Scooters today are relevant, popular and practical vehicles. People of various age categories can successfully move on them. For most owners, a scooter is their only means of transportation. Other owners use this technique as entertainment. During the operation of Chinese and Japanese mopeds, various malfunctions may occur. One of the common problems that many have encountered is the lack of spark on the scooter. Let's consider possible causes and ways to eliminate this problem.

Often the spark disappears at the most inopportune moment, and the driver is saddened by the stalled engine. Owners of Chinese equipment especially often face this problem.

Troubleshooting

What to do if the hoverboard does not charge? Here are some simple tips for troubleshooting:

- First, disassemble the hoverboard.

To remove the bottom panel, use a screwdriver or screwdriver with the appropriate bit. This will allow you to get to the inside of the vehicle and try to find the problem of poor charging.

The side of the scooter with the charging port is the area you need to work on. Be careful during disassembly. Do not lose screws or washers, or use a drill to remove screws or bolts that will not come loose. There will be several wires directly on the inside of the plastic cover you just unscrewed.

They are responsible for charging the hoverboard: they connect the charger ports and the lithium-ion battery. The other wire line goes to the motherboard. You can temporarily disconnect it to avoid an unexpected power surge (only if the board is disconnected by a connector). If the wires are soldered, it is better not to touch them.

Is there blackening of the wire or oxidation of the contacts, is there a large amount of dust present? This may well be the reason for the device to not work correctly. Accumulations of dust must be removed, damaged wires must be replaced, and contacts must be cleaned to a metallic shine.

Having completed such an impromptu diagnosis, screw the cover back to the hoverboard, tightening all the removed bolts one by one.

They will help you make diagnostics more efficiently and without risk to the scooter. True, it is no longer free.

If, despite all this, your scooter continues to work incorrectly, you will need to contact the manufacturer and request repair instructions. In the worst case, the hoverboard will have to be sent back to the manufacturer under warranty. It may be that the device was initially faulty and will be replaced under warranty. It often happens that a newly purchased hoverboard does not charge.

How to restore starting from the starter

How to start a car with a pushrod

The moped does not start well from the starter, however, doing it from the foot is simple and easy. If the engine does not start well from the starter, you must first check the fuse located in the battery compartment.

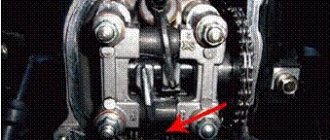

The location of the fuse on the battery is marked with an arrow.

Due to the often poor quality of the manufacture of the fuses, and, consequently, the entire starter, the wire located inside the starter glass bulb can barely touch the contact caps, which is why the fuse contact becomes unsuitable. After the low-quality fuse has been replaced, the moped can be started using the starter.

Reasons for lack of spark

Often, owners may encounter cases of starting failure in the cold season, although the moped drove well in the autumn. Initially, you need to unscrew the spark plug and carefully inspect for spark, oiliness and color.

Carbon deposits on the electrode

There may be no spark, if the electrode is covered with carbon deposits, then they are cleaned with a metal brush. If there is even the slightest doubt about the serviceability of the spark plug, you should replace it immediately, thereby making your life easier in the future.

Acidification of contacts

If the external signs of the spark plug correspond to suitability, and there is also no spark, then you need to check whether there is a discharge. It is worth noting that you need to be extremely careful, as it can give you an electric shock. If there is no spark and the external signs of the spark plug are normal, then the scooter is checked electronically for acidification of the contacts.

Insufficient fuel

If there is a spark, but the moped still has difficulty starting from the starter in cold weather, you should pay attention to the fuel tank. If it is empty, then it is filled. It is worth noting why old gasoline pours out of the carburetor float chamber. How to do it? There is a bolt at the bottom of the carburetor; it is unscrewed, and after all the fuel has flowed out, it is screwed back in. Before putting the moped in the garage in cold weather, fill the tank full of fuel.

Unscrew the bolt and pour out the old gasoline from the carburetor float chamber

If the above has been checked and done, and the scooter does not start well from the starter, then you can make the following repairs:

- The carburetor is removed and the air filter is cleaned;

- The carburetor is cleaned, the jets and channels are purged;

- Everything is coming back together.

Dealing with the candle

If the dio 34 does not start, then first of all we check the serviceability of the spark plug. We unscrew the candle, insert it into the candlestick and connect the ground to it using an additional wire. We pull the kickstarter leg. Let's see if there is a spark.

If it is not there, then disconnect the battery. And again we check with kickstarter for its availability.

If it does not appear, then you can determine the performance of the spark plug on another scooter or using a test gun.

In order not to waste time checking the old spark plug, it is better to immediately take a new one and continue working with it. I always take branded NGK or Denso from the catalogue, it is guaranteed to last for a year, or 5 - 6 thousand km.

When checking, with the battery disconnected, a weak spark may appear. The scooter will even start, but will not develop speed and will not move. The first impression is that the switch is faulty, but there is no need to rush to conclusions.

How to do your own engine repair

For a scooter engine to function properly, it requires the following components: spark, fuel and compression. The main slogan of a scooter mechanic is that miracles do not happen. Remember that in the process of troubleshooting and repairing a scooter, you can find out whether there is a spark and compression, or why there is no fuel flow. Therefore, if the engine does not start from the starter, then some component is missing or is in a faulty condition.

Many people are familiar with the situation when they are not only too lazy to take their scooter to a workshop, but also don’t want to pay for it all. Then you can repair everything yourself.

How to fix a scooter

You will need

- — a set of open-end and ring wrenches, socket heads;

- - screwdrivers with flat and Phillips blades;

- - tester, insulating tape.

Instructions

If the engine does not start, check whether the ignition key is turned to the desired position and whether one of the brake levers is pressed. Check the serviceability of the brake light bulb or its electrical circuit. Look and replace if necessary the fuse in the main electric starter circuit. Check the terminals on the battery. Clean them from oxides, measure the battery voltage and charge if necessary. You can temporarily start the scooter using the kickstarter.

Check the serviceability of the electric starter circuit. Clean the contacts on the relay and starter, test the relay, starter windings and scooter wiring. If the kickstarter spins, check and replace defective kickstarter gears or ratchet gears. Unscrew the carburetor float chamber drain screw. If there is no gasoline in it, clean the gas tap filter and blow out the fuel line, check the serviceability of the gas tap itself and the tightness of the vacuum hose of its control. If the carburetor fuel valve is stuck, remove the float chamber cap and clean the valve seat. If this does not help, replace the valve. Unscrew the spark plug. If it is covered with a layer of unburned fuel, disassemble the carburetor, check the fuel level in the float chamber and clean the air filter. Check the serviceability of the automatic starter enricher and the spark at the spark plug. If it is missing, clean the spark plug electrodes with sandpaper or replace them. If this does not help, check the serviceability of other elements of the ignition system.

If the engine runs unstable, check the tightness of the carburetor inlet pipe and replace the gasket. Replace the crankshaft seals. By unscrewing the drain screw of the float chamber, get rid of the water in it. Blow out the carburetor jets and channels. Replace the gasoline in the tank. Remove the spark plug. If there is water on the insulator and electrodes, get rid of it in the carburetor float chamber by unscrewing the drain screw.

If there is black oily deposits on the insulator and electrodes of the spark plug, replace it with a similar one with a lower heat rating. Check and clean the vent hole in the fuel tank cap. Check the compression using a compression gauge. If it is not within specification, replace the piston, cylinder and piston rings. If there are oily marks on the head and cylinder, replace the gasket under the cylinder head or tighten the nuts securing it firmly and in the order recommended in the repair manual.

If there are extraneous sounds when the engine is running, adjust the thermal clearances in the valve drive of four-stroke engines. Check the tension and adjust the valve timing chain. Replace worn pulleys, rollers and other variator parts with new ones. If the engine stalls when the throttle valve is opened sharply, check whether the engine has warmed up sufficiently, check the carburetor adjustments and its main metering system, and the correct operation of the variator. If the engine does not pick up speed, smokes, consumes a lot of fuel, and a black coating has formed on the spark plug electrode, adjust the carburetor or install a smaller main fuel jet. If there is detonation and white deposits on the spark plug, also adjust the carburetor or install a larger main fuel jet. Also, check for clogged muffler, cylinder bores and ports. Clean them. If the muffler cannot be cleaned, replace it. If the engine begins to lose power while driving, check the fan blades and shrouds on the air-cooled engine. Replace damaged, broken or cracked ones. On a liquid-cooled engine, check for coolant leakage by checking its level in the reservoir. If necessary, replace the water pump, thermostat, radiator.

www.kakprosto.ru

Insufficient fuel

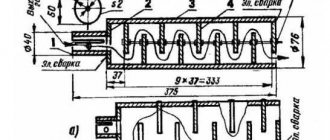

Fuel may not flow due to a jammed carburetor shut-off needle. This is possible when it is clogged, or because the level in the float chamber is out of whack. It is necessary to disassemble the carburetor, blow out all channels and jets with compressed air. You can use a bicycle pump for this. After cleaning, check that the float and the rubber seal on the shut-off needle are intact, and adjust the floats. The position of the floats must be horizontal. Otherwise, by bending the tongue under the locking needle, achieve a horizontal position of the floats on the inverted carburetor. After putting it back together, use a transparent hose to accurately check the fuel level. You can use the VAZ washer hose. by connecting it to the carburetor sump and unscrewing the drain screw, the fuel level should be level with the joint of the bottom cover +/- 2mm as in the figure below:

By the way, if the scooter does not start in the cold, in the morning, or in the fall, then the solenoid enrichment valve is most likely faulty.

Ignition coil

If everything looks intact, check the ignition coil. To do this, disconnect it (remembering how the wires are connected) and use a multimeter to check the resistance of the windings.

The primary winding is made of thicker copper wire. Its terminals are connected to two terminal connectors at the end of the coil. It has a small number of turns and therefore its resistance is low, approximately 0.5-5 Ohms. One wire of the coil is connected to ground - you need to check it, attach one multimeter probe to the nearest metal part of the moped, and the second to the coil connector. The resistance should be close to zero.

The high-voltage coil consists of several thousand turns of very thin copper wire, so its resistance should be on the order of 2-5 kOhms. The resistance must be measured between the coil contact connected to ground and the core of the high-voltage wire.

In this way, we will check the coil for a break, but without special equipment we cannot check for other coil faults, for example, an interturn short circuit, so we will leave the coil alone for now, also because a coil without visible mechanical damage is most likely working.

Breaks in the spark plug cap

This reason can also be considered simple. If there is no spark on the scooter, you should remove the cap and then check its resistance level. After disconnecting the cap from the wire, take measurements. The multimeter probe is inserted into the spark plug hole. The other is attached to the pin that the wires go to. If the cap is working properly, the multimeter will show about 5 kOhm. On most modern scooters, the high-voltage wires, spark plug cap and ignition coil are made one-piece.

All these parts are filled with rubber or compound. Therefore, you can test the cap, wire and ignition coil as a whole. One of the probes of the device is inserted into the spark plug hole on the cap. The second is connected to the ignition coil. This is how the resistance on the primary and secondary windings and the high-voltage wire itself are revealed. The reading on the primary winding should be between 0.1 ohm and 0.4 ohm.

Secondary resistance ranges from 6.35 ohms to 9.7 ohms on most scooters. Sometimes a high-voltage wire becomes unusable. To replace it, you need a cable with a metal core. A car part with carbon filler is not suitable for this procedure.

Let's summarize the above

First, use a light bulb to check whether the switch generates a pulse or not:

- If the light is on, the switch and the modules that ensure its operation are 100% operational

- If the light does not light, it means that the switch or some module that ensures its operation has failed. And to understand for sure that the switch is faulty, we need to check all the modules.

- If the modules turn out to be serviceable, but the switch does not generate a pulse, then it is faulty and you can safely replace it with a new one

In conclusion, I would like to warn you against the temptation to take a known-good switch from someone and plug it in instead of your own. Yes, with this express method the faulty switch will be identified immediately. If it was really faulty, then with a known good one, a spark will immediately appear.

But how can we be 100% sure that the wiring of the scooter is in perfect order and no one has managed to put their smart personality into it before you?.. What if something shorted or some tusk messed up the wiring in his own way and then the working switch will receive a “complete butt”. And then you will buy two switches - one for the person you asked for, the second for yourself. Do you need it?

Posts 1 page 16 of 16

Share12011-08-22 23:47:12

- Author: andrykevi4

- 70cc Visitor

- From: Karaganda

- Registered: 2011-05-25

- Posts: 195

- Gender: Male

- Age: 25 [1994-03-05]

- Time spent on the forum: 3 days 15 hours

- Last visit: 2016-01-22 15:55:53

No spark. Diagnostics and repair of the CDI ignition system.

Frequent questions on the forum prompted me to write this article. Let's start from the beginning, the ignition system of most scooters and mopeds, as well as small-capacity motorcycles (Minsk, Voskhod) is built on the capacitor principle, such an ignition system is called CDI (capacitor). Its operating principle is simple, the ignition coil constantly receives power from the high-voltage windings of the generator (VG), at this time the capacitor is charged, at the moment of a sudden power outage, the VV coil is short-circuited to the housing using a thyristor (key), the capacitor remains connected to the ignition coil, quickly discharging into With its accumulated charge, when the primary winding of the ignition coil (SC) is quickly discharged, the magnetic circuit of the coil (core) cannot maintain induction and dumps its energy into the winding where there is current consumption (along the path of less resistance) into the secondary winding (BB). There are 2 windings on the coil, low-voltage and high-voltage, the high-voltage is connected to the spark plug and has the property of air breakdown, therefore the energy of the magnetic circuit goes into the high-voltage winding, from it to the spark plug, at this moment a spark occurs. The function of the key to turn off the explosive coils is performed by a thyristor; the moment the thyristor is turned on is controlled by an inductive sensor. (Not Hall) The engine is stopped by a violation of the supply voltage or signal from the sensor, that is, when the sensor or explosive coils are shorted to ground, for this purpose a special wire comes out of the switch and goes to the alarm and ignition switch. That's really all you need to know.

The engine will not start, they found out that there is no spark (they unscrewed the spark plug, leaned the spark plug body (thread) against the engine body, turned it with the starter or kick). Let's start diagnostics. We visually assess the condition of the spark plug; usually it is already dripping, which means it is possible that the spark plug has already broken (the spark passes along the top or inside the damp insulator, soot (carbon) is a conductor, and metal-containing additives in gasoline too) and we will not see the spark. We put this candle aside to dry, take another dry one and check the spark again, making sure there is no spark. We check the serviceability of the cap; usually there is a resistance in it that could burn out. The simplest check is to attach the explosive wire directly to the spark plug or bring the wire to the engine body with a gap of 2-3 mm and check the spark. Next, we check and repack all the connectors, these are the wire connectors going from the sensor to the switch, from the explosive coils to the switch, the body (ground) from the generator to the switch, the wire going from the switch to the ignition coil, the connection of the engine housing to the body terminal of the ignition coil. It happens that the spark at start-up is weak or absent; this happens when starting from the starter with a discharged battery and with a large gap between the sensor and the magnetically permeable strip on the rotor. The smaller the gap, the better, but the sensor should not rub against the strip (there will be no spark), that is, we set the minimum gap by calculating the play of the crankshaft bearings, that is, a gap of 0.2-0.5 mm. If a spark does not appear, we dig deeper, take a multimeter and check the resistance of the sensor (200-470 ohms) and the explosive coils (500 ohms-4 kOhms) after disconnecting these wires, I don’t remember the exact data, but this is not so important, the main thing is to show that no break. Next, we unhook the jammer wire from the switch and, with the ignition on, check the resistance between the wire and the engine housing with a multimeter; the resistance should tend to infinity in Ohm mode. If it shows a short circuit, then turn off the alarm, still a short circuit, then disconnect this wire from the ignition switch, still a short circuit - the wire is worn out and touches ground, change it. There is no short circuit - the lock is at fault, we change the lock or install an additional button jammer by removing these wires from the lock and connecting them to the button. If everything is fine, but there is still no spark, then it is further recommended to replace the switch with a known-good one and then the ignition coil. Often a situation arises where there is nothing to change, there is no one to take it from, and it is expensive to buy. I used this method: right at the switch, I stripped the insulation on the wires of the output to short-circuit and ground, tied an LED to these wires and turned it with a starter, if the switch is working properly, the LED flashes at full intensity, if it doesn’t flash, then we change the polarity of the diode and check. If it doesn’t flash at all, then the switch is faulty; if there are flashes but no spark, the short circuit is to blame. We open the cover, get to the short circuit and test the windings with a multimeter. The resistance of the low-voltage winding is 0.3-0.4 Ohms and is measured at the contacts where the wires are connected; the high-voltage winding is up to 20 kOhm between one of the contacts and the high-voltage wire. And lastly, if the continuity test shows that the short circuit is working, but there is no spark, we check the wire going from the switch to the short circuit, as well as the wires connecting the engine housing, the switch and the short circuit. Good luck!

Weight check

If there is any suspicion of a malfunction of any scooter ignition module, the ground is first checked. Although, mass in two-wire wiring is a relative concept, but for now let’s call it that.

We take the tester, switch it to the “continuity” mode (diode icon or sound signal icon), look for green wires on the switch - this is something other than ground (in Feng Shui - negative wire), touch the metal part of the engine with any probe of the tester, with another poke the probe into the green wires:

- If there is mass, the tester will beep

- If the mass is bad, numbers will appear on the tester display

- If there is no mass, the tester will be silent, and the screen will show only zeros

Depending on what the tester shows you, fix the problem or continue testing:

- If the ground is bad, look for a break or oxidation in the wiring

- If there is no ground, look for an open circuit or connect it directly from the engine

- If there is mass, but there is no spark, we continue checking

An example of a good mass: the tester beeps in the “dialing” mode, the display shows solid zeros

Troubleshooting

Malfunctions of electrical equipment and fuel systems are the most regular of all problems that arise among scooter owners.

It often happens that a breakdown suddenly occurs to the scooter. Repairing the carburetor, as a rule, allows you to resume the functioning of your “faithful horse”.

Usually, to do this, it is enough to remove the carburetor, clean the dust from the outside and the tarry deposits of gasoline and other debris inside. Clean and blow out the air and fuel channels and jets, check the condition of the fuel needle and throttle valve, and then reassemble and adjust it.

Fixing more complex breakdowns at home is not always possible, since specific tools are often required that are not widely available.

Thus, for a technically literate person, repairing a scooter with your own hands will not be very difficult if you have minimal knowledge and skills in handling equipment, as well as the necessary tools.

Check by appearance

A serviceable part must be clean. Only slight soot on it is allowed. However, if the electrodes are melted or black, then the spark will not occur. Spark plugs deteriorate if the fuel mixture is too rich. If the insulator is white, but there are small black spots on it and signs of erosion on the electrode, this indicates overheating. This is also evidenced by melted electrodes and insulator in bubbles. If there are oil deposits on the part, it can be considered faulty and it is better to replace it with a new one. This simple DIY scooter repair will help you use this vehicle again.

Scooter won't start

Doesn't spark appear on the wire?

In most cases, a Chinese scooter will not start due to a current leak, that is, a spark does not flow to the wire at all. Experts note that the reason usually lies in insulation, which is missing in a certain place, which leads to the bare part touching the body of the scooter or another place where all the current goes. You need to solve the problem with diagnostics; first of all, inspect the entire high-voltage wire in order to find a bare spot.

If the wiring is intact, the reason for the lack of current will be more serious. Current will not flow to the spark plug for the following reasons:

- broken switch;

- ignition sensor is broken;

- The ignition coil is faulty.

The three above parts are the main ones in generating and supplying current to the spark plug, so any damage to them threatens to prevent the 4t scooter from starting. But if there is a spark, but your scooter does not want to start, move on to the next step - checking the fuel system.

Checking the fuel system

It is gasoline that plays the most important role in whether the scooter will start or not, so sometimes certain factors affect the supply of fuel to the carburetor and the engine itself. Fuel can be supplied either insufficient or in too much quantity, which in any case affects the performance of the scooter. The process of diagnosing the fuel system begins with the gas tank; check the presence of gasoline, its supply, and whether the hole is clogged.

After checking all the fuel lines and the valve for operability, we proceed to diagnosing the carburetor

This is often the cause of improper fuel supply; it is important to keep the carburetor in a fully tuned state without any dirt or other debris. Clean the carburetor and blow out all its channels, you will also have to adjust all the jets

If your 4T scooter does not start after cleaning the carburetor, you are most likely getting too much fuel.

If an excess of fuel is detected, you will see that the spark plug is quickly flooded, this does not allow a spark to form. You can verify this after diagnosing the fuel pump. If you disconnect the fuel hose and start the scooter with the kickstarter, a uniform amount of gasoline should come out of the hose. If the fuel pump does not work, the flow of fuel is uneven and there is too much fuel, replace or clean the pump.

Other reasons

In general, there are many reasons why a 4t scooter is difficult to start; this may be due not only to the fuel system and ignition; experts also point out that sometimes the scooter does not work due to a damaged CPG or lack of compression. If there is no compression, the piston will not create the necessary pressure to start the engine. In some cases, simply replacing the rings on the piston helps; in more advanced cases, you will have to replace the entire CPG.

General diagnostics

If the moped engine stalls, you should first find out why this happened. Indeed, among the main reasons why an engine stalls on the road or refuses to start, only two are the lack of fuel or the inability to ignite the mixture. Often, during the first diagnosis, it turns out that there is gasoline in the tank, and the fuel mixture is supplied to the cylinders due to vacuum. And therefore, the reason for everything is that the spark on the scooter disappeared. To verify this, you simply need to unscrew the spark plug from its standard hole in the cylinder head. Then it is inserted into the cap, its end is applied to the motor body.

Next, start the engine and look at the electrodes. You should also check the element not only for the presence of a spark, but also for the condition of the electrodes. The candle can be dry or wet. If the electrode is wet, then the fault is not the power system and carburetor, but the lack of a spark. If there is no spark on a 4T scooter, the reasons may be different. We will look at the most likely ones below.

Principle of operation

Why won't my scooter start? There can be many reasons for this - from a small malfunction of the engine to a serious breakdown. A moped differs from other types of vehicles in that it is an economical mode of transport. A typical average scooter has a 50cc engine, which is unable to burn too much fuel while driving. This explains the fact why it cannot reach very high speeds. The maximum he can do is move at a speed of no more than 60 kilometers per hour. At the same time, the safety of the moped driver is at risk, since no side safety bars are provided here, as on full-fledged motorcycles. But the reliability and simplicity of the design of this relatively cheap vehicle are so convenient for everyday use that the scooter has always been, is and will be popular among the people.

But even the most unpretentious equipment sooner or later begins to act up and let down its owners. And then one fine day you are faced with the fact that the scooter will not start. This may be due to careless handling, lack of timely technical inspection, as well as objective extraneous causes, consequences of an accident, and the like.

Solutions

This problem can be resolved in two ways. For example, use the kick starter located on the left side near the engine. Pressing it will activate the remaining energy in the generator, and this small dose of energy will start the battery. This charge will not last long, but will allow you to get to the nearest place to charge. The generator's armature and brushes store enough energy to revive the battery. But this is not the only way to “save” the battery:

- if the scooter does not start (there is a spark, there is gasoline), just charge the battery for several hours. The current level should be similar to that in the battery. Otherwise there is a risk of the battery burning out.

No spark on scooter

scooter: 4t, 80cc. no spark. changed: switch, armored wire, spark plug, generator, relay regulator! in short EVERYTHING.

still no spark! what to do??

Is voltage supplied to the coil from the switch? did you change the cat?

It seems the hall sensor is lagging)

I'm sorry, of course. but you can read. read the advertisement again. “in short, EVERYTHING. "

EVERYTHING RELATED TO ELECTRICAL. That's why I'm writing here.

I also changed the sensor!! 3 pieces!! 3 generators! switches, etc. killed the whole day! and I didn’t make them.

let's look at the diagram and see if according to the diagram, the black and white wire that goes to the switch to ground is not shorted when it is turned on

I looked at the wires! everything seems to be normal. started after winter. everything worked before! Then I replaced the engine wedge and reassembled it after the winter. I'll try it now. no spark blah((

No. but the generator is working! I took it off another scooter! everything is ok there! and filmed everything from another working scooter. how to check? how much of what should there be??

A friend of mine was looking for a spark for a week, but the reason turned out to be trivial - the connector on the commutator was not connected properly. and by the way, it’s one thing that you looked at everything, but it’s another thing if you double-checked everything!

Well, I'll take a look at this tomorrow. and so idk. Looks like I checked everything.

I, too, was looking for a spark, the scooter sat for almost half a year, just like you bought spare parts, but I removed the signaling and a miracle happened. And if there is no current from the generator, check the power supply.

But I don’t have an alarm system anyway)))) and I set it anyway! ta ok masa. I don't know what's wrong with him!

Call Father, let him sanctify him, cast out the evil one. But seriously, I don’t know what could happen to him, he’s just a poltergeist. This may be stupid, but I'll ask anyway. Do you completely replace the generator with magneto or do you not remove the magneto?

how is it possible without removing the magneto!! remove the generator. blah. What are you talking about?

Damn confused))) sorry

I tried 3 generators!))) my friend and I got really fucked up..

Did you call the wiring tester? I apologize if every posting has already been rung.

Checking the Zener diode

Before moving further, you need to once again verify that the zener diode is faulty.

To do this, remove the connector from the lock and use a meter (2 kOhm included) to measure the conductivity at the two outermost contacts. It should be like on a diode: if you swap the probes, then in one direction it will show 0, and in the other it will show resistance. If this is not the case, then the zener diode is definitely faulty.

Feel free to disassemble the ignition switch.

You will need the following tools: a T10N bit, a small key for a 6.5 mm bit, a soldering iron.

With the zener diode unsoldered, go to radio stores and buy a couple just in case. They are available everywhere and cost around 10 rubles.

We solder the zener diode, assemble the ignition switch, and connect the connectors. We connect the battery, turn on the ignition and again measure the voltage on the pink wire. It should be 8 - 9 V.

We look at the spark on the candle. If it is, then screw the spark plug into place, start the engine and ride all summer.

And if there is still no spark, then we look further and check: the ignition coil, Hall sensor, voltage regulator - rectifier, generator, switch. But more on that in the next article.

Subscribe.

Write how it works out for you, we’ll discuss it together.

Bye everyone.

Chinese scooter lovers club

Chinese scooter lovers club forum

Time zone: UTC + 3 hours [Summer Time]

Forum Rules

If your question concerns a malfunction of your scooter, or you have any difficulties with operation or tuning, first indicate: Model and manufacturer of the scooter: Engine model: Engine stroke and estimated volume: After that, explain the essence of the problem. Don’t forget, the title of the post should reflect the essence of the problem as closely as possible.

We are trying to start the engine

So, we figured out why the spark plug on the scooter floods. The repair methods and starting methods below apply to scooters with 2T and 4T engines.

- The method is suitable if there is no tool. If you flooded the spark plug while trying to start the scooter, then give it time to stand for about 5 minutes. Then turn the gas handle all the way and turn the engine with the starter for about 10 seconds. You can use the foot several times if the starter is faulty. Release the throttle and try to start the engine again - it should work.

- If you have a spark plug wrench, you should unscrew the spark plug and warm it up over a fire, after cleaning it from carbon deposits. With the spark plug removed, you should “blow out” the cylinder by rotating the engine with the starter or foot. Screw in the spark plug and try to start. If unsuccessful, the spark plugs should be replaced.

Piston problem

The scooter does not start for this reason. Very often, problems can occur based on wear of the piston complex. An internal combustion engine (two-stroke or four-stroke - it doesn’t matter) consists of several parts: a cylinder, a piston and its pin, as well as piston rings. Worn and worn parts cause the engine to lose power and then break down completely. It is not necessary to buy a new cylinder, since the old version can be restored or bored. It can be made higher than zero. This saves a lot of money.

When replacing it, it is advisable to purchase all components of a new piston in one set. This is necessary so that wear and tear occurs evenly in the future, and not in parts. The piston, like the rings and the pin, must work synchronously. Then the likelihood of your vehicle breaking down will be significantly reduced.

Any breakdown in the case of an inexperienced driver can seem catastrophic, especially if we do not see explainable reasons for what is happening. However, a minimum of knowledge and skills will help to identify the reason that prevents you from starting a scooter and leading a full motorcycle life. Contact a specialist at a car repair shop or try using the recommendations above - any problem can be solved.

Now you can stock up on the information received and figure out in time the reasons why the scooter does not start, and take the necessary measures to resuscitate it on your own in your personal garage or under the supervision of an experienced friend.

So, we have found out the main causes of moped breakdowns and how to fix them yourself. At this point, the main question of the article “why the scooter does not start with the starter” can be considered closed.

Switch

Even a beginner will find its location. This is a plastic box with a terminal block. Multi-colored wires are connected to it. The switch is necessary to control the operation of the ignition system. Both the switch and the ignition coil are made non-separable. If the element fails, then the problems can only be solved by replacement. The price of these parts is low - up to 500 rubles. Some service stations have special instruments that allow you to test the switch. However, in order to avoid searching for the appropriate services for a long time, the easiest way is to purchase a new switch. In the process of searching for the reason for the failure of the switch, you do not need to listen to “experts” who claim that the failure occurred due to driving without a battery. This is an unreliable opinion. The fact is that in modern scooters the power supply system and the ignition system do not depend on each other in any way.

Failure of ignition system components

This is not a common reason. But if the spark on the scooter disappears and there are no visible reasons, then it is necessary to test the switch, coil, and generator winding. You can check all these devices with the same multimeter. To make sure that the winding and pulse sensor are working properly, you need to connect one tester probe to the wire from the sensor, and the second to the engine crankcase.

A normally operating pulse sensor has a resistance of about 500 ohms. The generator winding resistance is two to three times less. If the multimeter shows infinity, then one of the components has failed. It should be replaced with a new one. If the value is less than 150-200 ohms, then the problem is in the supply coil, and therefore the spark is lost on the scooter. What to do in this situation? Buy a new generator. Such a device can be repaired, but if there is no time, it is better to simply replace it. Fortunately, the cost of the generator is low.

Let's continue to figure it out

We remove the beak. It is secured with three bolts at the front, four self-tapping screws on the other side under the steering wheel, and two clips at the bottom, on the wheel side.

We get to the switch (with a 5-pin connector), the ignition switch (with three wires - two red, one pink) and the voltage regulator - rectifier.

We measure the voltage. Connect a charged battery to the scooter. We take a multimeter (tseshka) and set it to “V -” 20 V. Normally, when the ignition is turned on, the two red wires are closed together, +12 V on them,

and on the third pink one it goes through a zener diode to the switch 8 - 9.3V.

If the pink one shows 12 V or 0 V, then the fault is in the ignition switch, namely the zener diode has failed. And not a switch, as it seemed at first glance.

What to do if there is no spark on the scooter?

Your scooter's engine suddenly stops, what should you do? Don't rush to panic. First, check if there is gasoline in the tank. If the reason is not due to running out of fuel, the problem must be looked for in the ignition system. The first thing that comes to mind is that the spark plug has gone bad. In this case, it is recommended to have a working candle in stock.

By the way, you can determine the condition of a candle by its appearance. A normal candle has no external changes. Minor electrode erosion and small deposits are acceptable on its surface. If you see the formation of dry black carbon deposits on the spark plug elements, it means that carbon contamination has occurred as a result of an overly enriched fuel mixture. The spark plug should be cleaned or replaced, and the working mixture adjusted. The air filter will also need to be replaced.

Overheating can result in melted electrodes and bubble formations on the insulator. Using such a spark plug can cause serious damage to the engine.

Another cause of spark plug malfunction can be oil contamination. The appearance of such a candle is clearly visible in the photograph. Typically this occurs in two-stroke engines. These spark plugs need to be replaced.

Spark plug condition

So, install a spare spark plug and start the engine. Did it work? Great! But if there is no spark on the scooter, but the spark plug is working, most likely the problem is in the ignition system itself. Therefore, we will have to look further for the reason.

The simplest and most accessible reason for self-repair may be lack of contact. In order to find out, we check the connection points of the terminals and the integrity of the wires.

Then we begin to study the electrical circuit: electric current flows from the generator to the switch, accumulating in the capacitor. The latter transmits a signal to the ignition coil, where the voltage increases several thousand times and, traveling along a high-voltage wire, enters the spark plug, bypassing the cap. Be careful not to touch your finger to the area where the spark should come from - this is a high voltage area.

A wire is pulled from the electromagnetic sensor in the engine or from the switch to the ignition switch to turn off the engine. When the engine is turned off, the wire shorts to ground and the spark goes out. To check whether this is the reason for the lack of a spark, you should find two contacts on the ignition coil: ground “-” and on the switch “+” (do not confuse it with a high-voltage wire!). The contact going to the commutator is disconnected, after which the resistance between the ground and the coil contact is checked, and then between the ground and the commutator.

Scooter engine

During normal operation, there should be a lot of resistance in both cases. If the resistance on the coil is insufficient, it needs to be replaced, and if the resistance on the wire is low, most likely the reason is in the switch.

If the above steps do not reveal any defects, most likely the problem is in the electromagnetic sensor or generator. These items are checked depending on the scooter model.

If, when checking, all of the listed elements operate normally, the switch is most likely faulty. To check its operation, you will have to go to a workshop, since this is impossible to do in a garage.

To carry out the above steps, you will need a multimeter with resistance measurement mode. Judging by the description, all this is very simple, but what to do if there is no spark in the scooter, and you have never seen a switch, a generator, or a coil, and you don’t have the slightest idea about them?

What do the ignition system elements look like?

Of course, in different scooter models, the type of elements in the ignition system may differ slightly. But basically, they all have common features. So, remove the plastic panel and take a look. The switch is a miniature plastic box with a connector. 5-6 wires with colored insulation are connected to the connector.

The thickest high-voltage wire comes from the spark plug. It leads directly to the ignition coil.

Condition of the spark plug and its malfunction

The simplest way is external verification. If it has a normal color and looks natural, the part is most likely working. Signs of use such as erosion and sediment from long-term use are acceptable. When a vehicle's fuel mixture becomes too rich, the result affects not only the engine, but primarily the spark plug itself. Thus, black dry deposits appear in some areas. , as well as replacing the air filter, will help correct the situation Do not use a dirty or damaged spark plug, otherwise the engine will not operate properly and will soon need repairs. This is one of the reasons that answers the question of why there is no spark on the scooter ?

There have also been many cases when the wrong amount of oil entered the engine, which contributed to the contamination of the spark plug. It is easy to distinguish carbon deposits from oil contamination; examples are in the photo. And according to statistics, such malfunctions occur precisely with 2t scooters that have an oil pump. Immediately replace the spark plug in the oil with a new one.

Power check

In order for a spark to jump between the spark plug electrodes, the commutator capacitor must be charged from something. And it is charged either from a battery or from a generator. Means what? Right! We check whether power is supplied to the switch.

Before you start measuring power, let’s determine what type of switch is on your scooter. Visually, switches of the DC CDI type are twice as large as AC CDI. But this is not an exact criterion. The most accurate criterion is to look at the output of the high-voltage coil of the generator:

- If it is not activated, it means that your scooter is equipped with a DC CDI type switch

- If enabled, then vice versa - your scooter is equipped with an AC CDI type switch

The output of the high-voltage coil of the generator is located in the same place as the output of the generator itself: we are looking for where the wires coming from the generator are connected to the on-board network of the scooter and if one of the two wires with round terminals is not connected, then the coil is not activated

Sequence of repair actions

The main rule for detecting malfunctions and repairing a scooter is to step-by-step eliminate the elements of the system when identifying the causes of a breakdown in any of them. Search and repair, especially when starting from the starter, must be done in accordance with a strict sequence, where the chain may act as the beginning, and the end, for example, if there is or is no spark. It is worth noting that you do not need to immediately run for a new switch for the scooter, first make sure that the generator is functioning perfectly, only after that test the wiring if there is no spark, etc.

Checking Basic Systems

It is important to remember that gasoline has the ability to lose its properties if it sits in cold weather and may not even ignite. Also, before making a final diagnosis and starting to repair the moped, if it does not start from the starter, you need to make sure that the spark plug can do its job and the carburetor is functioning normally.

Remember that the scooter starts from the starter when it has an integral part with proper operation of the variator, clutch, camshaft group and valve. To put it simply, if all power systems are in normal condition, then there is a problem in the transmission, thanks to the crankshaft torque, which works closely with the variator.

In the process of diagnosing and repairing a scooter, in some cases it is necessary to do a thorough check of not only individual elements, but also the entire system. For example, if there is debris in the carburetor, provided that it is intact and the air filter is saturated, the presence of dirt in the cavity of the gas tank and the fuel filter is also carefully examined.

If the scooter starts with the kickstarter, but does not start with the button

If the scooter starts without problems from the “leg”, but does not want to start from the electric start button, then you should pay attention to the central fuse (it is located in the compartment with the battery). If the voltage in the scooter’s electrical network is too low due to a faulty fuse, it will no longer start using the “Start” button.

To check the serviceability of the central fuse, you should measure the voltage at the battery terminals and compare with the voltage after the fuse.

If losses are detected during measurements, the fuse should be replaced. In most cases, after replacing the faulty fuse, the scooter starts without problems.

The problem when the starter button on a scooter does not work may not only be in the fuse. It is likely that the integrity of the connecting conductors in the engine starting circuit is broken.

VIDEO INSTRUCTION

It will be difficult for a beginner to deal with such a malfunction, so for a complete diagnosis of the electrical circuit it is better to contact an auto electrician.

Breaks in electrical wiring

This happens very often, especially on Chinese-made scooters. Here, wire breaks in the ignition system are possible.

The reason may also be oxidized contacts and terminals. Do-it-yourself scooter repair, in this case, consists of checking the integrity of all wires in the ignition system. Also pay attention to the terminals. If the contacts are oxidized or do not hold tightly, then they should be cleaned and tightened. It would be a good idea to check the wire that comes from the switch. You need to make sure the connection is secure and the terminal is clean.

Cleaning the elements correctly

Every owner of motorcycle and automobile equipment should know how to properly clean spark plugs from carbon deposits. Most beginners try to restore parts themselves and then wonder why they don't work. The main mistake is that the spark escapes to the spark plug body along the soot - it is not a conductor of electricity. The engine cannot be started. Plaque forms not only on the electrodes, but also on the ceramic insulator. Therefore, it is necessary to clean not only the side and central electrodes, but also the insulator.

A better effect can be achieved if you use a sandblaster. If there is none, you can try cleaning with just sand. To do this, you should purchase an electric drill and sand in a bucket. Next, take the candle and clamp it in the drill chuck by the thread on the top. Large threads are wrapped with tape. The part is then lowered into the bucket and the tool is started. After some time, the electrodes and insulator will be cleaned. If the spark is lost for this reason, the scooter spark plug will work properly again.

Comments

Ahi Muslim:

My scooter has a weak spark, I can't find the reason

With Your Own Hands:

wow, it’s easy for me to have a switch just like the carb

Vika Chernenko:

the sound is shit can't hear shit

Alexey Tolstikov:

I called everything about it, I pulled the spark plug 2-3 times, there was a spark, I screwed in the spark plug again, I pulled the kick, first it caught something and then there was silence, I pulled the spark plug out again, the spark was barely visible, the Chinese was half a centimeter 4x. What to do help.

Vanches201:

thank you dude, it helped a lot, I also had a problem, it was hard to start, the problem was in the switch on the tray, the switch itself went sour and drizzled, the so-called “floating error”.

Mikola Petrov:

you shit in your pants

Victor Zamkov:

Please tell me I have a 49cc Gilera moped, there is no spark, could it be a problem with the regulator or a problem with the camutator? I contacted one specialist, he says that the snout regulator has no relationship with the camutator. Is this true? The generator is new!

Chingiz Kapasov:

Could the scooter not pick up speed because of the switch?

Victor Matonin:

And if it shows not 60 volts but 30 volts, does that mean the hone coils? I have a spark but it's weak and won't start.

NoNAME BPAN:

I have an Orion 100 moped, I changed the engine to a larger one, the cubator won’t start, there is a weak spark, what should I do?

msha garbachev:

Hello! I have the same scooter as you have in the video. There is no blue wire on the four-pin pin, but green, red-white and black-yellow. None of them have 160 ohm resistance. The problem is that the spark is weak and the scooter will not start. Help me please. Thank you in advance.

Slaff4ik:

Please I need your answer. You measured the voltage on the high voltage coil of the generator when starting with an electric starter, the voltmeter showed about 60 volts, and what voltage will the generator produce when starting with a kick starter?

IVAN IVANYCH:

The fundamentals of the theory are correct and almost all are presented correctly. BUT not everything is diction. I had a hard time staying awake! But in fact, the first thing to check is the ground circuit, not only the terminal - switch, but also the switch - engine. Often the mass on the engine shows a large resistance (the bolt is not tightened, oxides, damage to the cores of the wire itself.)), accordingly, the voltage from the sensor and the supply winding will be incomplete. And most importantly, the layouts on scooters may differ! Although everything looks similar in appearance, they are essentially different. So let me add a little to the video, before we mess with the scooter, we CAREFULLY study the manuals for it!

Alexey Semenov:

Thank you for the video . Tell me, the switch receives a signal from the generator, but not from it. The switch is OK. Can a faulty relay-regulator have such an effect on the switch and the absence of a spark? Thanks again ! I have a quad – an analogue of the stealth 100 rs. Everything is absolutely the same as on your scooter.

Asker 316:

Spark plug coil wire

Asker 316:

On my scooter the coil burns out and what could be the reason.

Nicolae G:

I have such a problem with the button buzzing and turning off, the battery is draining. And with an electric drill, it wants to start but immediately stalls. When I started it the day before yesterday, there was no fuel in the filter and I got it, I just forgot to remove the spark plug, I’ll clean it today, but I don’t know what to do with the power supply. Is it possible to leak current?

Denis Rypa:

Could there be a weak spark due to the cracked magnets on the generator rotor? At idle it works and you let the gas choke and stall (who knows what?

Maxim Russ:

ok explained I'll go look at the step otherwise I have a weak spark

Oleg Babych:

and if the resistance to the magnetic induction sensor is less than 140, for example 120 for me?

Spark plug gap

Spark plug gap is an important factor for proper engine operation. This parameter plays an important role in the process of spark formation, ignition of the fuel mixture, and efficient operation of the scooter throughout the entire speed range. The gap should be specified in the documentation for the specific scooter - this parameter may vary among manufacturers. Generally speaking, for most modern four-stroke Chinese and Japanese mopeds, the gap on the spark plugs is from 0.5 to 0.8 millimeters. It is necessary to monitor this parameter. For this reason, the spark may disappear. She leaves because the gap is too big.