Pros of a motorcycle

The more than seventy-year history of Ural bikes speaks volumes. These motorcycles are powerful, ride smoothly and quickly thanks to a powerful engine. The prevalence of the Ural all over the world is due, first of all, to its excellent performance indicators. In addition, the manufacturer is constantly making various improvements to the motorcycle engine, improving the bike.

The main unit of the Ural is considered to be the power unit. The ability to drive depends on its functioning. Each motorcycle comes with an instruction manual. It specifies the type and size of the engine, and also indicates what oil it runs on. According to the manual, the bike has a combined engine. Lubrication of contacting parts is carried out by 2 methods: from the oil pump or by spraying engine oil.

Motorcycle engine URAL

Because the engines in bikes are four-stroke, you need to choose a suitable lubricant for them. You can find out what kind of oil to pour into the internal combustion engine in the operating manual. You cannot pour motor oil into the engine, as it has inappropriate parameters. Any manufacturer of popular lubricants has an oil fluid designed specifically for bikes. There is no separate specification for oils that can be poured into a motorcycle engine. In view of this, they have the same markings as lubricants poured into the internal combustion engines of cars. When choosing a petroleum product, you need to take into account the climatic conditions in which the bike will be used. Consumables can be intended for summer, winter, or be universal.

Brand popularity

Although Ural is found everywhere in the Russian Federation, a large number of manufactured mopeds are sold to other countries. Only three percent of the total volume remains in Russia. This is due to the considerable cost of the motorcycle. For the same price it is possible to purchase a used car of excellent quality.

Realizing that this bike was very popular abroad, I decided to reconstruct it, started buying spare parts abroad, and carrying out the assembly in the Russian Federation. About a thousand bikes are produced annually and are already sold in advance. It’s hard to imagine which countries they drive on.

"Ural" is made on the basis of military bikes "BMW R71". They were produced by the Germans in the forties of the last century. The first “Ural” was manufactured during the Second World War and had additional devices that distinguished it from German motorcycles. To make the army more maneuverable and mobile, Iraq purchased many bikes from the Russian Federation. They were equipped with additional channels, machine guns and flamethrowers. It was after the Iraq war that America began to become interested in these bikes.

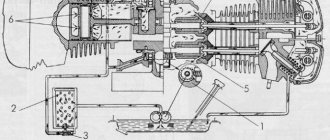

Diagram of the gas distribution mechanism of the Ural M67-36 engine

1 - rod; 2 — rod casing; 3 - pusher; 4 — pusher guide; 5 — camshaft driven gear; 6 — breather leash; 7 — breather; 8 — oil seal; 9 — camshaft; 10 — exhaust valve; 11 — valve guide; 12 — outlet pipe; 13 — lower valve plate; 14 — external valve spring; 15 — internal valve spring; 16 — upper valve plate; 17 — valve block; 18 — rocker arm; 19 — adjusting bolt; 20 — lock nut of the adjusting bolt; 21 — rocker axis; 22 — inlet valve.

Return to contents — ↑

Engine oil Moto Dnepr

__________________.

Who we are, why we are here, whether we are alive or not, the wild bee doesn’t care. For her, the world below is only a path of flowers. website support with voluntary donations Yandex wallet 41001876570803

Yurets usually recommends the opposite.

He has a favorite oil, M8-G, something tells me that this letter G in this name means something.

As always, you got everything mixed up! If the engine is already killed, then it really doesn’t care what kind of oil to pour, since a trickle flows from all the seals, and so as not to expose yourself to money, it’s better than M8, who knows what you’ll find.

__________________. Who we are, why we are here, whether we are alive or not, the wild bee doesn’t care. For her, the world below is only a path of flowers.

website support with voluntary donations Yandex wallet 41001876570803

Source

Brand popularity

Although Ural is found everywhere in the Russian Federation, a large number of manufactured mopeds are sold to other countries. Only three percent of the total volume remains in Russia. This is due to the considerable cost of the motorcycle. For the same price it is possible to purchase a used car of excellent quality.

Realizing that this bike was very popular abroad, I decided to reconstruct it, started buying spare parts abroad, and carrying out the assembly in the Russian Federation. About a thousand bikes are produced annually and are already sold in advance. It’s hard to imagine which countries they drive on.

"Ural" is made on the basis of military bikes "BMW R71". They were produced by the Germans in the forties of the last century. The first “Ural” was manufactured during the Second World War and had additional devices that distinguished it from German motorcycles. To make the army more maneuverable and mobile, Iraq purchased many bikes from the Russian Federation. They were equipped with additional channels, machine guns and flamethrowers. It was after the Iraq war that America began to become interested in these bikes.

Oil selection

Changing the oil in a Ural engine is a very important task, especially if it is already due. Since the bike’s clutch is completely immersed in lubricant, its choice must be approached with all responsibility. As mentioned above, automobile oils are not suitable for four-stroke Ural engines, since their viscosity does not meet the required one. Motor oil fluid for motorcycles has a completely different set of impurities and additives than for cars, which is why it works somewhat differently.

If the bike is used year-round, which is rare in the harsh Russian winters, then it makes sense to fill in all-season oil. This lubricant has a number of advantages over others, since it contains special additives that make the oil equally effective at low and high temperatures. Manufacturers of such oil conduct thorough and long-term tests of their products at various, even abnormal, temperatures, and at the same time its quality is not compromised in any way.

contents .. 1 2 3 6 ..MOTORCYCLE DNEPR-11. ENGINE LUBRICATION SYSTEM

The engine lubrication system is combined (pressure and splash). The lubrication diagram is shown in Fig. 12.

Oil is poured into the engine crankcase through the filler hole and closed with plug 2 with an oil measuring rod. From here, the oil is sucked through a strainer 3 by a gear pump installed in the front bearing housing, which is driven by a gear meshed with the drive gear of the timing mechanism. The oil pump has two gears that are installed in the housing and pump oil into the main line 7. To prevent the oil pressure in the system from increasing above the permissible level, a pressure reducing valve 5 is installed in the oil pump housing.

During normal operation of the oil system, excess oil pressure squeezes out the pressure relief valve and excess oil

is bypassed back into the suction channel of the oil pump.

The pressure reducing valve does not need to be adjusted during operation.

From the line, oil is supplied to the annular groove in the front bearing housing, from where it is supplied through a channel to the centrifuge housing. The oil, purified in a centrifuge, is fed through the oil drain channel E of the crankshaft and the oil supply channel B in the crankshaft cheek into traps G located in the crankpins of the crankshaft, from where through hole B it enters the connecting rod bearings.

The fast-moving parts of the crank mechanism contribute to intensive splashing of oil, the formation of oil mist in the crankcase, which lubricates the working surfaces of the cylinders, piston pins, upper connecting rod heads, pusher guides, main rolling bearings, timing gears, ball bearings and camshaft cams, pushers and other rubbing parts. details.

Sprayed oil, falling into the grooves O of the pushers, enters the rod casings, settles in them and flows into the cylinder heads. Here it is sprayed onto the valves, springs and lubricates the valves and rocker arms. Excess oil flows through drain tube 6 back into the engine crankcase.

If mushroom-shaped pushers 20 are installed on the engine (Fig. 5), atomized oil enters the rod housings through holes in the crankcase near the pusher guide bushings.

To drain the accumulated oil reflected by the flywheel oil seal, oil drainage channel A in the engine crankcase is used.

To prevent oil from leaking from the crankcase to the clutch, there is a rubber seal on the flywheel hub, and a rubber seal on the camshaft is provided to prevent oil from getting to the breaker.

The centrifuge is a fine oil filter. Before it, the oil is cleaned only by the oil receiver grid. The aluminum housing 8 (Fig. 13) and the centrifuge cover 6 are installed on the front journal of the crankshaft, secured with a key and secured with a bolt 1 through a special washer 3 installed in the centrifuge cover.

To prevent spontaneous unscrewing of bolt 1, a lock washer 2 is installed. A screen 9 is installed between the body and the centrifuge cover with one oblong hole for the passage of oil from the body cavity into the cavity of the centrifuge cover and further through the channels to the connecting rod bearings. The correct position of the hole in the screen relative to the channels is ensured by a tendril that fits into the centrifuge body.

The centrifuge body and cover are sealed with a special ring 7. To reduce oil leakage, an o-ring 4 is installed between the washer and the end of the crankshaft.

Maintenance of the lubrication system

When operating the motorcycle, the oil level in the engine crankcase should be maintained at the top mark of the oil dipstick. When the level drops to the bottom mark of the rod, engine operation is not allowed. Oil must be added from a clean container and always through a funnel with a mesh, preventing dust, dirt and moisture from entering the engine crankcase.

When checking the oil level, you need to wipe the oil measuring rod and lower it into the crankcase filler hole until it stops, without screwing in the plug. The oil is changed when the engine is hot.

When changing the oil in the engine crankcase, carefully clean the crankcase drain and filler plugs from dirt and unscrew them. Next, drain the used oil, screw in the drain plug, and add fresh oil.

Every 10,000 km, the engine lubrication system should be flushed. To do this, unscrew the drain plug, drain the used oil, screw in the plug and pour 1.2-1.5 1 oils into the crankcase for flushing, start the engine and, after letting it run for 2-3 minutes, drain the oil again. Remove and wash the oil pan. After this, pour fresh oil into the crankcase.

In winter, the oil must be heated to a temperature of 70 - 80°C before filling.

It should be remembered that even a short-term disruption of the lubrication system can lead to engine failure.

Signs of insufficient lubrication include excessive overheating of the cylinders and heads, loss of power and engine knocking.

The operation of the lubrication system is controlled by sensor 8 (Fig. 12) of emergency oil pressure of the membrane type, which is activated when the pressure in the system drops to 0.13–0.18 MPa (1.3–1.8 kg/cm2).

The pressure drop indicator is the warning lamp of the emergency oil pressure sensor installed on

instrument panels. When the ignition is turned on, the warning lamp lights up and goes out after the engine starts. Illumination of the warning lamp while the engine is running indicates a sensor or engine malfunction. In these cases, operating the engine until the defect is detected and eliminated is unacceptable.

If the warning lamp of the emergency oil pressure sensor instantly lights up at medium engine speed, which is possible due to metal particles getting under the ball 44 (Fig. 6) of the pressure reducing valve, it is necessary to clean its seat. To do this, it is necessary to drain the oil from the engine crankcase, remove the pan, disassemble the pressure reducing valve (remove cotter pin 41, plug 42, spring 43 and ball 44) and clean the seat.

It is recommended to clean the socket using a 10 mm diameter drill, sharpened at an angle of 90°, turning it by hand with light pressure. It is allowed to seal the valve seat with a ball 10 mm in diameter using a light blow (2-3 times) with a hammer weighing 0.1-0.2 kg through a mandrel (you can use a wrench with squares in the tool bag as a mandrel). After this, you need to turn the crankshaft 2-3 times and assemble all the parts in the reverse order.

When the engine is overheated or operating at low idle speed (engine speed 800 r/min), the warning lamp may light up if the lubrication system is working properly. It is recommended to periodically unscrew the sensor and check the oil pressure using a control pressure gauge. The oil pressure at medium speeds of a warmed-up engine should be no less than 0.3 and no more than 0.6 MPa (3 and 6 kgf/cm2, respectively).

During engine operation, due to centrifugal forces, dirt is separated from the oil and settles on the body and lid of the centrifuge. Therefore, the centrifuge must be cleaned every 10,000 km.

contents .. 1 2 3 6 ..