Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at [email protected]

Why won't my gasoline generator start? Solution

Looking at the demand for gasoline generators today, it may seem that the production of these devices is one of the leading branches of modern mobile energy. In view of this situation, the conclusion arises in my head that such power supplies probably have an excellent safety margin and an assembly mechanism that has been fine-tuned over many years and does not misfire.

In reality, as is usually the case, the picture is less rosy. Even the newest fuel generators can be completely useless, simply refusing to start despite the user's efforts. Hence, numerous questions arise about the reasons for such situations, which often cast a shadow on even the most popular brands. Today we will talk about several possible sources of the problem of a non-working engine in a gasoline power plant, while simultaneously proposing ways to solve them.

How to fix a scooter

You will need

- — a set of open-end and ring wrenches, socket heads;

- - screwdrivers with flat and Phillips blades;

- - tester, insulating tape.

Instructions

If the engine does not start, check whether the ignition key is turned to the desired position and whether one of the brake levers is pressed. Check the serviceability of the brake light bulb or its electrical circuit. Look and replace if necessary the fuse in the main electric starter circuit. Check the terminals on the battery. Clean them from oxides, measure the battery voltage and charge if necessary. You can temporarily start the scooter using the kickstarter.

Check the serviceability of the electric starter circuit. Clean the contacts on the relay and starter, test the relay, starter windings and scooter wiring. If the kickstarter spins, check and replace defective kickstarter gears or ratchet gears. Unscrew the carburetor float chamber drain screw. If there is no gasoline in it, clean the gas tap filter and blow out the fuel line, check the serviceability of the gas tap itself and the tightness of the vacuum hose of its control. If the carburetor fuel valve is stuck, remove the float chamber cap and clean the valve seat. If this does not help, replace the valve. Unscrew the spark plug. If it is covered with a layer of unburned fuel, disassemble the carburetor, check the fuel level in the float chamber and clean the air filter. Check the serviceability of the automatic starter enricher and the spark at the spark plug. If it is missing, clean the spark plug electrodes with sandpaper or replace them. If this does not help, check the serviceability of other elements of the ignition system.

If the engine runs unstable, check the tightness of the carburetor inlet pipe and replace the gasket. Replace the crankshaft seals. By unscrewing the drain screw of the float chamber, get rid of the water in it. Blow out the carburetor jets and channels. Replace the gasoline in the tank. Remove the spark plug. If there is water on the insulator and electrodes, get rid of it in the carburetor float chamber by unscrewing the drain screw.

If there is black oily deposits on the insulator and electrodes of the spark plug, replace it with a similar one with a lower heat rating. Check and clean the vent hole in the fuel tank cap. Check the compression using a compression gauge. If it is not within specification, replace the piston, cylinder and piston rings. If there are oily marks on the head and cylinder, replace the gasket under the cylinder head or tighten the nuts securing it firmly and in the order recommended in the repair manual.

If there are extraneous sounds when the engine is running, adjust the thermal clearances in the valve drive of four-stroke engines. Check the tension and adjust the valve timing chain. Replace worn pulleys, rollers and other variator parts with new ones. If the engine stalls when the throttle valve is opened sharply, check whether the engine has warmed up sufficiently, check the carburetor adjustments and its main metering system, and the correct operation of the variator. If the engine does not pick up speed, smokes, consumes a lot of fuel, and a black coating has formed on the spark plug electrode, adjust the carburetor or install a smaller main fuel jet. If there is detonation and white deposits on the spark plug, also adjust the carburetor or install a larger main fuel jet. Also, check for clogged muffler, cylinder bores and ports. Clean them. If the muffler cannot be cleaned, replace it. If the engine begins to lose power while driving, check the fan blades and shrouds on the air-cooled engine. Replace damaged, broken or cracked ones. On a liquid-cooled engine, check for coolant leakage by checking its level in the reservoir. If necessary, replace the water pump, thermostat, radiator.

www.kakprosto.ru

Principle of operation

One revolution of the crankshaft is one cycle of the operating process of an internal combustion engine.

Fuel (gasoline + oil) with air is supplied to the working combustion chamber of the cylinder, after which, due to the formation of a spark from the spark plug, an explosion of the combustible mixture occurs, the energy of which sharply pushes the piston down.

The fuel mixture enters the engine crankcase through a window that opens due to vacuum as the piston moves upward from bottom dead center (BDC) to top dead center (TDC). This movement also opens a window for the release of gases from the burnt mixture. After milliseconds, the purge window opens. A new portion of fuel is supplied through the purge window.

Petrol mower and chainsaw.

No matter what country of origin the mini equipment equipped with a simple two-stroke engine belongs to, any malfunction will depend on what the engine is “fed” and on the quality of the assembly. Of course, one can doubt the quality of the assembly units themselves, and one can talk about this for a long time. Some are satisfied, but others are not.

For example, we only need a chainsaw for one day. We rent or buy the cheapest one. Professional sawyers will need a chainsaw with a long service life, and its cost is noticeable. But what to do when they sell one-time equipment as professional or semi-professional at an appropriate price? We, the ignorant, do not know about this. So everything breaks down, and sometimes all at once.

Failure to operate a two-stroke engine or its breakdown occurs in different ways and depends on a wide range of reasons.

Here's an example. The owner has been using the lawn mower for several years. The scythe fell into other hands and this is the result. The engine jammed, and the user did not understand why it stalled. 'A good knock comes out.' The piston had a casting defect, which came to light at that very unnecessary moment. We tried to start the day, but to no avail. When opening the piston, aluminum particles of the piston were ground to the cylinder wall. What is the compression here? The spark plug hole was pressed with a finger and a newspaper wad was inserted by the craftsmen. They blamed the carburetor, and in vain.

Is it possible to increase engine power

Increasing engine power is called boosting; it is not easy to do, but it is possible. Today there are two options to increase engine power:

- Remove the limiter and change the valve clearance, only suitable for small engines.

- For larger units: replace some spare parts and motor components.

You need to approach such work responsibly, because it is not only difficult, but also expensive. Each type of engine has its own techniques:

- Strengthening a two-stroke engine can be achieved by making some improvements in the reed valves and, better yet, with the help of knowledgeable people.

- Four-stroke: bore the carburetor, this way you can increase the diameter of the diffuser.

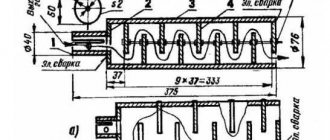

Domestic production

During the summer holiday season, many people dream of riding on the water with the breeze, while having an inexpensive but reliable engine. But they don’t have great speed, which means they can hardly please you. But any mechanism, if desired, can be modified to increase power.

- First you need to increase fuel combustion in the chamber. And also increase the diameters of the channels for its supply. In this case, you need to buy a new carburetor. External fastenings only need to fit.

- Next we change the piston system. It is necessary for the fuel combustion chamber to be larger and able to cope with large volumes of fuel. And it is necessary to increase the screw blades.

Make it a rule, on every fishing trip, the first thing you do is start.

Foreign production

They almost always make engines with too much power, but they put a limiter on it. This is a common marketing technique; they present only one engine, but in different transformations and different powers.

This means that by purchasing an inexpensive and low-power motor, you remove the limiter and get a more powerful motor for the same money. And besides, it is possible to apply a technique to speed up the engine.

Two-stroke engine - disassembly and assembly

The engine-transmission unit is removed from the scooter frame, the variator cover is removed, the variator belt is removed, the drive pulley and variator are removed, the driven pulley and clutch are removed (To disassemble the engine, it is not necessary to remove the driven pulley and clutch, but for ease of operation this can be done) , the exhaust system has been removed.

Having removed the cooling casing from the cylinder, unscrew the cylinder fasteners crosswise.

Having removed the head, carefully, lightly hit the cylinder with a wooden mallet in order to move it from its place. Carefully remove the cylinder.

ATTENTION:

Quite often the head “sticks” to the cylinder and it is impossible to move it. To remove the head, you need to apply several light blows with a mallet or rubber hammer, alternately from opposite ends of the head.

It is important not to break or deform the cooling fins!

Note

:

Immediately place a clean rag in the engine cavity to prevent foreign objects from entering.

Note

:

It is recommended to replace the gaskets with new ones, but if the used gasket was removed without any damage, it can be reused.

Carefully remove one retaining ring with a sharp object, holding it with your finger. Using an object of suitable size (a 3/8 square tool is ideal), push out the piston pin. It is not pressed in, it is simply installed a little “pull-in”.

ATTENTION:

Do not knock out a finger with a hammer. This will inevitably lead to deformation of the connecting rod itself, or the ends of the upper head of the connecting rod. This operation generally requires special care, since if you do not secure the piston sufficiently, you can easily bend the connecting rod

In addition, it is important not to damage the working surfaces of the piston bosses

After removing the piston, remove the needle bearing from the upper head of the connecting rod.

Removing the piston rings

Tools for taking measurements

To obtain accurate information regarding engine compression, compression gauges with rubber seals or threaded connections can be used. Each of them has features and scope.

Pressure compression gauges

The first type of device is most often cheaper and is used to take measurements in gasoline internal combustion engines. The permissible pressure indicator of such a compression meter is 16 atmospheres.

Such a device is inconvenient to use alone, since it is necessary to hold the device tightly in the spark plug hole, but, nevertheless, its use makes it possible to obtain information regarding compression in the cylinder.

Thread compression gauges

Thread compression meters are often used to diagnose diesel engines.

The maximum permissible pressure value for such devices is 40 atmospheres. The threaded connection makes it possible to securely install the device and ensure accurate data regarding compression, despite high pressure.

Hydraulic front wheel disc brake

The disc brake mechanism on a scooter is usually hydraulically driven, as opposed to a drum mechanism. The disc (or two discs) is rigidly attached to the wheel hub, and the brake caliper (caliper) is attached to the fork. During braking, the disc is clamped on both sides by the brake pads. Brake calipers vary in design and can have from one to eight pistons. Scooters typically use two- and four-piston options. The brackets also differ in the way they are attached to the fork - they can be fixed or floating. The difference between them is that in fixed calipers, each pad is pressed by its own pistons, but in a floating caliper, the piston is located on only one side and uniform force is applied to the pads due to the movement of the entire brake caliper along the guides. When the pressure on the pads decreases, the bracket returns to its original position, forming gaps between the pads and the disc. However, on small-capacity vehicles, drum brakes are often sufficient, since the speeds here are low, but on modern “large” scooters there are often disc brakes both front and rear; there can be two brake discs on the front wheel hub, and, accordingly, two brake discs. hydraulic calipers on the fork. The brake systems on most scooters are separately controlled, meaning the rear and front wheel brakes are operated independently of each other. The rear brake is usually operated by a lever on the left handlebar. The front brakes are applied with the right handle (like on a motorcycle). Recently, scooters with large engine capacities have also begun to use combined hydraulically driven brake systems, where the right lever controls not only the front brake caliper, but also directs part of the force to the brake of the rear wheel. In addition to service brakes, some “older” scooter models may have a parking brake, which is used to hold the scooter on a slope. Typically, it consists of a drum brake built into the rear wheel hub and operated by a separate lever. On modern models of scooters with large engine capacities, anti-lock braking systems are not uncommon, which help to avoid wheel locking during sudden braking. There are several varieties of such systems, but they all have the same ultimate goal: to prevent the brakes from locking the wheel, which can lead to the scooter falling. ABS systems are integrated into the hydraulic braking systems of scooters, and consist of a control unit, wheel rotation sensors and a system of hydraulic valves that are “responsible” for reducing the pressure in the brake line when signs of wheel locking appear.

Checking the spark

So, you've unscrewed the spark plug. After you are sure whether fuel is flowing or not, check for the presence of a spark. To do this, insert it into the tip of the high-voltage wire (popularly the “mouthpiece”) that was on it when it was twisted, and attach the outer electrode to any metal part of the engine (to ground). It’s just better to connect it away from the twisting point, so that the resulting spark does not accidentally ignite the fuel evaporating from the cylinder.

After applying the spark plug electrode to the ground, you need to pull the starter. If there is a spark, then everything is in order. If not, then there can be a lot of reasons for its absence: from banal wear of the spark plug to an electrical malfunction.

To make sure that the problem is in the spark plug, you need to either put the same spark plug on a known-good unit, or on a generator that won’t start, check the spark from a known-good spark plug.

Troubleshooting

Malfunctions of electrical equipment and fuel systems are the most regular of all problems that arise among scooter owners.

It often happens that a breakdown suddenly occurs to the scooter. Repairing the carburetor, as a rule, allows you to resume the functioning of your “faithful horse”.

Usually, to do this, it is enough to remove the carburetor, clean the dust from the outside and the tarry deposits of gasoline and other debris inside. Clean and blow out the air and fuel channels and jets, check the condition of the fuel needle and throttle valve, and then reassemble and adjust it.

Fixing more complex breakdowns at home is not always possible, since specific tools are often required that are not widely available.

Thus, for a technically literate person, repairing a scooter with your own hands will not be very difficult if you have minimal knowledge and skills in handling equipment, as well as the necessary tools.

Cold generator won't start

Hi all. Good people, maybe someone knows what needs to be turned in the carburetor of a five kilowatt generator. It doesn't want to start at least at -10, or even at 0. Gasoline, ignition and air damper (closing) are swept aside, when pouring 5 cubes into the cylinder, it rumbles on the third attempt. Plugging the carb with a rag without a breather also helps, albeit with the stem. But you understand, all this does not bring pleasure. There is an 8-9 mm hole in the air damper, I thought that the Chinese forgot to supply the spare part, but in the photos on the Internet the hole is also empty. Gene WOLSH GB6500E 5 kW, motor 188F clone GX-390. The carb brand is not filled and there is no label, there are no wires. I'll post pictures one of these days. Hello everyone and thank you in advance. Sincerely. Victor.

Victor, hello. Go to the forum of Mobloc manufacturers of Dviglov Honda, everything is sorted out there. They seem to recommend installing the A17 DVR spark plug, sometimes it helps.

lipilo wrote: Victor, hello. Go to the Dviglov Honda mobloc forum, everything is sorted out there. They seem to recommend installing the A17 DVR spark plug, sometimes it helps.

Thank you dear, I'll come in now. Good health to you. Victor

lipilo wrote: Victor, hello. Go to the Dviglov Honda mobloc forum, everything is sorted out there. They seem to recommend installing the A17 DVR spark plug, sometimes it helps.

Yesterday I sat up past midnight, but apparently I’m the only one with this problem. I'll try to change the spark plug now, although there's little hope. It's already -13 outside. Apparently I was very “lucky” in the lottery, because no one else has such a carburetor and is also on sale.

Thanks again and best regards. Victor.

And more history: how much did you earn, how did you behave, and then began to fool around? what kind of oil is in it? How does it start when hot? is there a fuel filter? Has the carburetor ever drained the sediment? condition of the original spark plug? is there compression? etc. more information if available.

Basic batteries for hoverboards

If a smart balance type hoverboard is not charging, and it comes to replacing the battery, here is some information on which battery is best suited for almost all models.

There are several different types of lithium batteries. However, despite all their differences, almost all of them are made on a “one size fits most” basis. The most common battery replacement usually occurs on 2021 and 2016 model years - the most common hoverboard battery during these years was the blue shrink-wrap battery. Gray batteries are less likely to fail. The most durable (from personal experience) are green ones.

The blue shrink battery is the base battery that was included in most all hoverboard brands and models from 2020 to 2021. Gray and green batteries were also from the same era, but were much less popular at the time due to their high cost.

The UV2271 rechargeable battery is the best battery on the market today. A company known as UnderWriter's Laboratories, a professional safety standards and compliance testing firm, has developed a methodology to guide their release and therefore installation on most models.

So we looked at the problems why the hoverboard does not charge, as well as their causes and possible solutions. Happy renovation!

Examples of power increases

All reconstructions are also cheap, almost free, but sometimes this may require a significant amount of money, let's look at some models:

It's a four-stroke engine, and adding another horsepower to it is very easy. You just need to buy a carburetor for a boat with a Tohatsu 6 engine and change it, you get a Tohatsu 6. It will cost about $170, and the difference between these two engines is $450. A little, of course, but you can save money.

The Yamaha 5 two-stroke engine also has slightly underestimated technical characteristics and, therefore, simply replacing the carburetor will not work:

- The throttle valve delimiter must be located and removed.

- In a petal valve, you need to press out the petal, but it is advisable to first consult with knowledgeable people.

The limiter is installed due to increased environmental requirements. They are banning them in many countries and protecting nature from excessive carcinogenic emissions into the atmosphere.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Checking the fuel supply

In order to check whether gasoline is entering the cylinder, you need to unscrew the spark plug and look at its electrodes. If the spark plug is dry, then gasoline apparently does not flow, but if it is wet, then it does.

Sometimes it happens that the spark plug is “flooded” with fuel during starting. That is, there seems to be a spark, but for some reason it was not possible to start the engine right away, and at the same time gasoline flowed while pulling the starter, the spark plug became damp and the spark no longer breaks through the fuel at the electrode. In this case, the electrodes can simply be wiped.

Troubleshooting

What to do if the hoverboard does not charge? Here are some simple tips for troubleshooting:

- First, disassemble the hoverboard.

To remove the bottom panel, use a screwdriver or screwdriver with the appropriate bit. This will allow you to get to the inside of the vehicle and try to find the problem of poor charging.

The side of the scooter with the charging port is the area you need to work on. Be careful during disassembly. Do not lose screws or washers, or use a drill to remove screws or bolts that will not come loose. There will be several wires directly on the inside of the plastic cover you just unscrewed.

They are responsible for charging the hoverboard: they connect the charger ports and the lithium-ion battery. The other wire line goes to the motherboard. You can temporarily disconnect it to avoid an unexpected power surge (only if the board is disconnected by a connector). If the wires are soldered, it is better not to touch them.

Is there blackening of the wire or oxidation of the contacts, is there a large amount of dust present? This may well be the reason for the device to not work correctly. Accumulations of dust must be removed, damaged wires must be replaced, and contacts must be cleaned to a metallic shine.

Having completed such an impromptu diagnosis, screw the cover back to the hoverboard, tightening all the removed bolts one by one.

They will help you make diagnostics more efficiently and without risk to the scooter. True, it is no longer free.

If, despite all this, your scooter continues to work incorrectly, you will need to contact the manufacturer and request repair instructions. In the worst case, the hoverboard will have to be sent back to the manufacturer under warranty. It may be that the device was initially faulty and will be replaced under warranty. It often happens that a newly purchased hoverboard does not charge.

Detonation

Causes and solutions:

Ignition system malfunction

- Poor condition of contacts (put contacts in order)

- Faulty or clogged spark plug (cleaning or replacing the spark plug)

Fuel system malfunction

- Unsatisfactory quality of the fuel mixture (cleaning, adjusting, or replacing carburetor components)

- Poor carburetor performance (disassembling and cleaning the carburetor)

- Fuel hose is damaged or clogged (clean or replace)

- The intake manifold sucks in air (tightening the manifold pipe or replacing the gasket)

Cylinder head failure

- The walls of the combustion chamber are covered with carbon deposits (cleaning the combustion chamber)

- Leaky cylinder head gasket, which leads to blow-by (gasket replacement)

- The valve clearance is different from the clearance set for this model (adjusting the clearance)

- Worn valves due to overheating (replacement of valves)

- Worn valve springs (replace springs)

- Incorrect valve timing (valve timing adjustment)

Petrol mower and chainsaw.

No matter what country of origin the mini equipment equipped with a simple two-stroke engine belongs to, any malfunction will depend on what the engine is “fed” and on the quality of the assembly. Of course, one can doubt the quality of the assembly units themselves, and one can talk about this for a long time. Some are satisfied, but others are not.

For example, we only need a chainsaw for one day. We rent or buy the cheapest one. Professional sawyers will need a chainsaw with a long service life, and its cost is noticeable. But what to do when they sell one-time equipment as professional or semi-professional at an appropriate price? We, the ignorant, do not know about this. So everything breaks down, and sometimes all at once.

Failure to operate a two-stroke engine or its breakdown occurs in different ways and depends on a wide range of reasons.

Here's an example. The owner has been using the lawn mower for several years. The scythe fell into other hands and this is the result. The engine jammed, and the user did not understand why it stalled. 'A good knock comes out.' The piston had a casting defect, which came to light at that very unnecessary moment. We tried to start the day, but to no avail. When opening the piston, aluminum particles of the piston were ground to the cylinder wall. What is the compression here? The spark plug hole was pressed with a finger and a newspaper wad was inserted by the craftsmen. They blamed the carburetor, and in vain.

Motorcyclist

THE ENGINE IS LOW POWER

1. Start the engine and slightly increase the gas to observe.

If the speed does not increase as it should, then it could be:

clogged air filter; clogged gas filter; clogged muffler; clogged carburetor; faulty starting enrichment; clogged or leaking rubber gas and air pipes leading to the gas valve and carburetor.

Why is there no revs on the scooter?! We continue to search:

faulty or dirty spark plug; over-enriched mixture; inappropriate spark plug heat rating; problems with the piston - it splashes with oil.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

The generator does not start in cold weather

There can be two most likely reasons here - non-frost-resistant oil or, again, low-quality gasoline. In order not to “rack your brains” on how to start a gasoline generator in such conditions, it is better to take care of this in advance and change the oil for the winter. 5W30, 0W30 or any other winter oil recommended by the generator manufacturer will do.

If this is not done in time, then sooner or later the question will arise - how to start a gasoline generator in cold weather? There are many possible solutions, but they all boil down to one thing - warm up the generator. This cannot be done with an open fire; the easiest way is to bring it into a warm room for 1.5-2 hours.

After this, the generator should start, unless there are other reasons not related to frost. It is better to change the oil after work, then it will be warm, liquid and easier to drain.

The best advice would be to buy generators from branded manufacturers and fill them only with high-quality gasoline, then there will definitely be no problems.