Suspension tuning

Motorcyclists are not satisfied with the suspension, and they are thinking about what to replace the front fork with. One of my friends left his original fork, but replaced the springs with Izhevsk ones. The suspension became more comfortable, but comfort was not enough.

There is another option for upgrading the suspension, this is a fork from a Japanese motorcycle. The Japanese market is famous for its bikes. The first rather successful option, which will have to be digested a little, is the fork with the CBR 900 RR. This is a classic inverted fork that has proven itself very well.

If you decide to replace the fork, then take it with the wheel, brake discs and calipers, this will give you the opportunity to get rid of many problems in the future. But if your budget does not allow you to buy a Japanese part, then the Izhevsk fork with homemade traverses made of aluminum alloy should satisfy you.

Return to contents — ↑

Engine tuning

The power of the original engine, despite its fairly large volume, is not always enough. If you decide to take such a step.

The following steps should be followed:

- Polishing the cylinder bores to remove carbon deposits and casting defects will give your motorcycle an extra 2 hp. With. And if you also adjust the compression ratio in each cylinder, then this procedure will add power due to the coordinated operation of the two cylinders.

- Check valve timing.

- Check the integrity of the ignition design in absolutely all cylinders. The ignition overtake should be around 40°-42°. The simultaneity of the ignition organization can be achieved if the arrogance of the fight in the distributor is knocked down and continued up to the same value of the ignition timing of 2 cylinders.

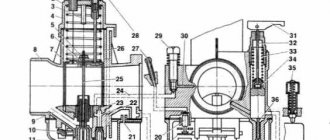

- A couple of “horses” are given to you by the K-301 B carburetors.

- I advise you to install air filters from Moskvich-412 cars (2 pcs.) or Volga GAZ-24 at your discretion.

- Adjust the carburetor for smooth operation.

- Select the length and diameter of the exhaust pipes and mufflers.

If you did everything correctly, the increase in power will increase noticeably.

Return to contents — ↑

Checking and repairing cylinder heads and gas distribution mechanism of Ural, Dnepr motorcycle engines

If compression in the engine cylinders decreases as a result of loss of valve tightness, then the gas distribution mechanism must be repaired. Signs of a malfunction: decreased power, difficulty starting the engine, increased gasoline consumption, loud noise in the upper part of the engine crankcase (where the pushers are located) and in the cylinder heads.

To repair, you need to remove the head and determine the condition of the parts of the gas distribution mechanism. Before checking the cylinder head, carbon deposits are removed from the walls of the combustion chamber and from the surface of the valves with a metal brush. Then the cylinder head is thoroughly washed, checking for breakdowns, cracks, burnt valves, or broken threads.

To inspect the condition of the springs, guides, seats, valves and carry out the necessary measurements of their wear, the valves are removed using a special device that makes it possible to compress and release the valve springs. When there is no device for compressing the spring, you can use a 19x22 socket wrench installed

vertically.

After removal, markings are placed on the valves so that they are not mixed up during the assembly process. The removed parts are thoroughly cleaned of carbon deposits and resinous deposits and washed. Then the head channels and valve guides are cleaned and washed. Before installing them in place, their rods are lubricated with graphite grease or engine oil. If cracks are found, the cylinder head is replaced. To restore the broken thread in the hole for the spark plug, the hole is drilled out to a larger diameter and the thread is cut. Then a bronze bushing is made with a collar 1.5 mm high with the same thread on the outer diameter. On the inner diameter, a thread is made for a candle 14x 1.25. The finished sleeve is secured with a pin. If the working chamfers on the valves and seats are slightly worn and have shallow cavities, and the conical chamfers are preserved, then the valve seats are ground in. If the chamfers have stepped shapes or deep cavities, and the chamfers of the saddles associated with them are rounded, then these surfaces must be restored. The seats are processed with conical cutters, the angle of which is 45°, 75°, 15°, relative to the valve guide (Fig. 34). First, using a cutter with an angle of 45°, remove the metal from the surface of the working chamfer, then cut off the sockets with an angle of 75°, then with a cutter with an angle of 15°, remove the chamfer from the bottom of the socket. The width of the working chamfer should be within 1 - 1.5 mm (Fig. 2.39). Metal removal with a 45° angle cutter should be minimal so that defects on the seat chamfer are removed (Fig. 34).

Rice. 2.39. Valve Angle Machining Angles

The working chamfer of the valve is machined or ground at an angle of 45° to the axis of the valve stem. The removed layer of metal should be minimal. The thickness of the cylindrical part of the valve head after processing is not less than 0.5 mm. When this is not observed, the valve must be replaced. The runout of the working chamfer relative to the rod should not exceed 0.003 mm. If the valve head is heavily grooved or cracked, the valve must be replaced. After processing the valve and seat, their working chamfers are ground in. If the valve seat of an MT and Ural engine has defects that cannot be removed with cutters, it must be replaced. To remove the valve seat, a thread is made in it, and the part is pressed out of the seat with a special puller (Fig. 2.40).

If there is no tool, the valve seat can be cut with a countersink. The dimensions of the workpiece for the new seat of the MT 10-32 and M67-36 engines are shown in Fig. 2.41. During its manufacture, the outer diameter is determined by the socket in the head with the condition that an interference of 0.2 - 0.3 mm will be ensured. The head is heated and the seat is pressed into place using a mandrel. Then the working chamfers on the seat are processed relative to the valve guide (Fig. 2.42). The runout of the seat chamfer relative to the guide bushing hole should not exceed 0.05 mm (Fig. 2.43).

To determine the condition of the valve guides, check the gap between them and the valve walls. The inner diameter of the guide bushing is measured in two planes located at a distance of 10 mm from the ends, and the diameter of the valve stem in three planes: the first and third planes at a distance of 10 mm from the ends of the working part, the second plane - between the first and third in the middle. In each plane, the largest and smallest diameters are measured without indicating their relative positions. If the gap between the valve stem and the hole in the guide bushing exceeds 0.25 mm, the valve must be replaced; if the wear of the guide bushing exceeds 0.15 mm, then it must also be replaced. In MT 10-32 and M67-36 engines, the worn-out bushing is removed using a mandrel. The head is heated to a temperature of +150 - 200°C and a new guide bushing is pressed in, maintaining 20 mm from the support plane of the lower spring washer to the edge of the bushing. The dimensions of the bushings are given in Fig. 2.44.

When making bushings, the outer diameter is determined so that the interference is 0.028 - 0.080 mm. After installing the guide bushings, their holes are processed with a reamer to a diameter of 8±0.022 mm. If old valves are used, it is recommended to grind their stems to a diameter of 7.8″0.035, and make the bushings with an internal diameter of 7.8±0.022. After replacing the guide bushing, check the concentricity of the chamfer near the seat relative to the axis of the bushing and, if necessary, modify the seats with cutters or grinding.

The worn-out valve guide of the K-750M engine is treated with a reamer for the valve with a thickening rod to ensure a gap of 0.05 - 0.10 mm. Valve springs are checked for elasticity and absence of cracks. For MT10-32 and M67-36 engines, the force required to compress the external spring to a length of 34 mm should be 1.45 - 16.9 N (14.8 - 17.2 kg) to a length of 26 mm - 2.49 - 29 .7 N (25.8 - 30.3 kg). To compress the internal spring to 30.5 mm, a force of 0.95 - 11.2 N (9.85 - 11.4 kg) is needed, up to 22 mm -2.06 - 2.82 (21.15 - 25.85 kg).

For the K-750 M engine, the spring compression force to a length of 37 - 39 mm should be 2.87

- 4.36 N (39.5 - 44.5 kg). If the elasticity of the springs is less, then they need to be replaced. The valve spring washer of the MT engine is checked to ensure that there are no cracks or kinks; if it is broken or worn out, then new ones are installed. It can be made from textolite or a clutch friction disc. The outer diameter of the washer is 31 mm, the inner diameter is 15.5 mm, and the thickness is 2.5 mm. Springs cannot be installed without a washer, because in this case, their force decreases sharply and during engine operation at high crankshaft speeds, the piston may collide with the valve head. In addition, the washers protect the springs from excessive heat. The valve tip of the MT engine is checked for increased wear and cracks, and the fit on the valve stem is checked. If wear is detected on the surface of the connection of the tip with the toe of the rocker arm or with the end of the valve, the tip is replaced. When installing a new tip, you need to check its fit over the entire area of the end of the valve stem. To remove the rocker arm, you need to unscrew the nut and remove the rocker arm axis from the cylinder head brackets. In this case, the rocker arms with bushings must be marked so as not to confuse these parts when installing them in their old place. After removing the valve rocker arms, the parts are washed, inspected and the necessary measurements taken. First of all, check for cracks, nicks, burrs on the axles, in the rocker arm holes and in the head brackets, as well as wear of the bushings and internal holes of the rocker arms. If the gap between the rocker bushing and the axle exceeds 0.12 mm, replace the bushing. After pressing, the new bushing is processed so that there is a gap of 0.02 - 0.06 mm. A small wear on the cylindrical surface of the rocker toe is eliminated by grinding using a pattern of R = 10 mm. The adjusting screws, which have wear on the spherical bearing surface and play in the threaded connection with the rocker arm, are replaced.

The rocker arms on the cylinder head are installed in the following sequence:

- insert a steel bushing into the rocker arm hole, the lower thrust washer, the rocker arm with the bushing and the upper support washer into the cylinder head brackets;

- lubricate the axle and rocker bushing with engine oil and insert the axle into the cylinder head brackets;

- put a flat and spring washer on the axle and screw on the nut;

— put the control block in place, screwing it in until it stops;

- screw in the locknut.

When it is necessary to remove the valve rocker arms of the M67-36 engine with axles and brackets from the cylinder head, they must be marked so that they can be installed in their old place during assembly. For disassembly, the rocker arm axle is pressed out from the bracket. After disassembling and washing, the rocker parts are inspected and the necessary measurements are taken. If the axles and holes in the rocker arms are damaged by more than 0.07 mm, then the parts are replaced. If the bronze bushings are pressed into the rocker hole, they are replaced with new ones. After pressing, they are processed so that the gap is 0.040 - 0.082 mm.

Rice. 2.42. Dimensions of valve seats of the MT10-32 engine: a - intake; b - graduation

Is it possible to make pressing out the valve seats easier?

To facilitate this operation, it is necessary to make a special mandrel (Fig. 2.45). And then insert mandrel 2 into the head from the side of the combustion chamber (the guide bushings are already pressed out), aligning the edge of the mandrel with the connector of the seat and head (Fig. 2.46). Insert a screwdriver into the gap formed on the other side and lightly hit it with a hammer.

And then press out the seat with gentle blows on the shank of the mandrel. Attention! During pressing out, you need to turn the mandrel along the diameter of the seat and wedge it with a screwdriver. The operation takes just a few minutes.

Rice. 2.46. Scheme for pressing out the seat: 1 - screwdriver; 2 - mandrel; 3 — head body; 4 - saddle

ARE THERE ANY TECHNICAL NUANCES WHEN REPLACING CERAMIC VALVE GUIDES ON “URAL” CYLINDER HEADS?

Yes, before pressing into the head body, the new bushing must be soaked in engine oil for 1.5-2 hours. After replacing the bushing, be sure to process the seat chamfers using cutters.

HOW TO “DRY” A VALVE IF THERE IS NO PULLER?

If there is no puller, there is the simplest solution. Take a piece of metal pipe with an internal diameter of about 20 mm or a spark plug wrench from the standard tool kit. Place some kind of stop under the valve from below, or, at worst, crumple up an old rag and fill the combustion chamber with it, and place the head itself on the floor. Place the pipe on the top valve plate and hit it with a hammer. With the second or third blow, the crackers will leave their place and release the spring. Remove them together with the upper and lower plates and remove the valve.

• HOW TO REMOVE THE OLD VALVE SLEEVE?

To remove the old valve bushing, you will need a mandrel made according to the sketch shown.

ensures that the bushing comes out freely downwards, insert the mandrel into the bushing from the side of the combustion chamber and knock it out with hammer blows. Be careful: the bushing is quite fragile, so try to strike strictly vertically so as not to break the bushing or damage the seat under it in the head.

Rice. 2.47. Mandrel for removing the valve sleeve Place the head on some support that

contents .. 21 22 ..

Motorcycle Ural tuning

Many people want to stand out from the crowd with their vehicles. You can make an excellent chopper from the Urals, and in general the Ural motorcycle is a good option for tuning. Recently, you can increasingly see tuned motorcycles on the street. Choppers came to us from America. And if you are planning to make a chopper from your Urals, then you should listen to the materials that are located further.

The first thing to start with is the wings. According to many bikers, they should not be in a chopper. Next we will talk about the tank. Here they listen to the expression, the less the better, but this does not mean that the tank should have a volume of two liters, everything should be in moderation. The seat was only for the driver, because the bikers rode alone.

Return to contents — ↑

Adjusting the valves of our boxers (Page 1 of 12)

To post a response you must login or register

Messages [1 to 20 of 232]

1↑ Topic by mexanik62 03-01-2013 11:09:31

- mexanik62

- Mechanic from the 30s.

- Inactive

- Name: Uncle Vitya

- From: Evpatoria

- Registered: 03-08-2011

- Messages: 10 831

- Reputation: 1 136

- Motorcycle: 12-volt K-750, ZAZ Sens Hatchback

Topic: Adjusting the valves of our boxers

The valves are adjusted in COLD mode (10 - 20 degrees above zero). There are two methods: First: It is used when there is no procedure for adjusting the gaps, it is difficult to set TDC or after repair. Rotate the crankshaft until the intake valve is completely closed (the rocker arm is hanging, the pusher is pushed in as far as possible. Set the exhaust valve clearance. Without removing the feeler gauge, rotate the crankshaft until the feeler gauge clamps or the rocker arm stops swinging and set the intake clearance. Repeat for the second boiler. For greater accuracy, adjust again. Second: Set the pistons to the TDC position. Set the gaps on the boiler where both rocker arms swing. Rotate the crankshaft 360 degrees and adjust the gaps of the second boiler. Check the gaps. Method of setting the gap without a feeler gauge. On our motorcycles, the thread pitch of the adjusting bolt is 1.0 mm. Let's take advantage of the fact that the rocker arms are equal-armed (there are none at all on lower valves). Use the adjusting bolt to set the position in which the rocker arm does not swing and the pusher rod easily rotates with your fingers (there is no play). Loosen the adjusting bolt 1/12 of a turn (that is, there are 6 edges on the head of the bolt and 6 corners and you need to turn it so that the edge replaces the corner, this will be 1/12 of a turn in size 1/12 = 0.08 mm approximately and in general it is similar to the existing gaps). Clearances in our motorcycles: M72 and inlet and exhaust 0.1 mm K750 inlet 0.07 mm exhaust 0.1 mm Overhead valve Dnepr 650 cc and inlet and exhaust 0.07 mm Overhead valve Urals 650 cc and inlet and exhaust 0.05 mm Overhead valve Urals 750 cc inlet 0.05 mm exhaust 0.07 mm The main thing to remember is that there should be a gap and it is better to let it be more than less. A reduced gap (well, the engine whispered) is a direct road to valve burnout and impacts on the piston. Sometimes there are cases when a slightly warmed-up engine does not pull and starts to fail - it is necessary to increase the gap!

Edited by mexanik62 (04-08-2016 12:12:30)

+7

2↑ Reply from Ural*4uK 03-01-2013 13:39:16

- Ural*4uK

- Elder

- Inactive

- Name: Igor

- From: Russia, Bryansk region, Mglin

- Registered: 03-03-2012

- Messages: 1 451

- Reputation: 39

- Motorcycle: Ural IMZ 8103 with sidecar

Re: Adjusting the valves of our boxers

hmmmmm. Why complicate everything so much, put it at TDC and use a feeler gauge to make the gap and it’s fine!! I don’t know about others, but from time to time the control nut would loosen and the setting would go wrong. I had to adjust everything all over again, although I tightened the nuts with decent force.

3↑ Reply from solex 03-01-2013 17:36:41

- solex

- Experienced

- Inactive

- Name: Artem

- From: Ukraine. Lugansk region.

- Registered: 24-01-2012

- Messages: 107

- Reputation: 5

- Motorcycle: Ural IMZ 8.103-40