of the carburetor

Most motorists know the principle of operation of the carburetor unit and the necessary conditions for its stable operation. The main indicator for the full functioning of the engine is the composition of the combustible mixture, which should consist of 15 parts air and 1 part gasoline. Violation of the ratio leads to enrichment or, conversely, to depletion of the composition.

The main signs of a lean mixture:

- instability XX;

- difficult starting;

- popping sounds in the carburetor;

- the engine does not gain momentum;

- white carbon deposits on the candle.

Signs of over-enrichment of the combustible mixture:

- increased fuel consumption;

- candle covered in soot;

- popping sounds in the exhaust pipe;

- slow acceleration.

Adjustment procedure

Proper engine operation depends on compliance with operating rules and strict compliance with technical inspection requirements. Before you start setting up the carburetor on the Alpha moped, you need to first carry out a number of works:

- Clean the carburetor body.

- Replace the spark plug.

- Replace the air filter.

- Make sure the connections are tight.

Now you need to accurately set the gasoline level in the float chamber by bending the float tongue. By connecting a transparent hose to the drain fitting, it is possible to determine the absolute fuel level. To do this, the hose is lifted up. Typically the height is at the junction of the carburetor caps.

The next step is to adjust the idle speed system using quantity and quality screws. The whole process takes place on a warm engine. The quality screw is screwed in until it stops and then unscrewed two turns. Start the engine and, by rotating this screw in both directions, achieve maximum speed. Then use the quantity screw to reduce the speed to the minimum stable speed. It is possible that the procedure may need to be repeated several times until the desired result is achieved.

Adjustment of the middle speed range occurs by raising or lowering the needle. To do this, you need to unscrew the throttle nut, remove the needle and move the corkscrew into one of the grooves: above the middle division to lean the mixture and below to enrich it.

Popping sounds in the carburetor of the 402 engine

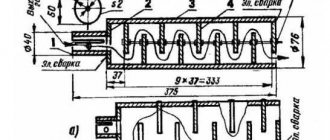

The four-cylinder gasoline engine ZMZ-402 has a carburetor-type fuel system and a gas distribution mechanism with a lower camshaft.

The reasons that the ZMZ-402 shoots into the carburetor may be:

- Pusher fracture.

- Damage to the distributor cap.

- Breakdown of armored wires or their incorrect connection.

- Clogged jets.

- Insufficient gasoline level in the float chamber.

- Malfunction of the fuel pump.

- Changes in the geometry of the intake valve or valve plate.

- Supply of lean mixture to combustion chambers.

The repair method is different for each case. To identify a malfunction, it is necessary to carry out a number of diagnostic measures.

The essence of the problem

Most often, loud pops in the muffler of two-wheeled vehicles are heard when a lean mixture is supplied to the engine. The reason for its formation may be the use of low-quality gasoline, saturated with water and non-flammable impurities, or incorrect adjustment of the intake system. The air-fuel mixture burns only partially - its remains splash out into the hot muffler, where they explode with sharp, unpleasant sounds. A symptom of a lean mixture is popping sounds in bursts, which intensify as the speed increases.

In powerful motorcycles, the completely opposite problem is more common, associated with the supply of an excessively rich mixture. There is not enough oxygen for its combustion, which leads to the deposition of gasoline condensate on the walls of the muffler. When the “critical mass” is reached, the fuel outside the engine ignites, resulting in one loud bang. If the problem is not corrected, within 1–2 months the contents of the muffler will simply burn out and it will turn into a “direct flow”.

Incomplete combustion of the mixture may be caused by a malfunction of the ignition system. In the absence of a spark, the cylinder misses a power stroke and the full amount of gasoline enters the muffler. Loud sounds are most often heard in this case at high speeds. The problem is also fraught with complete burnout of the muffler from the inside. Misfires are often accompanied by beautiful visual effects - when the engine is overloaded, jets of flame fly out of the exhaust pipes.

Another option is a lean mixture in the intake system caused by air, dirt or water getting into it. Naturally, the fuel does not burn completely and drops of gasoline form on the walls of the muffler, burning with a sharp, characteristic sound. In any case, the motorcycle malfunction must be repaired as soon as possible so as not to encounter more serious repairs.

What do the shots affect?

Problems with the ignition system do not bode well. In such a situation, with prolonged engine operation, not only the aesthetic impression can deteriorate. A dirty carburetor or low-quality fuel will eventually disrupt cylinder compression, which in turn will lead to engine failure.

To understand why a Ural motorcycle shoots at the muffler, or any other bike, you should check the problem areas. Here are possible ones:

- not tightness of the pipes that can suck in air, or the exhaust tract;

- faulty spark plugs;

- dirty air filters or carburetor;

- difficulty in supplying fuel;

However, the problem may also be with the racers' rev limiter. The spark plugs do not charge continuously, causing most of the mixture to go straight into the exhaust system, where it hits the hot metal and ignites, creating a loud bang. A clear example of such a process is a motorcycle equipped for special show programs. On such bikes, some of the fuel mixture ignites directly in the exhaust pipe, which is why you can see a flame coming out of the muffler.

Under no circumstances should you install direct flow

if you experience popping noises. This will only increase the noise in the exhaust system. This happens due to an even greater depletion of the fuel-air mixture and a “gutted” muffler.

On domestic motorcycles, a problem often arises associated with the appearance of loud sounds in the muffler. Even drivers of foreign vehicles often suffer from “machine gun bursts” that accompany a sharp increase or decrease in speed. Getting rid of this trouble can be quite difficult. However, if you understand why a motorcycle shoots its muffler, you can eliminate loud noises that disturb public peace.

Reason and solution

The easiest way to get rid of pops on a carburetor motorcycle is to simply move the needle valve to a different position, changing the degree of saturation of the mixture with gasoline. It is better to entrust this operation to a specialist, since not everyone can fine-tune the carburetor. If there is electronic fuel injection, it is impossible to change the gasoline supply parameters yourself - the control unit will have to be flashed at a specialized service station.

It happens that the motorcycle shoots into the muffler and carburetor - this is often found on domestic Urals and imported choppers with a large cylinder capacity. The problem is a clogged air-fuel mixture at the inlet. To eliminate it, it is worth changing the filters and sealing gaskets, and also checking how tightly the pipes fit to the inlet fittings and whether there are any large cracks in them.

Very often, popping noises appear after replacing the muffler with a non-standard one or cutting holes in it to eliminate resistance to escaping exhaust gases. Particularly unpleasant sounds appear when installing a “direct flow”. The reason is the creation of a strong vacuum, which leads to a lean air-fuel mixture. Powerful imported motorcycles often use an exhaust gas afterburning system, which reduces their toxicity - after removing the standard muffler, its operation becomes clearly audible. To eliminate shots after changing the silencer, you must:

- Reconfigure the carburetor or reflash the control unit;

- Install filters with a different capacity;

- Disable the exhaust gas afterburning system.

On sports motorcycles whose engines run at high speeds, the problem with shots may be related to the speed limiter or crankshaft speed limiter. When a certain indicator is reached, the fuel supply may remain unchanged for some time, while the number of flares is reduced. Accordingly, a huge amount of gasoline enters the muffler, which explodes with a jerky sound, forming a “machine gun burst.” It can be heard especially well when releasing the gas after active acceleration. It is impossible to eliminate such a problem without reducing the life of the engine - you have to change your driving style so as not to irritate yourself and others with unpleasant loud bangs.

It is worth paying attention to the ignition system - missed flashes may be due to its malfunction. Carefully inspect the high-voltage wires - there should be no cracks or peeling of the insulation on them. After unscrewing the spark plugs, check to see if there is a specific deposit on their surface that appears when using low-quality gasoline or when the ignition timing is set incorrectly. If the motorcycle is equipped with an electronic ignition system, the problem can often be solved by reprogramming the control unit. Some motorcycle owners decide to make drastic changes by installing a new control unit with preset sport settings - this solves the problem of shots in the muffler, and also increases engine power and improves dynamic characteristics.

Quick diagnostics

Since in the future the problem of popping noises in the muffler can lead to breakdown of the engine and other important components of the motorcycle, it needs to be solved as quickly as possible. You should consistently check the performance of systems such as: intake, ignition, exhaust. All damaged parts are replaced with new ones, connections are sealed. It is also better to temporarily replace tuning components with “stock” ones to check how the engine will perform with factory settings. If all else fails, the motorcycle should be inspected by a professional mechanic, who will find the cause and tell you how to eliminate it at minimal cost and without reducing the life of the power unit.

Adjusting the carburetor on an Alpha moped. Which is correct?

If one of the parts breaks down, the motorcycle will no longer work smoothly, intermittently, or not work at all. Another thing is setup. You may need it after an accident, winter, or after break-in. Adjusting the carburetor of an Alpha moped is often an almost obligatory maintenance item, especially if the owner has identified problems with it. If your motorcycle stalls, uses too much fuel, or makes abnormal noises, it may mean that the carburetor needs adjustment. How to do this and how to then determine that everything is set correctly? First, it would be a good idea to determine what processes are taking place there.

What to do if the scooter shoots

Since we know why the scooter fires, we need to check the spark plug.

We twist the spark plug and clean its adjustment if necessary, screw the spark plug into the scooter and check whether the problem is solved. If the scooter no longer shoots, then it is radium, and if the scooter shoots, then the candle can be thrown away. We buy a new spark plug, screw it in and voila, the problem is solved. Therefore, you need to have a spare candle with you; it is not expensive but can cause quite a few problems. But note that the reason why the scooter fires may not only be that the spark plug is out of order, as it may be preventing it from working. It may be that the mixture is too rich. You need to check the carburetor, maybe it is poorly tuned or it just got damaged.

A few more reasons why the scooter shoots:

Shots may occur due to the fact that the membrane in the carburetor is leaky. – When the engine is running, the battery takes a lot of current to charge. – Large load on the generator. – There is not enough magnetic field for a spark and the switch produces a spark a little later (while the capacitor is charging) - and at this time the valves are already opening.

Now you know why the scooter shoots.

How does a carburetor work?

On one side the air comes in, that’s where the air filter is attached, and on the other side the cylinder comes in, and that’s where the mixture comes out. At the bottom there is a float chamber, a jet and a tube. When the piston moves down, it sucks air from the air filter. The speed of this air is quite high, which causes a vacuum: the atmospheric pressure increases, and because of this, gasoline begins to flow from the float chamber through the nozzle and the emulsion tube. The fuel mixes with the air and actually breaks down into dust. Moving on, it calmly flies into the cylinder. With such work, it may not be necessary to adjust the carburetor of the Alpha moped (110 or 72).

If the gasoline level changes, it will flow out through the drain pipe. This happens due to the overflow of the float chamber: floats, shut-off needle with a rubber tip and hole. When gasoline rises, the float blocks the flow of gasoline. There is a shaft at the top where the spool with a needle runs, and a cable to the throttle handle stretches to it. The needle enters the emulsion tube and nozzle. With gas, the space increases and the amount of mixture changes. This is controlled by the mixture quality screw. The idle jet with the screw facing outwards is intended for dosing the mixture. This is the second screw.

Causes of malfunction

You can determine that the carburetor is overflowing by several signs:

- Condition of the candle. A dirty spark plug indicates a rich fuel mixture, which means high gasoline content. Even a serviceable or new spark plug may not be able to cope with the flow of fuel entering the cylinder and over time it will become covered with soot, will be constantly wet and the engine will stop starting.

- Gasoline leaks through the air filter. Signs of fuel may be found in the air filter housing.

- Gasoline leaks through the float chamber gasket.

What is the need?

In order to prevent parts from wearing out too quickly, it is important to select the correct mixture at idle, at full throttle and in modes when the throttle is not fully open. What should make the owner think about adjusting the carburetor of the Alpha moped in these modes? Violation of the ratio of air and gasoline. Ideally, it should correspond to 1:15, where there is only 1 part of gasoline. Signs of a violation may include:

- Difficulty starting the engine.

- Any instability in idle speed can be heard as irregular engine operation.

- When you turn the throttle all the way, the engine does not rev up and accelerates slowly.

- Popping sounds in the carburetor or exhaust pipe.

- Candle color is white or black.

How to adjust the carburetor?

Before adjusting the carburetor of the Alpha moped, it must be started and warmed up. Tighten the screw for the quantity (idle speed) and quality of the mixture until it stops. The latter is necessary so that the engine does not stall. When the engine begins to stall, you should increase the speed of the speed screw. When the engine is ready to stall, you need to unscrew the quantity screw. Now the mixture quality screw follows the moment when the engine reaches maximum speed. If too high, adjust the engine speed screw (idle speed screw). Then you need to spin it until the engine stops gaining momentum.

Now at low speeds the engine can run easily and not stall. Tighten the mixture quality screw until the engine begins to lose speed. The idle speed screw should be set to idle speed. The norm is approximately 1500-1200 rpm.

How to check the quality of adjustment of the carburetor of an Alpha moped?

At this stage, you need to adjust the quality of the mixture on the go. To do this, you need to start the moped and go for a ride with the throttle turned half way. After this, you can look at the condition of the spark plug: black - too much gasoline while driving, white - air. How to be in this case? You can pull out the needle and grooves that regulate the amount of gasoline. When moving the locking ring upward, less fuel will be supplied and more air will be supplied, and vice versa. After this, the check is performed again, and if the engine does not stall when turned to full throttle, then this is a sign that everything is fine.

In addition, the problem may be in the main jet, which is responsible for the “full throttle” mode: in this case, it should be replaced with a smaller or larger one. The following steps will serve as a test: when driving at full throttle, you need to slow down a little. If popping noises are heard, a smaller jet is needed.

Trouble-shooting

What to do if you had to face such problems? Let's go in order. You need to start with the air filter - if there are no problems with it, then proceed to the next steps.

Fuel tap problem?

If gasoline constantly flows from the fuel supply hose, even when the vacuum hose is removed, then the valve is faulty. It simply does not work, but is always in the open position. In this case, the tap must be replaced with a new one.

If, when you remove the vacuum hose, gasoline stops flowing, then the reason is a constant vacuum - you need to climb into the cylinder head.

Locking needle

Provided the faucet is in good working order, you can play the shut-off game. How to get to the needle of a scooter or moped?

- To remove the carburetor, you need to disconnect the air filter; hoses suitable for it; unscrew it from the intake manifold and remove the throttle cable.

- Next, use a Phillips screwdriver to remove the float chamber housing.

- Assess the condition of the shut-off needle and float antennae.

- If necessary, replace the needle and bend the float antennae. If the needle is in good condition, then its seat should be thoroughly washed and blown out.

- Reassemble everything and install it on the engine.

Vacuum accelerator (if all else fails)

In addition to the locking needle, Chinese scooters are also equipped with a vacuum needle (vacuum accelerator). This device also works from a vacuum hose connected to the “carb”. This needle has 5 (usually) adjustment positions. When the scooter accelerates, the vacuum opens this needle and more fuel is supplied to the combustion chamber.

The system is correct, however, everything breaks down. Over time, none of the needle positions produces results. This problem can be solved simply by removing or cutting the vacuum hose (not the one to the fuel tap)! And the engine no longer overflows - miracle of miracles.