MY MOTORCYCLE

A QUICK SHIFTER IS A MANDATORY ELEMENT OF A SPORTBIKE SERIOUSLY PREPARED FOR COMPETITIONS. LET'S FIND OUT IF IT REALLY HELP YOU DRIVE FASTER

Dynamics is one of the components of the popularity of a sports motorcycle. But in fact, in order to realize the acceleration seconds declared by the manufacturer, much less make these figures even more impressive, certain skills are required.

Let me remind you that internal combustion engines, in particular those that are installed on modern sports motorcycles, give maximum output in the upper rev range. In order to use the engine in the maximum torque range at different speeds, direct transmission alone is clearly not enough. Therefore, a gearbox is installed between the engine and the main gear, which makes it possible, by changing gear ratios, to keep the engine at the desired speed.

It is in supporting the engine at its “peak form”, that is, shifting gears, that the “human factor” manifests itself. Moreover, it often manifests itself negatively. How to minimize wasted time? It’s very simple: install a quickshifter - a device that allows you to increase, and, with a certain complexity of execution and the corresponding price, lower the gear without releasing the gas or opening the clutch. They are divided into two types: pneumatic and electric. Pneumatic quickshifters come in single- and double-sided versions. Double-sided ones allow you to change gears by pressing the corresponding buttons - both up and down, since they implement clutch release. Switching is carried out based on a signal from a special sensor that the clutch discs are open. Such shifters can be either specialized (for certain engines) or universal. The single-sided quickshifters only upshift – also at the push of a button. The cost of double-sided pneumatics is extremely high, and they are produced almost exclusively by an American company with the German name PINGEL. They position their products mainly for custom, heavy-duty tourists and sports tourists. Single-sided shifters are in demand mainly in drag racing to reduce the human factor to zero. Another type of shifters is electric. They use a feature of a motorcycle gearbox and operate from a standard gear lever. Read more about them.

Electric speed shifters

As a tuning element, quick shifter is a visually almost invisible detail

A motorcycle sequential transmission has a wonderful feature: when you let off the gas, you can upshift without pressing the clutch. In this case, you need to press the shift lever, release the gas to a quarter, and at the moment of reset, the next gear is “stuck”. I will not talk about the benefits or harm of such switching for the box, but I will say that the loads on the gears of the box that arise due to errors when switching according to the standard scheme are disproportionately large. It was this feature of the box that was used when developing electric quickshifters. A special sensor (inductive or electromechanical) is installed on the gear lever rod, sending a signal to a special module, which in turn instructs the ECU to skip one ignition stroke, stop fuel supply for a certain time, or both. The sensor is triggered when the rider operates the gear lever. Actually, everything else, except for this very impact, is done for the pilot by the electronic unit. All manufacturers of the latter are engaged in electric quickshifters as an addition to injection correction modules. Examples include DynoJet, Yoshimura, Dimsport. For normal gearbox switching at different speeds and different gear ratios, different engine shutdown intervals are required. There are several approaches to the complexity of design and setup. The two parameters that determine the correct operation of the shifter are the time to disengage and the disengagement time. In different implementations of shifters, they can have either a constant or variable value. A constant value is suitable for sports motorcycles with their evenly spaced gear ratios. And if you remember in what modes their engines operate, it will become clear that setting the minimum operating speed allows you to make the quickshifter design extremely simple. It is enough to be able to adjust the delay time, response time and minimum speed, and using such a device on a sportbike in the correct modes will not cause any problems. There are also more complex schemes with the ability to configure parameters for each gear and crankshaft rotation speed. This option of shifters is necessary for comfortable use on tourists and sports tourists with their uneven distribution of gear ratios and a wider range of used revolutions.

Strictly on schedule

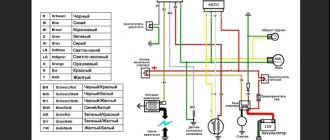

Installing a quickshifter also involves its subsequent adjustment according to the following parameters: response threshold (rpm; delay before the shifter is activated (ms); time for which the engine is turned off (ms)

I decided to test the operation of the quickshifter from personal experience by using: the Honda CBR1000RR '05 motorcycle and, in fact, the Rapidbike quickshifter manufactured by Dimsport. The control of the parameters of this shifter is integrated into the Rapidbike 3 injection control module. As an accessory necessary for the implementation of the quickshifter, Dimsport offers an induction sensor that is built into the gearbox shift rod. The sensors are made in two versions: tension-triggered and compression-triggered. The kit also includes special software for setting the trigger parameters. Quick sfifter is made according to a simple scheme, that is, it has constant parameters: delay, shutdown time and permissible operation speed.

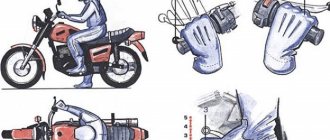

Installing a shifter on a motorcycle involved integrating an induction sensor into the gearshift linkage. For this purpose, a special adapter was machined. Induction sensors have a direction of operation, depending on the direction of operation of the sequential mechanism and the foot when shifting gears up. Our case is compression. The sensor was connected to the Rapidbike 3 module, and further adjustment of the shifter was carried out using software.

As mentioned above, three parameters are configured in the shifter: the lower threshold of operation, the time before operation, the shutdown interval. Since the time to actuation and the shutdown interval differ at low and high speeds, the actuation threshold was set at 7000 rpm, accordingly, the settings were made specifically for high speeds.

You get used to good things quickly, and adapting to the new switching scheme for me personally did not exceed ten kilometers of focused attention. Then I switched gears in a new way almost automatically, occasionally remembering how much easier it had become to accelerate. The sensor response threshold is less than the force required to change gear, and the effect of “turning off the engine without shifting” is obtained.

I have the permissible response speed set to 7 thousand, and in tourist mode you can drive, switching according to the usual pattern. In the range from 7 to 9, the shifter operates quite harshly, transmitting a slight jerk to the wheel. After 9, the switching is practically not felt. Actually, there is no “before and after” here: the shifting simply becomes softer as the speed increases, and after 9000 rpm you simply don’t notice it. This is explained by the delay and engine shutdown time values selected during setup.

source BIKE magazine No. 8/2007

How does Quick Shifter work on a motorcycle?

The first answer is good and quite complete, and I would add it as a comment if I had the reputation... This may help to understand how a motorcycle gearbox differs from the traditional design you'll see in most explanations. The gears in a motorcycle gearbox do not slide along shafts to engage and disengage gears; they are constantly engaged with each other, but at least one of each pair is free to rotate on its shaft. The gear shift mechanism moves dog clutches around to change which gears are locked on the input and output shafts. The dog clutch slides along the splines on the shafts. The dog paw sliding sequence is controlled by a cam drum connected to the shift lever. This means that the motorcycle can change gears very quickly without a clutch. All you have to do is relieve the gearbox so that the dog clutches can slide freely over the splines as you move the shift lever. Due to the sequential cam mechanism, only very small and fast lever movements are required. Many riders (myself included) almost never use the clutch to change gears. You just need to lightly press the lever, close the throttle momentarily, and the transmission will shift smoothly and very quickly to the next gear. Downshifting is harder to do smoothly because you're typically loading the transmission back and braking at the same time. You need to press the lever and open the throttle momentarily. This requires some dexterity to control the throttle and brake at the same time. Due to the sequential cam mechanism, only very small and fast lever movements are required. Many riders (myself included) almost never use the clutch to change gears. You just need to lightly press the lever, close the throttle momentarily, and the transmission will shift smoothly and very quickly to the next gear. Downshifting is harder to do smoothly because you're typically loading the transmission back and braking at the same time. You need to press the lever and open the throttle momentarily. This requires some dexterity to control the throttle and brake at the same time. Due to the sequential cam mechanism, only very small and fast lever movements are required. Many riders (myself included) almost never use the clutch to change gears. You just need to lightly press the lever, close the throttle momentarily, and the transmission will shift smoothly and very quickly to the next gear. Downshifting is harder to do smoothly because you're typically loading the transmission back and braking at the same time. You need to press the lever and open the throttle momentarily. This requires some dexterity to control the throttle and brake at the same time. Close the throttle momentarily and the transmission shifts smoothly and very quickly into the next gear. Downshifting is harder to do smoothly because you're typically loading the transmission back and braking at the same time. You need to press the lever and open the throttle momentarily. This requires some dexterity to control the throttle and brake at the same time. Close the throttle momentarily and the transmission shifts smoothly and very quickly into the next gear. Downshifting is harder to do smoothly because you're typically loading the transmission back and braking at the same time. You need to press the lever and open the throttle momentarily. This requires some dexterity to control the throttle and brake at the same time.

So all the quick shift does is measure the force on the shift lever and turn off the spark plugs when the lever is operated. This only works at higher revs, but cutting off the spark rather than closing the throttle means the air path is less in the way and power returns faster.

If you're worried that clutchless changes are bad, then you can rest assured that my 2004 Yamaha R1 has 105,000 miles on it (with very little freeway use) when driven this way, and still on the original transmission and clutch

An interesting development in MotoGP is seamless gearboxes. They allow you to shift gears at full power. There is little information on how they work, but I suspect they use one-way clutches between the shaft and gears. Conceptually, this is very similar to how a traditional three-speed bicycle hub works: when you shift into a higher gear, the lower gears simply engage their clutch. (on some gears with these hubs you can hear the ticking of uncontrolled ratchets)