Motorcycle fork repair

Fork bulkhead

The fork is one of the main components of a motorcycle, which performs the function of shock absorption, smoothing out all the unevenness of the road. Over time, like any other component, it requires maintenance. A damaged plug or its components can lead to serious consequences such as falls or accidents. Therefore, monitoring her condition is very important. Depending on the situation, the bulkhead will be required differently. Standardly, the forks need to be replaced with oil seals and anthers, guide bushings, springs, and fork oil.

What types of forks are there? What is their difference?

Before you start rebuilding, look at what fork is installed on your bike. They come in two types - telescopic and inverted.

Most often, motorcycles (especially old and small ones) are equipped with telescopic ones. It consists of two feathers clamped by transverse crossbars. The axis of a wheel with such a fork passes through the lower part of the stays, and the wheel itself is located between them. The telescopic upper pipes are clamped in traverses. These fixed pipes are supported by movable pipes, often made of light alloys. Inside the racks there are cylindrical springs that help the movable pipes move along the stationary ones. To ensure their best sliding, replaceable bushings lubricated with oil are installed in the pipes. Standard forks do a good job of front suspension and provide sufficient travel length, but it also has disadvantages, which include insufficient rigidity and easy deformation in an accident. According to these indicators, “reversals” outperform standard forks. Nowadays, “shifters” are used more and more often on new models, as well as on sportbikes, where fork rigidity is very important. In fact, an inverted fork is a standard part turned upside down, but has its own distinctive features: high strength and reduced unsprung weight in the front wheel. Thanks to this, “shifters” have become indispensable in motorsports and are gradually gaining popularity on city motorcycles. On scooters where the speed is lower, a simplified telescopic suspension is usually installed, in which two upper pipes with a lower crossbar and a steering column pipe are assembled into a single structure.

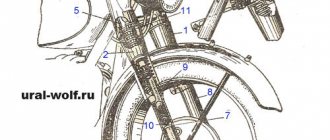

Plug device

Despite the different types of plugs, their structure is almost the same. The main components of a fork are the feathers and the glass. The feathers contain a plug (feather plug) with a rubber seal that holds the other parts in place. The plug is equipped with a rebound adjustment mechanism - a screw that allows you to adjust the stiffness of the fork (this part is more often found on inverted forks). Next come springs that serve to smooth the fork stroke, spacers, bushings, guides - tightly closed solid rings made of copper or steel, coated with graphite coating, reducing friction between the cups (depending on the model of the bike, each feather has two or more guides bushings), as well as a cartridge containing the shock absorber rod, piston and fork oil. Seals and anthers are installed between the glasses and feathers - consumables that perform an important protective function, preventing the entry of dirt and moisture, and also soften the friction of parts. There is a drain bolt at the bottom or top (depending on the type).

When is it necessary to do a bulkhead?

Many steering parts require maintenance and timely replacement, because the correct operation of the front control unit depends on them. Most often, they become unusable over time and from exposure to external factors (bad roads and off-road conditions, aggressive driving style, dirt and dust). In extreme cases, the fork will have to be replaced after an accident; this will require more complex and expensive repairs. Typically, feathers are damaged in an accident; if the damage is minor, they can be straightened, but if the damage is serious, they must be replaced. To do this, it is better to contact the service, which will save you effort and time. Standard overhaul of any type of fork requires time and skill, but if you decide to do it yourself, then our article is for you.

Rebuilding the fork piece by piece

To work, you will need tools and equipment: a set of keys and hexagons, a container for draining oil, a plastic pipe (with a diameter equal to the diameter of the pen) or a special tool (mandrel). If you have a manual with the front part, use it, it will make disassembly easier. 1.

The first thing to do before disassembling is to hang the motorcycle. Loosen all bolts and remove everything attached to the fork, including the axle and front wheel. Unscrew the top cap of the pen (cork), this procedure is best done with a special tool. When removing the fixing nut, remember its position (the number of turns on the thread) so that when reassembling it, it will be easier to install it. Disassemble the feathers. Be careful and disassemble carefully, as they contain springs that are in a compressed state, due to which they can quickly fly out. After the spring is removed, drain the liquid into a prepared container. If you are working on a bike without a bottom plug, then the removed fork should be turned over so that the oil flows out of it through the only hole. After draining, the fork needs to be rinsed; to do this, use a special liquid. Having done all this, blow out the part from the inside with compressed air from a compressor or using a special spray can.

2.

Next, take care of the main consumables that most often require replacement -

anthers and seals.

They are used in motorcycles to seal the gaps between rotating and stationary parts, and they also prevent the leakage of coolant (in the engine) and fork oil, and protect parts from the penetration of dust and dirt. Usually these consumables deteriorate due to age and stress. The boot begins to let dirt and water through, and the seal begins to rot. Worn-out spare parts affect the control of the bike: in sharp turns it can skid, and oil will begin to leak. Oil seals can leak from old age, due to sudden temperature changes (off-season) or from improper installation, when during installation, instead of a mandrel, an improvised tool is used that is not intended for this purpose. A leak is not always associated with a defect in the seals themselves; sometimes it indicates general wear of the fork components (usually guides) or damage to the stays due to an impact. Damaged anthers and seals can damage equipment and make it unsafe to operate. To maintain proper, efficient operation of the motorcycle fork, replacement is recommended at least once every 2 years. It is better to change oil seals and anthers together, since they work together in the fork. They need to be selected not by size, but by bike model. Not all fork seals that are the right size will fit your motorcycle, since they can be produced in different configurations (for example, for an upside-down fork, the seal will come with two springs, but a simpler analogue with the same load dimensions will not withstand). To change these parts, first carefully remove the boot using a thin, straight screwdriver. Behind it there is an oil seal; it can also be removed with a screwdriver. If on your bike the guide ring is installed on the feather, the glass is removed with sharp pushes, and the oil seal is knocked out using the guide ring. Next, place the new consumable on the pen with the outer spring facing down. Place a mandrel on the feather - this is a tool made of high-strength steel, has a cylindrical shape and is divided into two halves for easier installation and proper fixation of the oil seals (the frame for forks comes in diameters from 35 to 51 mm). If you don't have one, use an old oil seal or plastic tube of the appropriate diameter, but be careful, these methods are not so reliable. Once the oil seal is installed, replace the retaining ring and boot.

3.

Replace the guides. These parts are tightly closed solid rings made of copper or steel, coated with graphite, placed inside the pen and reducing friction between the glasses. Depending on the bike model, each chainstay may have two or more guide bushings. High-quality guides ensure precise operation of the fork without backlash, and also extend the life of oil seals and anthers. Over time, the bushing wears out, its thickness becomes less and less, and the old part will begin to show signs indicating some kind of malfunction. The appearance of play in the movable tips of the feathers (this can be determined when the wheel is raised) and a characteristic knock indicate wear on the bushings. To get to the sleeve, release the inner cartridge from the pen, remove the retaining ring and the seal. The guide bushings can be easily removed and put on quickly. For easier installation of the guides, lubricate them or part of the pen with fork oil. When placing parts in place, we advise you to use mandrels to install the oil seals without damage. American All Balls guide kits will help you quickly replace fork guides and internal seals. They can withstand up to 500,000 strokes with less wear than stock and guarantee long, efficient fork operation.

4.

Pay attention to the steering column.

It is a mechanical part of the entire steering system, and for its high-quality operation, another element is needed - a bearing. The steering column and its bearings are constantly under load, their condition affects the controllability and safety during operation of the motorcycle, so they require maintenance and timely replacement. Damaged consumables can cause play, the motorcycle will start to steer in a straight line, and very old ones can even jam the steering column, which is not safe. Also, the main reason for the formation of play is the penetration of moisture, sand and dirt into the base of the steering column, which damage the bearing. To inspect this part for wear, move the fork on a hanging bike; knocking and play will indicate the need for replacement. Typically, motorcycles are equipped with standard ball bearings, which wear out quite quickly and do not withstand such heavy loads as, for example, tapered roller bearings. The advantage of conical ones is that they are designed specifically for use in difficult conditions and prevent the formation of backlash for a long time. Sometimes, to remove the play, it is enough to simply tighten the adjusting nut. But if this method does not help or you do not know how long and which bearing has been installed on the bike (on a used motorcycle), then it is worth replacing it. You will also need new boots that will prevent moisture and dust from entering. To change the column bearings, unscrew the spline nuts (using a round spline nut wrench). Next, remove the upper boots and bearings, pull out the yoke with the steering axle and bearing. Remove the bearing and boot and install new consumables in their place. For easier shrinkage, the part can be heated. Install the yoke and the axle with the bearing back into the steering column, tighten the nut to the initial torque of about 30-50 N.m.

, check the traverse for play and smooth movement.

The adjusting nut must be tightened again ( 103 N.m.

) After this, you can put the entire fork back together.

It is recommended to re-adjust and tighten the adjusting nut (after 100-200 km

).

5.

After all these changes, you can fill in fresh fork oil.

Tighten the drain bolt to prevent it from leaking out. Before pouring, pull out the inner aluminum tube. While holding the rod with your fingers, fill in the liquid. The optimal amount of oil will be indicated in the manual. It is usually recommended to pour about 400-500 grams into each pen

.

Many manufacturers recommend replacing fork oil every 12-15 tons.

km .

It is recommended to change the oil after long-term winter storage; during cold weather it may lose its properties. On asphalt surfaces and during quiet driving, fork stiffness is not as important as, for example, on off-road and bumpy terrain. If the equipment is used in extreme sports conditions (circuit racing, motocross, stunt riding), then you will have to fill in a more viscous fluid ( 5W 7.5W

) and change it more often - approximately every 5 tons.

km. After all, if the oil is too thin, strong “pecks” may occur at high speeds and sudden braking; this behavior can lead to destabilization of the bike on the road. Liquid lubricant can cause vibrations and jerking, which will affect the comfort of sports driving. At the same time, the same thick liquid negatively affects comfort in urban environments. There is less load and the ride is smoother. But on any uneven or poor surface, a rigid fork will make itself known in the form of a strong blow, which can even knock the bike off course. In most modern motorcycles, depending on the type and model, the viscosity most often used is 10W or 5W, 7.5W

is intermediate and is suitable for those who want to either lower or increase the stiffness of the fork.

15W

is stiffer, and some bikes use it as standard, such as older Kawasaki GPZ, GPX, ZR, Vulcan, Voyager and Suzuki GSX models from the 90s, as well as Kawasaki KLR enduros and Suzuki XF650.

Fork oil is designed to absorb the pressure that comes to the fork when operating a motorcycle and make riding the bike more comfortable. Despite the recommendations in the manual, for many people choosing fork oil becomes problematic. The problem is that motorcycle manufacturers often specify ideal viscosity parameters at operating oil temperatures that are many times higher than the temperature at which the fluid is poured into the fork. Therefore, it is necessary to pay attention not only to the standard designation of viscosity, but also to the coefficient of its change with increasing temperature. You cannot add any other oil (for example, motor oil), as it can damage the components of the fork. With the wrong or low-quality oil, the motorcycle can become dangerous and lose control, leading to accidents or falls. Correct and competent selection will help you obtain the necessary parameters of suspension stiffness and ensure good vehicle controllability. Oil indicators are classified by viscosity according to the internationally accepted standard SAE J300

.

If the viscosity class designation contains the letter W (Winter), this means that such a composition is seasonal, that is, it can be used even in winter. For motorcycles used off-road (motocross), you need to purchase technical fluid marked “Off-Road”

.

For tourism 10W oil

, for sports and urban

- from 2.5 to 5

.

The first change is always made with oil with the same viscosity

as specified in the vehicle's operating instructions.

With a significant reduction in fork stiffness, you will need to gradually increase the viscosity - by 2.5W or 5W

with each subsequent replacement, depending on your personal preference. We advise you to choose one quality oil that suits you and use only that in the future. Squeeze the stay a couple of times to pump out excess air, after which the fork can be installed back on the bike.

6.

If your motorcycle is equipped with corrugations, check their condition. The front fork corrugations are designed to protect it from external influences such as sand, moisture and stones that can easily get on the fork while riding off-road. It prevents the formation of corrosion and dents on the bike's stays, and also prevents sand from entering, damaging the seals and the outer layer of the stays. The corrugations are made of durable heat-resistant rubber. This material is resistant to compression/expansion, friction, temperature changes, and chemical influences (during washing). Due to the use of rubber, the part stretches well, has a wide range of sizes and fits many models. Unfortunately, over time, any rubber hardens and becomes harder; such damaged corrugations can crack in the cold, from friction or from a fall. The worn part should be replaced. To keep the corrugations in good condition for a long time, it is recommended to treat the protection with silicone during the winter period. Most often, corrugations are used on motocross or enduro motorcycles of older models: on domestic ones - Java (Java), Voskhod, on foreign ones - Yamaha, Suzuki. Usually they were installed on telescopic ones, which made them difficult to replace. In modern models, plastic feather protection is more often used; it is much stronger, more resistant to damage and is not subject to aging. Due to the use of new technologies, thanks to which the fork is less susceptible to external influences (high-quality materials, spraying), there is no need to cover the part with rubber bellows. In addition, plastic ones are much easier to replace without disassembling the fork.

7.

With the entire fork disassembled and the wheel removed, the wheel bearings can be replaced.

The bearing ensures smooth and precise rotation of the wheels and ensures safe driving. They are used in wheel hubs, steering columns and other places on the bike. Motorcycle wheel bearings can withstand up to 25t.

km. , but bad roads, off-road driving, accidents and performing stunts on a bike can shorten the life of the bearing.

If the bearings are worn out, the motorcycle will begin to wobble a little at low speeds and noise will be heard from the wheels. Over time, wear will increase and this will lead to bearing failure. It is not safe to drive with such a part - the wheel may jam, which will lead to a fall and breakage. Wheel bearings for bikes are maintenance-free; inside they are coated with a special lubricant, and its walls are non-removable. A damaged spare part must be replaced with a new one. As a standard, a motorcycle with a conventional fork has 5 bearings in the wheels - 2 in the front and 3 in the rear (two for the wheel, one for the hub).

If you decide to replace a wheel bearing, then it is worth changing

two at once

(on each side) for more reliable operation.

To make removal easier, you can heat the bearing. Under no circumstances pull it out without heating, this action may break the spare part, its parts may get stuck in the connector and removing the bearing will become even more difficult. Once you have removed the part, simply install a new one in its place. New bearings should be checked after some time indicated in the manual; to do this, you can hang the motorcycle or inspect the wheels themselves during tire fitting. Rotate them, if they rotate easily and do not make noise, then the parts are in good condition. If you notice play or hear noise, change the bearings

. They can fail ahead of schedule not only due to external factors, but also due to lack of lubrication or improper installation. A small amount of grease in a bearing can cause it to overheat. When choosing a new part, pay attention to its parameters (size, load force, load direction, number of revolutions). Most often, size is measured in internal diameter, which is determined by the internal design of the bearing. Because of this, different bearings are used for shafts of different diameters: for a shaft with a small diameter, almost all types are used, including needle ones; for large diameters - ball, roller, spherical. The load when choosing also plays a key role; for low and medium loads, ball bearings are used, for high loads, roller bearings are used. The load is also divided into three types: radial, axial, combined. To carry radial loads, radial ball bearings are suitable, for axial loads - thrust and angular contact ball bearings, for combined loads - single row and double angular contact ball bearings. Now there is a huge selection of them on the market, among the manufacturers are SKF (the largest European manufacturer), NSK, NTN, FAG (German manufacturer), All Balls and others.

Conclusion

In this article we figured out how to do a bulkhead. At first glance, it seems that the fork structure is quite complicated, but if you have enough time, effort and knowledge, you can safely do the rebuild yourself. But if you are a beginner and not confident in your abilities, use the services of a service so that such an important part of the motorcycle as the steering works correctly and without failures.

Flipped over

In the 70s and 80s, they tried to solve the problem of severe deformation due to the length of the shock absorber fork with the help of additional reinforcements, or by significantly increasing the diameters of the lags. Until the late 80s, the system was turned on its head. This trick is called upside-down (USD) and has several serious advantages.

The extreme bending forces generated at the bottom flange of the fork work on a very large diameter USD razor. In addition, during its compression, when a bending moment occurs, the lower razors enter the upper ones, which increases the rigidity of the assembly. This high stability of the upside-down fork is one of the reasons why many manufacturers have increased the diameter of the shank over the last 20 years. Therefore, most production cars use forks with shanks with a diameter of 41, 43, sometimes 45 mm. USD is a good solution in terms of mass distribution and at the same time reduces friction.

The Duolever suspension is complex and heavy. Advantage? Minimum dive when braking

The special coating (such as titanium nitride) that coats the fork legs reduces friction between the journal bearings and seals, but also increases the surface's scratch resistance.

Cutouts on the top shelf of racing motorcycles provide the necessary flexibility and improve the feel of the front end of the motorcycle. And by the way, they reduce weight

The disadvantage of the classic fork was high friction, which is why, for example, BMW uses the Telelever front suspension, which combines the features of a telescopic fork and a swingarm. A more radical solution is the Duolever system (the principle of operation dates back to the Hossack suspension of 1979), in which components move in low-friction rolling bearings. In this solution, the wheel rests on massive rocker arms, and the suspension and damping are carried by a shock absorber placed between them. Thanks to this arrangement of the rocker arm mounting points, this design practically does not dive during braking.

Many thought that this would be the end of the telescopic fork's career. In 2009 they must have been very surprised, because the BMW S 1000 RR, fitted with USD forks, proved superior to the Duoiller in tests. The WS 1000 RR was an element produced by Sachs.

Big Piston = big piston

With limited volume shock absorbers housed in narrow shanks in which they work with relatively small and difficult-to-align pistons, the Japanese replaced the Big Piston system . These are hydraulic damping systems with large pistons that provide very sensitive and extremely precise damping.

Big Piston fork that goes straight to the shin. Below are traditional small-diameter fork pistons with rebound damping adjustment (right) and rebound damping, all housed in a single shock cylinder (called a cartridge).

motorcycle front suspension

Large diameters here mean better control over damping control, especially in the low to medium speed range (we're talking suspension speeds of around 10-150mm/s). Thanks to this, a soft response with excellent stability and feedback was consistent.

The next step was to place the damping system in one joist and the rebound suppression in the other. Asymmetrical load sharing is not a problem. The rigidity is quite sufficient to avoid deformation during deep and quick fixation of the fork.

The next step in evolution has already been established in racing: the gas engine fork (closed cartridge) has a small gas-filled shock absorber, which provides a constant damping force because the oil does not mix with the air in it and does not form an emulsion.

Post Views: 4,671

A lot of good things

About 20 years ago, the guys from Bimota and Yamaha, like Pinky and Brain of the cartoon, planned to take over the world with motocross motorcycles. In the case of Yamaha we are talking about the GTS 1000, in Bimota we are talking about the even more technically complex Tesi model.

The sport tourer GTS 1000 failed to translate its theoretical merits into everyday use, which is probably why it was not a bestseller among others, which is why it disappeared from the market after five years. Although the Tesi can still be purchased, it is a motorcycle for fans of the brand and alternative solutions. The design solutions of both motorcycles had many disadvantages: they were technically complex and, therefore, expensive to manufacture, provided a turning radius that was too small for a road motorcycle, and did not provide the best transmission of torque.

Countless racing prototypes with alternative suspensions have led to the fact that today, even in racing, the compact and not very expensive USD fork rules the roost.