Size markings on the Ural motorcycle engine crankcase

The factory designation of the interaxal dimensions KB and PB of the motor crankcases, on which the correct fit and correct operation of pairs of gear wheels (GK) depends, or in other words, the marking (numbers) of the size group (RG) is carried out by the manufacturer's workshop using an impact method outside and on top of the crankcase, to the right of the generator.

The filled-in RG number allows you to identify the assembly unit by its individual parameters without wasting time on measurements and allows the worker to select an appropriately sized set of gears for subsequent installation according to the index available on them according to the recommendations presented in the table below. There can be seven crankcase groups in total: 0; 1; 2; 3; 4; 5; 5.5. Place of application of RG on the crankcase

Messages [1 to 20 of 26]

1↑ Topic by Azrael 05/02/2012 04:47:01

Topic: Marking of normal size Ural pistons

In general, this is the case. The motorcycle does not start, and if it starts, it is on the right cylinder. When it works, you can only hear one right cylinder. although you pull the left throttle, it responds, albeit sluggishly. I cleaned the left carb, cleaned the spark plug and checked to see if there is a spark (it does). The power dropped to 20-40 km/h.. tell me what the problem might be. I myself blame the worn piston. And is it difficult to replace it?

2↑ Reply from 230686angel 05/02/2012 05:47:59

- 230686angel

- Pro

- Inactive

- Name: Sergey

- From: Balakovo. Saratov region

- Registered: 17-02-2012

- Messages: 577

- Reputation: 17

- Motorcycle: imz 8-103.10

Re: Marking of normal size Ural pistons

It’s not difficult to change (remove the locking keys and knock out the pin) the crap with the piston or look for another one that’s the right size (so that it doesn’t wobble like x.. in an ice hole) or you need to take it to boring, preferably both.

3↑ Reply from Yuri 05/02/2012 13:37:39

- Yuri

- Pro

- Inactive

- Name: Yuri

- From: Moldova, Balti

- Registered: 07-11-2010

- Messages: 657

- Reputation: 49

- Motorcycle: Dnepr MT 10-36

Re: Marking of normal size Ural pistons

What does it have to do with the piston, the rings didn’t fit. In general, if it’s enough when the throttle is raised, it means it doesn’t have enough gasoline - try raising the needle or, with the engine running, press pump and hold for 15 seconds

4↑ Reply from Serega294 02-05-2012 13:42:11

- Serega294

- Assistant

- Inactive

- From: Berezniki. Perm region.

- Registered: 16-10-2011

- Messages: 278

- Reputation: 9

- Motorcycle: IMZ 8.103.10

Re: Marking of normal size Ural pistons

trim the carbs

5↑ Reply from KARENDJ 02-05-2012 16:02:59

- KARENDJ

- Pro

- Inactive

- Name: Evgeniy

- From: Chelyabinsk

- Registered: 17-09-2010

- Messages: 529

- Reputation: 9

- Motorcycle: KMZ-750

Re: Marking of normal size Ural pistons

it is truth too. I’ll tell you how it happened to me: 1 the valves were not adjusted. 2 carburetors are not adjusted. 3 Ignition is not adjusted.

This happened to me with a crap ignition setting.

6↑ Reply from Azrael 06-05-2012 14:51:08

Re: Marking of normal size Ural pistons

where is the ignition set? )

7↑ Reply from rema-krim 06-05-2012 20:07:02

- rema-krim

- Experienced

- Inactive

- From: Feodossia

- Registered: 06-02-2012

- Messages: 332

- Reputation: 7

- Motorcycle: MT10-36

Re: Marking of normal size Ural pistons

There is a cover on the front of the engine, unscrew it and you will see the ignition and how to adjust there are a lot of topics here

8↑ Reply from partizan 05/06/2012 20:11:20

- partizan

- Elder

- Inactive

- Name: Andrey

- From: Lamborg

- Registered: 22-12-2011

- Messages: 1 179

- Reputation: 59

- Motorcycle: URAL-solo

Size markings on gear set

The index of a set of gears is currently indicated on the large gear to the right of the notch.

On the KV and RV gears, the factory applies a dimensional index marking on the end part with an electrographic pencil, in the same place where the notches are made.

These marks are applied for precise installation of the timing belt in the TDC position of the crank mechanism. There are 7 indexes of the ZK set until 1991: 13-18; 12-17; 11-16; 10-15; 9-14; 8-12; 6-10. Subsequently, the same numbers began to be stamped on the gearbox as for the crankcase. According to the requirements of the design and repair documentation, when operating the coupled gearboxes KV and RV, a lateral clearance of 0.1-0.12 mm should be provided for new gears, and should not exceed 0.3 mm for worn ones. If you do not comply with these requirements, you will soon have to make another repair.

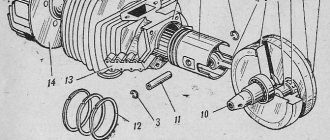

Piston, piston rings and pins of a Ural motorcycle

The piston is cast from aluminum alloy. Aluminum alloy has low density and good thermal conductivity, as a result of which the piston is light and does not create large inertia forces, and is also well cooled. Together with a cast iron cylinder of increased hardness, the aluminum piston forms a good anti-friction pair, resulting in reduced wear on the CPG parts. However, the aluminum alloy has one significant drawback: the linear expansion coefficient of the aluminum alloy is twice as large as the linear expansion coefficient of cast iron. In addition, the piston temperature is approximately twice the temperature of the cylinder, so when the engine overheats, the piston expands so much that it jams in the cylinder. A so-called “sticking” occurs. To avoid “sticking”, the possibility of engine overheating should be excluded.

The Ural motorcycle piston has a bottom, a side surface - a skirt and bosses for the piston pin. The piston has four grooves for piston rings. During operation, the upper part of the piston heats up more and expands more than the lower part. Therefore, in order for the piston to have a cylindrical shape in working condition, it is made conical, i.e., the diameter of the piston head, where the piston rings are located, and the upper part of the skirt is smaller than the lower part of the skirt. When selecting a piston for a cylinder, the largest diameter of the piston skirt is decisive.

During operation of the crank mechanism of the Ural motorcycle, a lateral pressure force acts on the piston, which presses the piston to the cylinder wall and deforms it. The piston in working condition must have a large contact surface with the cylinder, so it is made elliptical in cross-section. The major axis of the ellipse is perpendicular to the axis of the piston pin (Fig. 1).

Under the influence of force N, the piston is deformed (shown by the dashed line) and takes on a cylindrical shape. The difference between the major and minor axes of the ellipse is 0.18 mm. Since the force N is always directed perpendicular to the piston pin, the side surface of the piston near the piston pin does not participate in the work. To prevent the piston from jamming due to its deformation due to force N, part of the metal around the piston pin is removed, so-called “coolers” are made.

Pistons, like cylinders, are divided into groups depending on the diameter of the skirt Dу, measured along the major axis of the ellipse at a distance of 13 mm from the lower end (Fig. 2.).

| Piston skirt diameter, mm | 77,94 — 77,93 | 77,93 — 77,92 | 77,92 — 77,91 |

| Index | 77,94 | 77,93 | 77,92 |

The Ural motorcycle piston group index is stamped on the piston bottom. In addition, pistons are distinguished by the diameter of the hole for the piston pin and are divided into four groups according to table. 2.1. The holes in the piston, like the piston pin, are marked with paint.

Table 2.1 Markings of the piston and piston pin

| Color index | Diameter of hole in piston, mm | Piston pin diameter, mm |

| White Black Red Green | 20,9930-20,9905 20,9905-20,9880 20,9880-20,9855 20,9855-20,9830 | 21,0000—20,9975 20,9975—20,9950 20,9950-20,9925 20,9925—20,9900 |

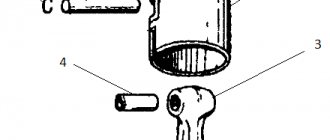

The piston pin is installed in the piston with an interference fit of 0.045-0.095 mm, however, when heated, the piston expands more than the pin and the latter rotates freely in both the piston and the connecting rod. This fit of the piston pin of a Ural motorcycle is called floating. Due to the floating fit, the finger wears less and more evenly throughout its entire circumference.

How to select timing gears depending on the crankcase group

The selection of an internal combustion engine seal kit is selected according to the table below, where an index is indicated under the crankcase group.

| Crankcase group | 0 | 1 | 2 | 3 | 4 | 5 | 5,5 |

| Suitable indexes for gear sets after 1991 | 0 | 1 | 2 | 3 | 4 | 5 | 5,5 |

| According to labeling before 1991 | 13-18 | 12-17 | 11-18 | 10-15 | 9-14 | 8-12 | 6-10 |

| Correspondence of the indices of the timing gears “HERZOG” of the new Ural 750cc engines. | 0 | 1 | 1 or 2 | 2 | 2 or 3 | 3 | — |

If you do not find a set of timing gears with the required indices, you will have to make a test shaft from an old CV with a mounted bearing for installation in the seats without interference. To do this, you need to grind the outer race of the bearing and the seats for the gear and bushing. Try to maintain minimal clearances so that the shaft with the bearing and the gear do not dangle in the fit. In this way, you can use the selection method to select the gear with the smallest lateral clearance when mating with the KV gear, but in this case you need to take the crankcase and the test shaft with you to the store.

Ural motorcycle pistons marking

Motorcycle engine pistons Ural, Dnepr

The pistons of the Dnepr and Ural motorcycle engines are cast from a heat-resistant aluminum alloy and heat-treated. The piston consists of a head with a spherical or flat bottom, a skirt and bosses. Piston rings are installed on the piston (two compression rings and two oil scraper rings). In the grooves under the piston rings there are through holes for oil drainage. The piston skirt is made of a special oval shape. The larger diameter of the skirt is located in a plane perpendicular to the piston pin axis. The piston skirt also has a conical shape. The difference between the larger and smaller skirt diameters is 0.015 mm. The diameter of the upper part of the skirt is 0.03 - 0.05 mm less than the diameter of the lower part. The ovality and taper of the skirt are necessary so that, with a small gap between it and the cylinder, the piston, expanding from heating, does not jam in the cylinder. The pistons are the same for both cylinders. Depending on the diameter, the cylinders are divided into groups (Table 2.1).

To reduce the noise of the piston during operation, the axis of the hole for the piston pin in the MT 10-32 engine is shifted relative to the axis of symmetry by 1.5 mm. To correctly install such a piston in the cylinder, an arrow is stamped on the bottom of its bottom. During installation, the arrow on the pistons of both cylinders must point forward towards the centrifuge. In this case, if you look at the engine from the rear, the pin in the piston of the right cylinder should be moved down, and in the piston of the left cylinder – up.

The holes for the pin in the pistons of the K-750M and M67-36 engines are made without displacement of the pin axis from the center plane of the piston. The pistons of the K-750M and M67-36 engines have a flat bottom, and the MT 10-32 piston has a flat bottom with an ejector.

The finger holes are divided into groups every 0.0025 mm and marked with paint on the sidewall (Table 2.2). The permissible wear of the piston pin hole should not exceed 0.02 mm. These holes contain grooves for the circlips, which promote axial movement of the piston pin. Pistons are selected to the cylinders with the required clearance. To make selection easier, pistons and cylinders are sorted at 0.010 mm intervals. Their dimensions are stamped on the inside of the piston bottom.

In addition, pistons are divided into groups according to mass, which coincides with the color index of the piston pin hole. The difference in the mass of the engine pistons should not exceed 0.004 kg. The piston assembly with rings and pin are weighed. For selected pistons, the color marking of the holes for the piston pin must correspond to the marking of the hole in the upper head of the connecting rod. The marking paint on the pistons is applied to the bottom

the surface of one of the bosses, on the connecting rods - at the upper head.

Tell me what the letter “A” on the bottom of the Ural pistons means

Either a size rejection group or a weight group

piston size. A is the smallest, B is larger, C is even larger. The cylinder with the same letter is selected for the piston.

I don’t know about the Ural ones, but on the VAZ ones complete with group A - the pistons are identical in group C - there is a slight discrepancy in size

Priprihkin, look here. So, the letters are the so-called group index (the spread of piston sizes in one size group). There is a normal piston size with a tolerance of 78 -0.060; -0.090. This means that all pistons that fall within the dimensions from 77.91mm to 77.94mm meet the requirements. But if you take one piston with a size of 77.91 mm and another 77.94 mm, nothing good will come of it, so they were divided into groups: A - 77.91-77.92 mm B - 77.92-77.93 mm C - 77.93-77.94 mm Correct if anything is wrong.

Ural motorcycle cylinder size table

Ural motorcycle engine

IMZ-8.103-10

Cylinders

engine

Ural

IMZ-8.103-10

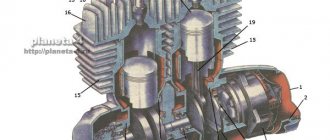

Engine cylinders 8 are identical and interchangeable (Fig. 4). A head 10 is screwed to the engine cylinder, on the outer surface of which there are ribs that increase the cooling surface. At the top of the head there is a threaded hole for a spark plug.

A sealing gasket is installed between the cylinder and the engine crankcase.

Piston, piston rings and piston pin

The engine piston has four grooves machined into which the piston rings are installed. The two upper compression rings create the necessary tightness between the piston and the cylinder and prevent the breakthrough of gases from the combustion chamber into the engine crankcase. The lower oil scraper rings are used to remove excess oil from the cylinder walls. All rings have straight locks. The gap in the locks when installing the piston with rings into the cylinder should be 0.25-0.50 mm.

The piston is connected to the connecting rod by a floating piston pin, the axial displacement of which is prevented by two spring retaining rings inserted into the annular grooves located in the piston bosses

Rice. 4. Engine (cross section): 1 - generator; 2 — camshaft; 3 - pusher; 4 — pusher guide; 5 — sealing cap; c — pusher rod; 7 — tube (casing) of the rod; 5—cylinder; 5 - piston; 10 — cylinder head; 11 - valve; 12 — valve springs; 13 — adjusting bolt; 14 rocker axis bracket; 15 — lock nut of the adjusting bolt 16 — rocker arm; 17 — rocker axis; 18 — head cover; 19 — cylinder head mounting pin; 20 - gasket; 21 — spark plug; 22 — oil drain channel from the cylinder head; 23 - gasket; 24 — cylinder drain pipe for oil; 25 — compression rings; 26 — piston pin; 27 — oil scraper rings; 28 — connecting rod; 29 — roller bearing; 30 — crank finger; 31 — engine crankcase; 32 - pallet; 33— oil pump; 34 — crankshaft cheek; 35 - oil catcher; 36 - cylinder fastening nut; 37 — carburetor; 38 — candle tip; 39 - high voltage wire; 40 — filler plug with dipstick; 41 — driven gear of the oil pump drive; 42 — oil pump drive plug; 43 - oil pump drive gear

Source