One of the most important disadvantages of any motorcycle is the unpleasant sound produced by a high-speed engine - its tonality has a depressing effect on the human nervous system. At the same time, the volume of such sounds leaves no doubt that they will be heard by people within a radius of several city blocks. That is why engineers created a special muffler for a motorcycle, which not only reduces the volume of unpleasant sounds, but also seriously changes their tonality. However, any obstacle in the path of exhaust gases forces you to reduce engine power for the sake of its safety. Therefore, many motorcycle owners are interested in how to make two-wheeled vehicles more powerful without sacrificing their health and the comfort of those around them.

Purpose and principle of operation of mufflers

Despite its apparent simplicity, the exhaust pipe solves a number of important problems. Among them:

- suppression of sound vibrations that occur during combustion of the fuel-air mixture;

- reducing the degree of heating of gases with critically high thermal parameters;

- reduction of exhaust toxicity.

Progressive exhaust systems are capable of removing exhaust gases from the power plant, as well as converting them. For smooth operation, the unit is equipped with the following elements:

- corrugated pipes that connect to the exhaust manifold. The part does not have a rigid structure and is intended to suppress vibrations;

- a catalyst that ensures the deactivation of components harmful from an environmental and hygienic point of view that appear when hydrocarbons burn out;

- a resonator made in the form of a small expansion, which stops the movement of gases through the pipes. The standard element only suppresses exhaust system pulsations, but does not reduce the noise level. Therefore, it is equipped with auxiliary components;

- muffler, where the exhaust cools and loses its initial velocity by dissipation.

The design is complex and is intended to distribute the flow of gases and suppress vibrations caused by the operation of the system.

The performance of all components of the exhaust system is determined not only by design features, but also by the mass of the products. If heavy metal is used, the operation of the equipment will be quieter, since such materials are less susceptible to vibrations.

Light alloy products with thin walls not only wear out quickly, but are also vulnerable to rattling. Therefore, they themselves produce unwanted noise.

DIY sandblasting cameras 6 photos

A sandblasting chamber is a useful thing in the house. Do you need to clean some coating, remove metal corrosion, or remove contamination? No problem. The cleaning process occurs by spraying an abrasive material under pressure inside a closed space. In self-built sandblasting chambers, you can use the following as an abrasive:

- Quartz sand of different fractions.

- Cast iron or steel shot.

- Slag remaining after processing copper and nickel.

The chamber can be built from a regular OSB sheet. You can buy it at any lumber market. The camera can be any size, you need to choose it for yourself and understand what it will be used for.

Detailed operating principle. Only the size and body of the structure can differ.

Such chambers are called habitable because the part is processed directly by a person. Wearing safety glasses is recommended. Thick rubber gloves are attached to the holes. It is prohibited to climb into a working chamber with bare hands!

It was made to be portable. Total weight – 10 kg. The base is made of iron profiles and aluminum sheet.

Transparent storage container. Volume – 30 liters. You can buy it at a building materials store.

According to the author, it was made by eye from what was in the garage. I just wasted my time. Intended for cleaning car rims.

Read in full (link)

DIY straight-through muffler

Today, a large number of additional accessories have been developed for motorcycles that serve various purposes. Direct flows are suitable for bikers who love to hear the sound of a roaring engine. They are produced by various companies. Thanks to this, everyone has the opportunity to choose the most optimal option for themselves. However, there are motorcyclists who have a limited budget, but for them, re-equipping and equipping a bike with everything necessary is not a difficult task. After all, they can do everything they need on their own.

It is best to make a do-it-yourself forward flow onto a motorcycle from a high-quality steel tube of the optimal size. It can have different shapes and lengths. The main thing for its fire resistance is to cover the surface with a protective layer.

For the tube, you need to assemble two end caps and make holes in them. All work is carried out using a welding machine.

Assembling a muffler with your own hands is not difficult. The main thing is to have welding skills in order to assemble all the parts together. If you do everything correctly and carefully, you can assemble a muffler similar in quality to those sold in motorcycle dealerships.

Main details of the direct-flow system

A direct-flow system on any car will work correctly only if all the parts are optimized for the model. Installing only the muffler itself will give partial results. In general, the system will consist of the following components:

- Collector. It is made of stainless steel, which reduces weight and makes it possible to configure it with resolution zones. This allows you to remove resistance to gas flow.

- Catalyst. Usually here there is a replacement with a sports version (flame arrester), which has an increased throughput. It is also possible to replace it with a simple pipe.

- Resonator. Here it is possible to completely remove this part or replace it with a sports one.

- Muffler. The dimensions and length will depend only on whether the resonator is installed or not.

How to make a straight-through muffler with your own hands? This homemade muffler is now widely used by many motorists. And each of them boasts some specific installation technology. Below we describe one of the most popular options.

Making a direct-flow muffler from scratch

You can make such a muffler from scratch. This will be a completely new version made from several components. The difficulty of this operation, called tuning from scratch, lies in finding the diagram of the exhaust system of a particular moped.

Tools and materials

In this case, again, you need to prepare the necessary tools and materials.

- Purchase in a store or find two pipes with a diameter of 33 mm;

- Buy plexiglass;

- Bolts M8 and M3;

- Prepare glue and nails;

- Welding machine;

- Needles;

- Hacksaw for metal.

Let's start assembling

First of all, you need to cut 18 cm from one of the pipes. It is recommended to carefully process the place in the cut with a needle file. From the second pipe we cut a circle with a diameter of 1.5 cm. We process it using the method described above. Glue the cut out circle in the section of the first pipe. We cut off another piece of pipe, 18 cm long. We make many holes in it. This can also be done with a sharp nail.

We connect all the parts using a welding machine. We fill the cavity formed at the junction of two pieces of pipe with mineral wool. We wrap the finished product with a special fire-resistant material. The homemade muffler is ready. To install it, you will need to attach the element to the scooter body mount.

Making a muffler mounting element

From plexiglass, which is indispensable in this matter due to its strength and easy paintability, we cut out a special type of ring, the edges of which can be bent outward by 180 degrees. We attach the resulting circles with serifs to the moped using the required bolts. We polish the muffler using sandpaper. To be sure, the joints between the homemade product and the moped body will need to be lubricated.

Homemade muffler for moped disassembled

If homemade production causes certain difficulties, you can find a lot of models of mufflers already in finished form. They are usually inexpensive. On the other hand, only a homemade version can provide the ideally expected option.

DIY flute for direct flow

If you have the desire and skill, then making a flute with your own hands in order to muffle the forward flow is not at all difficult. It will turn out cheaper than the branded one, but not always better than the Chinese one.

To work, you will need a 20 mm steel (preferably stainless) pipe and a piece of sheet metal 0.8–1.2 mm thick. It is advisable to cook using arc welding, following the rules for working with stainless steel. A pre-bent steel sheet plug with holes for fastening is welded to the pipe. You can screw it with three M8 bolts, but for installation in a few minutes, one threaded connection is enough.

During manufacturing, you should try to carefully measure the internal diameter of the muffler at the air end so that the plug fits in loosely, but without a gap. Then, when heading out to the track, you can quickly remove the flute from the hot pipe with a pair of wrenches or pliers.

Why is forward flow needed and why sometimes it needs to be muffled

A car with an exhaust louder than 96 dB will not be able to pass a technical inspection and will not cross the border - in Europe, traffic rules are strict, and the police are incorruptible. Even in motorsports, sound is limited. Only Formula 1 promoters don't like the attempt to drown out the noise from cars. They even opposed the new regulations for the transition from eight-cylinder engines to V6, fearing for the prestige of racing.

When properly configured, resonant exhaust provides an increase in torque by 3–9% for naturally aspirated engines, and more than 10% for turbocharged engines. But in production cars, the increase in the rate of filling the cylinders with the working mixture during modernization is less than 2–3%.

Installing a direct-flow muffler on regular stock cars is only needed as a decorative option for a pleasant exhaust timbre. The main criterion for the quality of direct flow operation on a production machine is the euphony and velvety noise of the motor, and not the increase in power. The car will scream louder or quieter - this will not affect the speed and dynamic characteristics. In this case, when there is an urgent need to stop the forward flow, you can do this without thinking about the consequences.

Types of mufflers

Many people associate the roar of sports motorcycles with a muffler. And they believe that filling the muffler can reduce the power of the car. But that's not true. When replacing or modifying a muffler, only a small amount of horsepower is lost.

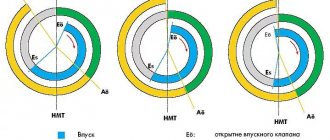

There is an intake and exhaust silencer. And scientific research has proven that if you choose the right basic elements, you can improve the filling of the cylinder. Such mufflers are called resonant mufflers.

Noise suppression is carried out by the part of the muffler located behind the first partition, and it consists of an acoustic filter. These filters on sports motorcycles are made simpler, since a higher noise level is allowed in sports motorcycles.

When deciding to remake a muffler, you need to remember the following. Sometimes, when improving one part, you have to sacrifice the quality of another. No one has yet succeeded in creating a universal motorcycle.

Manufacturers recommend using factory mufflers for your motorcycle. The muffler cavity becomes covered with carbon deposits, which can close the acoustic filter channels. Therefore, the cavity of the device must be cleaned regularly. The resulting carbon deposits prevent the exhaust gases from escaping, and engine power is reduced. After every five to ten thousand kilometers, mufflers need to be cleaned.

The original mufflers are quite quiet and good. Their disadvantage can be considered their heavy weight and size. Many consider their high price to be a disadvantage. Silencers are produced by many companies, and you can use a non-original muffler if you wish. Most often these are open mufflers. In them, exhaust gases exit the engine without any obstacles. But they make a lot of noise.

Those who love the loud roar of motorcycles can buy the cheapest muffler, which does not muffle anything. But if the roar of the motorcycle does not suit you, then you will have to buy an expensive option.

These mufflers differ in design and material of manufacture. There are four types:

- Titanium. He is considered the best. It's light, looks nice, and doesn't get too hot.

- Aluminum. Light enough. It looks worse than titanium, but there is a drawback. You can get seriously burned.

- Carbon. Looks nice, light and cool. But its significant drawback is that even with vibrations it can crumble.

- Stainless steel. Strong and heavy, but very hot.

Each type of muffler has its own advantages and disadvantages. Therefore, you need to choose for yourself.

Chinese scooter repair: engine

A working mechanism, including any engine, produces noise of varying degrees of volume. A change or increase in the noise level indicates wear of one of the parts inside the structure. All parts have a service life and, depending on the mileage, the quality of gasoline or lubricants, sooner or later they become unusable. If the owner listens to the running engine during idle, acceleration and at maximum speed, he will remember the correct noise, and will immediately recognize if foreign elements are added to it. If there is no experience, when starting to repair a scooter in China with your own hands, a phonendoscope is used to determine the cause of the malfunction. Let's consider the nature of extraneous noise, the reason for its appearance and the place where the part was worn out:

- A knocking sound is heard in the engine when fuel detonates. When the fuel detonates as it burns, this is expressed by the occurrence of a metallic knock due to the heavy load on the cylinder parts. They occur when using low-quality fuel or gasoline with a low octane number, in case of heavy accumulation of carbon deposits inside the combustion chamber and when the engine overheats. It is necessary to carry out diagnostics using available methods, reduce the engine load and replace the fuel with another one with a higher octane number. If the knocking continues, clean the combustion chamber or replace the spark plug. Do not operate the scooter with signs of detonation, this will lead to increased wear and malfunction of the loaded parts.

- The howl of worn main crankshaft bearings. It is difficult to confuse with other noise; the howling appears when you add gas and increases the volume as you continue to use the scooter. If the bearing is not replaced promptly, the balls will spill out of the main part and, mixed with the broken race, enter the crankcase, causing serious damage. Negligence in operation leads to serious damage and the need to carry out expensive repairs of Chinese scooters at a service center.

- Piston pin knock. The knocking sound is heard when the engine warms up at idle speed, and becomes noticeably louder if you turn the throttle sharply. Appears when the surface of the piston pin is worn out, the size of the piston boss holes is increased and the bushing located in the upper part of the connecting rod is worn out. A specialist in the workshop will restore the Chinese scooter (engine repair, identification and replacement of worn parts) as quickly as possible.

The reason why the scooter does not pull up or accelerates poorly may be a decrease in compression. This problem occurs due to:

- Active operation of equipment at maximum capacity.

- Wear of cylinder rings.

- Incorrectly selected parts.

- Error when boring the cylinder.

You can check the compression using a compression gauge. Ideally, the pressure should be 10 bar, but 7-8 bar is also good. If the readings are lower, then you need to lubricate the assembly, replace the ring and make sure that all parts are in good condition.

Cleaning the muffler

The cleanliness of the muffler affects the power of the moped

Before you start changing anything in the exhaust system, I would like to give one piece of advice. The power of the scooter is directly affected by the cleanliness of the muffler. If it were possible to see the exhaust in a cross-section of the muffler, the owner of the scooter would be very surprised. After a certain mileage, the scooter's dynamics decrease, and owners begin to look for the reasons for this, finding them in a complete rework of the standard muffler or its replacement.

The reason for the loss of power, meanwhile, may be hidden in the condition of the engine itself. This will help determine the specialist you should contact before tuning. But the most common cause of loss of dynamics is soot that clogs the muffler. In this case, it is recommended to carry out cleaning in three ways.

First method: mechanical

It involves cleaning the muffler section (it is done with a grinder). The inside of the muffler is cleaned of soot using a wire or cable. The section in the section is closed by welding.

Second method: chemical

It involves pouring water with some kind of cleaner into the muffler. For example, caustic soda is suitable for this purpose. This cleaning has the advantage that the appearance of the muffler will not be affected in any way.

Third method: heat treatment

The muffler is heated either on the scooter with a blowtorch, or dismantled in an oven or on a grill. It will be necessary to repaint the muffler only after it has cooled.

Why do people around you irritate your updated motorcycle?

First of all, the deafening volume that is inherent in most straight-through exhausts puts pressure on your eardrums and echoes throughout the surrounding area. This is really unpleasant, however, it is even worse when motorcyclists accelerate in place for the sake of self-affirmation (or who knows what else).

They break the silence and exceed permissible noise limits. Their roar causes car alarms to go off falsely, cell phone conversations become shorter due to the inability to hear the interlocutor, and a small child wakes up every now and then. They seem to accurately guess the time when you are going to sleep or relax on your day off.

If you yourself are a motorcyclist, then it’s worse for you =) You will certainly be identified with “noisy bikers” just because you ride a motorcycle (and it doesn’t matter which one). Get ready for stereotypical thinking.

If you like to tune your horse and try to be polite on the road, have patience and some indifference (in moderation, of course). It often happens that a few “rotten apples” will ruin the entire harvest.

Forward flow on a motorcycle

Not all people like the noise that direct-flow mufflers make while driving on the roads. They do not allow people in residential buildings to sleep peacefully; the noise of the mufflers has a frightening effect on children.

Some motorcyclists who oppose the use of mufflers on motorcycles argue that they prefer a quieter ride that does not cause inconvenience to others.

However, those who use forward flow on a motorcycle say that this part is necessary to ensure safety.

Direct flows help in the following situations:

when it is necessary to signal your presence to drivers on the road

Everyone knows that not all car drivers like motorcyclists.

They try to harass them and not pay attention to the fact that a biker is riding next to them. This leads to the fact that if you do not signal your presence to the car driver while driving on the road, he will not notice you

When the use of sound signals and other things is not enough, the input can enter a forward flow. It makes a roar, which makes it possible to move along the highway without unnecessary trouble.

when you want to equip your motorcycle with an attractive attribute to change its external qualities.

Almost every motorcyclist has moments when he wants to change something. It can be installed for safety and as a decorative element of the arc on a motorcycle; when it is already there, you can try to make a forward flow. It will give you the opportunity to experience the new capabilities of any motorcycle device.

How to reduce motorcycle exhaust noise

Have you been thinking about muffling your exhaust

but worried about loss of productivity? No need. Just read this guide and you won't have to think about it or visit a mechanic anymore.

Let's be honest, we've all been there. loud growls and howls

that comes from our cars

can be annoying

. Not to mention it could get us into trouble with neighbors or other people who don't like motorcycles.

I know some of you have motorcycles, they're beasts

.

And although they sound great, they are too loud. And this reduces the overall impression. In general, you want your exhaust to not be loud. And , even if you like the way it sounds, others may not

, so you should make it as quiet as possible. When it comes to the exhaust on my motorcycle, I want to hear music. I want to hear Mozart when I start the engine.

Now, if you have the above mentioned exhaust problems, you should understand that there could be many reasons for this. Sometimes , reducing exhaust noise means that you will simply need to buy a new one, or maybe at least get it fixed and patch the tiny holes in it

.

DIY straight-through muffler

You can buy a direct-flow muffler in any specialized stores. They are usually of interest to young motorcyclists who dream of high speeds. But real bikers are not sold on stickers from famous brands. They do everything they need with their own hands.

If you want to enter the world for real men, you need to make a direct-flow muffler with your own hands. When riding at normal speed, its noise will not be different from other motorcycles. But as the speed increases, the characteristic rumble of the engine appears. What needs to be done for this?

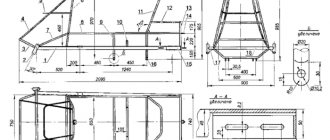

- Take a piece of pipe that has a diameter of 60 mm and cut it in half. First, one part is processed and a flange is welded in the middle. The outer part does not change. This is the inlet pipe. In half of the pipe, which is located in the muffler, you need to drill a large number of holes using an electric drill. You need to use a 5-6 mm drill. Recess the flange with a ten-millimeter tip into a pipe with a diameter of 100 mm and weld it.

- We are preparing the second pipe. Weld a flange to the second section of pipe. It should be 80 mm from the edge. This part of the pipe will be inserted into the muffler.

- Carefully lay mineral wool insulation into a pipe with a diameter of 100 mm. This is to combat noise reduction. To do this, roll the cotton wool along the diameter of the pipe and push it to the opposite side.

- Roll up the mesh and lower it inside the insulation that was inserted into the pipe. The mesh should fit onto the pipe with holes.

- Now you need to insert the flange with the pipe, which you prepared in advance, into the pipe with the short end. It needs to be recessed to a depth of 10 mm and welded.

- You can cut off the fastening elements from the old muffler and transfer them to the direct-flow muffler by welding them.

Are there any advantages to direct flow?

Why are some motorcyclists desperate to turn up the volume on their steed? Their classic argument: “Loud exhaust saves lives.” This argument works in occasional situations that are typical on our roads, but there is no scientific evidence of the benefits of loud exhaust in avoiding accidents.

Moreover, this argument presupposes the correct behavior of road users when they hear a motorcycle roar. But this is an extremely risky assumption: the driver may be frightened by a loud roar next to him and behave completely differently from what is expected of him, which can be dangerous for the motorcyclist. A loud exhaust may be noticeable, but it is unlikely to be a more effective means of preventing accidents than safe driving skills coupled with reflective elements on equipment and a mandatory helmet on the head.

Even if the "loud exhaust saves lives" argument works in some situations, it doesn't do enough to compensate for the unpleasantness of it. To be honest, many motorcyclists use forward flow to attract attention and show off their own “coolness”, without caring about their safety or those around them.

This justification for using direct flow is too selfish, don’t you think? On one side of the scale is the joy of motorcyclists, on the other is the peace of those around them. Which of these is most important?

Why do motorcyclists need forward flow on a motorcycle?

The exhaust system is designed to perform several tasks. Exhaust gases are removed. The exhaust gases better fill the engine cylinders. And dampens the noise. The spent mixture leaves the cylinders at a very high speed and therefore creates a loud noise. It is the muffler that reduces the noise of exhaust gases due to the obstacles installed in it.

A direct-flow muffler or direct-flow muffler on a motorcycle produces a peculiar engine roar and is not accepted by many people. It is believed that motorcycles with such a muffler disturb people and pollute the atmosphere.

Motorcyclists who promote quiet riding in the city do not accept straight-through mufflers. But experienced bikers are sure that forward flow is not only passive safety, but even active safety on the roads. How? The fact that you can indicate your location in the traffic.

Sometimes it is difficult to show some drivers even with a signal or headlights that you are nearby. And only the roar of the muffler helps to do this. And it happens that the sound of the muffler stops the driver from a careless maneuver that could lead to an accident.

How to make a muffler for a motorcycle is a question asked by many owners of motorcycles, especially domestic ones, whose appearance of standard factory mufflers leaves much to be desired. The need to make a homemade muffler may even arise among owners of imported motorcycles, for example, when tuning them (customizing). You can, of course, pay a certain amount of money and buy ready-made mufflers from some company, but often they are not suitable for some models of bikes and their mountings have to be redone. Yes, and they cost a lot. In this article we will look at how to make mufflers for a motorcycle with your own hands, on a minimal budget, and what you will need for this. In general, in one article it is simply not possible to describe the manufacture of mufflers for all types and models of motorcycles, because all bikes are different, the mounting points for mufflers are different, and there may be several options for the shape of mufflers and their mounting points, even for one motorcycle model. But still, having described the manufacture of a muffler of a certain type and shape, this will serve as an example for the manufacture of any other exhaust pipes and mufflers, because the manufacturing principle is almost the same, with the exception of some small details (pipe diameters, sizes and attachment points of pipes).

Below we will describe the manufacture of two different versions of mufflers, which differ in their internal design. That is, I will describe the manufacture of an ordinary quiet muffler with partitions, similar to the factory one. And the manufacture of a direct-flow muffler will also be described, which will add power to the bike, but will also sound louder. And so let's go.

How to make the exhaust on a dirt bike quieter

A loud exhaust can save lives on the street, but on the track or trail, most riders prefer quiet is golden.

A loud exhaust can damage your hearing, cause a call from an annoyed neighbor, and prevent you from participating in sanctioned off-road racing that requires emissions to be registered at a certain decibel level or lower. A deep throaty sound is the most preferred sound coming from an SUV's exhaust pipe, it makes a fantastic impression but can still register too loudly. Sometimes a high-pitched racquet pops out and needs to be fixed, or a low-frequency or well-used exhaust system no longer covers the racquet, while some riders may simply prefer a softer sound for personal reasons.

How to muffle a loud exhaust

You have several options to consider to make your dirt bike's exhaust quieter, from simple maintenance to a complete exhaust system upgrade, so let's look at the methods and you can decide what best suits your needs.

Replace exhaust system seal

A dirty exhaust pipe packing makes something like the high-pitched sound of a tin can. If the noise does not bother you, it means there is not enough power. Dirty packaging can also cause decibel levels high enough to disqualify you from racing off-road with sound restrictions. Replacing your dirt bike exhaust seal offers the cheapest and easiest solution to reducing noise levels on your dirt bike, but don't expect drastic drop in noise level.

Read How to Repack Exhaust on a Dirt Bike or ATV for more information.

Add spark arrestor

The spark arrester replaces the muffler on a 4-stroke engine or the muffler on a 2-stroke engine. This requires some mechanical ability to remove and replace the existing pipe. Luckily, you don't have to replace the entire exhaust system, but you'll still be spending several hundred dollars on a spark arrestor, plus the time it takes to replace it, or the additional cost of hiring a professional. Most trail bikes already come with a spark arrestor, so keep that in mind mind at the shopping stage, but if you plan on riding your motocross bike on the trails in the off-season or off-road racing, you will need to invest in a spark arrestor.

Alternatively, on a 4-stroke engine, you can convert the existing muffler to a spark arrestor muffler by adding a spark arrestor end cap, a cheaper alternative to replacing the muffler entirely. The plugs remain in place permanently, but you can remove the spark arrestors during racing.

Exhaust system upgrade

Standard exhaust systems often produce a high-pitched noise that irritates most riders - one of the reasons many people purchase an exhaust system after purchasing a motorcycle. Aftermarket exhaust systems also provide more power and weigh less than stock, both attributes racers consider easy reasons to justify the expense. An aftermarket exhaust system likely won't meet your off-road racing decibel requirements, but you'll find the sound much more pleasant than the stock whine.

Read Do I Need to Upgrade the Exhaust on My Dirt Bike? for more information and be aware of all other necessary changes after replacing your stock exhaust system.

Go Electric

Electric dirt bikes have arrived, and while purists have tried their best to keep plug-and-ride bikes off the tracks or trails, more and more manufacturers are looking to the future. Electric SUVs make no engine noise, and in theory you could drive them around in your urban backyard with neighbors on either side and behind you, and they'd never be the wiser.

Most riders choose a quieter exhaust system when needed for trail riding or other off-road activities that have noise restrictions or rely on aftermarket systems for increased power. A quality set of earplugs helps with individual noise tolerance levels, but if your exhaust system sounds unbearable for one week compared to your last ride, take a look at your exhaust tip, you may find some relief there.

Direct flow muffler

The production of a direct-flow muffler begins with the preparation of material with increased heat resistance and 2 tubes of different sections. The smaller one should fit freely into the pipe from the previous node. Therefore, before manufacturing, you should remove the old kit, remove the partitions from the tank and begin calculating the required dimensions.

Then you need to take a thin tube and make several holes in it around the perimeter. It is then placed into a second tube and secured using welding equipment.

The finished product is fixed in the tank, and the free space is filled with insulation material. Next, you need to fill the free space with an insulator and weld the container. This action will minimize noise during engine operation.

It is important to understand that the slightest deviations from the standard configuration can prevent normal installation of the part. Therefore, you will need to spend more than one day in the garage, solving minor problems and refining the system

Inexpensive structures rust after a few months of use, and serious defects appear within a year after installation. To prevent such problems, reliable and durable materials should be used - in this case, the service life will be extended to several years.

High-quality forward flow

Despite the apparent complexity of such an operation, you can make a direct-flow muffler for a motorcycle yourself, saving up to $1000 on the purchase of a product from a famous brand. First of all, you should decide on the type of materials you will use in your work. Experts give the following recommendations:

- The best option would be titanium, since it has very high strength with minimal weight. However, bending titanium sheet to produce a muffler will be very difficult, as will finding welding equipment. You don't even need to mention the incredibly high cost of titanium;

- Aluminum is excellent for muffler production for the reasons described above. However, when using it, it will be problematic to connect the device to the motorcycle engine;

- Stainless steel has a large mass, but is durable and quite easy to bend. To weld a motorcycle component from this material, you will need specialized equipment;

- Ferrous metal is heavy, has low reliability and requires repeated processing. However, it is recommended for use by beginners due to the ease of bending and welding.

The thickness of the metal should be approximately 0.8–1.5 mm so that it can easily bend and weld without burning. Once you've selected the metal that best suits your muffler, spend some time researching the required equipment to cut and weld it.

Now it’s time to make muffler patterns for a motorcycle. The first thing to make is the resonator cone, which connects the device you are making to the motor of the two-wheeler. You can also make it yourself - to create the correct pattern, you need to remember that the planar projection of the cone is a sector of a circle. Next, pipes are taken that correspond to the diameter of the exhaust system - there should be three of them. Remember that it is better to take pipes for a motorcycle muffler ready-made, although if desired or if there are no suitable materials, you can weld them yourself.

The first pipe will be approximately 50 mm long (more if necessary) - it will connect the engine to the new muffler. The second will serve as an outlet - it needs to be given a similar length. The third will go inside the muffler housing and will serve to reduce the intensity of sounds. To get a quiet enough muffler, you need to make the last pipe long enough. However, it is worth understanding that increasing it will lead to a lengthening of the motorcycle muffler housing.

All that remains is to cut out the body itself—whether it will be cylindrical or flattened depends only on your desire. The minimum case diameter is 100 mm, but if possible it should be 150–170 mm. The sides of the body are made of similar sheet metal, after which holes for pipes are made in them. The first and second pipes described above are processed, after which they should form a flange that allows them to be firmly secured inside the muffler. You need to drill a lot of holes in the third pipe - the best option would be holes with a diameter of 1 mm in increments of 10-15 mm, then insert it inside the body and securely fasten it between the first and second.

The last step in assembling a motorcycle muffler is to fill it with a non-flammable material that dissipates sound - fiberglass is suitable for this. It needs to be laid as tightly as possible in order to achieve maximum muffling of unpleasant sound. Now you can finally weld the motorcycle muffler and install it on the vehicle. If you are doing such work for the first time, it is better to first try to make all the patterns from thick cardboard and try on a similar homemade muffler for your motorcycle. If you make a mistake, you will be able to understand exactly what the mistake is and correct it without wasting expensive metal.

Another way

Direct flow motorcycles are created in many variants. If you work hard, including engineering, you will probably invent a new type of forward flow for bikes yourself.

With TIG welding, as well as some highly practical tools (grinder and rollers), you can create a different type of direct-flow exhaust from the standard one. This time, the use of stainless steel as the base material involves fastening its individual elements by arc-argon welding. The latter makes it easy to roll stainless steel into a pipe.

Using a special sheet, create a partition by drilling holes in it. How to make forward flow on a motorcycle without having any special skills for this? - Yes, very simple. In practice, you can learn a lot with just desire.

The above type of exhaust system also requires several end caps. Having created them, we can consider that most of the work is done. Now all that remains is to insert the non-flammable material, placing it between the walls of the inner and outer pipes.

Direct flow on a motorcycle can be installed using elements of the car exhaust system. The only difficulties, in this case, can only be caused by differences in car and motorcycle mounts. Having welding at hand, this contradiction is very quickly eliminated. All resulting welds can be hidden under chrome paint.

Alternative options

If you are interested in how to make a muffler quieter without losing precious horsepower, you can use a scheme that has been used in Chinese motorcycles for quite a long time. However, it is worth remembering that this option is only suitable for the production of mufflers for low-power motorcycles, whose performance does not exceed 40 hp. With. A pipe is inserted into the muffler body two-thirds of its length, the last 10 centimeters of which are covered with small holes according to the scheme described above. Having installed the inlet pipe, we are engaged in the outlet, which will be a pipe of a slightly larger diameter, inserted from the opposite side by two-thirds. It also remains to drill holes in 10 centimeters located closest to the motorcycle engine - such a muffler will represent a compromise between forward flow and the factory product.

If you know the structure of a motorcycle muffler, you can probably make a forward flow from an ordinary part. After opening the housing, you will see tubes that pass through special chambers, first to the end of the muffler, and then back and again to the exhaust pipe. These, as well as the motorcycle's catalytic converter, will need to be removed to achieve the desired effect. The perforated tube mentioned in the previous diagrams is inserted inside and wrapped with fiberglass. Of course, you can buy a special synthetic material used in the packing of original mufflers, but it will obviously cost more.

If you already know how to make a motorcycle muffler that fully meets your requirements, do not forget about fine-tuning the exhaust - for this you need to select the optimal diameter and position of the pipes, as well as the density of the holes. It is almost impossible to achieve an ideal result without using a special stand, so you will have to be content with approximate parameters obtained experimentally. In addition, after installing a different muffler, the motorcycle engine should be retuned. Modern injection engines will require the installation of new firmware, but carburetor motorcycles get by with a simple adjustment of the fuel system. Not every motorcyclist can do this kind of work, so it is quite possible that you will have to go to a specialized service center.

Independent work

Making a motorcycle muffler can be quite simple, but will it fully meet the requirements for it? Get ready for the fact that the first product you make with your own hands will require certain modifications and many hours of adjustments. However, practice shows that the second or third time it is possible to make a muffler for a motorcycle that initially meets all the required parameters. Sometimes it happens that it is not possible to make the required muffler for a motorcycle at all - this may be due to a lack of experience or certain design features of the equipment. In this case, it is better to buy a finished product from a well-known manufacturer or order the production of a direct flow from a real professional.

Two stroke and four stroke scooter

A scooter, as you know, can be with a two-stroke or a four-stroke engine. The operating principle of the entire exhaust system differs radically among analogues.

The muffler on a four-stroke scooter removes gases in a relatively shorter time, doing this with minimal noise. In addition, tuning the muffler in this case will be quite simple. On the other hand, in both cases, when carrying out tuning, it will be necessary to change the pipes.

Types of mufflers for scooters

For the muffler of a two-stroke scooter, selecting components that make it possible to carry out tuning will be much more difficult. The standard muffler itself for such scooters is more difficult to manufacture and configure.

The exhaust system of a two-stroke scooter works as follows. During the process of cleaning exhaust gases, part of the power is returned to the engine. This happens at certain speeds and if you manage to implement this whole process by tuning, the scooter will be unrecognizable.

You can install a high-quality and correctly tuned resonator on a two-stroke scooter. This will give a noticeable increase in dynamics up to a quarter. But in this case, it will be important to carry out professional settings of the entire power system.

How to get the most out of a scooter with tuning?

Scooter tuning is a fairly extensive process, but consists mainly of styling (improving appearance), chassis tuning (modifying driving characteristics) and engine tuning. The last point consists of many different operations that are aimed at increasing engine power, its better implementation and increasing acceleration and maximum speed. Below we will consider modifications to the engine and transmission.

It’s worth noting right away that the scheme is general and suitable for Italian, Japanese and Chinese models. Those who doubt the quality of Chinese scooters should be reminded that the level of production of modern models from the Middle Kingdom has increased significantly over the past 10 years, and most of the spare parts on the market for all models are from Chinese manufacturers.

There are many ways to speed up your scooter and, first of all, they depend on the current technical condition of the unit. Let's take, for example, an old scooter with an incorrectly configured variator, a clogged air filter, a dirty carburetor and a number of other problems that arise when the equipment is not properly maintained. Such an engine has great potential, but it can only be realized after proper tuning. After thorough cleaning and adjustment of all systems, even standard engine performance will seem like a significant improvement.

It follows that any work aimed at improving driving performance must begin with a complete revision of the engine.

Removing factory limiters is a very popular type of tuning and quite simple. Most of the Japanese equipment and similar Chinese equipment comes from the factory with special limiters that do not allow the engine to operate at full power. Fortunately, you can get rid of restrictions in any garage, and any tuning of a scooter with your own hands begins with the elimination of such restrictions.

When childhood illnesses are over, it is worth paying attention to real tuning, namely, improving or modifying existing components and assemblies. We are talking, of course, about the cylinder-piston group, carburetor, muffler, variator, air filter and ignition system. At this stage, the degree of involvement in improving a particular element depends on the budget. If funds are limited, then we will make the most of the existing set by modifying the described units.

If you have a certain budget for tuning, you can go the route of replacing parts with special tuning ones. Special parts designed for such modifications automatically improve the basic characteristics of the engine, plus they are designed for higher loads. We have figured out the general scheme of improvements, and below we will look at how tuning occurs, using examples of specific components.

Step by step guide

For the assembly to be successful, the following recommendations should be strictly followed:

- first you need to determine the dimensions, cut and bend the metal blank to form the shape of the muffler can;

- then you need to make perforations in the pipes of the can using drills or a grinder.

- Next you will need to weld the pipe parts to the reflectors and partitions, attach and fix the casing and plugs at the ends, and also attach the fasteners;

- The last step is to attach the new muffler.

If you do not deviate from the recommended instructions, the noise level from the exhaust will become either slightly louder or quieter. This will depend on the quality of the homemade product.

Direct flow with damper

To make a quiet direct-flow muffler, but not lose the additional power that modernization of the exhaust tract gives, use a direct-flow muffler with a damper. This exhaust design has been known for a long time and is found on many BMW models (usually with manual transmission).

When the engine is running at low settings, when the advantage of the coordinated exhaust is not taken advantage of, the exhaust gases exit through a conventional muffler, and the direct-flow muffler is closed with a damper. At optimal speeds, the damper opens the outlet into forward flow, and the motor produces maximum torque due to enhanced ventilation of the cylinders.

The damper control is automatic, but there are also manual models. In the city, such a car sounds almost no different from a stock one, and on the highway it not only sounds like a tuner, but has a real increase in power. It’s not cheap - for a full automatic machine, complete with a titanium “spider”, the price often exceeds a couple of thousand dollars.

Similar in capabilities, but not very famous analogues are moderately expensive, but it is better to select a suitable option with a specialist - the success of such an upgrade may require the knowledge of a motor engineer.

A budget option for direct flow with a damper can also be welded yourself from scrap materials. The upper part from an old carburetor will be suitable for the damper, if you bring the idle speed cable into the cabin. Making such a design with your own hands will take much more effort and time than for a homemade flute, and the result of the installation cannot be predicted in advance. It's not difficult to mute the sound, but to maintain power, even if you're lucky, you'll have to tinker with the settings.

Shape and length

As mentioned above, the volume of the exhaust pipe must be greater than the volume of the cylinder. Therefore, a short pipe will have less effect than a long one. In addition, hot gas from a short system will be dangerous for the pilot.

The shape of the structure should be round. At sharp corners, air movement will begin to slow down, causing the bends to become hot, resulting in a crack appearing over time.

The exhaust configuration also refers to the shape - these are pipes coming out of the cylinders. There may be different numbers of them:

- 2 in 1 system;

- 4 in 1 system;

- 4, turning into 2, and then into 1 system;

- other spider-like options connected by a common diffuser.

It depends on the motor itself. On two-stroke machines they usually have a separate pipe per cylinder. The volume of the exhaust then exceeds the volume of the engine so much that the air waves can expand enough at the exhaust to cool completely.