Choosing oil for the internal combustion engine of a URAL motorcycle

Few people know what oils to put into a Ural motorcycle. The Ural motorcycle is considered the most common vehicle in the Russian Federation after cars.

It is ridden by both urban motorcyclists and rural residents. This motorcycle is especially common in the southern and western regions of Russia.

- Brand popularity

- Pros of a motorcycle

- Lubricant selection

- Conclusion

Characteristics of the Ural M67-36 motorcycle

The only characteristics needed constantly throughout the entire operation of the vehicle. No motorcycle maintenance or repair is complete without them. It is not possible to keep all the data in memory at all times, and it is not necessary. It is advisable to always have them at hand.

Refill tanks

Fuel tank – 19 liters. Engine lubricant is poured into the crankcase of a 2.3-liter engine. Oil is poured into the gearbox housing - 1.2 liters. In the main gear - 0.110 liters. The front steering fork is filled with oil - 0.135 liters - into each feather. Oil must be poured into the air filter - 0.150 liters. In the rear shock absorber - 0.105 liters.

Adjustment data

Thermal clearance of valves on a cold engine is 0.05 mm. The breaker contact gap is 0.4–0.6 mm. The gap between the spark plug electrodes is 0.6-0.7 mm. The working gap between the brake pads and the drum is 0.3-0.7 mm. The free play of the brake and clutch steering levers is 5-8 mm. The adjustment gap of the main gear is 0.1-0.3 mm. The free travel of the foot brake pedal is ¼ of the full pedal travel. The pressure in the front wheels and the stroller is 1.5 + 0.1 kgf/cm squared. The pressure in the rear and spare wheels is 2.5 + 0.1 kgf/cm squared. The convergence of the wheel planes over the length of the motorcycle is 10-12 mm. The camber angle of the planes of the rear wheel and the stroller wheel is 1-2 degrees. Installing the headlight (motorcycle loaded): The position of the axis of the light beam of the high beam filament is horizontal. The distance between the upper boundary of the spot on the screen from the low beam filament and the projection of the center of the headlight onto the screen at a distance of 10 meters is 10 mm.

Return to contents — ↑

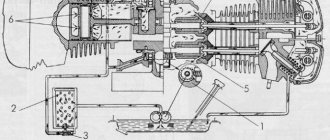

Motorcycle engine diagram Ural m67-36

1 - generator; 2 — camshaft; 3 - pusher; 4 — pusher guide; 5 — sealing cap; 6 — pusher rod; 7 — tube (casing) of the rod; 8 - cylinder; 9 - piston; 10 — cylinder head; 11 - valve; 12 — valve spring; 13 — adjusting bolt; 14 — rocker arm axis bracket; 15 — lock nut of the adjusting bolt; 16 — rocker arm; 17 — rocker axis; 18 — head cover; 19 — cylinder head mounting pin; 20.23 - gasket; 21 — rocker axis stand; 22 — oil drain channel from the cylinder head; 24 — cylinder drain pipe for oil; 25 — compression rings; 26 — piston pin; 27 — oil scraper rings; 28 — connecting rod; 29 — roller bearing; 30 — crankshaft pin; 31 — engine crankcase; 32 - pallet; 33- oil pump; 34 — crankshaft cheek; 35 - oil catcher; 36 — cylinder fastening hook; 37 — carburetor; 38 — candle tip; 39 - high voltage wire; 40 — filler plug with dipstick; 41 — driven gear of the oil pump drive; 42 — oil pump drive plug; 43 — oil pump drive gear.

Return to contents — ↑

Oil in box

pedestrian Thu, 02/19/2009 — 13:05

Focus, (https://www.liquimoly.ru/components/), (https://liquimoly.ru/catalog2008/Hochleistungs-Getriebeoil_(GL-4-GL-5)__75W-90.html), read here) ), and also add (https://liquimoly.ru/catalog2008/Getriebeoil-Additiv.html) I recommend)) What is the difference between gear oil with the API designation GL-4 and GL-5?

Answer: The API designation of a specific oil helps the consumer choose the right gear oil for their vehicle. Currently, the accepted API marking includes 5 GL categories: GL-1, GL-2, GL-3, GL-4, GL-5, respectively. There is also a category GL-6 or MT-1, but it is not widely used in Europe. An increase in the GL index means an increase in the load on the structural elements of the gearbox and differential and, accordingly, an increase in the number of additives that provide wear protection. Oil with the lowest category GL-1 is intended for non-synchronized gearboxes with light loads and is typically used in certain types of trucks. GL-2 oils belong to the category of industrial gear oils and are widely used in vehicles with classification according to API GL-4 and GL-5. Their main difference, as already mentioned, is the number of additives: GL-5 has more of them than GL-4. Since additives are chemical compounds of sulfur and phosphorus that are aggressive towards copper alloys, GL-5 oil can cause corrosion of structural elements of the box, in particular synchronizers designed for the use of GL-4 oil, and vice versa, the use of GL-4 oil instead recommended GL-5 will cause rapid gear wear. Therefore, every manufacturer of transmissions and gearboxes must indicate which API-classified oil must be used and you should not neglect their recommendations - this may in the future threaten the repair of an expensive unit. It is worth noting that many manufacturers produce oils with dual API classifications. For example, Liqui Moly produces semi-synthetic oil Hypoid Getribeoil SAE 75W-90 TDL with classification GL-4/5. This means that the oil can be used for transmissions and differentials requiring both GL-4 and GL-5 oils.

What are the filling volumes of the crankcase/box/axle/shock absorbers/forks, etc. on [. ]?

Important points: you need to measure the oil with a dipstick with the plug unscrewed! Those. unscrewed, wiped, inserted, took out, look into the box Uralov IMZ insistently recommends filling with engine oil. Engine oil must be type 20W50 SAE, mineral. Transmission oil is poured into the gearbox. M8 is not an oil, don’t be mistaken about that. It is suitable for lubricating door and window hinges, but it should not be poured into the engine or gearbox. M8 is mentioned in the Guide because there was no other one before. Don't ruin your equipment.

With an enlarged sump, the crankcase capacity naturally increases

According to the table: Shock absorber capacity for models for which it was not specified is 0.105 liters. (oil MGP-10 or I-12A) Fork leg capacity for models for which it was not specified is 0.135 l. (engine oil)

In URAL how much oil to fill in the engine and gearbox, someone tell me,

12 comments to “URAL oil for engine and gearbox.”

ENGINE 2 LITERS PER BOX 900 GRAMS

What kind of oil should I use? Preferably not an expensive one.

Follow the dipstick into the engine! Into the box until it drips from the neck where you pour it! I use diesel and it’s fine!

You put diesel in both the engine and the gearbox.

Mine is better than the M8, it doesn’t work on anything. even semi-synthetic lil

Not only diesel in the engine, but transmission in the box and axle!

Sergey, it’s better not to put diesel in the engine..

We pour water in ZIL at work and it’s fine!

I’m just an acquaintance who also used diesel, then there was such a mess in the engine.. I had to wash the filter, change it, etc. now he drives a car

Vladimir, come on, my dad has been driving a diesel engine for 20 years and has nothing, and I’ve been pouring water for the 3rd year and nothing wakes him up!

Smoke the manual people, everything is said and tested there. 10w40 in the engine and gearbox, transmission in the axle. Well, at the very least, you can put a diesel in the box, but not like a transmission, the box is designed in such a way that the 4th gear will be poorly lubricated and the gears on the secondary shaft will also be poorly lubricated, as a result the gear will stick and end up in the asphalt.

In the engine 10W40 motor, in the box and axle 70W90 transmission

content .. 41 42 46 ..Front fork of Ural motorcycle

IMZ-8.103-10

The telescopic front fork with internal springs and a double-acting hydraulic shock absorber (Fig. 22) consists of a steering column rod 8 with a bridge 16, a yoke 3, two stays with shock absorbers and a steering shock absorber (damper).

The steering column rod serves to attach the fork to the frame head on two support ball bearings. The lower end of the rod is pressed into the bridge, and its upper end is clamped in the frame head with a nut that tightens the bearings.

The crossbar is placed on top of the conical ends of the pipes of 24 fork legs and is attached to the rod with a nut. The fork leg tubes are inserted into the two side split holes of the bridge and secured with coupling bolts.

The fork spring softens shocks transmitted from the wheel to the frame. The lower end of the spring is screwed onto the nut 35 of the shock absorber tube, the upper end is screwed onto the upper tip 12 of the spring, placed on the rod, between the limit nuts. The spring connects the movable part of the fork (tip 25 of the fork leg) and the fixed pipe 24 of the fork leg and can work in both compression and tension.

An oil shock absorber is installed in each front fork leg to dampen vibrations. It consists of a tube 27, a rod 34, a tube nut 35 and a lower shock absorber guide 31. The tip 25 of the pen is filled with oil, the level of which should be above the lower guide. .

The shock absorber body is secured with a bolt 29 to the base of the fork leg tip. There are holes at the bottom of the shock absorber housing to allow oil to pass into the shock absorber.

The upper end of the rod is screwed into the tightening nut 11 of the feather tube. The lower shock absorber guide 31, which has the shape of a square with rounded corners, is attached to the rod from below with a nut. Above the guide there is a shock absorber piston 32, made in the form of a plate with a hole in the center. The edges of the piston fit tightly to the inner surface of the shock absorber tubes. The upward movement of the piston is limited by pin 26. At the moment when the piston rests against the pin, oil passes freely from bottom to top through the gap between the piston hole and the rod.

Nut 35 of the shock absorber tube serves as the upper guide of the rod and is a glass with a calibrated hole. The shock absorber body moves with the wheel axle.

135 cm3 of engine oil is poured into each fork leg through unscrewed tightening nuts 11. To remove oil and wash the fork legs, you need to unscrew and remove the tips (see section 9, page 89).

When assembling the front fork, it is necessary to ensure that there is a gap of 0.2-0.5 mm between the tips of the spring and the nut that locks the tightening nut of the airfoil tube, ensuring free rotation of the tightening nut with the rod.

Steering shock absorber. The motorcycle is equipped with a friction-type shock absorber (see Fig. 22). It consists of two steel washers, movable 37 and fixed 39, two friction washers 17 and a tightening bolt 7 with a head. Friction between the steel and friction washers makes the front fork difficult to turn.

The degree of tightening of the steering damper is selected depending on the road condition and driving speed. When driving at high speed, especially on uneven roads, the tightening bolt must be tightened; When driving slowly or with frequent turns, the bolt is released, since a tightly tightened shock absorber makes it difficult to turn the steering wheel.

The bearing tightening must be adjusted in the following sequence:

hang the front part of the motorcycle so that the front wheel does not touch the ground;

Unscrew the tightening bolt of the steering shock absorber, remove the spring and support washer, supporting the shock absorber washers with your hand;

by rocking the front fork (up and down) by the handlebars or by the tips of the stays, determine the presence of play.

If there is play in the bearings, you need to loosen the nut 4 of the steering column rod, move up the yoke 3 with the nut, having first loosened the tightening nuts of the fork legs, tighten the nut 9 of the bearings until it stops, and then loosen 1/6-1/8 of a turn. Check again for play in the bearings.

Rice. 22. Front fork: 1 — protective washer; 2 - oil seal;. 3 - traverse; 4 — steering column rod nut; 5 — support washer; 6 — spring washer; 7 — long bolt; 8 — steering column rod; 9 — bearing nut; 10 — upper angular contact ball bearing; 11 — tightening nut; 12 — upper spring tip; 13 — casing sealing ring; 14 — feather casing with headlight bracket; 15 — coupling bolt; 16 — steering column bridge; 17 — friction washers; 18— spring; 19— oil seal cuff; 20 — oil seal cuff; 21 — oil seal spring; 22 — opera ring; 23 — upper bushing; 24 — fork leg pipe; 25 — tip of the fork; 26 - pin; 27 — shock absorber body tube; 28 — shock absorber housing cone; 29 — shock absorber mounting bolt; 30— lower bushing; 31 — lower shock absorber guide; 32 — shock absorber piston; 33 — spring ring; 34 — shock absorber rod; 35 — shock absorber tube nut; 36 — oil seal housing; 37 — movable washer; 38 — lower angular contact ball bearing; 39— stationary washer of the steering shock absorber; 40 — head frame pipe; A - sub-piston cavity; B - supra-piston cavity

content .. 41 42 46 ..