It won't start and throws gasoline into the air filter, what's the reason?

- ministerial June 12, 2012 11:23

the valve is burnt out, does not close in time (timing marks are knocked off) or is jammed

- lockhart June 12, 2012 11:36

ministerial, the new valve is not clamped; the timing belt is set according to T on the rotor and according to JL in the head and still such a problem ((

- minsk June 12, 2012 11:40

It was. Reduce the gasoline level in the float chamber

- lockhart June 12, 2012 12:04

minsk, and what will this give me? I have no way of getting gasoline to the valve!

- usher June 12, 2012 12:17

lockhart, then the valve will suit you.

- usher June 12, 2012 12:20

Is this after disassembling the head?

- lockhart June 12, 2012 12:22

usher, yes, the exhaust valve was changed and, in principle, why can the moped valve not even pass 1000 yet!

- usher June 12, 2012 12:25

lockhart, It’s possible that your sprocket turned in the chain during assembly. In this case, the intake valve will close at the wrong time for a split second and when the piston moves upward, the mixture is simply partially thrown into the filter.

- lockhart June 12, 2012 12:26

usher, the fact of the matter is that not partially but completely the gasoline does not get into the head, but how to fix this screw-up, otherwise I completely threw off a star (

- usher June 12, 2012 12:28

lockhart, ha. Here it is possible that you have mixed up the beat. when you re-set the marks, insert a screwdriver into the hole for the spark plug and catch the top dead center. In this position, place the marks. On the gene it looks like a “T”. I don’t remember exactly.

- usher June 12, 2012 12:31

lockhart, the valve type has changed places.

- lockhart June 12, 2012 12:35

usher, but they’ve already done everything and he still throws it away)

- usher June 12, 2012 12:36

Did you remove the filter and try it by hand?

- usher June 12, 2012 12:38

lockhart, The plan is to put your hand on the nozzle and try how it shoots the mixture?

- usher June 12, 2012 12:39

Have you checked the valve seal for tightness with gasoline?

- lockhart June 12, 2012 12:41

usher, for some fucking reason, oil gets into the combustion chamber and onto the piston itself, on its surface, there’s a kind of coating, and when I took apart the valve today, I looked between the head and the cylinder and the oil was fucked up

- usher June 12, 2012 12:44

lockhart, Did you change the valve stem seals? How did you grind the valves? Maybe the lapping paste got on the caps? Then they were finished.

- lockhart June 12, 2012 12:46

usher, I changed the cap only at the outlet, ground it in with a drill, the paste shouldn’t have gotten in, the mark doesn’t clearly stand in the head either lower or higher, but the point and the slot don’t clearly match (

Gasoline Gets into the Air Filter, Why Gasoline Leaks and Throws on Scooters, Mopeds and Motorcycles

Check Also

Replacing a silent block is a job that does not cause difficulties even for beginners and entails minimal costs. For this reason, there is no point in contacting a service station.

A cast wheel on a car is more practical than “stamping”, but in addition it also gives the car an attractive aesthetic appearance. The shapes and colors of alloy wheels are varied.

During operation of a car with a manual transmission, the clutch parts wear out, and because of this, the idle speed of the drive of the clutch release mechanism changes. Therefore, every car has a .

How to tint headlights with film yourself? Advantages and disadvantages of the film method Tinting the headlights will help give your car a unique, sportier and more original look. This is a fairly common type.

Molding on a car door: how to remove, install, why it is needed Design is the first thing drivers pay attention to when buying a new car. It is created in

Replacing the vacuum brake booster on a VAZ 2108, VAZ 2109, VAZ 21099 Vacuum brake booster - it is attached to a bracket to the engine shield (This is the shield that .

We independently change the timing chain on a Mazda 6 car. The timing chain is the main element of the device. And although the chain is considered a more reliable component than the belt, periodically.

We sharpen the brake discs with our own hands without removing them. The most important thing for ensuring safety when driving a car, without a doubt, is the braking system. And the condition of the working surface of the brake discs.

The movement of any vehicle begins with the start of its power unit, therefore, to carry out this procedure, it is necessary that the starting device, in particular the starter solenoid relay, is due to.

From year to year, people try to make their work easier, introducing more and more new inventions into life. So once upon a time the spray gun came into our everyday life. .

I want something strange, comrades. make a carbon back cover for your phone. but not like ara-tuning, one layer of fabric and a thick layer of varnish on top. and “for real”, remove with sandpaper.

Detection and elimination of car radiator leaks. How to repair a copper or aluminum radiator If, in a short period of time, there is a decrease in the level of antifreeze in the cooling system of the machine,...

Some car owners are not satisfied with the sound of the standard radio. The situation can be corrected by installing an active or passive subwoofer. Installation of the device in a car is possible on your own, for which purpose.

KIA Cerato Koup N-ice (ツ) › Logbook › Damage to springs from autobuffers. Removing part of the bump stop. While studying automotive springs, and in particular STORM springs, .

For many car enthusiasts who love power and speed, the issue of buying a car with a turbocharged engine is very important. In turn, the task of a turbocharger is to supply more.

The appearance of oil in the spark plug wells Priorities: causes and solutions Any problems in the car must be repaired immediately, otherwise complications may follow and as a result.

No responsible motorist would argue that brake pads are one of the most important parts of a car. They are installed on all wheels and.

Self-replacement of rear suspension springs: signs, tools and algorithm of actions The suspension of a modern car consists of many elements and parts that are complex in design. They all have .

Causes of popping sounds in the injector air filter

The use of gas helps to save money; the cost of re-equipping a vehicle quickly pays off. Malfunctions in the machine system, as well as inept driving, give rise to a number of questions, the most common of which is the problem associated with the appearance of pops in the injector air filter

.

Characteristic sounds can be the result of many reasons, some of which relate to the mechanics of the vehicle, others to the car owner’s lack of understanding of the combustion process. The article examines some of the problems and provides recommendations for eliminating defects.

The locking needle is worn out and does not perform its functions

Due to a worn needle, gasoline enters the air filter in the same way as in the case of debris in the carburetor. The symptoms are similar in both cases. Blowing and flushing the carburetor can slightly improve engine performance, but fuel will be thrown into the air filter with the same force.

Diagnostics and inspection of the condition of each element can eliminate the reason why fuel appears in the filter element. In the future, a decision is made to replace components or purchase a new carburetor.

The reason is the ignition

When the damper is opened abruptly, if the ignition timing is not precisely set, i.e. If there is early ignition, then it is felt like cotton in the air filter. Please note: the working mixture is formed in the intake manifold and if the intake valve is open, this liquid ignites not only inside the cylinder, it ignites throughout the entire manifold - this is very bad for the engine. The reasons why cotton occurs are as follows:

- Old candles - see if there is carbon deposits on the candles. Replace with new ones if necessary. Please note: special spark plugs have been developed for gas vehicles; they last longer than usual. If, when replacing spark plugs, lubricant is visible in the well, replace the valve cover gasket. Otherwise, the oil will lead to failure of the spark plugs, explosive wires or coil.

- The valve does not fit tightly due to carbon deposits. Untimely ignition leads to incomplete combustion of the fuel, and a large amount of soot is formed.

- Burnt out valve. With such a breakdown, the car should fire even at idle speed.

- The ignition angle is not adjusted. Check the vehicle dealer's recommendations or contact a service center.

- Use of low-quality fuel.

- Wear, short circuit of explosive wires, incorrect connection. Usually the spark plugs are checked first. If replacing them does not help and the car continues to fire, look at the explosive wires. You can determine where the high voltage goes at night with the engine running and revving up.

The membrane has leaked and is leaking fuel.

The reasons that caused the appearance of holes in the membrane and, as a result, the appearance of fuel in the air filter may be:

- natural wear and tear of the membrane and its physical aging;

- mechanical damage caused by unprofessional repairs;

- Road accident or extreme driving.

A symptom of membrane damage is deterioration of vacuum in the intake manifold and air filter. There is a gradual deterioration in the technical characteristics of the car. It may take more than one month before the iron friend finally stalls.

To determine whether fuel is leaking through the membrane, it is necessary to disassemble the carburetor. Diagnostics is performed by visual inspection.

To repair, you will need to replace the membrane with a new one. Before replacing, you should bleed the carburetor to prevent debris from getting into the jets or under the shut-off needle.

Getting rid of oil in the filter

In order to make sure that oil does get into the filter (or this option is excluded), we recommend conducting an experiment: the crankcase air ventilation outlet must be extended so that it passes below the engine. If after some time the filter is clean, then the problem lies in the ventilation system itself, so you cannot delay in identifying the problem and repairing it.

One of the common practices among drivers when removing oil from the filter is to carefully remove the tube from the breather. The hose is suspended and routed under the bottom. Despite the effectiveness of this method, it should be remembered that its use lengthens the process of warming up the throttle assembly in frosty weather by an order of magnitude.

You can also solve a similar problem by installing another oil deflector under the cylinder head cover. It can be used as a scourer for cleaning the throttle valve, made of metal. You can purchase this simple tool at almost every hardware store. After this simple procedure, the idle speed will become more even, and the problem will disappear by itself.

The most dangerous reason for the appearance of oil in the filter is compression difficulties; all other cases are less serious. However, this does not mean that you can treat them carelessly and not delay troubleshooting. Negligent attitude towards such a malfunction can completely “kill” the engine. Then the driver will have to fork out heavily for major car repairs.

If you want to protect yourself as much as possible from the negative effects of oil in the filter, then regularly carry out preventive maintenance, which does not take much time and is simple. Inspect and evaluate the components of your car to be able to identify the problem at an early stage and quickly deal with it.

For example, if during the next inspection of the filter you find mechanical damage or there are breaks in the cartridge, then immediately replace the filter. The filter should be selected individually, in accordance with the characteristics of the engine of your car.

In conclusion, we would like to add that timely replacement of filters will save you from various types of malfunctions and save a lot of financial resources and effort required for auto repair work. Remember that replacing the filter early can be just as destructive as replacing it late, especially when it comes to a “wet” filter.

Good luck on the roads!

Causes of a malfunction associated with gasoline in the air filter

When using scooters, not all owners think about the quality of the fuel poured into the gas tank. Gas stations skimp on timely replacement of filter elements, so the quality of gasoline will not meet the standards. This is especially noticeable in places remote from megacities.

Debris gradually moves from the gas tank through the fuel system and into the carburetor. If a small grain gets under the shut-off needle, it will not allow it to take its place and will cause an overflow of fuel in the float chamber. After leaving the carburetor it will end up in the filter element.

Also, the reason why gasoline pours out may be excessive wear of the needle or physical aging of the membrane. With a long mileage, abrasion of the metal and its deformation are observed. The needle may get stuck or not close properly. In the case of a membrane, its long-term operation leads to its breakthroughs. In this case, particles of the ruptured membrane can interfere with the normal movement of the locking needle.

There may also be gasoline in the air filter due to the owner’s inability to correctly adjust the screw responsible for the idle speed of the motorcycle. Maximum twisting of it leads to operation on an over-enriched mixture and excessive fuel consumption. Having examined the spark plug of such a scooter, you can find black carbon deposits.

If the carburetor throws out fuel only after starting, the reason may lie in a malfunction of the pre-start enricher or vacuum valve. To successfully start the engine, a mixture with a high gasoline content is supplied at the first moment. The enricher may supply too much fuel, causing the air filter to flood. Loss of elasticity of the vacuum valve membrane can result in too much flammable mixture entering the float chamber by gravity. If additional pre-injection occurs, gasoline will enter the air filter.

Defect elimination methods

In order to delay the moment of spark formation (until the time the starter starts working), a number of devices and techniques have been developed and successfully implemented. One of them is that a special device is installed, the so-called octane corrector

. A device connected to the control unit detects the type of fuel used and adjusts the ignition system accordingly.

The second method is based on the “tricks” of controlling such engines. Before turning off the ignition system, the accelerator pedal is first depressed. As a result, the gas supply through the valve is stopped, and the engine, operating on the residual principle, consumes the remaining volume of gas from the receiver without a trace.

However, these methods for eliminating pops in the air filter of a machine injector

help only when working with a well-regulated system.

Listen carefully to the sounds the car makes when idling and while driving. They will help to identify the malfunction in a timely manner.

The reason for the appearance of oil in the filter housing

Now we can list the specific reasons that provoke the appearance of oil in the air filter:

- tar deposits in the ventilation system pipes, as a result of which excess pressure is created in the crankcase. It is the pressure that provokes the excessive spread of oil and gasoline vapors. This problem is caused by coking, which is formed when a large amount of oil vapor and exhaust gases are mixed. Operating a car with such a malfunction is fraught with squeezed out oil seals;

- a malfunction of the oil separator, as a result of which oil vapors are not fully captured. How to resolve this problem depends on the design of the unit. For example, the oil catcher in front-wheel drive VAZ models is a set of plates located in the valve cover, which, if dirty, can be washed in gasoline and purged;

- PCV valve malfunction, as a result of which crankcase gases circulate only through the reserve channel located in front of the throttle valve, which leads to saturation of the air filter with vapors. You can check the valve yourself. A working mechanism is only blown in one direction. If necessary, the PCV valve can be washed with carburetor cleaner;

- wear of the cylinder-piston group. When the piston rings no longer do their job, an excessive amount of exhaust gases enter the crankcase, which the ventilation system is physically unable to filter and deliver to the intake.

It is worth recognizing that the appearance of oil in the air filter is the prerogative of engines with a poorly developed oil vapor filtration system. In the absence of a PCV valve, the intake tract space before and after the throttle valve is permanently articulated with the crankcase. Therefore, when the CPG wears out, the filter element is saturated with oil vapor for some time after the engine has been turned off.

Debugg

If the problem is not in the PCV valve, then often only a major engine overhaul can solve the problem with oil in the air filter housing. It should be understood that a clogged crankcase ventilation system is a consequence of wear on the CPG, and not the main reason for the air filter being saturated with oil. Therefore, in most cases, cleaning the channels and oil separator only temporarily delays the onset of engine wear symptoms.

You can check the condition of the power unit using:

- measuring engine compression;

- checking the CPG with a pneumatic tester. Compressed air is supplied to the cylinders under pressure. The tester records the approximate amount of air escaping through leaks in the combustion chamber. If you hear a hissing sound from the dipstick hole when air is supplied, then the main leak is through the compression rings, but if the sound of escaping air comes from the oil filler neck, there are problems with the valve guides and valve stem seals.

https://youtube.com/watch?v=EF41K-aDRoU

Preventing Breakage

The sudden appearance of gasoline in the filter after visiting a gas station indicates dirty fuel. You should stop visiting unverified stations. It is also not recommended to buy fuel while replenishing the storage tank, as the flow from the fuel truck pipe lifts all the debris from the bottom of the tank.

When performing adjustment work, you should mark the positions of the mixture quality and quantity screws. To do this, you need to tighten the bolt completely, counting the revolutions. In case of subsequent unsuccessful setup, knowing the preset value, it will be much easier to return to the original state.

Driving should be as careful as possible. Any drop of the scooter may cause damage to the fuel system. Also, rust that comes off due to dynamic load can fix the locking needle, preventing it from taking the required position.

Whatever the reason for the appearance of gasoline in the filter, you should not delay troubleshooting. Operating the engine in such conditions leads to excessive wear of all parts, which increases the need for major repairs. A quick response to the first symptoms of malfunction of the fuel system will save the owner’s wallet from unnecessary waste.

Reasons for the appearance of gasoline in the air filter

In most cases, detection of fuel in the wrong place is a consequence of some other malfunction. In this case, the vehicle may stop starting altogether. The appearance of gasoline in the air filter occurs under the following circumstances:

- during the last trip I fell into a hole;

- the driver forgot to turn off the ignition at night;

- there is a loss of traction, especially at low speeds;

- a decrease in dynamic characteristics, which is especially noticeable when using 50 cc scooters, since they have no power reserve;

- gasoline flows from the carburetor drain hole, both when idle and when driving;

- drops in speed when sharply squeezing the gas handle or accelerator pedal, which is especially noticeable when driving in a traffic jam at a traffic light;

- the gas distribution unit or fuel system, for example, a carburetor, was repaired;

- the engine was running on an over-enriched mixture.

Significant mileage can also cause gasoline to get into the air filter. Physical wear of metal and gaskets leads to the creation of conditions for the occurrence of this malfunction. However, in this case, the engine will gradually start worse and worse, and the strong smell of gasoline from the air filter of a motorcycle or car will not allow the car owner to ignore the breakdown.

Debris that can cause gasoline to enter the air filter

The main sources of debris in the fuel system are:

- gasoline filled at an untested station, especially immediately after the fuel truck has left;

- rust from the inside of the tank, for example, coming off after hitting the gas tank;

- carburetor gasket elements crumbling due to physical aging;

- dirty fuel filter;

- the external environment, or rather a careless attitude towards the refueling process, when foreign debris gets into the gas tank.

This problem is especially relevant for scooters and motorcycles not equipped with fuel filters.

The debris, following into the carburetor, falls under the shut-off needle located in the float chamber. As a result, it does not descend into its seat and is not able to block the fuel channel.

To correct the problem, you need to disassemble the carburetor. After removing the float, remove the needle and put it in a dust-free place. Using compressed air, you need to blow out the carburetor. When reassembling the fuel system, it is important to protect it from debris, otherwise gasoline will end up in the air filter again.

To facilitate diagnostics, if possible, you can install a similar carburetor on your vehicle. If gasoline gets into the air filter even with a new unit, you should continue troubleshooting without wasting time disassembling the carburetor.

What are the signs of a rich mixture in the engine?

You don't need to be an experienced auto mechanic to recognize the signs of a rich mixture - they are impossible to miss and hard to ignore. If your car's engine runs on a rich mixture, you may notice a number of special signs:

- Popping noises and shots can be heard from the muffler, even at idle;

- Black or gray smoke coming from the exhaust pipe;

- The orange “Check Engine” icon on the dashboard came on;

- Computer diagnostics revealed error P0172;

- The dynamics fail - the car is “held back by something”, at the same time it “stumbles”;

- Fuel consumption has increased significantly;

- In the worst case, the car simply refuses to start when cold;

Operating a car with such problems is very difficult, sometimes even impossible. Inexperienced car owners may be frightened by this: images of satisfied mechanics at a service station and sums with zeros are drawn in their heads. The principle of treating a disease at an early stage suits this case perfectly. There is no point in starting this problem. How not to ignore the above symptoms.

Timing phases are knocked out

If the phases are out of order, this can also affect the ejection of fuel from the carburetor. At the same time, the following symptoms are observed.

- The engine starts hard, especially when cold.

- The speed is unstable.

- The spark plugs are constantly black, covered in gasoline.

- When cold, the four-cylinder engine can run on 3 or even 2 cylinders until it warms up to 90 degrees.

- Traction and throttle response disappear, acceleration characteristics deteriorate.

Timing phases

Phases go astray for various reasons. As a rule, this is a rotation of the generator pulley, an incorrect installation diagram, a malfunction of the ignition coil, etc.

Other reasons

For cars equipped with gas equipment, the formation of pops in the air filter is often caused by the failure of gasoline injectors. If the injectors leak, a gas-powered car begins to shoot into the air filter when starting. Plus, when switching from gasoline to gas, there is a need for dual-mode firmware, because the gas RCD is different from the gasoline RCD. It is also possible that the RCD is designed for one type of fuel and when switching to another, it does not work correctly. You can try resetting the ECU; this option is provided for any type of BC.

When installing gas on an injection car yourself, you must take into account the need to place the so-called anti-clap. It screws in between the throttle valve and the bellows connected to the air filter. When a blast wave occurs, the remaining gas escapes through holes located under the anti-cotton elastic band. This design does not allow gas to enter the filter device. Otherwise, a strong gas wave may occur that can rupture the filtration element.

Source

Incorrect operation of the starting enrichment

If gasoline enters the air filter only when the engine is started, you should pay attention to the starter enrichment solenoid valve. Diagnosis is made in two ways:

- The valve is powered directly from the battery;

- Starting the engine when the power supply to the starting enrichment is turned off.

In the first case, diagnostics are performed similarly with a vacuum valve. In the second case, the start will be on a lean mixture, so if fuel is pouring into the filter, then the reason does not lie in the solenoid valve and the search goes further.

Air leak in the intake manifold

If air enters the engine, which is not “seen” by the air mass meter or absolute pressure sensor, a too lean mixture of fuel and air will be formed. This problem is caused by air leaks in the intake tract.

Main reasons:

- overheating of the motor (affects the condition of the gaskets);

- external intervention;

- Damage to gaskets as a result of improper use of carb cleaner.

Very often, difficulties can arise if the seal between the intake manifold and the cylinder head is damaged, since such a leak is not easy to detect visually.

Search for suction in the manifold

On gasoline engines, excess air may end up in the manifold due to depressurization of the air ducts, wear of the rubber seals of the fuel injectors, or damage to the hoses leading to the vacuum brake booster.

In order to find air leaks, different methods are used:

- Shutting off the air supply. It is necessary to disconnect the pipe from the filter housing and start the engine. After this, cover the pipe with your hand - if there is no suction, the engine will stall. If the engine continues to run and you hear a hissing sound, there is definitely a leak.

- Clamping of hoses. You need to start the engine and after a certain time try to hear a hissing sound. If it was not possible to detect the location of the damage to the seal, you need to pinch the hoses connected to the receiver one by one. If you have pinched and released a hose and this has affected the operation of the power unit, look for a problem in this area.

- Compressed air. The intake system of an idle engine must be treated with a soap solution, then shut off the air supply from the filter and pump air through one of the tubes.

- Spraying with a flammable mixture. To find where air is leaking into the engine, use products such as gasoline, WD-40, or carburetor cleaner. Using the selected product, it is necessary to spray all joints. When the fluid appears at the leak point, you will notice changes in engine operation (the speed should rise or fall). It is better to use a medical syringe for spraying.

Using this method, check the following places: the pipe between the valve cover and the idle air control, the pipe between the mass air flow sensor and the IAC, the connection between the intake manifold and the throttle valve, the connection between the manifold and the cylinder head, the injector seals, all hoses in the areas where the clamps are attached.

- Smoke generator. Not all motorists have such a device, which is why it is usually used in auto repair shops. You can buy a ready-made solution or make it yourself (there are plenty of instructions and videos on the Internet). The bottom line is that it is necessary to ensure that smoke is supplied through any hose into the intake manifold. Smoke will seep out in problem areas.

Troubleshooting Methods

Most often, if fuel leaks from the filter, owners rush to change the carburetor. The mistakes of this approach to repair are:

- gasoline may enter the air filter not only due to the fault of the carburetor, so replacing it with a new one may not eliminate the problem;

- ridding the float chamber of debris is not a labor-intensive process and is carried out without resorting to financial costs;

- revising the settings of the quality and quantity screws can eliminate the malfunction without dismantling the carburetor.

Therefore, to correct the problem, it is recommended to adhere to the following action plan:

- If there has been interference with the idle speed or mixture settings, check that they are set correctly;

- Check the operation of the vacuum valve. When closed, fuel should not pass through;

- Check the electronic starter enrichment. After turning it off, you need to test run the engine;

- Remove the carburetor and disassemble it;

- If no significant wear, deformation, or damage is visible, blow it out. If plaque or fallen resins are visually detected, the float chamber will need to be flushed;

- Some fuel system designs include a reed valve. It has low maintainability, especially when made of metal. If any bent is found, it is recommended to replace it with a new one.

It is necessary to change the carburetor only if it begins to throw fuel due to excessive wear. In this case, the vehicle has a solid mileage on the odometer and gasoline begins to be thrown into the air filter not unexpectedly, but gradually with increasing volume. Initially, you can only notice the smell, but over time the amount of fuel in the filter can reach 100 - 150 grams.

Trouble-shooting

What to do if you had to face such problems? Let's go in order. You need to start with the air filter - if there are no problems with it, then proceed to the next steps.

Fuel tap problem?

If gasoline constantly flows from the fuel supply hose, even when the vacuum hose is removed, then the valve is faulty. It simply does not work, but is always in the open position. In this case, the tap must be replaced with a new one.

If, when you remove the vacuum hose, gasoline stops flowing, then the reason is a constant vacuum - you need to climb into the cylinder head.

Locking needle

Provided the faucet is in good working order, you can play the shut-off game. How to get to the needle of a scooter or moped?

- To remove the carburetor, you need to disconnect the air filter; hoses suitable for it; unscrew it from the intake manifold and remove the throttle cable.

- Next, use a Phillips screwdriver to remove the float chamber housing.

- Assess the condition of the shut-off needle and float antennae.

- If necessary, replace the needle and bend the float antennae. If the needle is in good condition, then its seat should be thoroughly washed and blown out.

- Reassemble everything and install it on the engine.

Vacuum accelerator (if all else fails)

In addition to the locking needle, Chinese scooters are also equipped with a vacuum needle (vacuum accelerator). This device also works from a vacuum hose connected to the “carb”. This needle has 5 (usually) adjustment positions. When the scooter accelerates, the vacuum opens this needle and more fuel is supplied to the combustion chamber.

The system is correct, however, everything breaks down. Over time, none of the needle positions produces results. This problem can be solved simply by removing or cutting the vacuum hose (not the one to the fuel tap)! And the engine no longer overflows - miracle of miracles.

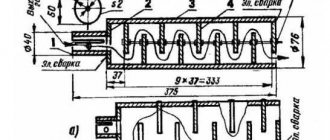

Design and principle of operation

The main principle of operation of the ventilation system is to supply gases from the crankcase to the intake manifold, where they will again be sucked into the engine cylinders. Ventilation is called forced ventilation because the pressure in the intake manifold is below atmospheric pressure, so gases from the crankcase are sucked into the intake manifold during the intake stroke. Schematic diagram of the system operation.

- Exhaust gases leak into the crankcase.

- A mixture of gasoline, oil and exhaust vapors enters the oil separator (oil particles settle on the walls and then fall back into the pan).

- After passing through the oil separator, the purified gases enter the intake.

- A mixture of clean air, purified vapors and gases is cooled in the intercooler, after which it enters the cylinders.

A valve with variable capacity allows for the removal of gases in proportion to their accumulation in the crankcase. As you can see in the figure, the system has a backup channel that bypasses the valve. Since our goal is to figure out how oil gets into the air filter and how to solve this problem, we will not delve into all the intricacies of the system’s operation, as well as its varieties.

Fuel level in the chamber

Most likely, this is due to an increased level of fuel in the chamber. In fact, the strictly recommended amount of gasoline should remain here. As a rule, the level should be 28-29 mm from the top edge of the case.

In more detail it looks like this:

- 28 mm in the middle of the inclined surface on the front wall;

- 29 mm - on the remaining surfaces of the camera.

The level is adjusted using a needle and float. The initial position is an empty chamber, with the float lowered to the bottom and the needle valve open. When fuel enters inside, the float rises and acts on the needle, which blocks access. Gasoline is no longer supplied. The operating principle is the same as on a regular toilet.

Fuel level too high

An overestimated fuel level always threatens to overfill. Gasoline is not sprayed, it flows through diffusers.

On the other hand, why does it hit upward? The flow in the intake manifold is always directed inward, i.e., towards the cylinders. In order for the fluid to change its direction, when the valve is open, the cylinder must go upward, which usually happens when the timing is out of order or the needle valve is stuck.

Main reasons

Similar malfunctions can occur in the engine design of a motorcycle, scooter, walk-behind tractor, and even a regular lawn mower. But since we have an automobile site, we will talk specifically about cars.

There are several reasons for the occurrence of these symptoms.

Most often, motorists are faced with the following factors:

- the oil deflector drain becomes clogged;

- piston rings are stuck;

- rings wear out or become deformed;

- exhaust gas exhaust hoses fail;

- these hoses simply become clogged;

- the air filter itself becomes dirty;

- There is a confluence of several factors.

Now we should briefly go through all the reasons considered. Usually they are observed one at a time. Although it is possible that 2-3 factors simultaneously led to a similar problem. During testing and diagnostics you will be able to understand this.

What to do if oil gets in

If oil flows into the air filter, this most often indicates a malfunction of the internal combustion engine. The deficiencies must be eliminated as quickly as possible before the engine fails. You can determine the reason why the air filter is in oil as follows:

- Check compression in all cylinders individually. 9-12 atm is considered normal. In this case, the compression values in different cylinders should be as close as possible - with a difference of no more than 1 atm. If the results obtained are below the minimum, this indicates serious problems with the engine;

- assess the color of the exhaust gases. If the exhaust is black or blue, the parts of the cylinder-piston group are worn out.

If the compression is normal and the smoke from the exhaust pipe is normal in color, the problem may not be with the engine. It is possible that oil is filling the air filter due to obstruction of the hoses for removing crankcase gases. In this case, it is enough to clean or replace the pipelines. If nothing has changed, you need to carefully check the internal combustion engine and related systems.

If you find that the engine air filter is oily, but you cannot postpone your trip, you can temporarily fix the problem and carry out a full repair after returning. To do this you need:

- remove the crankcase gas supply hose from the filter fitting;

- close the fitting;

- connect a longer hose to the crankcase ventilation so that the lower section of the tube is located below the level of the power unit.

This solution will allow you to use the car for some time without fear that the engine will suddenly fail. After completing the trip, you cannot postpone troubleshooting - major engine repairs will then be very expensive and take a lot of time.

Why the carburetor on a scooter floods: finding the causes and eliminating them

Technology has one bad property - it breaks. The scooter is no exception to this rule. A common problem in operating a scooter or moped is the carburetor, a device that prepares the air-fuel mixture. This article draws attention to the following problem: why a scooter’s carburetor floods.

Causes of malfunction

You can determine that the carburetor is overflowing by several signs:

- Condition of the candle. A dirty spark plug indicates a rich fuel mixture, which means high gasoline content. Even a serviceable or new spark plug may not be able to cope with the flow of fuel entering the cylinder and over time it will become covered with soot, will be constantly wet and the engine will stop starting.

- Gasoline leaks through the air filter. Signs of fuel may be found in the air filter housing.

- Gasoline leaks through the float chamber gasket.

It is worth noting that these signs can appear either on their own or after repairs. For what reasons can the carb overflow?

Failure of the fuel valve

The tanks are equipped with vacuum fuel taps with three outlets. One of them is taking fuel from the tank, the other is supplying fuel to the carburetor. The third outlet is intended for supplying a vacuum hose. When a vacuum is created in the engine, the valve membrane begins to pump fuel.

Advice! If the engine does not start after a long period of inactivity (fuel is not pumped in), in order not to wait for the engine to pump it in, you can remove the vacuum hose on the other side of the tap and create a vacuum with your mouth until the carburetor is filled.

Clogged air filter

If there is insufficient air supply, the scooter may also overflow fuel. You can diagnose the filter for air permeability as follows. Simply disconnect the air filter. If the engine now starts to work correctly, then it is necessary to change the air filter. When the carburetor on a scooter without a filter still floods, “dig deeper”!

Causes of malfunction

You can determine that the carburetor is overflowing by several signs:

- Condition of the candle. A dirty spark plug indicates a rich fuel mixture, which means high gasoline content. Even a serviceable or new spark plug may not be able to cope with the flow of fuel entering the cylinder and over time it will become covered with soot, will be constantly wet and the engine will stop starting.

- Gasoline leaks through the air filter. Signs of fuel may be found in the air filter housing.

- Gasoline leaks through the float chamber gasket.

It is worth noting that these signs can appear either on their own or after repairs. For what reasons can the carb overflow?

Failure of the fuel valve

The tanks are equipped with vacuum fuel taps with three outlets. One of them is taking fuel from the tank, the other is supplying fuel to the carburetor. The third outlet is intended for supplying a vacuum hose. When a vacuum is created in the engine, the valve membrane begins to pump fuel.

Clogged air filter

If there is insufficient air supply, the scooter may also overflow fuel. You can diagnose the filter for air permeability as follows. Simply disconnect the air filter. If the engine now starts to work correctly, then it is necessary to change the air filter. When the carburetor on a scooter without a filter still floods, “dig deeper”!

Locking needle

Briefly about the principle of operation of the float chamber. Fuel enters it, thereby raising the float. The float, rising, lifts the locking needle behind it. When there is enough fuel in the chamber, the shut-off function closes the fuel supply hole.

If the shut-off needle is worn out (the tip or metal body is worn out), then it cannot completely close the supply hole and gasoline continues to flow. The same effect occurs if a speck (grain of sand) gets under the locking needle.

Needle valve

This mechanism, or simply a needle, is designed to maintain a certain level of liquid in the chamber. The valve is installed in the carb body and cuts into it using a threaded connection. It locks and unlocks the hole through which gasoline is injected into the chamber.

Needle valve

In some cases, when using low-quality fuel or when there is an increased level of contamination inside the fuel tank, deposits accumulate in the needle valve. The sticky mass prevents the needle from closing normally, causing the valve to constantly remain open. In such cases, it is recommended to replace the needle valve immediately.