The purpose of a muffler on a four-stroke scooter is to remove exhaust gases as quickly as possible with minimal noise. Therefore, tuning a muffler on a four-stroke bike is not at all a difficult task. Although, in both cases, it is necessary to change the pipes. In the case of a four-stroke engine, this is not so important in terms of which one to buy and whether anything needs to be configured. Everything is simple there.

But muffler for two-stroke engines are much more complex in production, settings and selection for each specific model for specific tasks.

The principle of operation of the exhaust system for two-stroke bikes is known and was discussed in the section “Scooter design”. It is known that part of the power is returned to the engine from the exhaust system during operation at certain speeds. If this whole process is implemented ideally, after tuning the muffler the scooter will be unrecognizable. Naturally, if other components were tuned before. After a general boost of the scooter, the stock muffler is not enough for adequate engine operation throughout the entire speed range and replacing the muffler with a tuning one is perhaps the only way to make your scooter run faster and more dynamically.

Two stroke and four stroke scooter

A scooter, as you know, can be with a two-stroke or a four-stroke engine. The operating principle of the entire exhaust system differs radically among analogues.

The muffler on a four-stroke scooter removes gases in a relatively shorter time, doing this with minimal noise. In addition, tuning the muffler in this case will be quite simple. On the other hand, in both cases, when carrying out tuning, it will be necessary to change the pipes.

Types of mufflers for scooters

For the muffler of a two-stroke scooter, selecting components that make it possible to carry out tuning will be much more difficult. The standard muffler itself for such scooters is more difficult to manufacture and configure.

The exhaust system of a two-stroke scooter works as follows. During the process of cleaning exhaust gases, part of the power is returned to the engine. This happens at certain speeds and if you manage to implement this whole process by tuning, the scooter will be unrecognizable.

You can install a high-quality and correctly tuned resonator on a two-stroke scooter. This will give a noticeable increase in dynamics up to a quarter. But in this case, it will be important to carry out professional settings of the entire power system.

How to select and configure a resonant muffler

At first glance, it is enough to simply screw the muffler to the model’s engine and its power will increase. But in reality it's not that simple. The performance of the muffler is influenced by the volume of the engine and the muffler itself, the diameter and length of the connecting pipe, the structure of the resonator and many other factors.

As a rule, all this is taken into account by ICE manufacturers already at the design stage of a resonant muffler.

Why do you need quality mufflers?

As you know, a certain amount of fuel combustion products accumulates in the cylinders of a moped engine. They must be thrown out and in this case it is the muffler that is responsible for this. In other words, this unit seems to smooth out the pulsations that are inevitable when combustion products are released at high speed.

The very design of the muffler, used not only on scooters and mopeds, but also on motorcycles and cars, implies a special exhaust system, which can be different, depending on what result the vehicle owner wants to achieve. For example, if the desire to improve the gas exhaust system is related to increasing the power of the scooter, a special type of muffler is required - a direct-flow muffler.

Direct flow type muffler

Direct-flow muffler device for moped

Installing this type of muffler will not only increase dynamic power, but will also significantly increase the noise emitted when gases escape. On the one hand, this is good, because this way you can attract the attention of other drivers, thereby increasing passive safety. As you know, drivers of large cars often complain that they do not notice motorcyclists, and mopeds and scooters even more so.

Making such a muffler from scratch or using a method that involves tuning is not difficult, but many technical aspects need to be studied.

Features of a direct-flow muffler

The features of direct flow are as follows: exhaust gases are ejected outside the engine immediately, the cylinders of the power unit have time to fill with the fuel mixture in the optimal amount.

I would like to remind all readers that at the moments of intake and exhaust, engine valves tend to open and close. Between these stages, a vacuum occurs, which allows the cylinders to be cleared of exhaust gases. As a result, free space is freed up, where the fuel mixture is supplied. It is easy to guess that the faster the cylinders are released from exhaustion, the faster they will be filled.

Thus, if you can ensure a faster exit of gases from the system, the performance and, as a result, the power of the scooter or moped will increase.

Exhaust systems of two-stroke engines

EXHAUST SYSTEMS OF TWO-STROKE ENGINES

The article was published in MOTO magazine March 1996.

You often hear talk among motorcyclists about the role of the muffler: some say that if you remove it, the engine will trample “like a beast,” others say the opposite. But most often, debaters do not specify what type of engine they are talking about - a two-stroke or a four-stroke. And the difference is fundamental. After all, if it is a four-stroke, then the presence or absence of a muffler will not greatly affect the power, but on a two-stroke it is the opposite - the operation of the engine can change so much depending on the presence or absence of a muffler that you are amazed.

We asked the famous amateur designer Alexey Garagashyan to share his experience in designing and tuning exhaust systems on numerous motorcycles of his own design.

The exhaust systems of two-stroke engines are very diverse, and before we begin to give any practical recommendations, we will try to classify them. We can count at least six well-known options. Let's start with the simplest.

The most common system today is a system consisting of a resonator (power part) and a muffler (muffling part). We will talk about what is needed for what later, but now we will continue the classification. Sports motorcycles twenty to thirty years ago used exhaust systems consisting of a single resonator.

Courageous racers and their fans agreed to endure the roar of engines, because the muffling part takes away part of the power. But not so long ago, standards were introduced to limit noise for racing motorcycles. Accordingly, such solutions are no longer applied.

On motorcycles you can also see exhaust systems with only one muffling part going after the exhaust pipe. This is exactly how Kovrovsky prepared them for the Altai Around the World. Looking ahead, we can say that they had fairly high fuel consumption, poor dynamics, but excellent traction at low and medium speeds.

You can often find motorcycles with only one exhaust pipe, without any changes in the cross-section inside. Most often, this is done either by the most ignorant owners, or by those who want to increase cross-country ability at any cost.

But the most advanced one today is the exhaust system, consisting of a power damper that regulates the height of the exhaust windows depending on engine speed or load, and a resonator and muffler following it.

Now let's talk about everything in order.

Numerous studies of the operation of two-stroke internal combustion engines show that with an untuned exhaust system or without it at all, the engine loses a significant part of the fuel-air mixture through the exhaust ports, from which, in fact, the exhaust system begins. The power and speed of the motor largely depend on their shape and size.

The angular width of the exhaust port is limited by the risk of damage to the piston rings, and according to research data should not exceed 65° for production engines and 70° for sports engines. If you need to enlarge them, make two or three windows separated by lintels. The height of the exhaust ports has a significant impact on engine power. An increase in height leads to rapid cleaning of the cylinder from exhaust gases, which contributes to an increase in speed, but at the same time, the proportion of lost stroke increases, since after opening the exhaust windows, the gases no longer exert pressure on the piston. This leads to a reduction in torque in the low and medium speed range. Power dampers help to get rid of such undesirable phenomena, they limit the height of the exhaust windows at low and medium speeds and open them completely at high speeds. By the way, power dampers have now become almost a mandatory part of a decent two-stroke engine.

Unfortunately, it is extremely difficult to manufacture such an effective device in our conditions, so we will not dwell on it for long, but will continue to get acquainted with the exhaust system. After the exhaust windows, as a rule, a resonator, or power part, scientifically speaking, is installed. Its main task is to prevent the release of fresh mixture. Choosing the optimal resonator parameters is quite complicated, but I will try to clarify this issue.

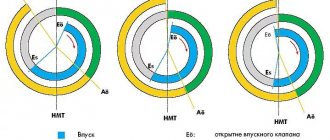

For a favorable gas exchange process, it is necessary that a low vacuum be created at the exhaust window in the first half of the purge phase, which helps clean the cylinder of exhaust gases. By the time the purge mixture approaches the outlet window, the pressure in the exhaust system (at the window) must increase and be maintained in this state until it closes. This pressure wave creates a reverse movement into the cylinder of part of the purge mixture that entered the exhaust system during purge.

If there is an unfavorable change in pressure, “clogging” of the exhaust system may occur, impairing cleaning and filling of the cylinder. A significant vacuum in the exhaust system at the end of purge facilitates the unimpeded ejection of the combustible mixture through the exhaust window.

The exhaust system is usually configured for one operating mode. It comes down to selecting the geometric dimensions of the resonator shown in Figure 2.

In most cases, these optimal RPMs are between medium and high. On motorcycles with a well-tuned exhaust system, a sharp pickup is often noticed when reaching a certain speed. It is often accompanied by such acceleration that an unlucky experimenter, not accustomed to such surprises, may have the opportunity to see a motorcycle moving away from him on its rear wheel, which is no longer possible to catch up with.

Cleaning the muffler

The cleanliness of the muffler affects the power of the moped

Before you start changing anything in the exhaust system, I would like to give one piece of advice. The power of the scooter is directly affected by the cleanliness of the muffler. If it were possible to see the exhaust in a cross-section of the muffler, the owner of the scooter would be very surprised. After a certain mileage, the scooter's dynamics decrease, and owners begin to look for the reasons for this, finding them in a complete rework of the standard muffler or its replacement.

The reason for the loss of power, meanwhile, may be hidden in the condition of the engine itself. This will help determine the specialist you should contact before tuning. But the most common cause of loss of dynamics is soot that clogs the muffler. In this case, it is recommended to carry out cleaning in three ways.

First method: mechanical

It involves cleaning the muffler section (it is done with a grinder). The inside of the muffler is cleaned of soot using a wire or cable. The section in the section is closed by welding.

Second method: chemical

It involves pouring water with some kind of cleaner into the muffler. For example, caustic soda is suitable for this purpose. This cleaning has the advantage that the appearance of the muffler will not be affected in any way.

Third method: heat treatment

The muffler is heated either on the scooter with a blowtorch, or dismantled in an oven or on a grill. It will be necessary to repaint the muffler only after it has cooled.

Who can you trust to change the sound of a motorcycle?

If you decide to change the sound of your motorcycle, then you will have to completely replace the exhaust system, while choosing the right equipment according to the requirements.

To select and replace a muffler, you must first find a specialist in this industry. It is worth understanding that only a qualified technician will be able to select equipment according to your wishes and requirements.

Tuning of the exhaust system is carried out at specialized service stations, where your issue is dealt with by specialists with extensive experience.

For work, only high-quality equipment is used, thanks to which the motorcycle can last for a long time without losing its new sound and engine power.

Depending on the choice of exhaust system, the external parameter also affects. By replacing the muffler with a new one, not only the sound and power will improve, but also the external characteristics.

Tips in the article “Long-term loan - what is it” here.

Car service "Lyoha Exhaust" +74951424327, +79031292000 https://lyoha-exhaust.moscow/ Moscow, Sokolnichesky Val 1k1

Source of the article: https://euroelectrica.ru/kak-uluchshit-zvuk-vyihlopa-na-mototsikle/

Muffler conversion

As a rule, many craftsmen not only assemble a muffler, but remake a standard one. This makes it possible to spend less time and get a more acceptable option.

Tools and materials

Before you start tuning, you need to prepare the necessary tools. In this case, the following components will be needed:

Let's start tuning

First we dismantle the muffler. Then we take a grinder and cut out a piece of metal on top of the muffler. With this cut it will be much easier to work with the muffler. You should almost completely cut out the top part. After this, it is necessary to clean the entire internal space of the muffler, dismantling the cut-away elements.

It's time to work with the piece of pipe that we have prepared. Using a powerful drill or welding, we make many holes in the pipe. We place the pipe in the section of the standard muffler. We select in advance a pipe of such a diameter that it fits inside the standard one. It is desirable that the pipe be without any obvious flaws and perfectly straight.

Straight-through muffler in the process of assembly

The space in the cut that remains between the two pipes must be filled with metal pipe cleaners or similar materials. We weld the top of the pipe as it was. We reinstall all structural elements that were dismantled during the process.

Making a direct-flow muffler from scratch

You can make such a muffler from scratch. This will be a completely new version made from several components. The difficulty of this operation, called tuning from scratch, lies in finding the diagram of the exhaust system of a particular moped.

Tools and materials

In this case, again, you need to prepare the necessary tools and materials.

Let's start assembling

First of all, you need to cut 18 cm from one of the pipes. It is recommended to carefully process the place in the cut with a needle file. From the second pipe we cut a circle with a diameter of 1.5 cm. We process it using the method described above. Glue the cut out circle in the section of the first pipe. We cut off another piece of pipe, 18 cm long. We make many holes in it. This can also be done with a sharp nail.

We connect all the parts using a welding machine. We fill the cavity formed at the junction of two pieces of pipe with mineral wool. We wrap the finished product with a special fire-resistant material. The homemade muffler is ready. To install it, you will need to attach the element to the scooter body mount.

Making a muffler mounting element

From plexiglass, which is indispensable in this matter due to its strength and easy paintability, we cut out a special type of ring, the edges of which can be bent outward by 180 degrees. We attach the resulting circles with serifs to the moped using the required bolts. We polish the muffler using sandpaper. To be sure, the joints between the homemade product and the moped body will need to be lubricated.

Homemade muffler for moped disassembled

If homemade production causes certain difficulties, you can find a lot of models of mufflers already in finished form. They are usually inexpensive. On the other hand, only a homemade version can provide the ideally expected option.

Source

Why doesn't the scooter pull?

Some motorcyclists are faced with a problem when the engine of the equipment works properly, but the scooter does not pull. The device simply does not move or moves slowly. Oddly enough, this is a fairly simple problem that even a novice rider can fix. Therefore, let's figure out why the scooter does not pull, and how to “reanimate” the equipment.

How should the device work?

First, you should find out what kind of dynamics the device has. This is especially true if you bought a used scooter and don’t know how it worked originally. It’s worth noting right away that this only applies to four-stroke 50cc models. Such devices simply do not have significant power, so their dynamics leave much to be desired.

But if “under the hood” of the equipment there is an engine with a capacity of 62 cc. cm, then you need to diagnose the device.

Main causes of the problem

There are several problems that can cause the scooter to pull poorly or not ride at all. Among them:

- Clutch failure.

- Broken variator belt.

- Reduced compression.

- Incorrectly selected variator rollers.

- Lean or rich fuel mixture.

- Clogged air filter.

- Faulty starting enrichment.

- Clogged muffler.

These are the main reasons why the scooter does not pull or moves slowly. But there are several more rare breakdowns, including: faulty switch, damaged spark plug, incorrectly configured brake system.

Checking the variator belt and rollers

If the rider notices that the dynamics of the scooter has decreased or the device refuses to move, he needs to check the belt and rollers of the variator. Most often, it is this node that causes the problem.

First you need to inspect the belt for breaks or severe wear. If the element is torn or thinned down to 1-1.5 cm, it must be replaced. It is best to use a Japanese or European belt, since they “live” longer than their Chinese counterparts.

After this, you need to make sure that the variator rollers are selected correctly. The part could be:

- Too heavy. Because of this, the dynamics noticeably drop, and the scooter takes longer to accelerate to maximum speed.

- Too light. In this case, the device accelerates well, but when it reaches 30 km/h, the dynamics begin to decline, which is why the scooter cannot reach its maximum speed.

To diagnose the problem, you need to weigh the rollers and make sure they are the right weight. The recommended weight of the part can be found in the instructions for the scooter.

Clutch check

If everything is in order with the rollers and belt, and the scooter starts but does not pull, you need to check the clutch. Attention should be paid to:

- Drum condition.

- The springs that hold the pads.

- Condition of the linings.

- Torque spring (it may burst).

The rider needs to inspect the entire assembly, as there may be other problems with it.

Compression check

The reason why the scooter does not pull up or accelerates poorly may be a decrease in compression. This problem occurs due to:

- Active operation of equipment at maximum capacity.

- Wear of cylinder rings.

- Incorrectly selected parts.

- Error when boring the cylinder.

You can check the compression using a compression gauge. Ideally, the pressure should be 10 bar, but 7-8 bar is also good. If the readings are lower, then you need to lubricate the assembly, replace the ring and make sure that all parts are in good condition.

Why is forward flow needed and why sometimes it needs to be muffled

A car with an exhaust louder than 96 dB will not be able to pass a technical inspection and will not cross the border - in Europe, traffic rules are strict, and the police are incorruptible. Even in motorsports, sound is limited. Only Formula 1 promoters don't like the attempt to drown out the noise from cars. They even opposed the new regulations for the transition from eight-cylinder engines to V6, fearing for the prestige of racing.

When properly configured, resonant exhaust provides an increase in torque by 3–9% for naturally aspirated engines, and more than 10% for turbocharged engines. But in production cars, the increase in the rate of filling the cylinders with the working mixture during modernization is less than 2–3%.

Installing a direct-flow muffler on regular stock cars is only needed as a decorative option for a pleasant exhaust timbre. The main criterion for the quality of direct flow operation on a production machine is the euphony and velvety noise of the motor, and not the increase in power. The car will scream louder or quieter - this will not affect the speed and dynamic characteristics. In this case, when there is an urgent need to stop the forward flow, you can do this without thinking about the consequences.

How to achieve maximum torque

It is best to tune a model engine to achieve maximum torque on a flat, paved area. Having prepared a sports stopwatch, it is necessary to measure and mark with chalk a distance of approximately 15 m. The engine must be well warmed up for the purity of the experiment and the accuracy of the measurements. The results must be taken into account arithmetic averages - after several races. Having shortened the pipe by about 2-3 mm, it is necessary to repeat the measurements.

Before shortening the pipe, you need to remove the muffler from the engine, separate the pipe by removing the silicone connecting tube. You can shorten the pipe in different ways - for example, using a regular hacksaw for metal. Burrs formed during sawing must also be removed from the end with a file or a sharp knife. If this is not done, chips may end up in the cylinder and this can be very bad for your engine.

After assembling the model, it is necessary to take repeated measurements. If the acceleration time takes a little less, everything goes as it should. You still need to shorten the pipe by about 2-3 mm and repeat the experiment. These operations must be repeated until shortening causes a deterioration in the result. In this case, you just need to pull the muffler about 3 mm further out of the silicone tube and secure it with a tie. Your resonant muffler is tuned!

Source

What is a flute in a direct-flow muffler, and what is its effect?

To make the forward flow quieter and get “passing” decibels at the output, a simple design is used, which motorists call a flute. This is a piece of perforated tube with a length of 180–250 mm and a diameter of slightly more than 1/3 of the exhaust, with a welded plug washer in the form of a disk, cylinder or cone, which is bolted inside the forward flow, at the air cut, thereby allowing it to be muffled.

The principle of operation of the flute for direct flow is that when the cross-section of the exhaust channel changes and exhaust gases exit through the perforations, the following occurs:

What you need to change the sound of a motorcycle

Many people believe that the exhaust on a motorcycle is a kind of decoration that is needed to remove gases from the engine and create a characteristic sound. In reality, everything is not so simple. It is worth understanding that each engine has its own volume and power.

When fuel burns, smoke and carbon monoxide residues come out, thereby ensuring the supply of gasoline and air. It is worth understanding that not only the sound, but also the power of the iron horse depends on the flow capacity of the exhaust pipe.

By tuning a motorcycle exhaust, you get:

- sound change;

- transport power;

- appearance.

A few decades ago, when in our country there were no more than ten types of motorcycles, changing the sound of the exhaust system meant removing the filter element from the pipe, resulting in a loud and not always pleasant vehicle sound.

Today, when the variety of models and brands of motorcycles is quite large, individual elements have appeared that can be replaced to improve the quality of the engine and, accordingly, change the sound.

DIY flute for direct flow

If you have the desire and skill, then making a flute with your own hands in order to muffle the forward flow is not at all difficult. It will turn out cheaper than the branded one, but not always better than the Chinese one.

To work, you will need a 20 mm steel (preferably stainless) pipe and a piece of sheet metal 0.8–1.2 mm thick. It is advisable to cook using arc welding, following the rules for working with stainless steel. A pre-bent steel sheet plug with holes for fastening is welded to the pipe. You can screw it with three M8 bolts, but for installation in a few minutes, one threaded connection is enough.

During manufacturing, you should try to carefully measure the internal diameter of the muffler at the air end so that the plug fits in loosely, but without a gap. Then, when heading out to the track, you can quickly remove the flute from the hot pipe with a pair of wrenches or pliers.

Direct flow with damper

To make a quiet direct-flow muffler, but not lose the additional power that modernization of the exhaust tract gives, use a direct-flow muffler with a damper. This exhaust design has been known for a long time and is found on many BMW models (usually with manual transmission).

When the engine is running at low settings, when the advantage of the coordinated exhaust is not taken advantage of, the exhaust gases exit through a conventional muffler, and the direct-flow muffler is closed with a damper. At optimal speeds, the damper opens the outlet into forward flow, and the motor produces maximum torque due to enhanced ventilation of the cylinders.

The damper control is automatic, but there are also manual models. In the city, such a car sounds almost no different from a stock one, and on the highway it not only sounds like a tuner, but has a real increase in power. It’s not cheap - for a full automatic machine, complete with a titanium “spider”, the price often exceeds a couple of thousand dollars.

Similar in capabilities, but not very famous analogues are moderately expensive, but it is better to select a suitable option with a specialist - the success of such an upgrade may require the knowledge of a motor engineer.

A budget option for direct flow with a damper can also be welded yourself from scrap materials. The upper part from an old carburetor will be suitable for the damper, if you bring the idle speed cable into the cabin. Making such a design with your own hands will take much more effort and time than for a homemade flute, and the result of the installation cannot be predicted in advance. It's not difficult to mute the sound, but to maintain power, even if you're lucky, you'll have to tinker with the settings.

Whatever option you choose to muffle the exhaust, you should understand that you can simply buy a ready-made solution if finances allow, or you can muffle it yourself by making a device from improvised means.

Is there a noise penalty due to the removal of the catalyst/particulate filter?

A number of motorists prefer to remove the particulate filter or catalyst from the exhaust system. Let us remind you that it protects the environment from harmful emissions. The reason for removal may be either a malfunction and the high cost of replacing the element, or the desire to increase the car’s power and reduce fuel consumption.

After removal, the vehicle will make a ringing sound, like hitting an empty metal can, especially at high engine speeds.

Accordingly, the sound and the unpleasant toxic smell intensified by the exhaust (which can even penetrate into the cabin) will sooner or later attract the attention of representatives of the State Traffic Inspectorate, and the driver will be fined under Article 8.23 of the Administrative Code.

How to make direct flows quieter

I installed direct flows. The sound is beautiful, the motorcycle is fast. but only at the top. The lows sagged, the engine performance turned from linear into some kind of broken twig. Laws against tuning are becoming stricter and traffic cops are looking disapprovingly. You can’t park a motorcycle near your house at odd hours - I’ll wake up my own people. In view of all these joys, I want to make the exhaust sound quieter (and, if possible, increase traction at the bottom). I don't want to change the silencers. What to do?

DB-killer, you can't think of anything else.

put the metal sponges inside and secure them with stoppers

I stuffed 3 pieces into each. I didn’t feel any difference. bullshit in short.

Direct flow and quieter are probably contradictions

It is not possible to drown out all sound frequencies, so they dampen one or two of the loudest ones and choose a compromise between a drop in power and muffling the exhaust.

but a mini flute helps eliminate the booming completely. I got it straight away and set it up for technical inspection and for long trips.

It’s like he’s an adult guy, but it’s all the same, childhood is playing in the ass. Install normal mufflers and don't give people a drink!