The first primitive carburetor appeared in 1895 and since then the basic principle of its operation has not changed, only the design itself has been improved. And after so many years, you can still meet people who not only do not understand how miraculously the fuel moves upward from the float chamber, but also try to adjust the carburetor according to the principle “I see a screw, I turn the screw.”

This applies, for the most part, to young novice motorcyclists who cannot afford the services of a good specialist, and the equipment they most often own is Chinese, due to its availability. Based on this, let's try to figure out how to configure the PZ30 carburetor, which is one of the most common for Chinese small-capacity motorcycles. It should be noted that much of what is written below will be true for other similar carbs, for example PZ27, which differs only in the diameter of the diffuser.

Adjusting the PZ30 carburetor float

Tuning a PZ30 carburetor is simple, but very time-consuming. Unfortunately, just as in Photoshop there is no “Make it good” button, the carburetor does not have one screw, by turning which you can achieve an ideal air-fuel mixture in all operating modes. But let's get started with the setup.

Of course, the carburetor must be cleaned, and all worn elements must be replaced. But even with a new carburetor it is necessary to carry out some manipulations. Unfortunately, many Chinese manufacturers, as well as domestic assemblers, do not always bother to adjust the carburetors on the motorcycles they sell. It is clear that this is a price to pay for being cheap, but still.

You need to start by adjusting the fuel level in the float chamber. Many instructions say that you need to connect a transparent hose to the drain, loosen the drain screw and determine by the fuel level in the hose whether the float needs to be adjusted. Let such advisers chew hauttuynia, but we are not supporters of half measures. Drain the fuel from the carburetor float chamber and remove it.

The float system consists of only two elements: a float and a locking needle, which clings to a tongue on a metal base. By bending this tongue we will set the float to the level we need.

The distance from the carburetor body to the bottom plane of the float should be exactly 14 millimeters. How to take measurements. Holding the shut-off needle in the position where the fuel flow is blocked, but without pressing on it, we put the float in the position where it just touches the spring-loaded stop on the needle. By bending the protruding tongue of the metal base of the float, we ensure that the distance from the edge of the float to the carburetor body is 14 millimeters. At this stage, accuracy is very important, so you need to be patient. Separately, you need to pay attention to the fact that both float chambers must be at the same level.

Looking ahead, it is impossible not to mention one of the adjustment methods, which dates back to Soviet times. If the mixture is lean, when the divisions on the needle have already ended, it is advised to increase the level in the float chamber. Accordingly, if the mixture is rich, reduce it. The advice is good, but it is good for that period and place where it was not possible to buy a jet of the required size, and reamers to increase the jet were a rarity. Now jets are sold both in sets and individually in any specialized store, and even if they are not in stock, they can be ordered. And this is not to mention buying online. In any case, you should only play with the level in the float chamber out of desperation.

But let’s not jump over our heads; we’ll return to the jets and needles a little later, but for now we’ll assemble the carburetor and install it in place.

Adjusting the idle speed of the PZ30 carburetor

First of all, you should warm up the engine. We poured a mug of coffee or tea, started the engine, lit a cigarette if desired and... went to the Internet to look for information about what idle speed should be set for a specific motorcycle model. If you don’t find this information, then continue searching not by motorcycle model, but by engine. By the time you find between 1000 and 1500 rpm, which is most single cylinder engines with this carburetor, the engine is just warmed up.

We look at the dashboard, understand that there are certain difficulties in the form of the absence of a tachometer, or we find a tachometer and rejoice. If there is no tachometer, then you will have to rely on your own ears, and since you are reading this article, you have no experience in setting up a carburetor, which means you need to find a reference sound that you can use as a guide.

The sound of a single cylinder engine at 1000 rpm

Single cylinder engine sound at 1500 rpm

So, we have two screws at our disposal: the mixture quality screw and the idle speed screw. This is the action plan.

- We tighten the idle speed screw until the engine stops working normally, that is, there are gaps in operation, and turn it back a little. We achieve the lowest engine speed possible while maintaining stable operation.

- We tighten the quality screw until the engine stalls. It is important to do this slowly and count how much you have turned it. It is most convenient to turn the screw a quarter turn, this way you will get the exact value and will not get confused. As an example, your engine stalled at ¾ turn of the quality screw.

- Return the quality screw to its original position, in our case ¾, and start the engine

- We begin to unscrew the quality screw, again in quarters, counting how far it was unscrewed. In the process of unscrewing the quality screw, the engine speed will begin to increase, so during the process you will have to periodically tighten the idle speed screw to reduce them to the minimum with stable engine operation. At some point the engine will stall again. But he must do this by turning the quality screw, and not the idle screw. If in the process of resetting the speed with the idle speed screw you turned off the engine, then you should unscrew it, and also return the quality screw to its original position and start over. As an example, the engine stalled when the quality screw was turned 2¼ turns.

- We add 2¼ and ¾, we get the number 3, which we divide by 2. Through simple calculations we get 1½. This will be the number of revolutions by which we need to tighten the quality screw. Let's twist it.

- We are trying to start the engine. If this does not work, loosen the idle speed screw. After starting the engine, use the idle screw to set the nominal idle speed for your specific engine brand.

This completes the idle speed adjustment. But the carburetor adjustment has not been completed.

Tuning the PZ30 carburetor at medium speeds

When the carburetor float was adjusted, it was possible to notice that the PZ30 has two jets: the idle jet and the main jet. The maximum amount of fuel is limited by the main jet, and the amount is adjusted by a needle that rises and falls when the throttle handle moves.

From this it is not difficult to conclude that the air-fuel mixture will have to be adjusted by moving the metering needle, and not by turning any screw.

You can determine the quality of the mixture in garage conditions purely by eye, by the color of the spark plug insulator. A black insulator will tell us that the mixture is rich and the fuel supply should be limited. A white insulator indicates a lean mixture; accordingly, the amount of fuel should be increased. The insulator has a brownish tint when the air-fuel mixture is normal. You can read more about the color of the insulator and what problems it indicates in a separate article, “What does the color of a candle mean?”

There is one more very important nuance when setting the air-fuel mixture for medium engine speeds. In order for the insulator to become an indicator of the quality of the mixture, you will have to drive several kilometers, maintaining stable average engine speeds. In this case, you should not allow the engine to idle (the spark plug will immediately turn black) and you should not turn the engine to high speeds, as this will blow out the spark plug.

So, you drove several kilometers along an empty highway at medium speed, pulled over to the side of the road and immediately turned off the engine. After this, you need to wait until the engine cools down to a temperature at which you can hold your hand on it. We unscrew the spark plug and see the black insulator. Unscrew the carburetor cap and move the locking ring on the needle one notch up. That is, we lower the needle and limit the amount of fuel in the air-fuel mixture. If the insulator is white, then the stopper needs to be moved down one notch, thereby increasing the fuel supply.

We repeat the motorcycle ride and, depending on the result, move one more division in the desired direction or rejoice at the brownish tint of the spark plug insulator.

In some special cases, there is nowhere to move the locking ring on the needle, and a normal air-fuel mixture was never obtained. In such a situation, you will have to replace the main jet with a larger one if the mixture is lean, or a smaller one if the mixture is over-rich.

Well, the icing on the cake of all these manipulations is that your idle speed will most likely be lost and you will have to adjust it again.

Description of carburetor pz 30

The peak of mass popularity and popularity of motorcycle technology in domestic spaces occurred in the 70s and 80s of the last century. Mopeds “Riga”, “Verkhovyna”. Light vehicles “Minsk”, “Voskhod”, “Kovrovets”. Motor scooters “Tourist”, “Tulitsa”, “Ant”. Heavy stroller models “Ural”, “Dnepr”, “Izh”. The cult dream of the reckless drivers “Jawa”, “CZ”.

A serious problem with most models was the power supply system:

- high fuel consumption (the cheap price of gasoline eliminated the problem);

- “dips” when the throttle is turned sharply, especially at medium and high speeds;

- constant need to adjust the carburetor depending on the load.

The beginning of the 90s changed the political map. The iron curtain fell. Mechanical engineering was going through a difficult period. The market began to fill with imported used two- and three-wheeled units, mainly from the Indo-Chinese region. Enterprising compatriots organized a flow of spare parts to support imported foreign rubbish. Internet trading has started. Carburetors became available for engines with a volume of 150 - 200 cubic centimeters.

The pz 30 carburetor is produced by Chinese machine manufacturers for mass-produced middle-class motorcycles.

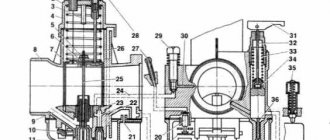

The mixer, traditionally copied from the design of the famous Japanese company Keihin PD, has undergone some changes:

- walls are strengthened;

- the diffuser cross-section has been increased;

- accelerator pump installed.

Externally, the PZ 30 carburetor resembles an inverted capital letter “T”, with a volumetric cover fitted at the bottom - a float chamber.

A horizontal passage with one flange (inner diameter is 30 mm) through a sealing gasket is seated on two studs and screwed to the engine cylinder. The other side (42 mm cross-section) is connected by a rubber curved pipe to the air filter.

Three holes from the channels are drilled into the chamber from below:

- idle speed (closer to the flange);

- transitional regime;

- main fuel supply.

The internal throttle valve, mounted on an axis piercing the walls of the chamber, rotates within an angle of 90 degrees to three fixed positions (fully closed, slightly open at an angle of 30 degrees, completely open), and changes the amount of air flow.

A cable is inserted into the vertical pipe to control the fuel supply throttle valve, which contains an adjustment needle.

Adjusting the PZ30 carburetor at high engine speeds

If at medium engine speeds the main jet and the regulating needle are responsible for the fuel supply, then at high speeds the needle is raised up and all that limits the flow of fuel is the throughput of the main jet. It was also said that at maximum speed the spark plug is blown out and will almost always have a whitish tint.

This raises two questions. How to adjust the PZ30 carburetor at maximum speed? How to determine the quality of the air-fuel mixture at maximum speed?

With the first question, the answer is obvious. You will have to regulate the quality of the mixture only by replacing the main jet and nothing else. But the second question is more interesting, but quite solvable.

Having unscrewed the throttle so that the engine speed rises to 65-70% of its maximum, you need to sharply turn the throttle to maximum and see what happens. If the motorcycle refuses to accelerate or even stalls, this will mean that the air-fuel mixture is lean and it is necessary to install a jet with a larger hole.

To check for a rich mixture, you should dial up the engine speed to maximum and sharply reduce it all to the same 65-70%. If you hear popping noises in the exhaust pipe, this will indicate a rich mixture, which means a smaller diameter jet is needed.

An important point is that in the case of a lean mixture, you can also hear popping noises, but they will come from the intake tract, that is, from the carburetor side.

It should be noted that after replacing the main jet in the PZ30 carburetor, you will have to re-adjust the idle speed and air-fuel mixture at medium speeds.

The end of the 2021 season was marked by an amazing discovery in the field of Chinese nanotechnology. After another rebuild, the original PZ30 refused to accept the throttle valve into its bowels. Long story short, one of the two components, either the throttle body (unlikely) or the hole where it fits, suddenly isn't cylindrical anymore. I took the damper out, but I couldn’t push it back in. The end of the season, it was not there - I thought, I sanded the damper and pushed it into place. I made it safely to the end of the season, but the understanding that this should not be the case did not leave me. And so, on cold winter evenings, after reading a lot of forums (hands-on and not so much), I bought a brother of my PZ30, burdened with an accelerator pump complete with a double throttle cable for 2000 rubles. They write all sorts of things on the forums and, having prepared for all sorts of difficulties, I climbed into the bowels of the moped. The new carb categorically refused to replace the old one. The accelerator pump rested against the frame, the exhaust manifold, and so on. People on the forums were sawing something, planing it, boiling it, pressing it with a hammer in order to shove the unfortunate man into the bowels of the motorcycle. I smoked, smoked, filed for half a day, but did not achieve anything meaningful. The next day I went to a motorcycle store and the seller, thanks to him, after rummaging through different boxes for half an hour, found me an intake manifold of unknown purpose (450 rubles) identical in fasteners to the original one, but different in shape and design. If the original one was a solid cast pig, then it turned out to be rubber, with aluminum flanges. It was successfully fitted to the engine, the heat-insulating gasket was thrown out as unnecessary, a new carb was attached to it, but a new misfortune occurred - the outlet of the airbox did not coincide with the inlet of the carb, and besides, the shitty trunk of the shitty airbox burst after painful manipulations. It was decided to remove it altogether and install a different air filter. Here I came across another miracle of Chinese engineering - it looks like the Chinese first put the airbox into an unfinished frame, and then finish welding it. In general, in order to pry the plastic box out of the frame, I had to cut off the left ear of the plastic fastening, use two pry bars to pry the box out of the frame, and weld the ear back. (Maybe it can be removed by removing the pendulum and everything that is screwed to it, but I had no intention of saving it.) After rummaging through the garage trash, I found two crooked hoses from the cooling systems of some cars - one with an internal diameter of 42 mm, the second with an external diameter 42 mm. From these two squiggles on clamps I assembled a crooked pipe, onto the end of which I put a 42 mm foam rubber zero (450 rubles). When installing the gas tank in place, I noticed that with its middle part it slightly rests on the upper part of the carb, but fortunately the manifold is flexible and these couple of millimeters are easily compensated for. When everything grew together, I tried to start the moped. I must say that usually, after a long period of parking, it was quite problematic to start it from the starter, and from the kick it was generally unrealistic. I twisted the throttle a little to spray gasoline into the intake, pressed the starter button and the engine came to life literally with half a kick. I added a little idle speed with a screw on the side and that was it. With the new carburetor, the moped starts up just perfectly in every possible way, it reacts instantly to a sharp opening of the gas, and does not try to stall, as was the case with the old carburetor. Due to weather conditions, I did not carry out sea trials, but I hope everything will be fine on the move. To summarize, we can say that the budget for the event was approximately 3,000 rubles. In addition to wrenches and screwdrivers, I needed a grinder and a semi-automatic welding machine. Access for servicing the air filter is simply amazing. Well, if you are thinking about such a modernization of your ZR200 - think carefully - can you? Good luck to everyone and the opening of the motorcycle season soon!

Let's sum it up

If you’ve read this far, it means you really want to understand how to set up your motorcycle’s carburetor, and the time spent writing above was not wasted. In fact, tuning the PZ30 carburetor, and others like it, is not the most difficult task and only looks like something incomprehensible. If configured correctly, even the famous Chinese quality will not interfere with the normal operation of the engine, although there will be nuances, such as the need to adjust the idle speed after each cleaning. But if you are patient and take one free evening, then as a reward for your time spent you will receive not only a motorcycle that responds to the throttle and consumes a minimum of fuel with maximum efficiency, but also a longer engine life. Which is, at least, nice, even though the piston engine for most Chinese motorcycles is quite inexpensive.

Having understood the nuances of tuning the PZ30 carburetor, you don’t have to be afraid of other carburetor models; the tuning algorithm, with very rare exceptions, will be absolutely the same.

Images used: china-moto.ru, alicdn.com, snegokhod-kayur.ru, jawa-store.ru, omoimot.ru

Keihin PZ30 carburetors

On the motorcycle were the K68s familiar to opposition riders. But from the very beginning I didn’t like how the bike worked for them. The spark plug has black carbon deposits, no matter how I try to reduce the fuel supply, it fails even with hard gas, I had to listen and catch how the engine picks up speed, and the Urals felt like they were consuming all 10l/100km. I decided to take the path of least resistance and change to a Chinese PZ30 with an accelerator pump (let's just walk). Moreover, their cost is humane. There are a lot of options and offers of ready-made solutions on the Internet. But all of them are delivered from other cities, and I’m really worried about the cost of shipping by SDEK, I don’t even consider Russian post. I decided to assemble all the components separately. I bought carburetors and cables at 139-qmb.ru. I cut the spacers myself from 4mm PCB and then glued them together into 8mm ones. In St. Petersburg, on a bulletin board, there was a person who sharpens adapter studs for these carburetors. The cost of the kit was about 4800-5000 rubles.

The result is a set like this:

The man makes hairpins in two versions - black and stainless steel. I wanted to get one made of stainless steel first, but he said that on vacation and for leftovers, they only have black ones. OK. The black pins turned out to be extremely soft and the first attempt to screw them in ended with a damaged thread of the head at the entrance and a chewed pin because it was bitten and had to be unscrewed by dogs. At first I wanted to throw away these studs, but the desire to try carburetors from the land of the rising sun was stronger. I took a tap and ran it with oil along all the threads in the heads. Then I went over all the studs with a die. In this way I restored the damaged threads both in the head and on the first stud. Then I screwed in all the studs in the same way with oil. This time they got in easily. The spacer had to be modified locally, because I had to cut it according to the K68 pattern, but I cut it according to the PZ30. No problem, I'll make new spacers later. So far, these aren't performing too badly either. I have not yet been able to install the purchased cables; during the first start-up I discovered that they lift the damper; naturally, all the tension adjusting screws are tightened to the maximum. They are not very suitable for the Urals and require a lot of modifications and adjustments. Therefore, I assembled everything using the original Ural cables without altering them, although without connecting the accelerator pump. The air pipes remained standard; of course, they had to be slightly persuaded to take an unusual shape, but this is not critical.

What's the result:

1. Starts have become more stable and are made with 1-2 kicks;

2. XX is stable, in cold weather you need to press the handle a little, as soon as it warms up, it holds XX;

3. There are practically no failures. Yes, the lack of an accelerator pump has an effect;

4. On the K68, one cylinder was always switched off. On the PZ30, both have always worked since launch;

5. I haven’t measured the consumption, but according to estimates it is no more than 7 liters, maybe 6 liters;

6. The candles changed color to white-gray, it’s a pity I didn’t take a photo, I wonder what the public would say;

7. It felt like the maximum speed had risen. On the K68 it was about 70-75 with a trailer, now it accelerated to 90 km/h and there was still some reserve at the handle. But these are very subjective assessments and do not deserve attention.

To sum up the short use of the PZ30 in the Urals, I must say that I am very pleased with the performance of the engine and do not regret the money and time spent. One cannot ignore the fact that the engine is very tired, there are cavities in the cylinders, and the pistons have play with the wall.

As for the K68, I don’t rule out the possibility that I’ll return to them someday when I delve deeper into their design and tuning. So far, as a novice boxer rider, I like the PZ30 option.

Tags

- PZ30

- IMZ-8.103-10