Here many people are interested in how to replace the old cam ignition with a new one. It's not that new. People call it Tyumenskoye.

|

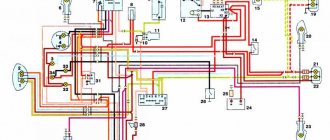

- adjustment plate

- sensor

- rotor

- lock washer

- bolt

- wiring

- switch

written and drawn by: SHTRLZ

if anyone can help write to asya 257-318-122, thanks in advance

Folks, I installed such a carbolite sensor and took a switch for the contactless ignition system from a GAZelle from the same and the ignition coil is all fine, the spark is good, but there won’t be a problem with a spark until I screw the switch to ground, when it is shorted to ground, a spark immediately breaks out, I connect tightly and the ignition goes out it’s like a little one, but it starts with half a kick, another problem is while the ignition is on and the motorcycle is not started, the switch gets very hot when it’s started, everything is normal

But how to install BSZ on motorcycles with PM05 breaker (k-750 for example)?

There is one item missing from this manual. Namely, it is necessary to correctly set the gap between the rotor and the sensor to be 0.2-0.3 mm. With a large gap at low speeds, interruptions in spark formation are possible. As for the electronic unit, it has a very unpleasant feature. He perfectly produces a spark somewhere on a stand, in which there are ideal electrical circuits, and at the same time, he doesn’t want to work at all in his home place. Without going into unnecessary details, I can say that part of the scheme needs improvement. Personally, I rebuilt several copies, after which I have no problems at low speeds or in bad weather conditions.

The reed switch has a lot of inertia. it will take a long time to open

Ural motorcycles produced after the 90s have a contactless ignition system. But the predecessors of the happy owners of new iron horses also roam the expanses of Russia.

In the outback you can still see a rarity - a three-wheeled toiler based on the M-72. These older motorcycle models have a contact type ignition system.

Contactless ignition system for motorcycle Ural, Dnepr

Solving the problem of the reliability of the ignition system on my Ural motorcycle, I came to the conclusion that it was necessary to install a BSZ...

Having considered the huge abundance of options for contactless ignition systems, both on the market and on the Internet, I decided to make for myself the simplest option for the electronic part. Namely, use a Zhiguli Hall sensor and switch. The reason for choosing this particular combination was that I like to travel far and for a long time, and you must admit that if a specific unit specifically for a motorcycle fails along the way, it is not always possible to find a replacement for Saurman or an opto sensor somewhere in the outback, just as it is not always possible to carry it with you contact ignition kit in reserve. And spare parts for Zhiguli can be found in any village.

Search for BSZ kit

So, the choice has been made, all that remains is to implement it. I went to the market. I bought a switch for a VAZ 2108, a Hall sensor and a piece of wiring from a VAZ 2107 distributor. I bought a two-terminal coil from Oka. I also needed an old breaker housing to make a mounting panel for the Hall sensor that I had.

How to make a butterfly for BSZ

The simplest, but not the most correct option was to make a modulator butterfly, ordering it from a turner, which could be rigidly fixed to the shaft. In this case, the ignition timing would remain constant all the time. Of course, it would be possible to add an additional FUOZ unit (ignition timing generator) to this option, but, based on my concept of “reliability in simplicity,” this option also did not suit me. I wanted the engine to work as it should, without complicating the electronic part, so I went to the market again and bought a new Ural cam with a centrifugal regulator. I approached the selection of the cam responsibly and bought the most reliable one, not a Chinese one.

We make a plate for the hall sensor

I took the old body from the breaker, removed all the insides from it, and sawed off the vertical walls to a horizontal plane. The result is a plate like this.

Next, having thought about how to secure the Hall sensor, I decided to “sink” it and secure it at the bottom of the plate, fortunately there was 3 mm of free space under the plate, just right for attaching the sensor. This mounting option seemed to me the most rigid, plus the sensor mounting screws will not be unscrewed due to engine vibrations, since they will rest against the housing. I made the necessary cut in the plate along the width of the sensor, drilled two holes and cut an M3 thread. I installed the Hall sensor on the plate and secured it with M3 screws with countersunk heads.

We manufacture a modulator for BSZ

I measured the vertical distance from the slot in the sensor to the edge of the plate. I got distances from the bottom edge of the sensor slot of 6 mm from the top of 10 mm. I installed the plate on the motorcycle, installed the cam with the centrifugal regulator in place, looked at how the lower edge of the cam sits in relation to the plate, it should be approximately at the same level. I transferred the distance from the plate to the center of the slot in the sensor to the cam body. In my case it turned out to be 8 mm. Marked a horizontal line. The curtains will be welded at this level. I left the marking line for release.

I measured the distance from the center of the shaft on which the cam sits to the Hall sensor housing through the slot - 28-29mm. I decided that the diameter of the butterfly should be 54 mm, so that there would be a gap of 2 mm between the edge of the curtain and the sensor body. Somewhere on the BSZ discussion forums I read that for the switch to work properly, a 2/1 cycle is required. That is, two parts of the sector are closed, one part is open. It turns out 120 degrees metal, 60 degrees slot.

Determined the central axis of the cam. If you look at the cam directly in the center of the hole, you will see that the cam is not round. Only two parts are round, and two seem to have been ground off. The axis passes through the centers of both rounded parts, i.e. where the contacts remain open. Using simple calculations, I marked four vertical lines on the cam. Got clear boundaries of sectors horizontally and vertically.

I ordered a mandrel from a turner - a round metal washer 8 mm thick, 54 mm in diameter and with an internal hole of 22 mm, so that the round part of the cam would fit tightly into the washer, without play. The sectors for the modulator were first cut out of cardboard. I did this with the metal: I cut out a round piece from a 1 mm sheet of iron with a chisel, and drilled a hole in the center for an M8 bolt. I drove a bolt into this hole, tightened it with a nut, inserted it into the drill, turned on the drill and carefully sanded the edges of the workpiece with a file to the desired diameter and shape.

I marked the resulting workpiece into 4 sectors, two at 120 degrees and two at 60 degrees. I carefully sawed one marked side into two halves, put both parts together, and made a cut along the remaining line. Got the required sectors. Next, holding the sectors again in a vice, I made it as on a paper blank, and drank the required shape under the welding site.

After all these manipulations I went to the welder. Well, everything is simple there. We inserted the cam into the mandrel turned by a lathe. We laid the petals on the mandrel, oriented them along the marked lines and welded them to the eccentric. The most difficult part of the BSZ butterfly modulator was ready.

Installing BSZ on a motorcycle

Installation on the motorcycle did not take long. The old ignition had already been removed. In its place I installed a plate with a Hall sensor and put the butterfly modulator in place.

Electrical or mechanical? Ignition for "Ural"

All Soviet motorcycles produced before the 90s are equipped with a contact ignition system, which after a certain mileage begins to cause headaches for its owners.

The heavy Ural motorcycle is no exception. Why is this happening?

In the contact ignition system, all processes are performed mechanically, which means there is friction, mechanical closing and opening of contacts and, as a result, their burning and wear of the unit.

When parts of such a system wear out, the gaps in the contacts are disrupted, the ignition timing is shifted, and spark supply deteriorates.

In addition, the contact system is dependent on engine speeds - the lower they are, the weaker the spark, the worse the mixture in the cylinder ignites, the engine does not develop its full power of which it is capable, idling is worse than on a contactless system with electronic ignition.

Advantages of a contactless system over a contact one:

- The power of the spark does not depend on engine speed; the discharge on the electrodes of the spark plug is always consistently powerful

- The switch operates at a voltage of 6 volts, while the contact system begins to fail at a voltage of 9-10 volts and the engine stalls

- There are no parts rubbing against each other, due to which the system has a long service life and high reliability, and the ignition timing is set only when it is installed on a motorcycle and is corrected only in case of interference in the sensor area

- In a contactless system, the ignition coil is not “afraid” of overheating: the switch automatically turns off the voltage supply to the ignition coil a few seconds after stopping the engine; in a contact system, turning on the ignition for a long time with the engine not running is prohibited, because the coil may burn out.

Today, for the Ural and Dnepr motorcycles, there are several ready-made options for contactless ignition systems, such as SoveK and Saruman, but if the budget is very limited, then you can assemble a more primitive system with your own hands.

Electronic ignition systems use three types of sensors:

- optical (optocoupler)

- Hall Sensor

- magnetic-inductive sensor (used on all Japanese and Chinese equipment, therefore quite common).

The most popular options are optical and Hall sensor. They are easier to install and organize the operation of the system.

Optical sensors have recently gained great popularity due to the fact that they are not afraid of any electromagnetic interference, which cannot be said about the Hall sensor - it must be installed away from any sources of the electromagnetic field, in particular the generator. But if we talk about a homemade system, then the easiest and cheapest way to assemble it is with a Hall sensor.

Let's look at ready-made systems from SoveK and Saruman

A complete ignition kit from Saruman is equipped with an optical sensor, an interrupt modulator, sensor mounting, an FUOZ electronic unit, wiring, a 761.3734 switch and mode switches.

The advance block has a built-in function (at the customer’s request) for spark cut-off at maximum engine speeds and a spark plug warm-up mode.

The system is installed easily, without any modifications to the engine in the standard place of the contact breaker; you only need to purchase an ignition coil 406.3705 or its equivalent and spark plug wires with the kit.

The ignition coil is also installed in its original place and placed under the cover.

The cost of the Saruman contactless ignition system is 2,750 rubles, without an ignition coil. The cost of the reel is about 500 rubles.

The configuration of the SoveK system is somewhat different, namely the presence of an ignition coil, the absence of a FUOZ unit and an inductive type sensor.

The switch is built into the sensor platform and is one piece. The cost of the SoveK system is about 1,620 rubles. This system is compatible with the Saruman FUOZ unit.

Building an electronic contactless ignition system for the Urals with your own hands. What is needed for this and how to put it all together?

For a homemade system you will need:

- Hall sensor from any domestic car

- car switch

- simple wiring harness BSZ VAZ without additional outputs for the carburetor and idle economizer connector

- latest generation VAZ/GAZelle ignition coil for two cylinders

- interrupt modulator

The system is assembled according to the following scheme:

The most difficult thing is to manufacture the modulator (curtain) - it must be perfectly symmetrical and of high quality, since the synchronization of the operation of the cylinders and the engine as a whole depends on this. Each modulator curtain should cover 30⁰ of its rotation.

The modulator can be combined with the original ignition timing mechanism. To do this, grooves are made on one side of the modulator into which the weights of the mechanism fit.

The modulator rotates freely on the axis of the advancing mechanism and at high speeds, when the weights move apart from the centrifugal force, the modulator will rotate, thereby providing a shift in the ignition timing depending on the engine speed.

To adjust the ignition timing, it is necessary to make a plate (disk) of any material on which the Hall sensor will be attached, with the possibility of its rotation.

To attach the Hall sensor, it is necessary to make a corner with slots so that it can be adjusted in two planes relative to the modulator.

The modulator curtains should run through the center of the sensor so that they do not catch and break it.

After everything is made and assembled, you can start installing the electronic ignition on the Ural motorcycle in place. The ignition coil is installed in place of the standard coil, the switch can be placed in any convenient place, but so that it is protected from water getting on it.

The disadvantages of a homemade system include:

- mechanical advance of ignition timing - the FUOZ electronic unit controls this process much more accurately throughout the entire speed range and allows you to get maximum power from the engine

- using a Hall sensor

- Precision manufacturing of the modulator

- time spent on manufacturing such a system yourself

The only advantage of such a system is its low cost.

And so the price for the electronic ignition of a Ural motorcycle, namely its components:

- Hall sensor –170 rubles

- switch 761.3734 – 350 rubles

- ignition coil 406.3705 – 500 rubles

- wiring – 200 rubles

We are going to cover the topic “Minsk motorcycle tuning” and how to improve the power with your own hands.

Tuning the Dnepr, engine, chassis, follow the link

twokolo.com

How to set up electronic ignition on Ural motorcycles

Ural motorcycles produced after the 90s have a contactless ignition system. But the predecessors of the happy owners of new iron horses also roam the expanses of Russia.

Ural motorcycles produced after the 90s have a contactless ignition system. But the predecessors of the happy owners of new iron horses also roam the expanses of Russia.

In the outback you can still see a rarity - a three-wheeled toiler based on the M-72. These older motorcycle models have a contact type ignition system.

Installation

Now you can install a new ignition system for the Ural motorcycle. Before starting work, dismantle the old BSZ. Installation is carried out in the following order:

- We install a new coil, here you will need a connection diagram, otherwise problems will arise further;

- We install the ignition module, it should be secured so that it is directed towards the coil.

- The engine rotor is installed in the position at which the ignition is adjusted.

Now you have a contactless ignition system installed, all you have to do is configure it to achieve optimal performance. Please note that setup here is only required once. In fact, you already know how to install the BSZ.

Leave it to mechanics or install electronics

Perhaps not all older motorcycle models are running. The Ural motorcycle sits and rusts in my grandfather’s barn because it won’t start.

The wheels are spinning, the engine is not jammed. Maybe the spark goes into the ground, as they say. In short, you need to look at the spark generation system. But even a working motorcycle, with a contact ignition system, causes unexpected and unpleasant problems for its owner:

- won't start when you really need it;

- with new oil rings in the engine, the spark plugs become covered with soot;

- there is no required engine power when driving with maximum load;

- the maximum speed is not reached;

- The battery is slightly discharged and the engine does not start.

Tuning a Ural motorcycle with your own hands - this article will help you decide in which direction to modernize your Ural.

The contact ignition system creates a lot of problems, especially when the moving parts in it have already worn out, backlash has appeared, and the geometry of the elements has changed.

The solution is simple - all cam ignition is thrown out, a modern electronic non-contact type spark generation system is installed. You will no longer have to deal with the thankless task of cleaning contacts and endlessly adjusting the gaps in the breaker. All this is possible thanks to the simple, but quite reliable design of the motorcycle. For example, it is quite easy to set the thermal gap and adjust the valves in the Urals with your own hands, using only your own tools from the garage. This way you will gain valuable experience and save money on visiting the workshop.

What does the contactless ignition system on the Ural and Dnepr motorcycle provide?

- No headaches for the motorcycle owner when operating it;

- Starting the engine in wet and cold weather;

- Failure-free operation of the ignition system;

- Increased driving characteristics of the motorcycle as a whole;

- Increased candle life;

- Starting the engine when the battery voltage drops to 6 volts;

- Constant, not changing over time, ignition timing;

- The ignition coil cannot overheat.

- Powerful, required color, sparking.

Briefly about the contactless ignition system

The contactless system, installed on all vehicles, includes:

- modulator i.e. Converter of magnetic flux into electrical impulses;

- magnetic flux sensors (for example, a Hall sensor);

- an ignition coil, slightly different in design from the traditional one;

- switch that distributes sparking;

- switching wires, terminals, fasteners.

The operating principle of a contactless ignition system is not complicated. A rotating plate mounted on the shaft, with its petals, opens and closes the path of magnetic flux (the magnetic field is formed by an installed magnet), which fixes the Hall sensor.

How to make an ATV from the Urals - this article will certainly be of interest to lovers of boxer engines and creators of real garage monsters.

These field breaks depend on the position of the distributor shaft. A pulse from a Hall sensor (or a similar one) occurs at a certain moment when the piston is at the required point for sparking. Next, instantly, the impulse is transmitted to the switch and to the ignition coil. The result is the formation of a spark in the spark plugs.

To mount the ignition system on a motorcycle, you need to either make its individual elements (modulator, plate) with your own hands, or purchase ready-made ESZ kits such as Saruman or Sovek.

Electronic ignition systems from Sovek and Saruman, equipment, features and differences.

If you don’t want to make electronic ignition elements for your Ural motorcycle yourself, you can purchase a kit ready for installation. Advantages of ready-made ignition systems:

- manufacturing takes place in a factory;

- the technical control procedure does not involve checking individual elements, but testing the performance of the entire system as a whole;

The most common and available for purchase are sez produced by SoveK and Saruman.

1. "Saruman". The package includes two options - with an optical sensor or with a Hall sensor. Any configuration includes an ignition unit, a platform for installing a sensor, a modulator with a flow interruption curtain, installation wires and installation instructions.

Features of the Saruman set:

- separate ignition timing generator (IAF);

- built-in system protection against generator overvoltage;

- LED indication to facilitate ignition setting

- microprocessor firmware is made for a specific motorcycle model;

- waterproof, locking connectors;

2. "SoveK". Several ignition system options are available. Microprocessor type and regular contactless.

The configuration can be with or without an ignition coil. Includes an ignition module, a modulator, and a switch with built-in FUOS.

Technical features of the Sovek kit:

- microprocessor module can work with various ignition coils;

- sparking is ensured both at low (6 volts) and at high voltage (16 volts) in the on-board network.

Contactless ignition systems

Not so long ago you could only find a homemade device. The reason is the lack of proper supply in stores. Craftsmen in garages remade the contactless unit from other motorcycle models and assembled it from individual parts. This is a rather complex activity that requires skills. Now you can purchase a ready-made kit without any problems.

There are many advantages to using ready-made products. At a minimum, they have been tested in the Urals, which guarantees reliable operation. It is also much easier to install a ready-made unit than to make it yourself. The following sets can be found on the market:

- "SoveK". Under this brand you can find regular contactless ignition, as well as a more advanced microprocessor ignition. The assembly can be supplied with or without a bobbin. Easy to install and practically does not respond to voltage changes;

- "Saruman." Quite an interesting and reliable assembly. There are two sensor options available here; there can be a conventional Hall sensor, or a modern optical one. There is protection against voltage surges, especially high current. To simplify setting the ignition, there is a light indication.

Using ready-made kits is currently the best option.

Replacing spark plugs before installing electronic ignition systems

Spark plugs are the last element of the spark generation system in any engine. They work under conditions of high pressure and temperature.

Sparking occurs on them when a high voltage pulse is applied. Therefore, it is not possible to test them, without a test bench, in domestic conditions.

The serviceability of a working spark plug can only be judged visually - by carbon deposits on its tip or presence on the “skirt”. To ensure reliable engine operation, change spark plugs according to the motorcycle operating rules, without expecting them to work forever.

Choose the correct heat rating when purchasing spark plugs. Set the gap in the spark plug electrodes to 0.7-0.8 mm.

We hope that these problems with the spark plugs are not observed and, after purchasing (manufacturing) a non-contact type ignition system and replacing the spark plugs, we begin adjustment work.

Selection of candles

The contactless system has certain requirements for candles. If they are faulty or do not fit a specific motor, then you will not get any positive effect from using this system.

Be sure to check the condition of the spark plugs. They should not have soot. It is optimal if the electrode has a sand color. If necessary, replace the spark plugs; when selecting, pay attention to the heat rating. When the spark plugs are in order, the electronic ignition can be installed.

Setting up and adjusting the ignition on Dnepr and Ural motorcycles.

The procedure for adjustment and tuning is the same for all motorcycle models. Features are associated only with the specifically installed electronic ignition system. General order:

- We install an electronic ignition system on a motorcycle;

- We set the ignition timing by turning the shaft and aligning the stamped arrow on the flywheel with the mark on the engine crankcase;

- We connect the wires according to the manufacturer’s diagram;

- Without turning the shaft, we adjust the position of: module, flow sensors (Hall, optical), modulator;

- We secure the elements of the ignition system.

- We rotate the shaft and control the formation of a spark;

- We adjust the optimal ignition timing after a test run.

When using 92 grade gasoline on motorcycles, we make adjustments from the standard ignition timing adjustment. We put it out a little earlier.

Installing an electronic ignition system will allow trouble-free operation of the motorcycle in any weather and climatic conditions.

Contactless ignition for a motorcycle, is it necessary? [IZH, Ural, Dnepr, TMZ]

Motorcycle owners of the past undoubtedly love their equipment. And one of the main attributes of a good motorcycle condition is care and correct operation. But even with all this, the motorcycle fails, and when it comes to cam ignition, many people think about replacing it with something more modern, is it worth it? And is this necessary at all?

The positive aspects that I noticed on IZH and URAL with BSZ:

1) Engine starting in cold weather is improved, as well as the ease of starting the engine on a dead battery. 2) The ignition coil heats up less, since less current flows through the winding, this should increase its service life. 3) More stable engine operation, as a rule, the spark is more powerful, and at high speeds there are no spark failures

And the manufacturers talk about this, I’m not sure about these points

1) Reducing the toxicity of exhaust gases, fuel consumption and carbon deposits on spark plugs due to an increase in the inductive phase of the spark.

2) Reducing the labor intensity of installation and maintenance of BSZ. (In fact, installing and dismantling the factory ignition is not much more difficult, a dubious plus)

Of course, if there is no desire to preserve the originality of the motorcycle, this improvement will only be beneficial. The market has long offered good systems of such ignition. But with little expense you can build this yourself, it’s quite simple, and in essence it will not differ from the factory version, only accuracy and precision are important. And it’s no longer worth coming up with systems for installing ignition based on generators for Minsk and Voskhod motorcycles.

Troubleshooting problems with the ignition system on a Ural motorcycle

Checking the ignition system, first of all, occurs with an initial check of the functionality of the breaker. It is important to pay attention to the operation of the incendiary advance machine , in which various complaints are undesirable. The resistance of the primary winding, which is measured by the tester, must be at least 6 ohms. Next, the secondary winding is checked, for which the tester is connected to the high voltage connections. The voltage of such a winding should be exactly 10 kOhm.

Repair of Ural and Dnepr motorcycles , like many others, cannot be done without all these manipulations aimed at optimizing its operation. Checking the ignition does not end there. Next, the spark plug caps and high voltage wires ring. Resistance indicators, in these cases, should vary. The plug caps should have approximately 2 kOhm, and the wires should have almost zero (this is an important aspect). During these manipulations, the problem will be found and eliminated.

Ignition adjustment and repair in the Urals and Dnieper

The ignition on a motorcycle can be checked by following the following procedure:

- We take the most ordinary incandescent lamp, which is naturally working. We connect one end of the wire contact to ground, and connect the second, which comes from the breaker, to the terminal. Setting the ignition on Dnepr and Ural motorcycles is done by turning the crankshaft until the marks on the crankcase and on the flywheel, which has the letter “P,” completely coincide. Next, turn on the ignition, while retracting the automatic weights to the very end. Under this circumstance, the incandescent lamp should light up instantly. If this does not happen, i.e. the lamp does not light up, or this happened before the weights were completely retracted, then ignition adjustment is necessary.

- We loosen the screws on the breaker. Next, you need to move the weights to the very end and slowly turn the breaker structure until the incandescent lamp starts to burn. This happens exactly the same as when contacts are closed, when a spark jumps between the electrodes of the spark plug itself. After carrying out these procedures, the structure of the breaker and its position must be securely fixed using fastening screws. It is worth noting that in all MT models, the ignition timing must be at least 34 degrees before dead center.

Adjusting the ignition of a Ural motorcycle

In general, installing an ignition on Ural and Dnepr motorcycles significantly increases the main technical indicators of this motorcycle. The ignition setting allows you to easily start the motorcycle even in the coldest time of the year, when consistently negative temperatures prevail. In addition, the ignition installation of the Ural motorcycle allows you to optimize and normalize the operation of the engine, increase the spark phase, which has a positive effect on the exhaust gases that come out of the motorcycle pipe. Simply put, these gases become less harmful to human health and the environment.

Ignition adjustment

Conclusion

With proper adjustment and installation of the ignition, the amount of fuel consumed is significantly reduced. If the battery has insufficient voltage, the motorcycle engine will be started in any case, naturally, provided that the Dnepr motorcycle ignition has been installed. Older models of the Ural motorcycle generally do not have electronic ignition, which is a definite problem for its owners. You shouldn’t despair, because you can completely adjust the ignition yourself, without going to specialized salons. This should be done at least because contactless ignition can significantly improve engine performance and also make it easier to start your bike.

Ignition on the Ural: electronic or mechanical, differences, installation features

One of the main pain points of heavy Ural motorcycles is the ignition system. Although currently motorcycles produced by IMZ are equipped with Italian-made Ducati Energia electronic ignition, only about three percent of the bikes produced today are sold in the Russian Federation. Most of the owners travel across the country using outdated mechanical ignition in the Ural. Electronic one has a number of advantages.

Mechanical or electronic

Initially, these motorcycles had mechanical ignition. Unlike BSZ, this option has low reliability. The reason is in the mechanical elements of the structure; they wear out over a certain mileage, which leads to regular failures. And you have to adjust the ignition on the Ural motorcycle much more often

The electronic ignition system on a motorcycle does not have such problems. There are practically no interacting elements here. Therefore, the service life is significantly longer. Also, thanks to improved spark formation, there are fewer problems with engine operation. The owner is also relieved of the need to regularly clean the contacts. All this leads to the massive spread of BSZ on this model.

Modern replacement

This system has been considered outdated for almost half a century. Motorcycle owners often complain about oxidizing and burning contacts, the formation of an oil film, and the need to constantly clean and reconfigure the ignition system. Of course, inquisitive minds have already found a solution to this problem, so installing electronic ignition on the Ural is currently not something extraordinary.

Electronic ignition for the Ural motorcycle is now produced by several companies. The most common models are the SoveK microprocessor contactless ignition system, the Saruman ignition system, the Stary Oskol ignition system and the UKTUS-2 microprocessor ignition. Unfortunately, the last two systems are quite outdated, although they are still popular. In addition, there are a huge number of options for homemade systems. Many owners of motorcycles of this brand make their own ignition for the Ural. Electronic (or contactless) is superior in all respects to the old mechanical model, whose adherents remain only those who support the postulate “the older, the better.”

MBSZ "SoveK"

Sovek LLC has developed and successfully implements a microprocessor-based contactless ignition system for heavy Ural-type motorcycles. This option is suitable for those who do not want to bother with homemade units. The manufacturer promises improved starting in cold weather, increased engine stability by reducing spark asynchrony and optimizing the ignition timing, reducing exhaust toxicity, fuel consumption, stable starting even when the battery is discharged to a voltage of 6 volts, as well as preventing overheating of the ignition coil, which was one of the main problems of old systems. The main components are a modulator and a Hall sensor. Installing the SoveK ignition is quite simple, described in detail in the instructions and will take no more than half an hour.

Care must be taken to ensure that the modulator does not touch the Hall sensor. It is also recommended to replace old high-voltage wires with wires with distributed resistance. Reviews from motorcycle owners are rather positive, although some note a slight drop in power. Since the Soviet motorcycle, which needed to replace the contact ignition with an electronic one, has a rather worn-out engine, it is difficult to say how objective these assessments are. But many owners are very pleased that they installed this ignition on the Ural.

Electronic ignition "Saruman"

The Saruman microprocessor ignition system is another way to quickly and without much hassle replace the outdated contact ignition of the Ural. Manufacturers promise the same set of advantages as the previous system. There are two configuration options: with a Hall sensor and with an optical sensor. The second option is somewhat more expensive, but it is usually recommended, since the optical sensor is more accurate and reliable. However, reviews from motorcycle owners are not as good as we would like, mostly complaints are made about the quality of assembly of parts. Another complaint is that the kit does not include an ignition coil.

Homemade electronic ignition system

The ignition for the Ural, electronic or contactless, can be assembled with your own hands. Such systems are assembled by craftsmen from improvised means. The main components necessary for operation are purchased at the nearest car market - a switch, for example, from a VAZ 2108, a Hall sensor and an ignition coil. The latter is often taken from Oka. Additionally, an interrupt modulator is assembled. The reliability of these systems leaves much to be desired, since the ignition timing is not always correctly adjusted in them.

The quality of the interrupt modulator is very important for such systems, but since high-precision tools are not available to many craftsmen, this negatively affects the result. Since for many Ural owners their motorcycle is not so much a vehicle as an object for technical experiments, sometimes very worthy examples appear.

Features of the electronic system

If you prefer to service your motorcycle with your own hands, then this ignition for the Urals will be an ideal option for you. It is much easier to maintain. There is no need to adjust the gaps on the contacts, which significantly reduces the time of service work. Also, the ignition timing does not change during operation.

Also, a huge advantage of this ignition option for a Ural motorcycle is that the spark plugs last longer. Thanks to more efficient spark formation, the load on them is significantly less.

Immediately after installing the new unit, you will notice an increase in engine efficiency. Fuel consumption is reduced and it becomes more responsive on the road. Also important is the absence of problems at low temperatures and wet weather.