“Please tell us about the gearbox of the Dnepr motorcycle with reverse gear,” ask motorcyclists A. Voronenko from Kakhovka, T. Kachura from Poltava and others.

We give the floor to the chief engineer of the Kyiv Motor Plant I. E. MURATOV and the head of the design bureau I. L. ENDELMAN. They will answer readers' questions.

The gearbox of the Dnepr MT-9 motorcycle, unlike previous gearboxes of heavy motorcycles, is equipped with a reverse gear and a mechanism that automatically disengages the clutch when changing gears. It makes the machine much easier to control and increases its maneuverability. The rear gear ratio is 3.67; the rest of the gears have not changed.

Although the new box is 15 mm longer than the previous one, with minor modifications it can be installed on all models produced by the Kyiv Motorcycle Plant (it is not suitable for Irbit motorcycles).

Rice. 1 Alteration of the elastic coupling disk. The thin line shows the previous profile.

On motorcycles with a short frame produced before 1969, it is enough to slightly shorten the rear end of the propeller shaft or make bevels on the elastic coupling disk according to Fig. 1. Since each box that goes on sale comes with instructions for its installation, operation and repair, there is no need to talk about this in more detail.

To increase reliability and durability, metal-ceramic bushings are used in the gears of the first, second and third gears of the secondary shaft, and bronze bushings are used in the fourth gear gear. The trigger mechanism is two-stage with a multi-tooth ratchet and a gear sector.

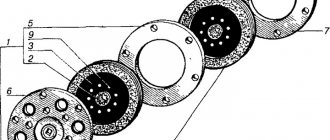

Rice. 2. Gear shift mechanism: 1 — shift pedal shaft; 2 — crank; 3 — crank pin; 4 - dog; 5 — disk pin; 6 - fork; 7— neutral sensor contact plug; 8—switching disk; 9 — pawl axis; 10 — neutral sensor spring; 11 — lever lock.

The gear shift mechanism (Fig. 2) has an original design, for which two copyright certificates have been received. It works as follows. When you press the gear shift pedal, the crank 2 rotates and, with a pin 3 entering the groove of the pawl 4, moves it along the axis 9 installed in the crankcase. The pawl, acting on one of the pins 5 of the 8G shift disk, rotates it to a certain angle. In this case, the shift forks, which fit into the shaped grooves of the disk with special spikes, turn on or off the corresponding gear.

A spring 10 is riveted to the shift disk, serving as a contact for an electrical sensor that turns on the warning lamp (located on the headlight) for the neutral position of the gearbox between first and second gears. The shift mechanism has another lockable neutral position between third and fourth gears for coasting.

The clarity of the neutral indicator depends on the depth to which the contact plug is screwed in. It should be positioned so that the neutral indicator lamp goes out when the plug is turned counterclockwise no more than 1/6 of a turn.

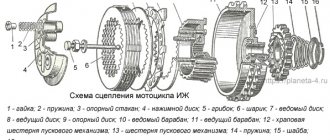

Rice. 3. Reverse gear mechanism: 1 - idler gear; 2 - reverse gear, sitting on the input shaft; 3 — reverse fork; 4 - sliding reverse gear of the secondary shaft; 5 — reverse gear handle; 6 — fixing screw; 7 — fork lever.

Reverse gear is activated by a separate manual lever 5 (Fig. 3), located on the right side of the gearbox. When it is moved to the forward position, the secondary shaft reverse sliding gear 4 meshes with the idler gear 1, which is in constant mesh with the primary shaft, due to which the propeller shaft, and therefore the wheel, rotates in the opposite direction.

The shift mechanism is equipped with a safety device that prevents the simultaneous engagement of reverse and any of the gears.

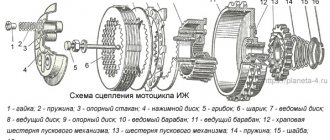

Rice. 4. Mechanism for automatic clutch release: 1 — gear shift pedal; 2 - cam; 3 - roller; 4 — lever; 5 — intermediate rod; 6 — adjusting bolt; 7 — clutch release lever: 8 — clutch release rod; 9 — manual clutch release cable; 10 — clutch.

The automatic clutch release mechanism (Fig. 4) is driven by gear shift pedal 1. When you press it, cam 2, sitting motionless on the same shaft, turning in one direction or another, raises lever 4, which pushes rod 5, connected to the clutch release lever. To adjust the forced clutch release mechanism, use bolt 6 in the lower arm of the lever. Between its end and the intermediate rod 5, such a gap is left so that when the upper head of the lever 4 is rocked, its free play is 1 mm, and the free play, measured along the front arm of the pedal, is 10 mm.

When operating the MT-9 gearbox, care should be taken when starting the engine and changing gears. Thus, the start pedal should be pressed only when the gear sector engages. Otherwise, you may break its teeth. If the teeth do not engage (which can be felt by the hard stop of the pedal), you need to push the motorcycle forward or backward. After each unsuccessful start attempt, you should not completely release the pedal, since, returning to the uppermost position, it disengages the sector. In the case when the gear is engaged without using the manual clutch lever, then, in order to avoid jerks in the transmission, it is advisable to return the pedal to the middle position smoothly after engaging the gear, holding it with your foot.

To lubricate the gearbox in the summer, in addition to the AC-8 oil recommended in the instructions, you can use, for example, automotive transmission oils TAD-17 and TAp-15.

Kyiv

1974N03P36-37